Welcome to the Corvair Forum!

Except for the psychedelic carpet, everything appears to be intact and stock in the photos. (The oil dipstick seems a bit tall). This could be a barn find in good condition, if it is truly rust and body rot free, and you sound like you have a good head for checking into that critical item.

This link will provide you with several useful websites that will provide you with technical references and the critical Corvair suppliers. Clark's Corvair Parts in particular should inspire you. Just browse through their online catalog. Click on any part number to reveal pricing and availability. Clark's makes just about all mechanical restoration possible. The online video tour will tell you a lot, if you want to spend some time and are entertained by that kind of thing. (Highly recommended!)

Common and Useful Corvair Websites

Corvair Forum

Common and Useful Corvair Websites

Corvair Forum  viewtopic.php?f=225&t=6007

viewtopic.php?f=225&t=6007

With the 1962 model year design stability began to creep into the Corvair. 1960 had something of a "prototype" personality, and many engineering changes appeared in 1961. 1961 still had an early design distributor, a manual choke (the only year for that), a master cylinder that went away in 1962, etc. I did notice that this 1962 Corvair engine has a PCV system. Most 1960-1962 Corvairs used a road draft tube for crankcase breathing, and the PCV system became firmly entrenched in 1963. But if your 1962 was a late bloomer in that model year, it is possible that the engine is really the original and it was one of the first to be fitted with a PCV system. (There was a lot of engineering "development" at GM during 1962-1969 as GM engineers struggled to deal with federal and state SMOG laws and government bureaucrats. The emissions control changes were phased in to production when ready — or not!) In any case, a PCV system is generally better than the road draft tube, and helped to reduce crankcase and oil contamination by doing a better job of removing fumes and piston blow-by.

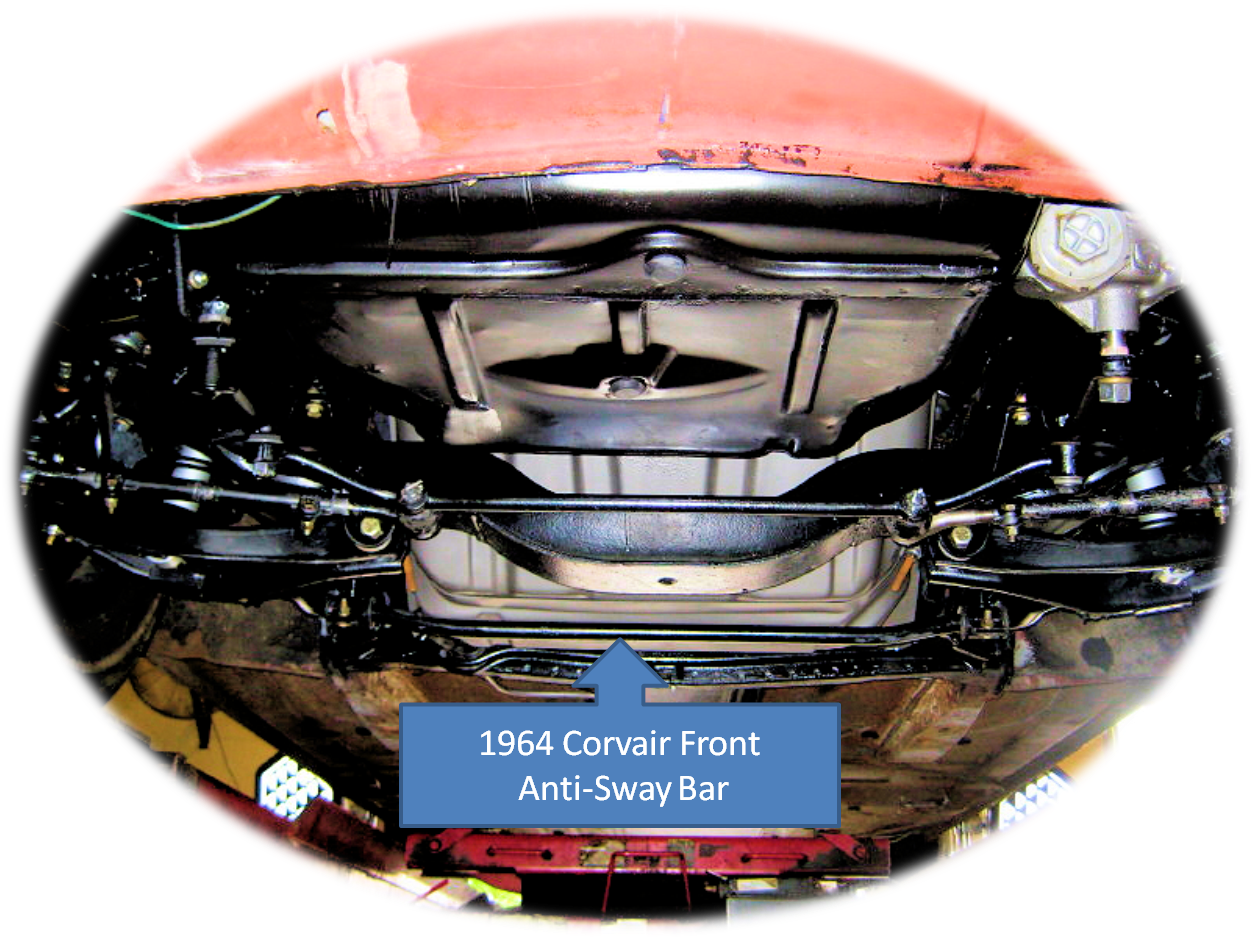

It may be possible to attach a front anti-sway bar if you transfer the needed components and associated attachment points. The rear transverse leaf spring is more difficult. It was unique to the 1964 model year and had unique attachment points on the differential case and suspension. The changes were an interim attempt to counter the negative publicity brought on by Ralph Nader and his book, but by 1965 the entire car body and rear suspension was redesigned. The 1965 rear suspension was a adaptation of the design found in the Corvette Stingray, and the Volkswagen-style rear swing axle suspension design was abandoned. I have driven and owned several 1962-1963 Corvairs that lacked these suspension components, and I was quite happy with those cars.

13" tires are increasingly obsolete, and even 14" tires are becoming more-rare. An upgrade of the 1962 suspension to fit 14" or larger rims and tires that represent modern design and engineering advances can pay big benefits in handling and braking improvements. I would recommend reading through the following article...

Sizing Corvair Wheels and Tires

http://autoxer.skiblack.com/tires.html

http://autoxer.skiblack.com/tires.html

If you buy this car, I would include a careful inspection of the parking brake and clutch cables and pulleys. Corvair Powerglide transmissions don't have a PARK position, so they rely totally on the emergency brake to keep the car from rolling away, but at least with a manual transmission you have the option of leaving it in gear when parked (I always do). But a broken clutch cable is a PITA, so I would recommend putting in a new cable and keeping the old one (if it isn't frayed) as an emergency spare in the trunk.

In your stem to stern inspection, check the steering linkage — particularly the rubber bushing in the pitman arm. They tend to rot and fade away. I had one with nothing but a center bolt and the steel portion intact, and a big air gap between the two. Also, flush the brake fluid. Brake fluid is hygroscopic and absorbs water from the air, which promotes rust and corrosion in the master cylinder, wheel cylinders, and steel brake lines. It also lowers the boiling point of the aging brake fluid, which can mean an early fade of the brakes if the fluid gets hot.

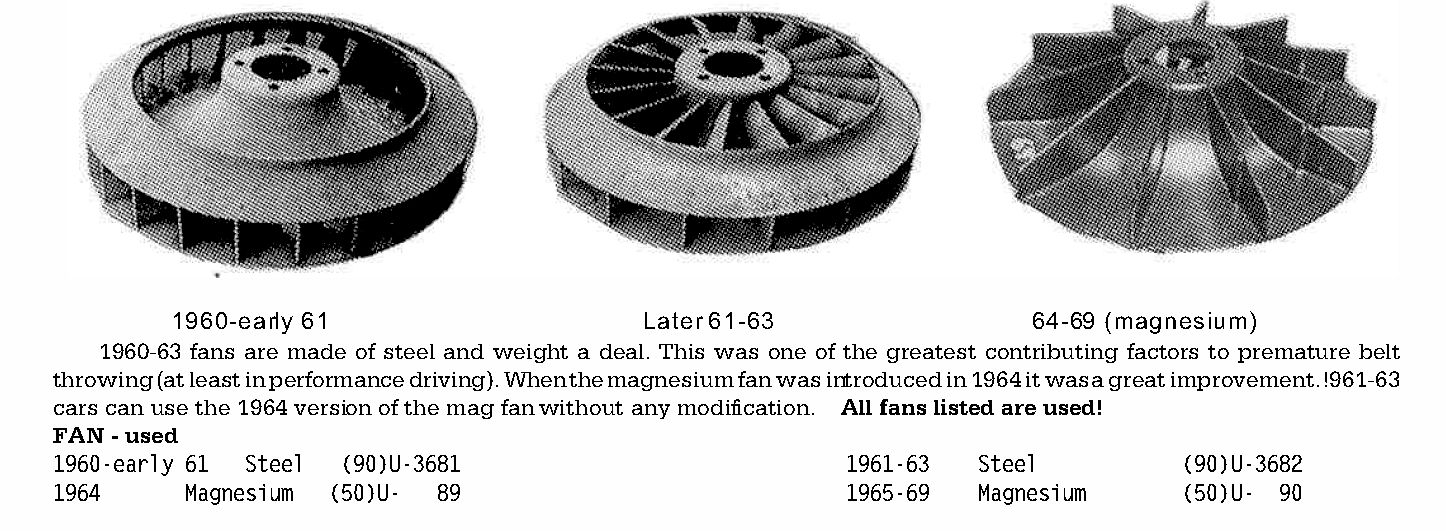

The magnesium cooling fan is a good add-on, as it greatly reduces fan belt stress. The 1964 fan fits the 1962 hub correctly. Magnesium blowers from 1965 and later will not fit correctly and may require a replacement hub and bearing to match. The Corvair Ranch in Gettysburg, Pennsylvania is probably a good source, as they have a very large inventory of used parts and good knowledge to go with it.

http://www.corvairranch.com/

http://www.corvairranch.com/

The information below pertains to the Interstate battery line that fits the limited, odd sized battery box area in Early Model Corvairs. Feedback I've heard from buyers of the Interstate battery line seems to indicate that this brand is a quality product.

If you need a new battery, the odd size and shape of the EM battery box might confuse things a bit. Clark's charges quite a bit for a battery that is similar in appearance to the originals...

Part number C12541: 61-64 CAR & 61-65 FC SCRIPT BATTERY *1960 SEE C13056

Weight: 30 lbs 0 oz

Catalog Pages(s): 79

Price: $ 262.00

But there are some other choices that will fit, will provide better service, are locally available, and cost less. The battery information below has proven to provide a good fit in the standard early model Corvair (1961-1964) battery box.

Here is a battery tip for early model Corvairs like yours that may help you to get an affordable battery for your early Corvair. Be sure to compare the battery dimensions with the available battery space in your Corvair. The dealer catalogs and references are unlikely to tell them if this battery will fit your car...

freedo wrote:In my EM i ran a Interstate 51 battery, might have been a 51R can't remember off the top of my head. its a honda civic batter, its small so it fits in there, but it doesnt fill in the whole space. worked perfectly fine for me. cranked everytime, never let me down

http://www.interstatebatteries.com/cs_e ... +++500+CCA

MEGA-TRON 51-R AUTOMOTIVE BATTERY 75 MONTHS 500 CCA

http://www.interstatebatteries.com/cs_e ... +++500+CCA

MEGA-TRON 51-R AUTOMOTIVE BATTERY 75 MONTHS 500 CCA

Get long life and premium performance with Interstate Batteries' Mega-Tron 51R. With 24-months free replacement and five-year performance, this 500 CCA automotive battery will meet or exceed your vehicle's starting requirements in any hot to moderate climate.

Sugg Retail Price: $107.95

List Price: $129.95

Dealer prices will vary

Product ID: MT-51R

Amps: 625

Cranking Amps: 625

Cold Cranking Amps: 500

Voltage: 12

Termination: A

Weight: 27.9

Width: 5.13

Length: 9.38

Height: 8.88

Plates: 24

WET/DRY: W

Here is some additional info on the use of the Interstate 51 battery...

freedo wrote:you have to make sure your tie down is tight or it will slide side to side. or you can make some plastic pieces to wedge it into shape. but interstate are strong good batteries. when i blew the motor up i had the lights on and the interior light on for almost a hour and when i went to start it up the next day it cranked right over

It appears that the only difference between the Interstate MT-51R and the MT-51 is the location of the positive and negative battery terminals...

MEGA-TRON 51-R AUTOMOTIVE BATTERY 75 MONTHS 500 CCA

http://www.interstatebatteries.com/cs_e ... +++500+CCA

http://www.interstatebatteries.com/cs_e ... +++500+CCA

MEGA-TRON 51 AUTOMOTIVE BATTERY FIVE-YEAR PERFORMANCE 500 CCA

MEGA-TRON 51 AUTOMOTIVE BATTERY FIVE-YEAR PERFORMANCE 500 CCA

http://www.interstatebatteries.com/cs_e ... L4%2f1.3L)

http://www.interstatebatteries.com/cs_e ... L4%2f1.3L)

As shown in the picture below, the correct battery appears to be the Interstate MT-51R, which places the positive terminal correctly on the right when the battery is placed in the battery area with the terminals facing the engine.

As shown in the picture below, the correct battery appears to be the Interstate MT-51R, which places the positive terminal correctly on the right when the battery is placed in the battery area with the terminals facing the engine.

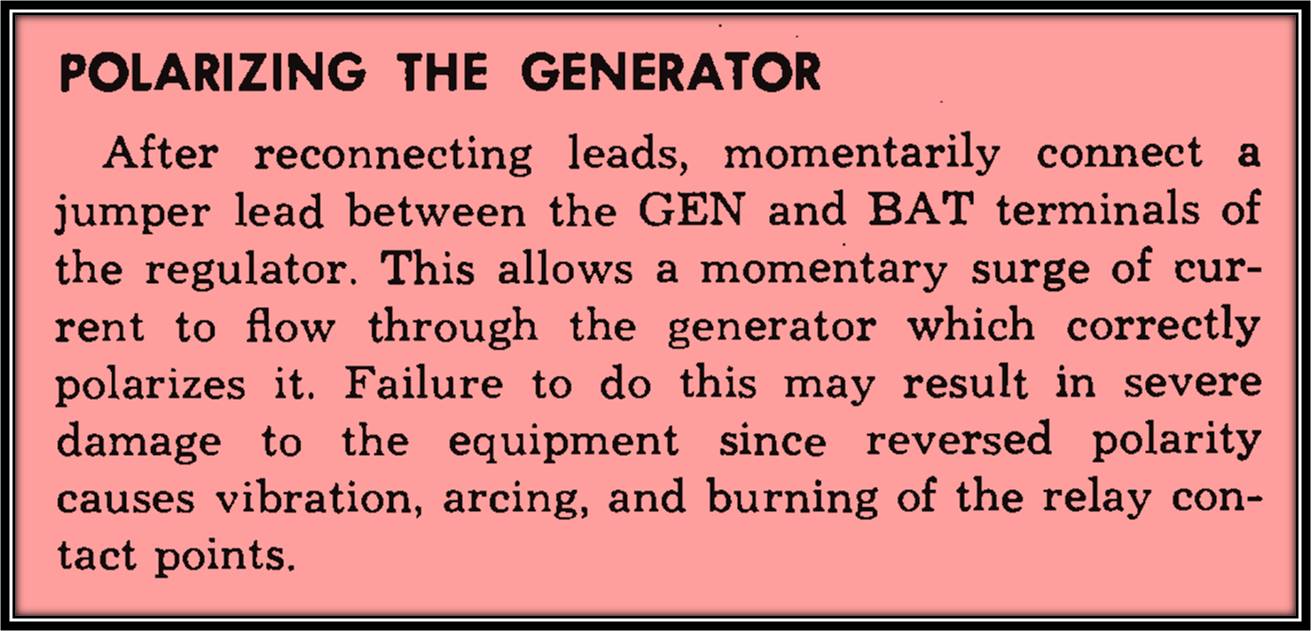

Whenever the battery is disconnected from the vehicle for any reason the polarization procedure should be performed.

The recommendation on how to polarize a charging system is the following:

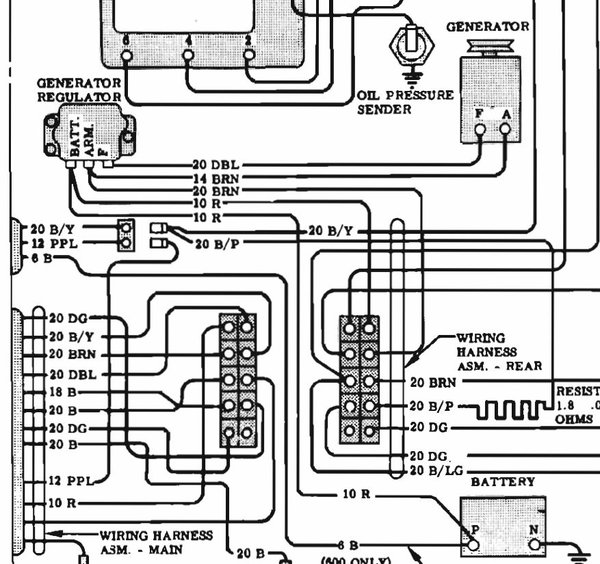

After the installation of a battery, generator or voltage regulator follow these procedures. The terminals on the voltage regulator are labeled with letters and this is where you will do the polarizing procedure. Both of the components will have battery power so do not start the vehicle or turn on the ignition switch before polarizing them. You will need a small piece of wire fourteen or sixteen gauge with alligator clips on the ends. Find the "

Batt" terminal on the regulator and attach one of the alligator clips, find the "

Armature" terminal and touch the terminal with the other alligator clip. You can touch the terminals a few times and it will produce a soft light spark.

Under no circumstances touch the "

Field" terminal or any other part of the regulator or you could damage the regulator.

http://www.vv.corvair.org/pipermail/vir ... 13475.html

http://www.vv.corvair.org/pipermail/vir ... 13475.html

What you want to do is polarize the generator. If in fact it ran with reverse polarity, everything should be fine after this process. You should not have damaged anything yet.

With key off, use a piece of 14 gage or larger wire to jump between the battery and armature terminals of the voltage regulator. I am at work without a shop manual, so I forget the actual writing on the terminals. BUT, it is the top and middle terminal on Corvairs (with the regulator mounted stock position, red wires on top terminal).

It will spark! Hold for 1 or 2 seconds. The wire may also get warm, be prepared.

Start engine again and check for red light going out.

IT IS IMPORTANT TO POLARIZE A NEW GENERATOR BY FOLLOWING THE PROCEDURES IN THE CORVAIR SHOP MANUAL. THIS PROCEDURE IS DESCRIBED ON PAGE 8-18 OF THE ATTACHED SHOP MANUAL SECTION. This polarizing procedure applies ONLY to vehicles equipped with a GENERATOR. It does not apply to vehicles equipped with an alternator.

When working on the Corvair engine, you will need to develop good habits with regard to working with aluminum components. Much of the Corvair engine was manufactured using aluminum, which is a relatively soft and easily damaged material. Bolts that screw into aluminum threads should be carefully threaded by hand to avoid the possibility of cross-threading. The use of anti-seize compound to coat the threads is recommended. A torque wrench should be utilized to properly tighten all fasteners using specifications listed in the Corvair shop manual. This will help you to avoid damaging any threads in the Corvair engine.

All suspension components should be examined. Ball joints and other front suspension components with grease fittings should be lubricated. Front wheel bearings should be cleaned, inspected, repacked and adjusted. With regard to the rear axle bearings (which are difficult to maintain and service, and are often neglected), here's a quote from the Clark's Corvair Parts catalog…

Clark's Corvair Parts Online Catalog, Page 165 wrote:REAR AXLE (WHEEL) BEARINGS — 1960-1964 CARS

The rear axle bearings are probably the most dangerous part of the whole car. It is not uncommon for the axle shaft to pull right out. In some cases the axle shaft just worked out and others the bearing has failed. The 1965-69 style fixed this but people with the earlier style should not ignore any possible bearing noises!

Rear axle universal joints also tend to be neglected — especially if they are not equipped with grease fittings. These also should be inspected and serviced or replaced, if needed.

1966 Corvair Corsa Convertible

1966 Corvair Corsa Convertible