Two Issues - Gas Mileage & Harmonic Balancer

Two Issues - Gas Mileage & Harmonic Balancer

Hello All,

Gas mileage on my '65 Corsa 180 Turbo, is unacceptable at 11.1 MPG. Carburetor is the Weber 45DCOE rebuilt by Ray Sedman. Car is running good, No Bogging, Good Pick and Go. Should not the gas mileage with the Weber be about 16? That is my first problem. I've completed a tune up with new NGK B6HS plugs, new points, rotor etc. My thinking was perhaps the timing was off. I had recently replaced the Harmonic Balancer due to rust issues chewing up the fan belt. The HB that I got from Clarks came unpainted - shiny raw steel. I thought, this kinda looks good but will rust, so I painted the HB with clear coat (I was careful to tape-off rubber). When I point the timing light to the right area I can NOT see the mark to set the timing. I've tried to paint the timing mark only, white - still cannot see the mark. Would it help to paint the outer edges of the HB a flat black?

Any help is greatly appreciated, before I trash this whole turbo thing, and install a reliable 110.

Gas mileage on my '65 Corsa 180 Turbo, is unacceptable at 11.1 MPG. Carburetor is the Weber 45DCOE rebuilt by Ray Sedman. Car is running good, No Bogging, Good Pick and Go. Should not the gas mileage with the Weber be about 16? That is my first problem. I've completed a tune up with new NGK B6HS plugs, new points, rotor etc. My thinking was perhaps the timing was off. I had recently replaced the Harmonic Balancer due to rust issues chewing up the fan belt. The HB that I got from Clarks came unpainted - shiny raw steel. I thought, this kinda looks good but will rust, so I painted the HB with clear coat (I was careful to tape-off rubber). When I point the timing light to the right area I can NOT see the mark to set the timing. I've tried to paint the timing mark only, white - still cannot see the mark. Would it help to paint the outer edges of the HB a flat black?

Any help is greatly appreciated, before I trash this whole turbo thing, and install a reliable 110.

-

corvair500

- Posts: 297

- Joined: Sat Oct 13, 2018 3:09 am

- Location: Virginia

Re: Two Issues - Gas Mileage & Harmonic Balancer

I cant imagine not being able to see the mark , take a piece of chalk and rub it on the timing mark that should make it clearer. Could there be a defect in manufacturing causing the mark to be off from where it should be ?

Last edited by corvair500 on Thu Apr 08, 2021 8:08 am, edited 1 time in total.

Re: Two Issues - Gas Mileage & Harmonic Balancer

Tried the chalk, before painting the notch on the HB - nada

Thanks,

Thanks,

- bbodie52

- Corvair of the Month

- Posts: 12142

- Joined: Mon Aug 06, 2012 12:33 pm

- Location: Lake Chatuge Hayesville, NC

- Contact:

Re: Two Issues - Gas Mileage & Harmonic Balancer

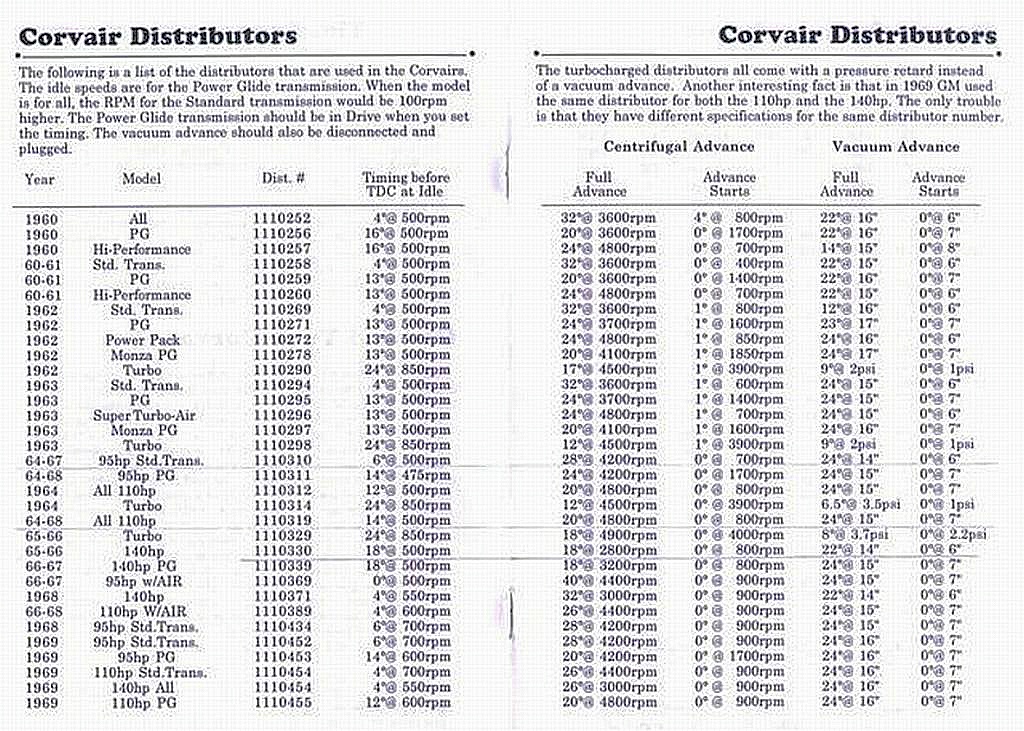

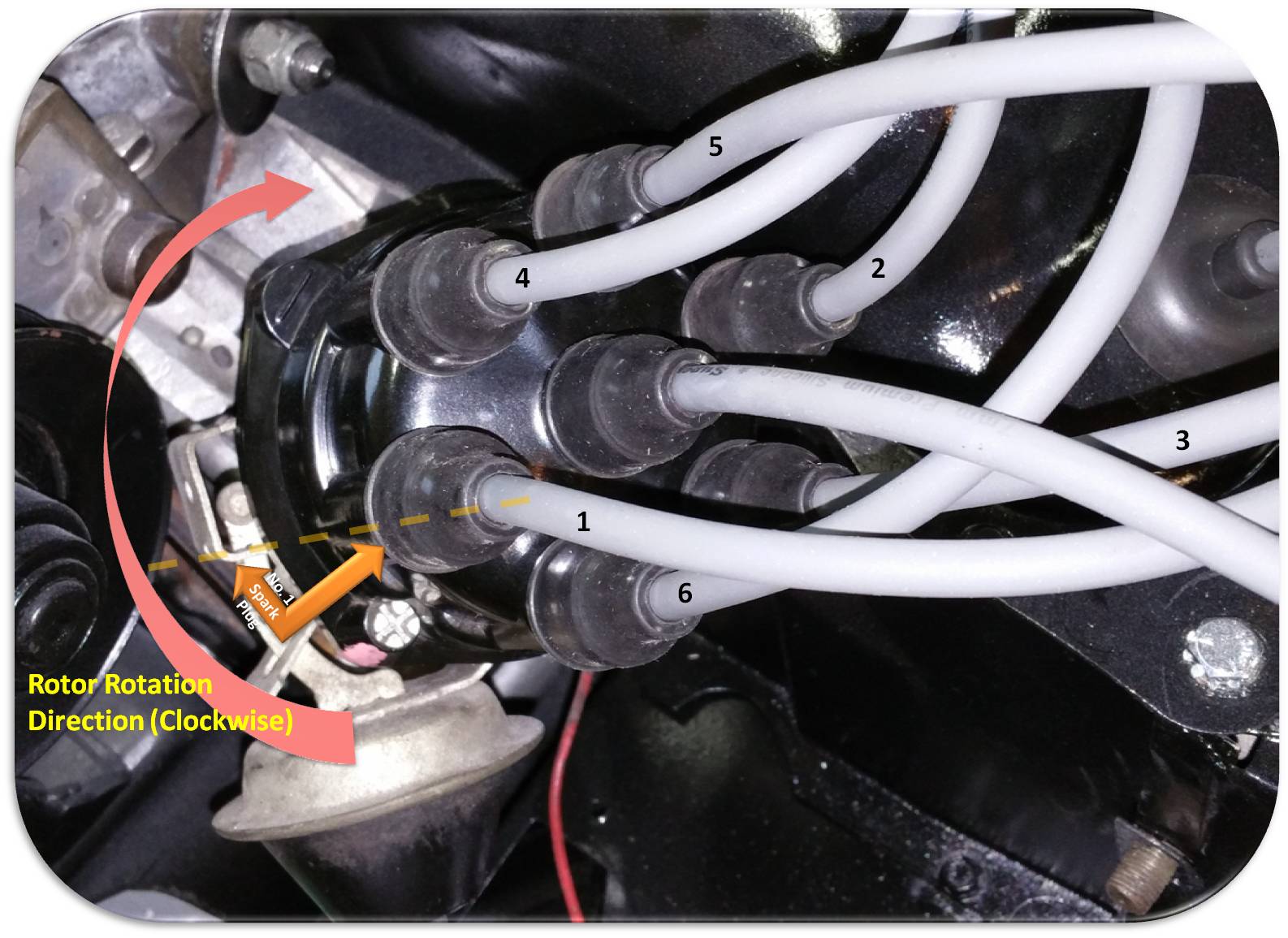

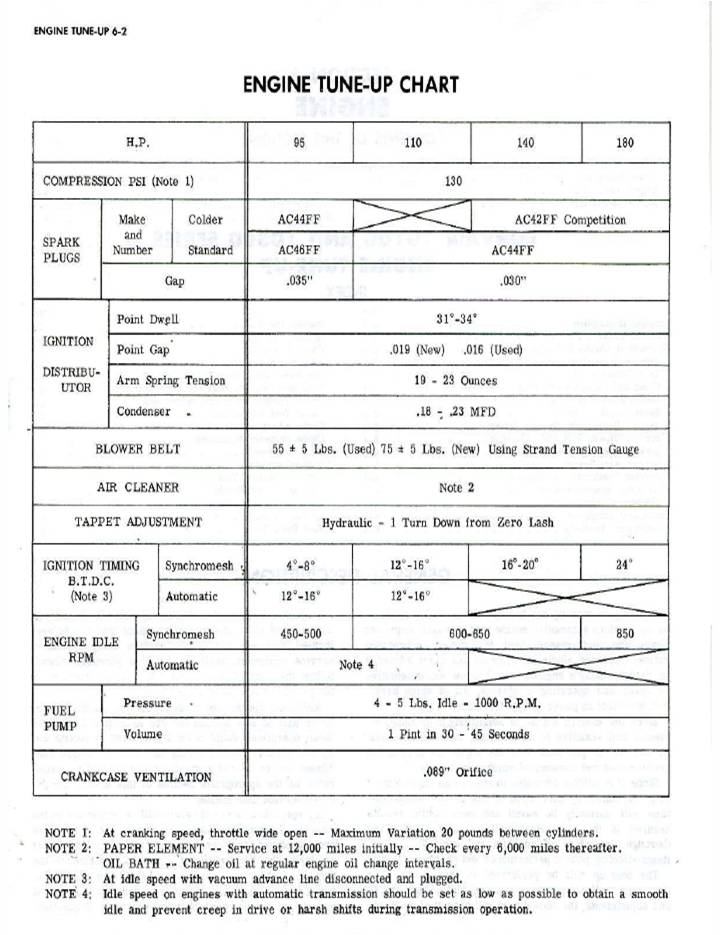

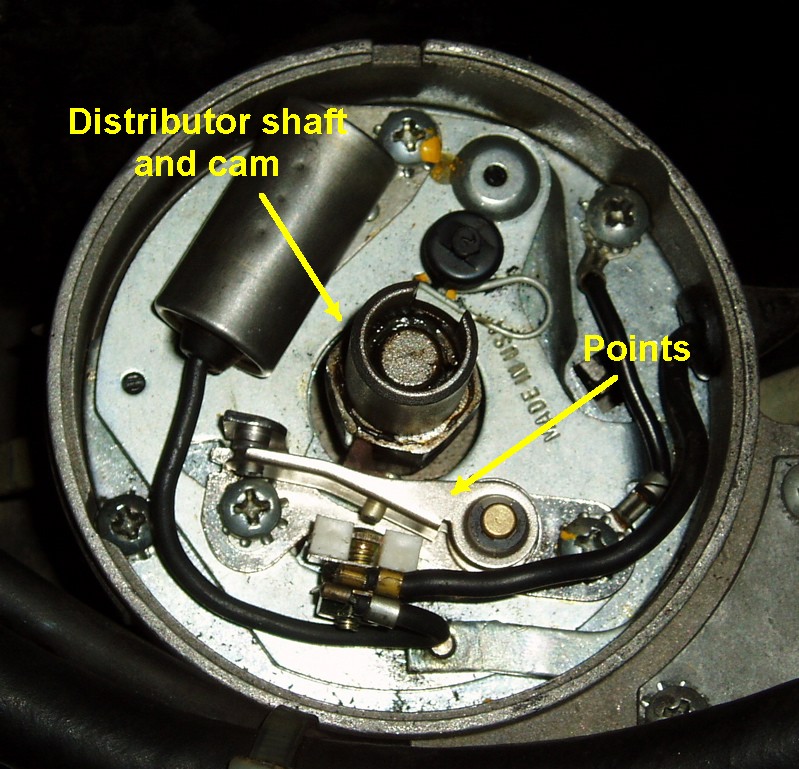

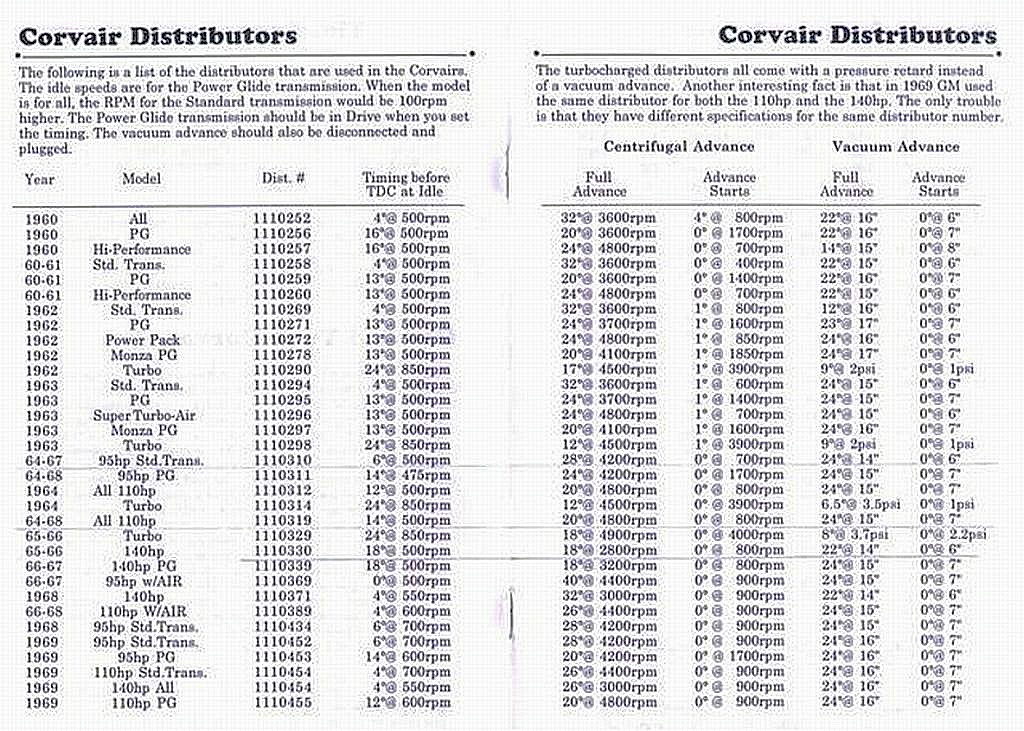

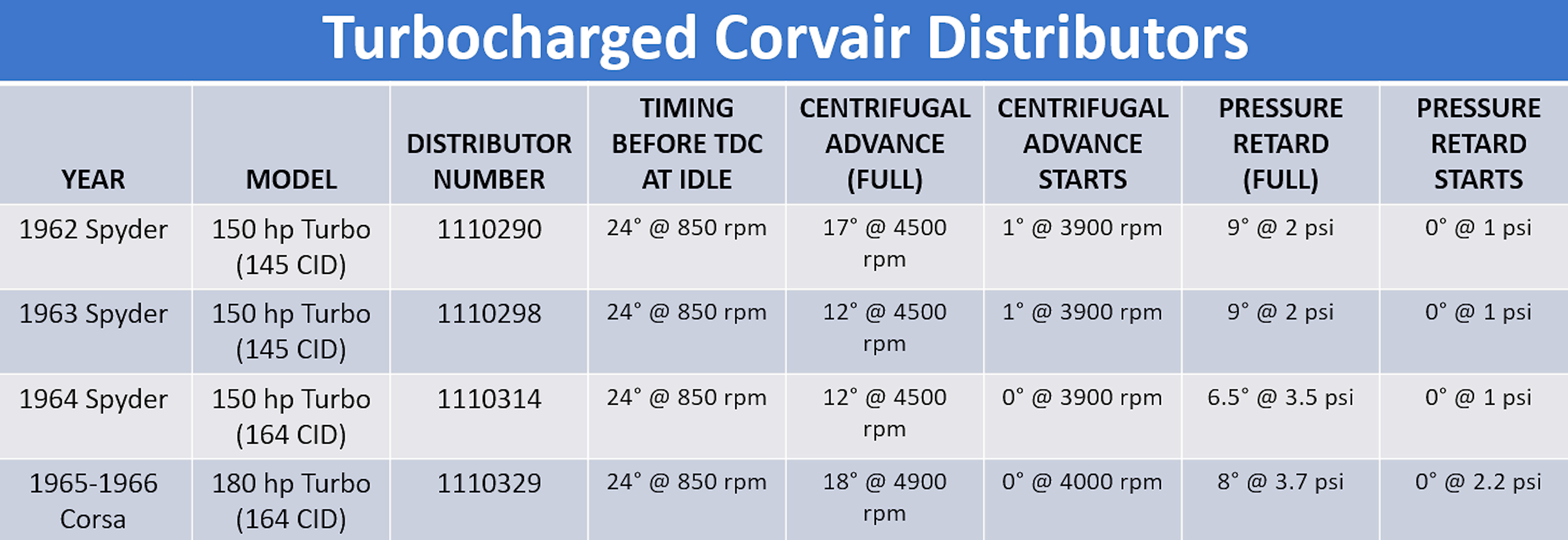

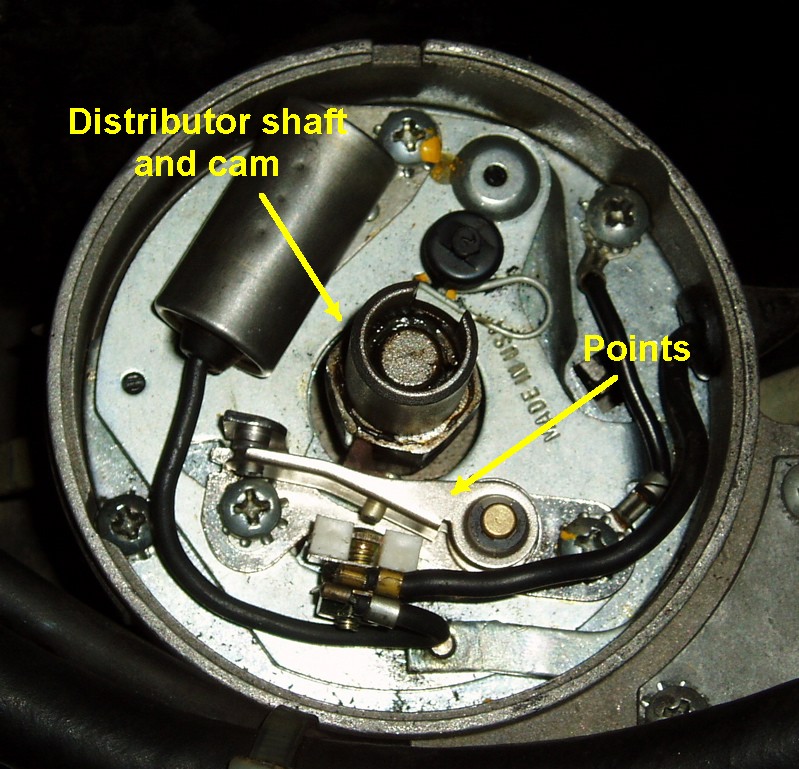

Not sure about your timing mark problem, unless there is a fault in the timing light or the timing light is not connected properly. Have you tried static timing the engine? I.E. rotate the crankshaft until the timing mark lines up with the scale (24° BTDC with the rotor pointing at cylinder 1 on the distributor cap). With ignition points, a strip of paper between the points will help you to detect when the points just open (and releases the paper). Make any necessary adjustments on the distributor housing position so that the points just open with the mark set at 24°. Put the cap back on and verify the timing with the engine running using your timing light.

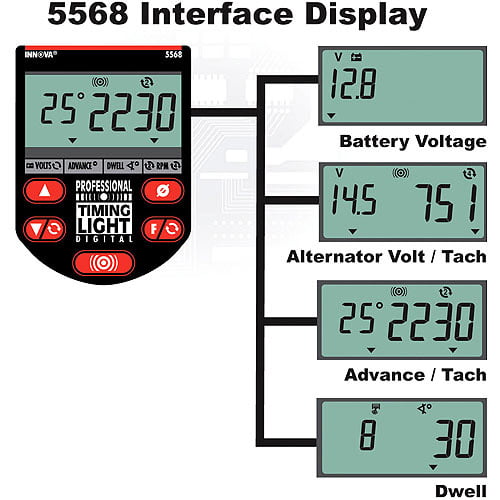

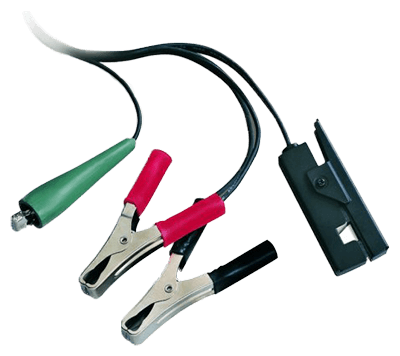

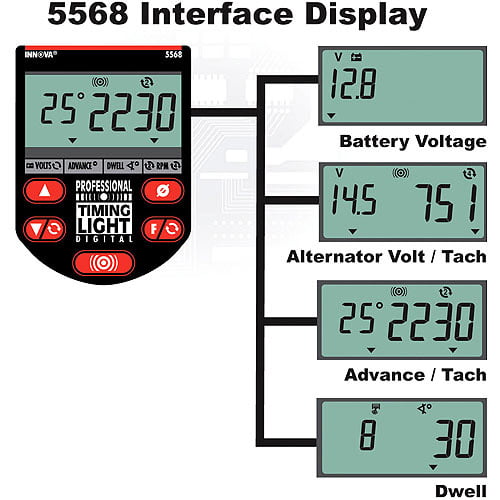

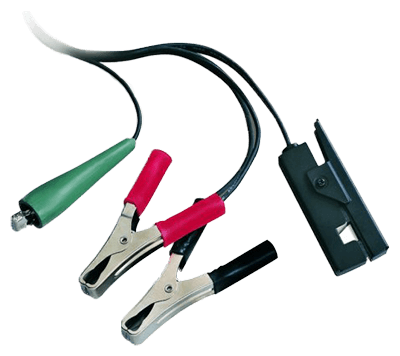

Here is some additional information. You will need a timing light and a dwell-tachometer to properly set up your ignition and fuel system on the Corvair. The model below is one that I purchased where the dwell tachometer and strobe timing light are fully integrated into a single unit.

INNOVA 5568 Pro Digital Timing Light with Storage Case

Timing Accuracy: Have you checked the harmonic balancer to verify that the outer ring has not slipped?

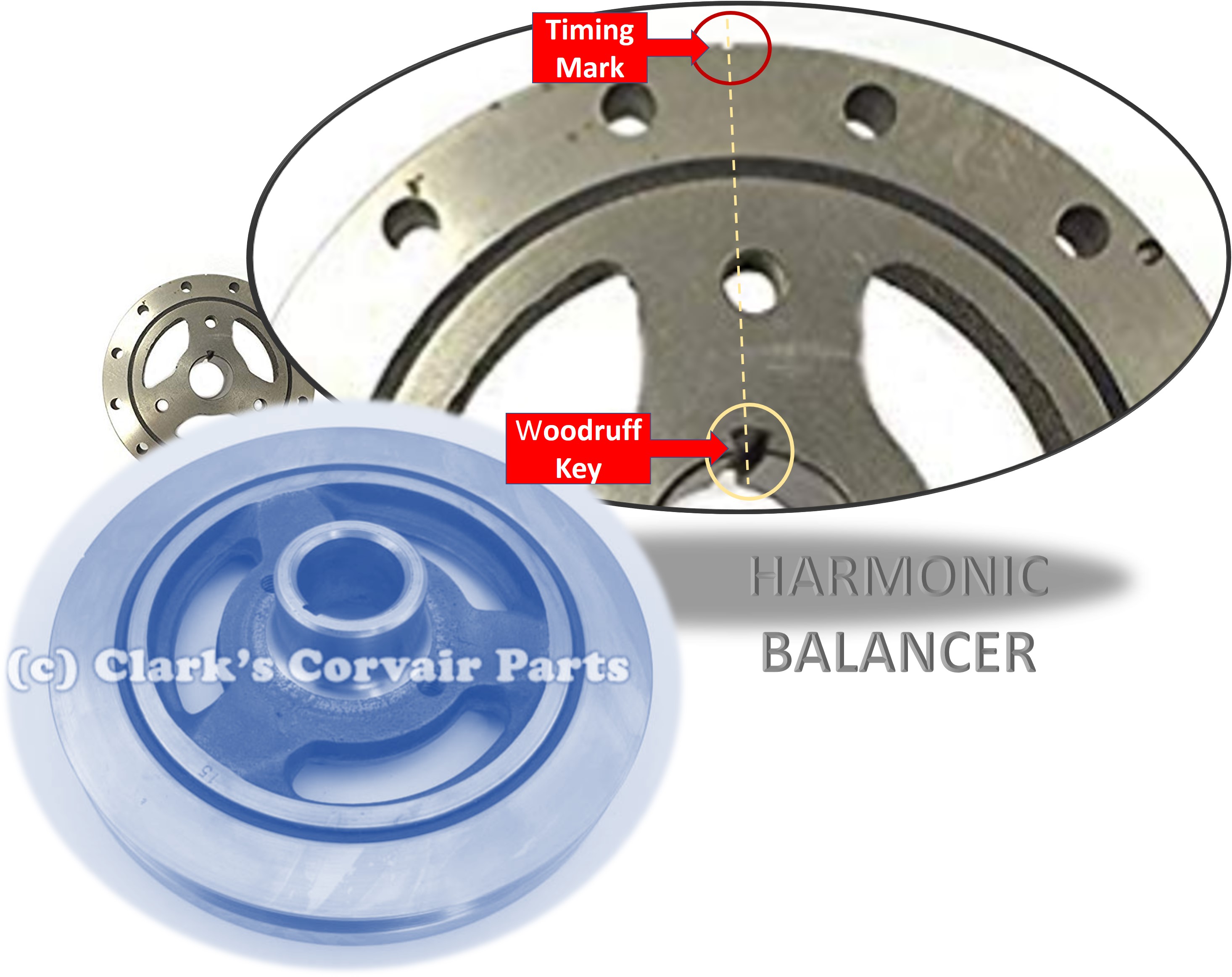

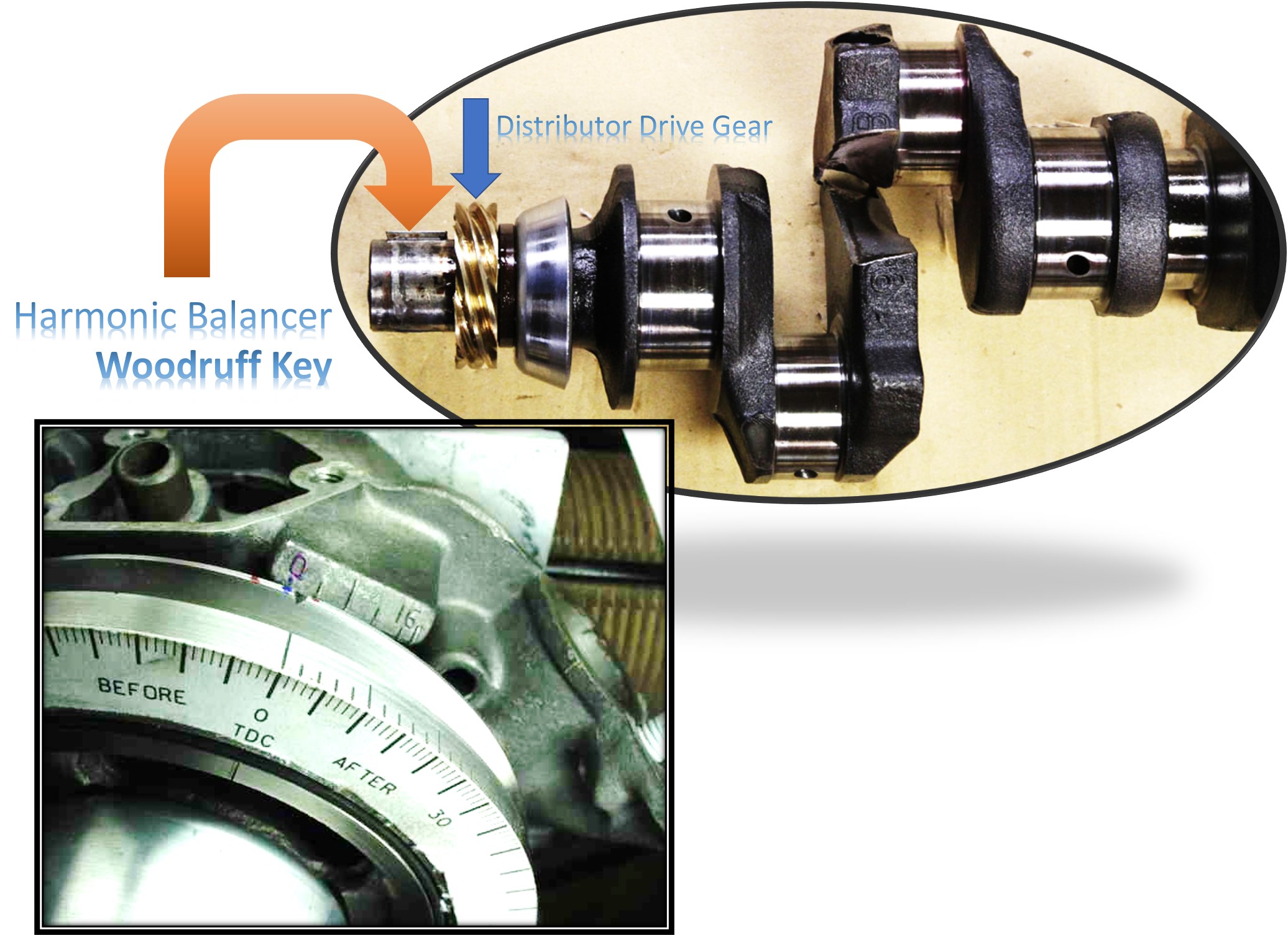

You may want to confirm the harmonic balancer timing mark registration posiiton with the location of the woodruff key on the crankshaft. I suppose it might be possible that your new harmonic balancer was not assembled properly when it was manufactured, and that the timing mark is not in alignment with the crankshaft mount key slot.

You may want to confirm the harmonic balancer timing mark registration posiiton with the location of the woodruff key on the crankshaft. I suppose it might be possible that your new harmonic balancer was not assembled properly when it was manufactured, and that the timing mark is not in alignment with the crankshaft mount key slot.

In this picture, you can see (from left to right) the woodruff key, the distributor drive gear, the fuel pump push rod cam lobe, the main journal, and connecting rod journals 1and 2.

If the distributor is worn, timing drive gear is loose, etc. there could be dwell variations in the points, causing timing variations and inconsistencies.

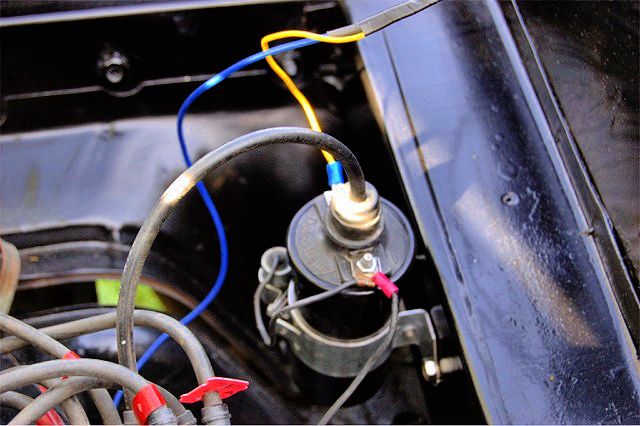

It is not a bad idea to relocate the coil mount position. The standard installation of the ignition coil was always mounting it directly on the right cylinder head. The cylinder head on an air cooled engine gets very hot, and a significant portion of that heat can be transferred via the coil mounting bracket to the coil body itself. I would recommend relocating any coil as shown in the pictures below.

if you have the budget for it, you might consider switching to an electronic distributor or a Pertronix or Crane Cams electronic upgrade for your existing distributor, in addition to a correct set spark plug wires. The elimination of points and condenser and general upgrade to a modern breakerless electronic ignition system can provide you with an ignition system that is almost maintenance free. The link below can provide you with some options and background information that you might consider.

if you have the budget for it, you might consider switching to an electronic distributor or a Pertronix or Crane Cams electronic upgrade for your existing distributor, in addition to a correct set spark plug wires. The elimination of points and condenser and general upgrade to a modern breakerless electronic ignition system can provide you with an ignition system that is almost maintenance free. The link below can provide you with some options and background information that you might consider.

ELECTRONIC DISTRIBUTOR UPGRADE/REPLACEMENT OPTIONS

viewtopic.php?f=225&t=15101

viewtopic.php?f=225&t=15101

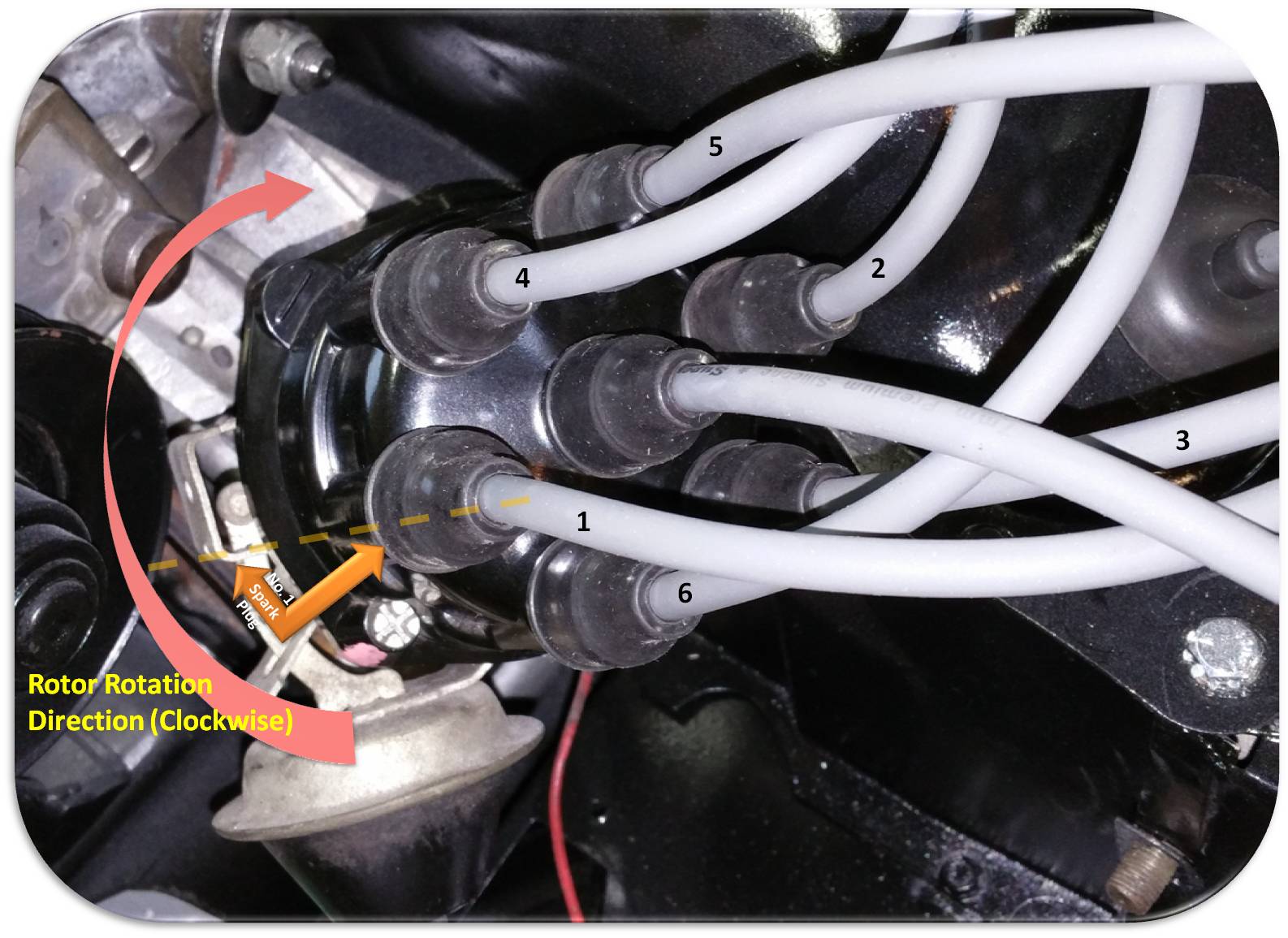

The distributor insertion coupled with crankshaft pulley timing mark setting for cylinder number one (on the compression stroke) will determine which distributor cap tower the rotor is pointing at to fire cylinder number one. Then you can position the spark plug wires with the correct firing order based on the distributor orientation. The distributor housing position sets the firing point for the coil by positioning the ignition points in relation to the rotor and distributor cam location. You have some flexibility in the distributor base housing orientation, and your main concern when the timing is correct is that the vacuum advance mechanism does not prevent a proper range of timing adjustment by bumping into an adjacent engine component.

I prefer to use the NGK B6HS spark plug in the Corvair. Because it has plated threads (a trivalent Zinc-chromate shell plating) there is less chance of thread damage in the aluminum heads, and the possible need for anti-seize compound on the plugs to protect the threads is eliminated. (See the attached NGK Spark Plug Tech Bulletin for more information).

Here is some additional information. You will need a timing light and a dwell-tachometer to properly set up your ignition and fuel system on the Corvair. The model below is one that I purchased where the dwell tachometer and strobe timing light are fully integrated into a single unit.

INNOVA 5568 Pro Digital Timing Light with Storage Case

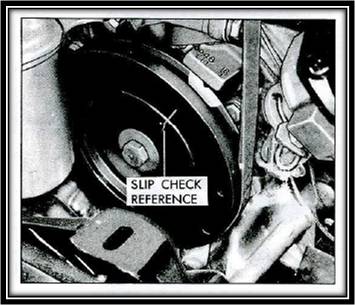

Timing Accuracy: Have you checked the harmonic balancer to verify that the outer ring has not slipped?

bbodie52 wrote:A harmonic balancer was specified on all 164 CI engines from 1964 through 1969 (except for the 95 hp version). The harmonic balancer was intended to prolong the life of the crankshaft by reducing the possibility of stress fractures from crankshaft harmonics in the long stroke crankshaft. If present and visible, the slip check reference mark should line up between the center hub and the outer ring, showing that there has been no slippage between the hub and the outer ring, which is held in place by a press-fit using a rubber component sandwiched between the two metal components. If the slip check reference mark is not present, the timing mark on the outer ring must be in-line with the crankshaft woodruff key. The woodruff key is a machine element used to connect a rotating pulley or harmonic balancer to the crankshaft. The key prevents relative rotation between the two parts, and ensures proper alignment with the crankshaft journal associated with the number one piston at Top Dead Center.

If you ever need to replace a defective harmonic balancer, a new harmonic balancer should be purchased because the lifespan of the three-piece harmonic balancer is limited and purchasing a used, aging harmonic balancer may not be an economical choice. This is because there is no way to predict how much life is left in the used component. The pictures below will explain the variations found in pulley design over the various Corvair model years, and shows how the pulley or harmonic balancer establishes a known reference point for crankshaft and ignition system timing.

In this picture, you can see (from left to right) the woodruff key, the distributor drive gear, the fuel pump push rod cam lobe, the main journal, and connecting rod journals 1and 2.

If the distributor is worn, timing drive gear is loose, etc. there could be dwell variations in the points, causing timing variations and inconsistencies.

It is not a bad idea to relocate the coil mount position. The standard installation of the ignition coil was always mounting it directly on the right cylinder head. The cylinder head on an air cooled engine gets very hot, and a significant portion of that heat can be transferred via the coil mounting bracket to the coil body itself. I would recommend relocating any coil as shown in the pictures below.

ELECTRONIC DISTRIBUTOR UPGRADE/REPLACEMENT OPTIONS

The distributor insertion coupled with crankshaft pulley timing mark setting for cylinder number one (on the compression stroke) will determine which distributor cap tower the rotor is pointing at to fire cylinder number one. Then you can position the spark plug wires with the correct firing order based on the distributor orientation. The distributor housing position sets the firing point for the coil by positioning the ignition points in relation to the rotor and distributor cam location. You have some flexibility in the distributor base housing orientation, and your main concern when the timing is correct is that the vacuum advance mechanism does not prevent a proper range of timing adjustment by bumping into an adjacent engine component.

I prefer to use the NGK B6HS spark plug in the Corvair. Because it has plated threads (a trivalent Zinc-chromate shell plating) there is less chance of thread damage in the aluminum heads, and the possible need for anti-seize compound on the plugs to protect the threads is eliminated. (See the attached NGK Spark Plug Tech Bulletin for more information).

Brad Bodie

Lake Chatuge, North Carolina

1966 Corvair Corsa Convertible

1966 Corvair Corsa Convertible

Lake Chatuge, North Carolina

1966 Corvair Corsa Convertible

1966 Corvair Corsa Convertible-

corvair500

- Posts: 297

- Joined: Sat Oct 13, 2018 3:09 am

- Location: Virginia

Re: Two Issues - Gas Mileage & Harmonic Balancer

Put a chalk mark across the hb directly where the mark should be . If your timing light is strong enough , try to find the mark at another location , maybe 180 degrees , but if its anywhere else than where it should be it is really no good . One thought , is there a key in the crankshaft that sets position of hb ? Best I remember there is ... Has this been left out

Last edited by corvair500 on Thu Apr 08, 2021 8:43 am, edited 1 time in total.

Re: Two Issues - Gas Mileage & Harmonic Balancer

Turbo engines can be frustrating. Although once you get them dialed in they are fine.

I'm not a fan of the Weber carburetor because it can be finicky, although the stock carburetor has it's issues. Steve Goodman at rear engine specialists in Colorado has a good reputation for sorting stock turbo engines and carburetors.

Without an exhaust gas analyzer all one can do is "guess" about the fuel mileage issue. However it's usually either fuel mixture, worn out engine (no compression), or ignition or cam timing. The fact you can't "find" the timing mark is a red flag. Even with a shiny damper if you can see a mark when it's not moving, you should be able to see it with a timing light. First thing to do is take off the distributor cap and rotate engine so the rotor points to the #1 plug wire terminal. BTW the #1 plug wire can be in ANY position on the cap as long as the other plug wires are in the correct timing order. With the rotor pointing to the #1 plug terminal the timing mark should be about in the area expected with respect to the timing indicator. If not the HB was may be wrong or the distributor advance is off. Make sure the distributor is working. I've had a few "it won't run worth a darn" cars were I found the timing set at an RPM causing the mechanical advance was in it's active curve. Static timing MUST be set with the boost canister nulled (vacuum advance on normal engines) AND the RPM low enough so the mechanical timing is not starting (make sure both advance springs are intact).

After all these decades I find all kinds of "changes" that can cause issues.

Not to be rude, but a few times when I could not find the timing mark with a timing light I double checked and found I had the timing light pickup on the wrong plug wire - happens. Also timing lights with "adjustable" timing delay knobs tend to be problematic.

Good luck.

I'm not a fan of the Weber carburetor because it can be finicky, although the stock carburetor has it's issues. Steve Goodman at rear engine specialists in Colorado has a good reputation for sorting stock turbo engines and carburetors.

Without an exhaust gas analyzer all one can do is "guess" about the fuel mileage issue. However it's usually either fuel mixture, worn out engine (no compression), or ignition or cam timing. The fact you can't "find" the timing mark is a red flag. Even with a shiny damper if you can see a mark when it's not moving, you should be able to see it with a timing light. First thing to do is take off the distributor cap and rotate engine so the rotor points to the #1 plug wire terminal. BTW the #1 plug wire can be in ANY position on the cap as long as the other plug wires are in the correct timing order. With the rotor pointing to the #1 plug terminal the timing mark should be about in the area expected with respect to the timing indicator. If not the HB was may be wrong or the distributor advance is off. Make sure the distributor is working. I've had a few "it won't run worth a darn" cars were I found the timing set at an RPM causing the mechanical advance was in it's active curve. Static timing MUST be set with the boost canister nulled (vacuum advance on normal engines) AND the RPM low enough so the mechanical timing is not starting (make sure both advance springs are intact).

After all these decades I find all kinds of "changes" that can cause issues.

Not to be rude, but a few times when I could not find the timing mark with a timing light I double checked and found I had the timing light pickup on the wrong plug wire - happens. Also timing lights with "adjustable" timing delay knobs tend to be problematic.

Good luck.

Re: Two Issues - Gas Mileage & Harmonic Balancer

Very much appreciate the comments of all! OK here are my findings.

- Rotor point to #1 Cyl.

- Points partially open

- Timing mark on HB on the wrong side of scale by about 2

- Points not quite on the high lobe of the Dist. Cam

- Timing mark on HB at 0

- Points partially open

- Points still not quite on the high lobe of the Dist. Cam

- Points on the high lobe of the Dist. cam

-Timing mark on HB on the wrong side of the scale by about 16

- Timing mark on 24 (as spec'd. for the 180)

- Points Closed

What is the above telling me?

What should my step be?

I am beginning to believe that the reason I could not see the timing mark, was because the mark was below the the oil filter/alternator casting?

Thank You All

Steve D.

- Rotor point to #1 Cyl.

- Points partially open

- Timing mark on HB on the wrong side of scale by about 2

- Points not quite on the high lobe of the Dist. Cam

- Timing mark on HB at 0

- Points partially open

- Points still not quite on the high lobe of the Dist. Cam

- Points on the high lobe of the Dist. cam

-Timing mark on HB on the wrong side of the scale by about 16

- Timing mark on 24 (as spec'd. for the 180)

- Points Closed

What is the above telling me?

What should my step be?

I am beginning to believe that the reason I could not see the timing mark, was because the mark was below the the oil filter/alternator casting?

Thank You All

Steve D.

Re: Two Issues - Gas Mileage & Harmonic Balancer

Rotor point to #1 Cyl.

- Points partially open

- Timing mark on HB on the wrong side of scale by about 2

- Points not quite on the high lobe of the Dist. Cam

I'm not sure what you mean by "2". Do you mean the HB timing mark is 2 degrees AFTER 0 on the timing mark indicator?

The distributor shaft and rotor moves clockwise. The HB rotates counter clockwise. So --- as the HP timing mark moves CCW to the 24 advanced timing mark on the case indicator the rotor should move CW toward plug wire #1 so the points JUST start to open (fires the coil) at 24 degrees advanced (I recall that's the turbo timing, but it's off the top of my head). Then the points stay open until the rotor moves about 30 degrees and the points close to charge up the coil for the next cylinder firing (cylinder # 4).

Keep in mind - HB moves CCW and distributor rotor moves CW. Also the distributor turns at half the speed as HB/crankshaft (four cycle engine).

I hope this helps.

- Points partially open

- Timing mark on HB on the wrong side of scale by about 2

- Points not quite on the high lobe of the Dist. Cam

I'm not sure what you mean by "2". Do you mean the HB timing mark is 2 degrees AFTER 0 on the timing mark indicator?

The distributor shaft and rotor moves clockwise. The HB rotates counter clockwise. So --- as the HP timing mark moves CCW to the 24 advanced timing mark on the case indicator the rotor should move CW toward plug wire #1 so the points JUST start to open (fires the coil) at 24 degrees advanced (I recall that's the turbo timing, but it's off the top of my head). Then the points stay open until the rotor moves about 30 degrees and the points close to charge up the coil for the next cylinder firing (cylinder # 4).

Keep in mind - HB moves CCW and distributor rotor moves CW. Also the distributor turns at half the speed as HB/crankshaft (four cycle engine).

I hope this helps.

Re: Two Issues - Gas Mileage & Harmonic Balancer

Yes, the Timing mark is about 2 degrees to the left of zero on the scale when the rotor is in line with #1 cyl. I can only say 'about' because the timing mark is right at the edge of the scale tab. I am aware that the crank/HB rotate CCW and that the distributer rotates CW.

At what point does spark occur at the points? My thinking is, when points are at there most open (.016). am I correct?

Thanks, Steve D.

At what point does spark occur at the points? My thinking is, when points are at there most open (.016). am I correct?

Thanks, Steve D.

- bbodie52

- Corvair of the Month

- Posts: 12142

- Joined: Mon Aug 06, 2012 12:33 pm

- Location: Lake Chatuge Hayesville, NC

- Contact:

Re: Two Issues - Gas Mileage & Harmonic Balancer

The ignition coil builds a charge while the points are closed (grounding the coil negative terminal and causing electrical current to flow through the coil primary winding). The moment the points open, the primary field collapses and induces an electrical field through the secondary winding, resulting in spark voltage into the distributor cap center tower, where it is directed by the rotor to the appropriate spark plug. So in static timing the engine, the crankshaft is manually rotated so that the timing mark aligns with "24" on your turbo engine. The distributor housing is positioned on the low portion of the cam lobe, to the left o the lobe, and then slowly rotated CCW so that the points rubbing block just contacts the cam lobe high point and opens the points. The opening of the points causes a spark discharge from the coil, which is routed via the rotor to spark plug tower #1.

Brad Bodie

Lake Chatuge, North Carolina

1966 Corvair Corsa Convertible

1966 Corvair Corsa Convertible

Lake Chatuge, North Carolina

1966 Corvair Corsa Convertible

1966 Corvair Corsa ConvertibleRe: Two Issues - Gas Mileage & Harmonic Balancer

If you are around 24 degrees for timing and using a stock turbo distributor, your gas mileage problem is most easily explained by overly rich jetting, which is actually a fairly common occurance with Webers on turbo Corvairs. I managed, at one point to get 12 mpg with my weber, trying to get rid of a ping, and proceeded to richen it beyond all reason. WRONG way to take care of it! If your DCOE has been modified for vacuum actuated secondary, then probably, the jetting on the primary side is just too rich. Check the choke size- if it is a 32mm choke, then the main jet on that side ought to be something like 130-135

but if its 150-175, you've found most of the issue right there. Check the idle jets, "get out of jail free" on these will be a 50 or 55 F9. The other thing- if the vacuum actuated secondary modification has not been done, this is probably the problem, because the hesitation that that comes with throttle opening was "jetted out" and is too rich on both the idle jets and mains. Check your jetting!

but if its 150-175, you've found most of the issue right there. Check the idle jets, "get out of jail free" on these will be a 50 or 55 F9. The other thing- if the vacuum actuated secondary modification has not been done, this is probably the problem, because the hesitation that that comes with throttle opening was "jetted out" and is too rich on both the idle jets and mains. Check your jetting!

Re: Two Issues - Gas Mileage & Harmonic Balancer

To restate --- just as the points OPEN when the rotor and cam are turning CW the coil will discharge to fire the spark plug.

Overly rich running Turbo's are not unusual. With the stock carburetor I finally found the cure ---- per well respected Steve Goodman (rear engine specialists) I installed a GOOD fuel pressure regulator and set it to 2-3 LBS (3LBS at sea level and 2 LBS at greater than 5,000 ft. ASL).

A good stock fuel pump will put out between 4-5 PSI, BUT lately folks have reported the new ones are putting out 9 PSI!!!!

Overly rich running Turbo's are not unusual. With the stock carburetor I finally found the cure ---- per well respected Steve Goodman (rear engine specialists) I installed a GOOD fuel pressure regulator and set it to 2-3 LBS (3LBS at sea level and 2 LBS at greater than 5,000 ft. ASL).

A good stock fuel pump will put out between 4-5 PSI, BUT lately folks have reported the new ones are putting out 9 PSI!!!!

- bbodie52

- Corvair of the Month

- Posts: 12142

- Joined: Mon Aug 06, 2012 12:33 pm

- Location: Lake Chatuge Hayesville, NC

- Contact:

Re: Two Issues - Gas Mileage & Harmonic Balancer

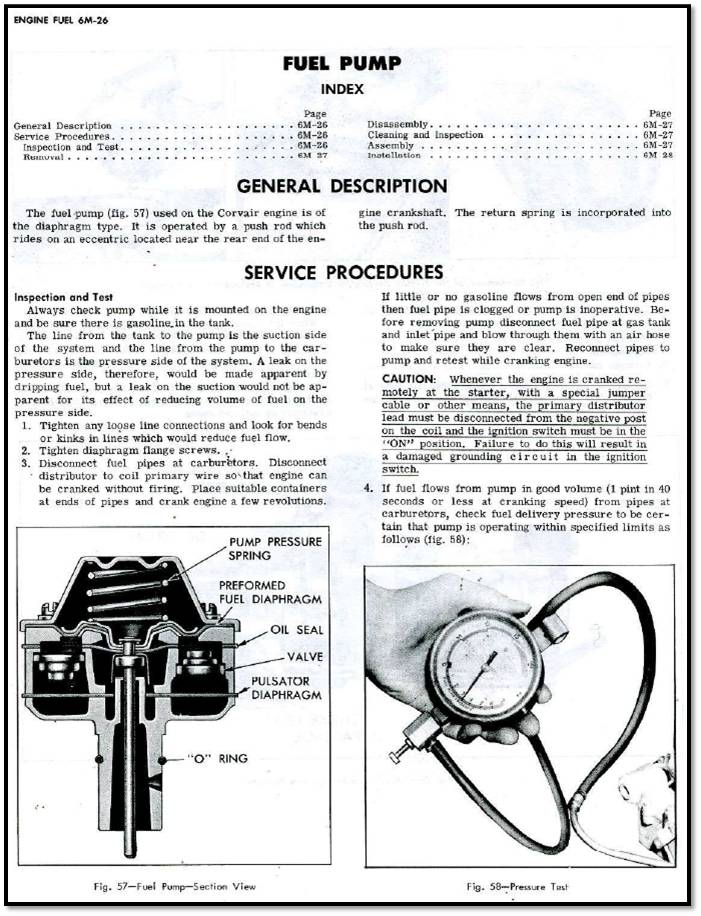

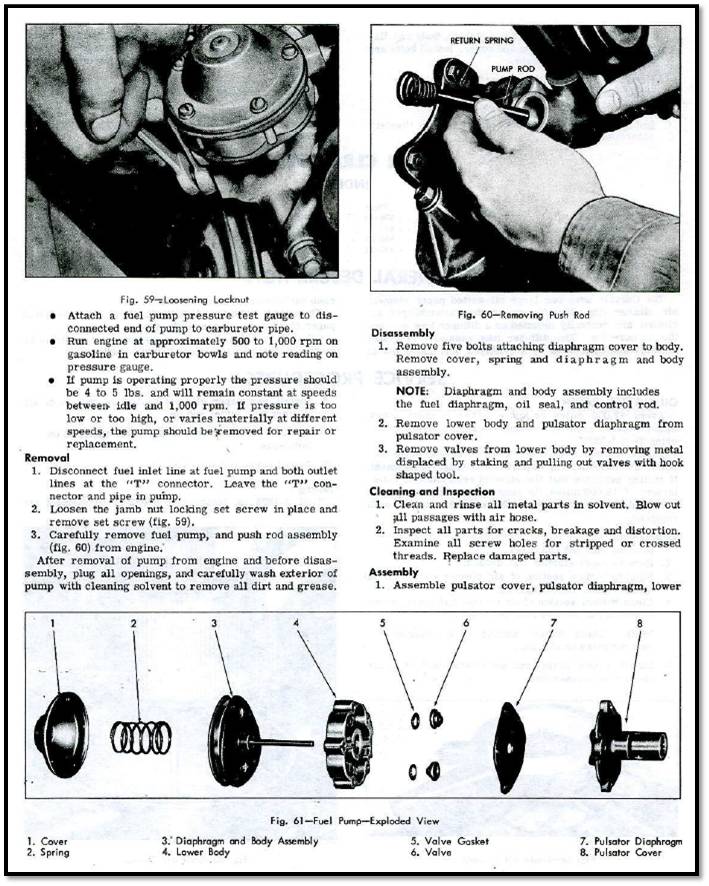

The spring in the Corvair mechanical fuel pump establishes the output pressure. The pushrod upstroke causes fuel to be drawn into the pump from the fuel tank, filling the space in the fuel pump chamber. (The two valves serve as one-way valves, permitting fuel in from the tank, and out toward the carburetor(s)). The spring applies pressure to force the fuel back out toward the carburetors, with an output pressure specified to be 4-5 psi. (Often seen as too high for the Carter YH carburetor on the turbocharged engines). If the carburetor float bowls happen to be full and the carburetor inlet valves are closed, the fuel chamber in the pump will remain full, since the fuel outlet has no place to go (until fuel depletion in the carburetor float bowls opens the inlet valves to accept more fuel). Additional pump pushrod strokes have no effect when the pump is in this idle condition. The spring establishes the output pressure, with flow being controlled by the carburetor float bowl needle and seat valves and the position of the carburetor floats.

To lower the pressure to about 2 psi for Corvair turbocharged engines, see the information toward the bottom of this post. If a faulty (leaky) fuel pump necessitates replacement, and if the output pressure is higher than the 4-5 psi standard, it may be that the new fuel pump spring is too strong. To correct this, it may be possible to transfer the spring from the original fuel pump to the new pump.

To lower the pressure to about 2 psi for Corvair turbocharged engines, see the information toward the bottom of this post. If a faulty (leaky) fuel pump necessitates replacement, and if the output pressure is higher than the 4-5 psi standard, it may be that the new fuel pump spring is too strong. To correct this, it may be possible to transfer the spring from the original fuel pump to the new pump.

/center]

/center]

The Carter YH carburetor has a well-known problem with fuel control... often due to excessive fuel pressure. If your fuel pump pressure is high you might consider adding a fuel pressure regulator between the pump outlet and the carburetor inlet, like the one from Holley shown below...

Holley manufactures quite a few fuel pressure regulators, but most have a range of 4.5 - 9 psi or higher, or are designed for a fuel injection system. This unit has the correct range and apparently a good reputation...

CHROME CARBURETED FUEL PRESSURE REGULATOR

Street/Strip Carbureted Applications

Two Port

Adjustable from 1 to 4 PSI

PART# 12-804

bbodie52 wrote:Holley fuel pressure regulators are designed to precisely control the fuel pressure from the fuel pump to the carburetor. Too much fuel pressure for a given needle and seat assembly can overload the needle and seat and may cause flooding or drivability problems. Each Holley fuel pressure regulator is fully adjustable so regulating the fuel pressure to your engines needs is a simple task. All Holley regulators are pre-set at the factory at 2.8 PSI so there is no guesswork when first installing the regulator. The Holley 12-804 fuel pressure regulator features 3/8" NPT in/out ports.

Features:

- Adjustable fuel regulation from 1 to 4 psi

- .220" (7/32") restriction

- 3/8" NPT ports ( 1 in, 2 out)

- Chrome finish

- Mounting bracket included

- Pre-set at 2.8 PSI

https://www.holley.com/products/fuel_sy ... rts/12-804

Listed on Amazon.com

https://www.amazon.com/Holley-12-804-Fu ... +regulator

HIGHLY RECOMMENDED:https://www.amazon.com/Identify-Rebuild ... s=bob+helt

This might also help with a more-reliable fuel control in the Carter YH...

Clark's Corvair Parts offers a replacement for the needle and seat that makes use of a ball in an all-metal assembly. It has many advantages over the standard needle and seat found in carburetor rebuild kits, as shown below...

https://ssl.corvair.com/user-cgi/catalo ... ow_page=58

Part number C3799: METAL FUEL INLET VALVE-60-69 FITS CARS & TURBOS

Weight: 0 lbs 2 oz

Catalog Page(s): 48(10),55(12),58

Price:

1 - 3 $ 9.25

4+ $ 8.35

Brad Bodie

Lake Chatuge, North Carolina

1966 Corvair Corsa Convertible

1966 Corvair Corsa Convertible

Lake Chatuge, North Carolina

1966 Corvair Corsa Convertible

1966 Corvair Corsa ConvertibleRe: Two Issues - Gas Mileage & Harmonic Balancer

To give the poster an idea as to what should be expected with a 45DCOE weber that is dialed in as well as can be expected,

16-18 mpg "driving around town" and approximately 20 on the freeway is a lot more like it. This is still safely rich and can easily hit 15 psi or more boost. 11.1 mpg is plain wrong and is likely a jetting problem and nothing more. Those carburetors

do need a fuel pressure regulator, and it needs to be set at 2.5psi. Emulsion tubes that work well that I used when my car was running a weber are F16, F12, F9, and F7. The only one that is a really bad choice, especially for gas mileage is an F2.

16-18 mpg "driving around town" and approximately 20 on the freeway is a lot more like it. This is still safely rich and can easily hit 15 psi or more boost. 11.1 mpg is plain wrong and is likely a jetting problem and nothing more. Those carburetors

do need a fuel pressure regulator, and it needs to be set at 2.5psi. Emulsion tubes that work well that I used when my car was running a weber are F16, F12, F9, and F7. The only one that is a really bad choice, especially for gas mileage is an F2.

Re: Two Issues - Gas Mileage & Harmonic Balancer

Hello All, First let me say, Thank you to all that contributed comments/suggestions, etc. I have put some of the suggestions into practice.

Timing mark on the Harmonic Balancer, turns out the engine was way-way out of time to where the mark was hiding under the oil fill tube casting.

I performed the static timing setup as described by 'bbodie52' This was the first time I had ever done the static thing. Worked pretty good once I began to understand 'Dwell' as described by bbodie. In the past, always had only set the points and called it a day.

Set the timing with a timing light to 24 BTC. engine started and went for a drive - about 20 miles. The car ran very good, but did 'ping' when under load, ie: up hill (this is the Ozarks and everything is uphill).

Today, In an effort to eliminate the 'ping' I utilized a dwell meter to check, results were 29*, I adjusted the points a bit to 31* The car ran well, but still has the 'ping'. Went for a longer test drive (about 50 miles).

I noticed the following during my test drive: Did not notice the gas gauge make a steady movement towards empty. To early to fill and do a calculation, will need several fill ups. Also noticed that the engine was running a cooler 50-100* cooler. defiantly had more power climbing the hills, but still has the 'ping'.

Tomorrow I will try to 'retard' the timing a bit in an effort to eliminate the 'ping'.

I am using what they call 'premium no alcohol 91octane' gas

I would welcome any and all suggestions/comments to eliminate the 'ping'

The Weber Carb, I know nothing of the Weber. It was rebuilt/set-up by Ray Sedman, so it should be ready to go.

I am very much afraid to touch anything on the carb (I have messed-up every carb that I've touched).

Thank You,

Steve D.

Timing mark on the Harmonic Balancer, turns out the engine was way-way out of time to where the mark was hiding under the oil fill tube casting.

I performed the static timing setup as described by 'bbodie52' This was the first time I had ever done the static thing. Worked pretty good once I began to understand 'Dwell' as described by bbodie. In the past, always had only set the points and called it a day.

Set the timing with a timing light to 24 BTC. engine started and went for a drive - about 20 miles. The car ran very good, but did 'ping' when under load, ie: up hill (this is the Ozarks and everything is uphill).

Today, In an effort to eliminate the 'ping' I utilized a dwell meter to check, results were 29*, I adjusted the points a bit to 31* The car ran well, but still has the 'ping'. Went for a longer test drive (about 50 miles).

I noticed the following during my test drive: Did not notice the gas gauge make a steady movement towards empty. To early to fill and do a calculation, will need several fill ups. Also noticed that the engine was running a cooler 50-100* cooler. defiantly had more power climbing the hills, but still has the 'ping'.

Tomorrow I will try to 'retard' the timing a bit in an effort to eliminate the 'ping'.

I am using what they call 'premium no alcohol 91octane' gas

I would welcome any and all suggestions/comments to eliminate the 'ping'

The Weber Carb, I know nothing of the Weber. It was rebuilt/set-up by Ray Sedman, so it should be ready to go.

I am very much afraid to touch anything on the carb (I have messed-up every carb that I've touched).

Thank You,

Steve D.

- bbodie52

- Corvair of the Month

- Posts: 12142

- Joined: Mon Aug 06, 2012 12:33 pm

- Location: Lake Chatuge Hayesville, NC

- Contact:

Re: Two Issues - Gas Mileage & Harmonic Balancer

It is good to hear of your progress. A few degrees of timing retard to maybe 20-22 degrees may be all that is needed for a good result. Sometimes slightly colder spark plugs make for an improvement. An upgrade to a breakerless ignition from Pertronix or Crane Cams/FAST may be in your future to eliminate those troublesome points and reduce maintenance. viewtopic.php?f=225&t=15101 Others with more turbo experience may recommend other improvements (especially with the Weber carburetor in the mix) to reduce the possibility of detonation. Resolving your tuning issues to eliminate detonation and pinging is an essential part of turbocharged Corvair engine survival. The Weber 2-barrel side draft carburetor may increase the boost output from the turbocharger, and it is essential to adjust the engine tuning for detonation control, or severe engine damage, such as a melted piston, could result.

Brad Bodie

Lake Chatuge, North Carolina

1966 Corvair Corsa Convertible

1966 Corvair Corsa Convertible

Lake Chatuge, North Carolina

1966 Corvair Corsa Convertible

1966 Corvair Corsa Convertible