Carb Venturi Drip after shutoff

Carb Venturi Drip after shutoff

On my '65 140hp, several of my carb's venturi's (both primary and secondary) drip gas on top of the throttle plate after I've shut off the engine, causing a slightly flooded situation when I re-start as much as an hour later. I've replaced float needles and varied float adjustments, but the problem persists. Is this a hot soak situation causing boiling of the gas in the venturi cavity and forcing gas out. Someone told me it was the fault of the ethanol additive that is now in our gas. Car runs great when I'm driving.

Re: Carb Venturi Drip after shutoff

Is your fuel line (From LR tire well to pump) resting on the shroud? HOT. Had that problem a cuppla years ago, and putting a spacer under the line fixed it!

- terribleted

- Posts: 4584

- Joined: Sun Apr 18, 2010 2:36 pm

- Location: Atlanta, GA

- Contact:

Re: Carb Venturi Drip after shutoff

It is possible. What are your float levels set at? Less than 1 13/64" might allow this.

Corvair guy since 1982. I have personally restored at least 20 Vairs, many of them restored ground up.

Currently working full time repairing Corvairs and restoring old cars.

https://www.facebook.com/tedsautorestoration/

Located in Snellville, Georgia

Currently working full time repairing Corvairs and restoring old cars.

https://www.facebook.com/tedsautorestoration/

Located in Snellville, Georgia

Re: Carb Venturi Drip after shutoff

The original factory level was 1-1/6, I'm using 1-1/8, but thinking of going to 1-3/16. I just got back from an errand with it and now only the secondaries are dripping steadily.

- bbodie52

- Corvair of the Month

- Posts: 12139

- Joined: Mon Aug 06, 2012 12:33 pm

- Location: Lake Chatuge Hayesville, NC

- Contact:

Re: Carb Venturi Drip after shutoff

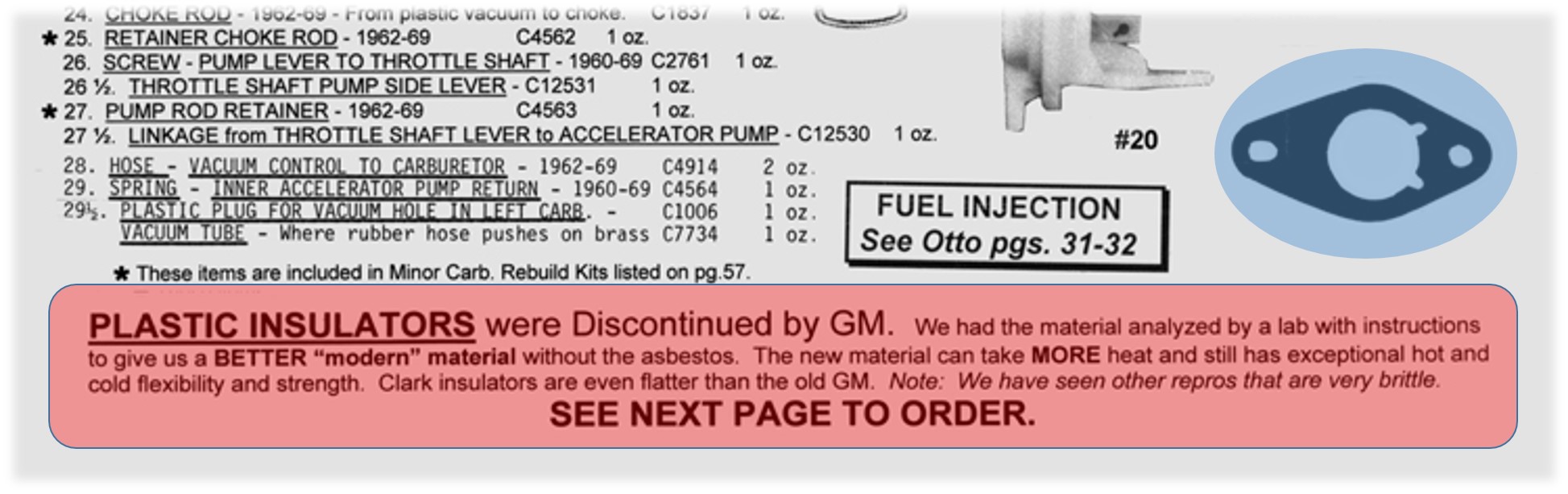

I wanted to make sure that some important insulators were not accidentally omitted when your car was worked on in the past…

Carburetor rebuild kits often contain a thin gasket to seal the underside of the carburetor where it mounts on the intake manifold. The Corvair carburetors need a plastic insulator to isolate the base of the carburetor from the intake manifold, which prevents the gasoline inside the carburetor from boiling or vaporizing if excessive heat is allowed to transfer from the hot aluminum intake manifold on the cylinder head to the carburetor body. These plastic insulators can be easily damaged when removed. Clark's Corvair Parts bundles gaskets and insulators together. They are listed near the top of page 56 in the catalog http://www.corvair.com/user-cgi/catalog ... ow_page=56.

If the insulators are not present, and only a single gasket is being used under each carburetor, the fuel may be close to boiling when the car is driven. The use of fuel may allow some effective cooling of the fluid in each float bowl as fuel is consumed and replaced with cooler liquid from the tank. But when the engine is shut down the remaining heat from the heads may continue to heat the gasoline in the float bowls of the idle engine, causing the gasoline to percolate and appear as it drips from the venturi cluster in each carburetor.

If the insulators are not present, and only a single gasket is being used under each carburetor, the fuel may be close to boiling when the car is driven. The use of fuel may allow some effective cooling of the fluid in each float bowl as fuel is consumed and replaced with cooler liquid from the tank. But when the engine is shut down the remaining heat from the heads may continue to heat the gasoline in the float bowls of the idle engine, causing the gasoline to percolate and appear as it drips from the venturi cluster in each carburetor.

FYI: Here is a method of cooling gasolnie that was added to Corvairs when SMOG pumps came on the scene...

Carburetor rebuild kits often contain a thin gasket to seal the underside of the carburetor where it mounts on the intake manifold. The Corvair carburetors need a plastic insulator to isolate the base of the carburetor from the intake manifold, which prevents the gasoline inside the carburetor from boiling or vaporizing if excessive heat is allowed to transfer from the hot aluminum intake manifold on the cylinder head to the carburetor body. These plastic insulators can be easily damaged when removed. Clark's Corvair Parts bundles gaskets and insulators together. They are listed near the top of page 56 in the catalog http://www.corvair.com/user-cgi/catalog ... ow_page=56.

FYI: Here is a method of cooling gasolnie that was added to Corvairs when SMOG pumps came on the scene...

The Corvair Fuel Pump Functional Operation

A careful examination of the fuel pump from the side would appear to show three gaskets that are sandwiched within the fuel pump body. These "gaskets" are really part of the flexible diaphragms that also serve as gaskets to seal the chambers of the pump. These diaphragms are made of a neoprene rubber material that has been reinforced with fabric to provide it with additional strength. The reinforced rubber diaphragms would be needed since the diaphragm must withstand the continuous motion and stress associated with the pumping action. Because of this it would not be possible to create a gasket using regular bulk gasket material to replace, for example, the lower pulsator diaphragm, because the pulsator diaphragm must have the necessary flexibility and strength to withstand the pumping action.

The Pulsator Diaphragm is inside the pump fuel cavity. It creates an air pocket to minimize the pulsating of the fuel as it passes through the pump.

As far as I can tell, the groove that radiates from the center cavity of the pump (pushrod area) is a vent of some type, but it only exposes crankcase pressure to the outside air. That groove appears to serve as a pressure relief. The pulsator diaphragm also serves to seal and isolate the vent groove from the adjacent chambers that would be exposed to fuel. That vent groove does not appear to be exposed to any portion of the pump body that would contain gasoline.

The two valves shown in the illustration below are one-way valves. The inlet valve allows fuel to be drawn into the pump chamber from the gas tank. This occurs during the upward stroke of the pushrod. When the pushrod moves downward the spring at the top of the pump applies pressure to the main diaphragm to push the diaphragm downward, forcing the gasoline out through the other one-way valve towards the carburetors. This spring serves as a pressure regulator, to establish the 4-5 pounds of fuel pressure to drive the fuel into the carburetor float bowls.

If the carburetor float bowls are full, the floats apply pressure to the needle valve, which closes the valve and prevents additional fuel from entering the float bowl. This would create a "fuel fluid lock" that would prevent additional fuel from exiting the fuel pump chamber. When this condition exists the fuel pump return spring would be unable to push the diaphragm and pushrod pin downward toward the pushrod. Since the diaphragm would remain in the "up" position, subsequent upward strokes of the pushrod would not reach the diaphragm actuating pin, since the gasoline being held stationary in the chamber by the closed needle and seat assemblies in the carburetors would not permit the downward pressure of the spring to move the diaphragm into contact with the pushrod. As long as the carburetor float bowls are full, the fuel chamber in the fuel pump would also remain full and the diaphragm would remain in the upward position and would be isolated from the pushrod. This is essentially a neutral position that remains in effect as long as the carburetors are closed and cannot receive additional fuel. As soon as the carburetors drain enough to open the needle and seat assemblies, the fuel pump chamber would be drained as the spring forces gasoline through the one-way outlet valve. This would permit the diaphragm pin to once again come into contact with the pushrod, so that the next stroke would open the inlet valve and would draw additional fuel from the fuel tank. This new quantity of fuel in the pump chamber would be pressurized by the spring to be pushed in the direction of the carburetors to replenish the fuel supply in the carburetor float bowls.

Gasoline has an initial boiling point at atmospheric pressure of about 95 °F.

A method for preventing vapor lock added a fuel tank return line at the brass fuel pump outlet. This was added in 1968 and later engines when SMOG pumps and increasing engine compartment heat were introduced, along with a potential for vapor lock as stagnant, non-moving fuel quietly heated to a boiling point in the fuel lines while the mechanical fuel pump idled in a neutral condition caused by full float bowls (described above in the section The Corvair Fuel Pump Functional Operation.

The fuel vapor return line is one of those unique features of the last few model years, along with the SMOG pump plumbing and other unique engineering features GM invented to satisfy the SMOG police, California Air Resources Board, etc.

The fuel return line "Z" shown below was added during the final few years of Corvair production. This fuel line runs from a "cross" 4-way connector at the fuel pump outlet. This small diameter fuel line is more restrictive than the lines routed to the carburetors. It permits a small but continual flow of gasoline to return to the fuel tank. Without it the fuel pump goes into NEUTRAL whenever the float bowls are full and the needle/seat valves are closed. This stops the flow of gasoline until the engine consumes enough gasoline to restore the fuel flow back into the float bowls again. By adding the fuel return line, some gasoline is constantly flowing through the fuel pump feed line from the fuel tank and then back again through the return line. Keeping a constant flow of fuel moving uses the cool liquid to cool the steel fuel feed line "D" to help prevent vapor lock.

http://www.corvair.com/user-cgi/catalog ... IN&page=67

Brad Bodie

Lake Chatuge, North Carolina

1966 Corvair Corsa Convertible

1966 Corvair Corsa Convertible

Lake Chatuge, North Carolina

1966 Corvair Corsa Convertible

1966 Corvair Corsa Convertible- terribleted

- Posts: 4584

- Joined: Sun Apr 18, 2010 2:36 pm

- Location: Atlanta, GA

- Contact:

Re: Carb Venturi Drip after shutoff

Funny the rebuild section of the shop manuals in section 6 all clearly specify 1 13/64 float level. I have always run 1 13/64 or a hair taller 1 7/32 and have only had issues you describe when the float levels are wrong or a float has stuck or sunk etc. I have never had any adverse issues like fuel starvation or anything else using these measurements from the shop manual. I know that the specifications chart in the back of the manuals say 1 1/16. I believe this to be an error as every engine I have seen with float levels near this small has had issues with flooding.

Corvair guy since 1982. I have personally restored at least 20 Vairs, many of them restored ground up.

Currently working full time repairing Corvairs and restoring old cars.

https://www.facebook.com/tedsautorestoration/

Located in Snellville, Georgia

Currently working full time repairing Corvairs and restoring old cars.

https://www.facebook.com/tedsautorestoration/

Located in Snellville, Georgia

Re: Carb Venturi Drip after shutoff

I have always followed the table for carburetors on page 5 of the specifications sections in the '65 manual which shows a level of 1-1/16. I did note the 1-13/64 in the text on page 6M-6, and years back thought an error, as i also have a J-21614 tool which measures 1-1/16. The '66 supplement table shows the 1-1/16 as well. I'm not saying that the 1-13/64 is wrong, but there is a discrepancy in the manuals. I also have a '64 coupe with a 95 hp which I've had since 1970 (my first car) and do not have this problem at all.

Re: Carb Venturi Drip after shutoff

Also to Brad Bodie's reply, I have always used the insulators plus a thin gasket top and bottom for additional sealing. I've always know why they are there. I will tho check them for cracks.

Re: Carb Venturi Drip after shutoff

Vapor lock and dribble are problems are not really an ethanol issue, more a problem with gasoline after lead was removed decades ago. To get the octane up the revised refining process made gasoline more volatile. With fuel injection it's not an issue, but for old cars it is.

Bob Helts excellent carb. book recommends setting the floats to 1-1/8" (LM carbs) from the GASKET, not bare frame to the square float. Often floats are at an angle or one is not the same level as the other. Also there should be an assist spring on the float(LM). If you DO NOT have a cluster dribble at idle then the float level is fine. Yes the new fuels will boil in the carburetor after a hot shut down. This was also an issue with the old gasoline in the 60's and prompted GM to add a vent at the base of the carburetor covered by a spring arm with a rubber pad in 1964. It's difficult to adjust so it is ONLY TILTED OPEN when the carburetor is at idle. This DID help alleviate the "hot start" problem. I find most folks get frustrated with trying to adjust this and just leave the vent covered or they plug it up.

Finally the mechanical fuel pump gets HOT from engine block heat. I eliminated vapor lock issues and flooded carburetors by installing an electric fuel pump and rotating the fuel lines 180 so the "T" is in towards the front of the engine compartment. Install plug in fuel pump hole (Clark's sells them).

I have nothing against mechanical fuel pumps, but the build quality of new units is poor and the fuel volatility is an issue. On a Corvair I've found eliminating the mechanical fuel pump and installing an electric pump makes for a more reliable set up. Since the carburetors will dry out after a few weeks setting and electric fuel pump can be activated to fill/prime the carburetors for a quick startup.

Bob Helts excellent carb. book recommends setting the floats to 1-1/8" (LM carbs) from the GASKET, not bare frame to the square float. Often floats are at an angle or one is not the same level as the other. Also there should be an assist spring on the float(LM). If you DO NOT have a cluster dribble at idle then the float level is fine. Yes the new fuels will boil in the carburetor after a hot shut down. This was also an issue with the old gasoline in the 60's and prompted GM to add a vent at the base of the carburetor covered by a spring arm with a rubber pad in 1964. It's difficult to adjust so it is ONLY TILTED OPEN when the carburetor is at idle. This DID help alleviate the "hot start" problem. I find most folks get frustrated with trying to adjust this and just leave the vent covered or they plug it up.

Finally the mechanical fuel pump gets HOT from engine block heat. I eliminated vapor lock issues and flooded carburetors by installing an electric fuel pump and rotating the fuel lines 180 so the "T" is in towards the front of the engine compartment. Install plug in fuel pump hole (Clark's sells them).

I have nothing against mechanical fuel pumps, but the build quality of new units is poor and the fuel volatility is an issue. On a Corvair I've found eliminating the mechanical fuel pump and installing an electric pump makes for a more reliable set up. Since the carburetors will dry out after a few weeks setting and electric fuel pump can be activated to fill/prime the carburetors for a quick startup.

Re: Carb Venturi Drip after shutoff

I actually added electric pumps years ago as a backup and for priming on both my Corvair's but never changed to full electric. Maybe time to do so.