Noob Questions

- Bruins_Fan

- Corvair of the Month

- Posts: 377

- Joined: Wed Aug 08, 2012 9:45 am

- Location: North Shore, MA

Noob Questions

A few noob questions from a new Corvair owner.

The previous owner of my '66 said that after maybe a couple weeks without using the car (i.e. in winter) he would have trouble starting the car as the fuel would leave the carbs and fuel pump (I assume lose it's prime and fuel leak down to the tank) and he would simply remove the top of the air cleaner/tube running to the left carb and use a turkey baster (along with a gas can) to squeeze some gasoline into the left carburetor, and the car would start. I guess fuel would then run down into the fuel pump, and he was good to go. I haven't had any issues yet, as the car hasn't sat more than a few days between starts so far, and starts right up. Being in New England, that will change over the winter as the car sits. I have a major addition starting at my house now, so I'm storing the car in a storage unit for the next six months before it moves into my garage. Any comments on this "procedure" to get the car started after sitting for a while?

I hope to drive the car at least once a week until the snow flies and the roads are treated with salt and sand, then it will stay in the storage unit until spring. From what I've read, I'm probably better off not starting the car to just run for 20 minutes at a time in storage?

And what's the opinion on adding stabilizer to the fuel tank for the winter? I've seen some conflicting thoughts on that topic.

The previous owner of my '66 said that after maybe a couple weeks without using the car (i.e. in winter) he would have trouble starting the car as the fuel would leave the carbs and fuel pump (I assume lose it's prime and fuel leak down to the tank) and he would simply remove the top of the air cleaner/tube running to the left carb and use a turkey baster (along with a gas can) to squeeze some gasoline into the left carburetor, and the car would start. I guess fuel would then run down into the fuel pump, and he was good to go. I haven't had any issues yet, as the car hasn't sat more than a few days between starts so far, and starts right up. Being in New England, that will change over the winter as the car sits. I have a major addition starting at my house now, so I'm storing the car in a storage unit for the next six months before it moves into my garage. Any comments on this "procedure" to get the car started after sitting for a while?

I hope to drive the car at least once a week until the snow flies and the roads are treated with salt and sand, then it will stay in the storage unit until spring. From what I've read, I'm probably better off not starting the car to just run for 20 minutes at a time in storage?

And what's the opinion on adding stabilizer to the fuel tank for the winter? I've seen some conflicting thoughts on that topic.

'66 Monza Convertible 110hp Powerglide

-

Jerry Whitt

- Posts: 887

- Joined: Thu Sep 26, 2013 2:42 pm

Re: Noob Questions

The fuel tank is near the front of the car, under the windshield area, just in front of the drivers feet. When the car sits for a while, the gas in the carburetors evaporates. When the car has the ignition key turned to the crank position, the fuel pump has to do a lot of pumping before the fuel gets to the carburetors.

Many Corvair owners install an electric fuel pump near the gas tank out let. Then when the key is turned on, wait a moment or two, the electric pump will push fuel thru the fuel lines under the car, and eventually fill the carburetors. This start up procedure works pretty good, even on very hot days when the car is parked on a very hot black top parking surface. The fuel lines absorb the heat from under the car, and a gas is formed. The

electric pump will help overcome this issue too.

Many Corvair owners install an electric fuel pump near the gas tank out let. Then when the key is turned on, wait a moment or two, the electric pump will push fuel thru the fuel lines under the car, and eventually fill the carburetors. This start up procedure works pretty good, even on very hot days when the car is parked on a very hot black top parking surface. The fuel lines absorb the heat from under the car, and a gas is formed. The

electric pump will help overcome this issue too.

Jerry Whitt

ASE CERTIFIED MASTER TECHNICIAN

Retired

Hemet, Callifornia

65 Monza, purchased new

65 Corsa convertible

ASE CERTIFIED MASTER TECHNICIAN

Retired

Hemet, Callifornia

65 Monza, purchased new

65 Corsa convertible

Re: Noob Questions

Jerry, that works unless the electric pump has a safety cutoff switch installed on the engine. In that case, the fuel pump will only operate when the starter is cranking the engine or there is oil pressure at the oil filter housing where the switch is normally installed.

Alec Carlson

Dahlonega, GA

1965 Regal Red Corsa 4 Speed Turbo Convertible

Restoration "In Progress"...

Dahlonega, GA

1965 Regal Red Corsa 4 Speed Turbo Convertible

Restoration "In Progress"...

- bbodie52

- Corvair of the Month

- Posts: 12141

- Joined: Mon Aug 06, 2012 12:33 pm

- Location: Lake Chatuge Hayesville, NC

- Contact:

Re: Noob Questions

This car has a stock engine with a mechanical fuel pump. A picture of his engine was attached to an earlier post...

As far as fuel for your Corvair goes, unleaded fuel is satisfactory and does not cause valve wear problems. It is important that you use a high-enough octane fuel to prevent pinging and detonation, which can harm your engine. There was some question earlier as to the nature of your engine (110 hp or 95 hp). The cylinder heads will tell the tale. If it is 95 hp the compression ration is 8.0:1, while the 110 hp engine has a compression ration of 9.0:1. The lower compression ratio on the 95 hp engine will help it to better-tolerate a lower octane REGULAR grade gasoline. But even with the higher compression ratio, you can probably tolerate a low octane fuel on flat terrain and with moderate temperatures. But when hauling a full load in your car, climbing hills, or even in hot ambient temperatures you need to be aware of any signs of detonation (pinging/rattling under load). If you hear that a switch to high octane PREMIUM is likely needed. Ethanol can be a little more of a problem because it absorbs moisture from the air more than non-Ethanol fuel, and tends to break down chemically faster. This is primarily a concern if you tend to leave your Corvair parked and unused for long periods, promoting problems with "stale" gasoline. Under such circumstances an additive like Sta-bil may help to some degree.

If you intend to park the car for long periods, Sta-bil will help to slow fuel decay. Draining the fuel tank might be better, but doing so is somewhat difficult.

More details below...

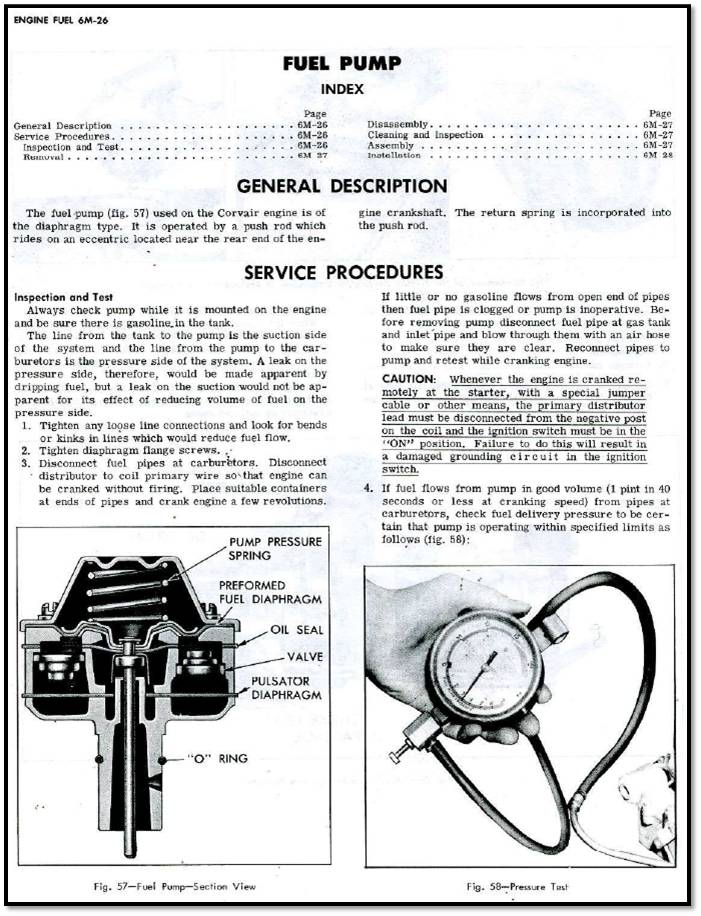

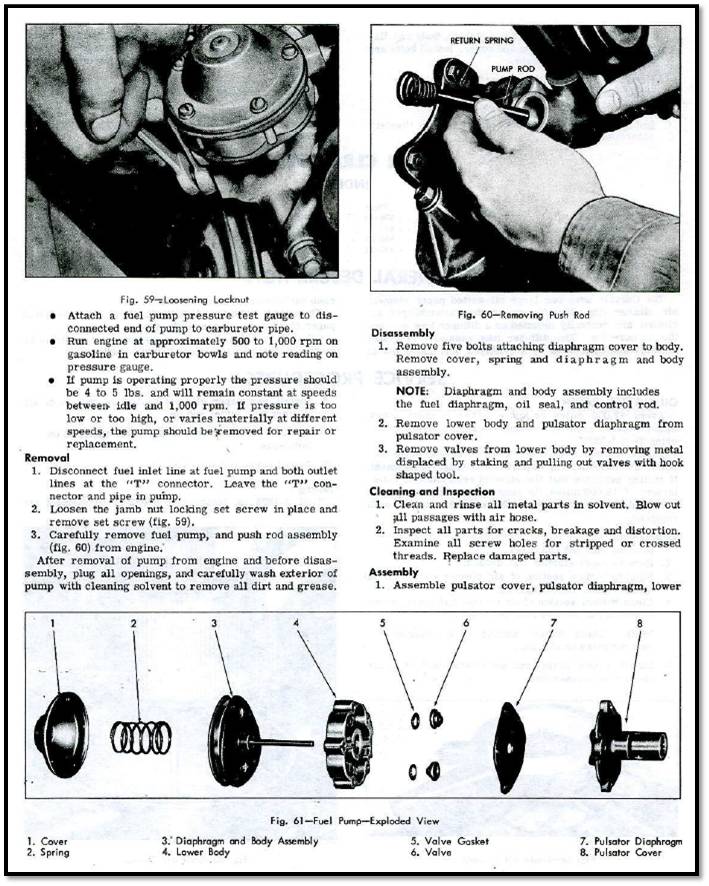

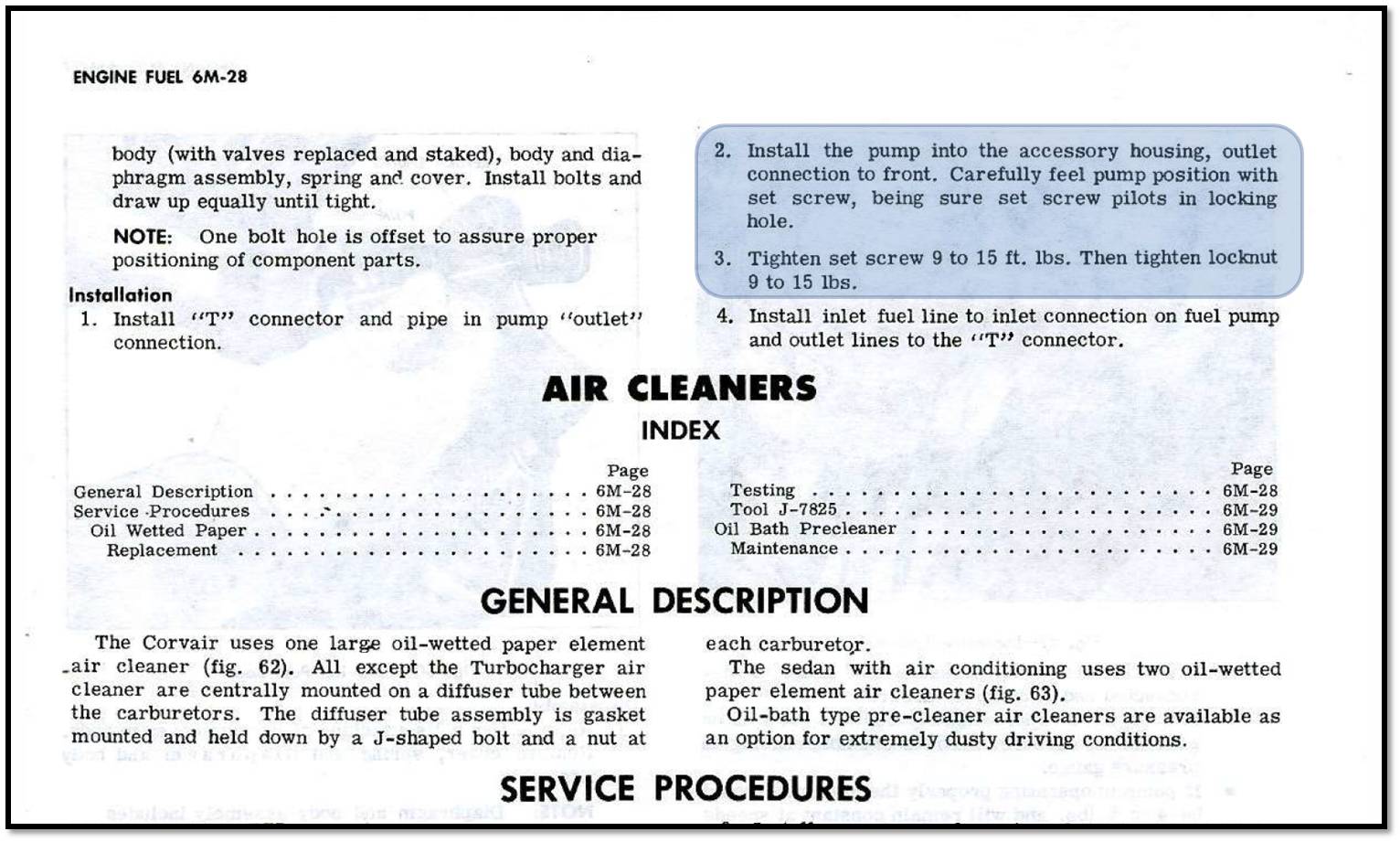

A new fuel pump should always be tested for output pressure. If the pressure is found to be excessive it may be possible to cut the spring or to exchange the spring from the old pump and fit it into the new pump. This may correct the output pressure.

The second test measures fuel flow at the fuel pump outlet. The standard in the shop manual states that the pump should be able to deliver 1 pint of fuel over a period of 40 seconds or less at engine cranking speed. If your pump does not appear to have any leaks and can pass the output pressure test, but fails to deliver the needed fuel volume, the problem may not be with the pump itself. There is a long fuel line that runs the length of the car from the fuel tank to the fuel pump. In order to pressurize and deliver fuel to the carburetors, the pump must be able to create a continuous vacuum in that fuel line to draw the fuel from the tank to the pump. Most of the fuel line is made up of steel tubing and is unlikely to develop a leak. However, there are two short lengths of rubber fuel hose in the fuel path. One section of hose is found at the fuel tank outlet, while the other is found adjacent to the starter motor — just before the line enters the engine compartment. The purpose of the second hose is to absorb vibration from the engine and prevent it from reaching the rigid steel fuel line. If either one of these two hoses develops a leak, the leak itself may not be apparent because the line is not under pressure so fuel will not be forced out. Instead, the leak amounts to a vacuum leak, which can allow air to enter the fuel line. This can prevent fuel from being drawn from the tank to the fuel pump, much like you might experience with a drinking straw if the straw was to split and developed an air leak in the side of the straw. What appears to be a faulty pump that is causing fuel starvation problems in the carburetors often turns out to be a leak in the fuel line at some point between the gas tank and the fuel pump. So if fuel starvation becomes a problem with your carburetors, there is a tendency to question the condition of the needle and seat valve inside the carburetor, or to blame the fuel filter at the carburetor inlet (thinking it is clogged), or to blame the fuel pump itself. Before you blame the pump and toss it, or abandon it and replace it with electric fuel pump, be sure to check the condition of the rubber fuel hoses at each end of the long fuel line between the fuel tank and the fuel pump. You may find that a couple of hose clamps and a few inches of replacement fuel hose is all that necessary to get you back on the road!

There is also a fuel tank strainer inside the gas tank on the outlet tube. It was listed as a part used in 1960-1965 Corvairs, but it could be installed on any model year. It is conceivable that this strainer could become plugged and could restrict fuel flow to the fuel pump.

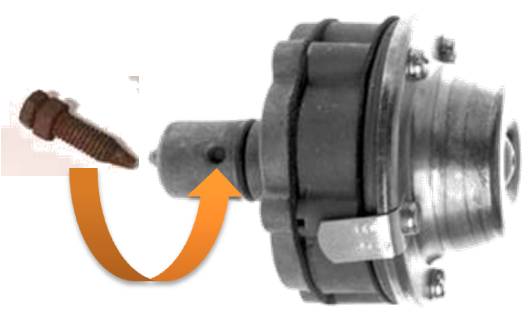

Also, if you have any reason to remove and reinstall the fuel pump, be sure that you have installed it properly. I would suggest confirming that the fuel pump is correctly seated and installed. There is a hole in the side of the pump shaft that the tapered bolt tip must seat into. If the pump is sitting too high and the bolt is simply pressing against the side of the pump housing, rather than seating inside the tapered hole, the pump push rod will not be doing its job. So first confirm proper pump installation, and then check the fuel pump output pressure and volume, as shown in the shop manual pages above. Fig. 57 in the shop manual page shows the tapered hole that the tip of the bolt fits into. This ensures proper installation and seating of the pump.

The link below will provide you with a list of useful websites that are Corvair-related. Some of the links will lead you to an extensive technical library that will allow you to download shop manuals and other technical references in Adobe Reader format at no cost. You will also find a list of essential Corvair parts suppliers. Clark's Corvair Parts is the biggest and oldest Corvair supplier in the world. You will find a link that can provide you with a series of videos that amount to a tour of the Clark's Corvair Parts facilities. I think you will be amazed at the quality of the reproduction components they offer — particularly the interior carpeting and re-upholstery items. Parts suppliers such as this truly make our Corvair hobby possible.

Common and Useful Corvair Websites

viewtopic.php?f=225&t=6007

viewtopic.php?f=225&t=6007

As far as fuel for your Corvair goes, unleaded fuel is satisfactory and does not cause valve wear problems. It is important that you use a high-enough octane fuel to prevent pinging and detonation, which can harm your engine. There was some question earlier as to the nature of your engine (110 hp or 95 hp). The cylinder heads will tell the tale. If it is 95 hp the compression ration is 8.0:1, while the 110 hp engine has a compression ration of 9.0:1. The lower compression ratio on the 95 hp engine will help it to better-tolerate a lower octane REGULAR grade gasoline. But even with the higher compression ratio, you can probably tolerate a low octane fuel on flat terrain and with moderate temperatures. But when hauling a full load in your car, climbing hills, or even in hot ambient temperatures you need to be aware of any signs of detonation (pinging/rattling under load). If you hear that a switch to high octane PREMIUM is likely needed. Ethanol can be a little more of a problem because it absorbs moisture from the air more than non-Ethanol fuel, and tends to break down chemically faster. This is primarily a concern if you tend to leave your Corvair parked and unused for long periods, promoting problems with "stale" gasoline. Under such circumstances an additive like Sta-bil may help to some degree.

If you intend to park the car for long periods, Sta-bil will help to slow fuel decay. Draining the fuel tank might be better, but doing so is somewhat difficult.

More details below...

Wikipedia wrote:Valve wear preventative

Tetraethyl lead works as a buffer against microwelds forming between the hot exhaust valves and their seats. Once these valves reopen, the microwelds pull apart and leave the valves with a rough surface that would abrade the seats, leading to valve recession. When lead began to be phased out of motor fuel, the automotive industry began specifying hardened valve seats and upgraded exhaust valve materials to prevent valve recession without lead.

You might consider testing the fuel pump pressure and volume delivery. If it takes a long time and a lot of cranking to replenish the carburetor float bowls after a long rest, the fuel pump may have some problems. There are two relatively simple fuel pump tests outlined in the Corvair shop manual. These tests measure output pressure and fuel delivery volume. The output pressure test utilizes a common vacuum/pressure gauge that is relatively inexpensive. The output pressure is regulated by an internal spring that is contained in the upper pump housing. Unless your pump springs a leak in one of the diaphragms or seals, it is likely that the output pressure will not change with age. However, new pumps may be fitted with a spring that produces an output pressure well in excess of the 4-5 psi standard. High-pressure can cause carburetor flooding, and is particularly a problem with the Carter YH carburetor found on turbocharged Corvairs, which is sensitive to excessive fuel pressure.bbodie52 wrote:There are several issues with modern fuels and Corvairs, as described below.

UNLEADED FUEL Leaded fuel was phased-out to provide compatibility with catalytic converters, as they became the norm for emissions reduction in cars. Catalytic converters would be damaged by lead content in fuel. The lead also had some lubricating properties that helped to reduce valve wear. As the lead was phased out, hardened valves and valve seats became the norm in engine production. Because of the higher valve temperatures in air-cooled Corvairs, Corvairs were already manufactured with hardened valves and valve seat material, so the loss of leaded fuel had no negative impact on Corvair valve wear.

ETHANOL Of greater concern is the use of Ethanol (E10) in fuel. There are a number of negative impact issues related to Ethanol that can have a negative impact on Corvairs, including poor long-term storage of Ethanol fuels, as they decay faster and build up water contamination faster than non-ethanol fuels. This has less impact on daily driver Corvairs because the fuel is used rapidly, but Corvairs that are driven infrequently can suffer from "stale" fuel more quickly if it is Ethanol based. Higher percentages of the Ethanol alcohol content in fuel can actually damage older fuel systems and are not compatible with Corvairs.

You may find the following article informative with regard to the pros and cons of using Ethanol in older cars...

Tech 101 – Ethanol in gasoline and its effects on collector cars

http://blog.hemmings.com/index.php/2012 ... ctor-cars/

FUEL OCTANE RATING A number of factors affect how high the octane rating must be to be tolerated in a Corvair. Turbocharged Corvairs should always use high-octane Premium fuel to prevent detonation. When driving a lightly-loaded normally-aspirated Corvair in moderate ambient temperature conditions, many Corvairs can tolerate Regular fuel. But if you add more passengers and cargo, tow a trailer, drive in hilly terrain with lengthy uphill driving, or increase ambient temperatures, Regular low-octane fuel may not be enough -- especially in the 102, 110, and 140 hp engine configurations with higher compression ratios. If you are planning on taking the family on a long trip in your Corvair, and if the journey may include some hilly terrain, you will probably need Premium fuel to avoid that deadly pinging, rattling sound of detonation. (Taking the family, luggage and camping gear to Lake Tahoe in the Corvair for summer vacation, anyone?)

A new fuel pump should always be tested for output pressure. If the pressure is found to be excessive it may be possible to cut the spring or to exchange the spring from the old pump and fit it into the new pump. This may correct the output pressure.

The second test measures fuel flow at the fuel pump outlet. The standard in the shop manual states that the pump should be able to deliver 1 pint of fuel over a period of 40 seconds or less at engine cranking speed. If your pump does not appear to have any leaks and can pass the output pressure test, but fails to deliver the needed fuel volume, the problem may not be with the pump itself. There is a long fuel line that runs the length of the car from the fuel tank to the fuel pump. In order to pressurize and deliver fuel to the carburetors, the pump must be able to create a continuous vacuum in that fuel line to draw the fuel from the tank to the pump. Most of the fuel line is made up of steel tubing and is unlikely to develop a leak. However, there are two short lengths of rubber fuel hose in the fuel path. One section of hose is found at the fuel tank outlet, while the other is found adjacent to the starter motor — just before the line enters the engine compartment. The purpose of the second hose is to absorb vibration from the engine and prevent it from reaching the rigid steel fuel line. If either one of these two hoses develops a leak, the leak itself may not be apparent because the line is not under pressure so fuel will not be forced out. Instead, the leak amounts to a vacuum leak, which can allow air to enter the fuel line. This can prevent fuel from being drawn from the tank to the fuel pump, much like you might experience with a drinking straw if the straw was to split and developed an air leak in the side of the straw. What appears to be a faulty pump that is causing fuel starvation problems in the carburetors often turns out to be a leak in the fuel line at some point between the gas tank and the fuel pump. So if fuel starvation becomes a problem with your carburetors, there is a tendency to question the condition of the needle and seat valve inside the carburetor, or to blame the fuel filter at the carburetor inlet (thinking it is clogged), or to blame the fuel pump itself. Before you blame the pump and toss it, or abandon it and replace it with electric fuel pump, be sure to check the condition of the rubber fuel hoses at each end of the long fuel line between the fuel tank and the fuel pump. You may find that a couple of hose clamps and a few inches of replacement fuel hose is all that necessary to get you back on the road!

There is also a fuel tank strainer inside the gas tank on the outlet tube. It was listed as a part used in 1960-1965 Corvairs, but it could be installed on any model year. It is conceivable that this strainer could become plugged and could restrict fuel flow to the fuel pump.

Also, if you have any reason to remove and reinstall the fuel pump, be sure that you have installed it properly. I would suggest confirming that the fuel pump is correctly seated and installed. There is a hole in the side of the pump shaft that the tapered bolt tip must seat into. If the pump is sitting too high and the bolt is simply pressing against the side of the pump housing, rather than seating inside the tapered hole, the pump push rod will not be doing its job. So first confirm proper pump installation, and then check the fuel pump output pressure and volume, as shown in the shop manual pages above. Fig. 57 in the shop manual page shows the tapered hole that the tip of the bolt fits into. This ensures proper installation and seating of the pump.

The link below will provide you with a list of useful websites that are Corvair-related. Some of the links will lead you to an extensive technical library that will allow you to download shop manuals and other technical references in Adobe Reader format at no cost. You will also find a list of essential Corvair parts suppliers. Clark's Corvair Parts is the biggest and oldest Corvair supplier in the world. You will find a link that can provide you with a series of videos that amount to a tour of the Clark's Corvair Parts facilities. I think you will be amazed at the quality of the reproduction components they offer — particularly the interior carpeting and re-upholstery items. Parts suppliers such as this truly make our Corvair hobby possible.

Common and Useful Corvair Websites

Brad Bodie

Lake Chatuge, North Carolina

1966 Corvair Corsa Convertible

1966 Corvair Corsa Convertible

Lake Chatuge, North Carolina

1966 Corvair Corsa Convertible

1966 Corvair Corsa ConvertibleRe: Noob Questions

Yes today's gasoline (even the rare non-ethanol blends) evaporates faster. The fuel articles say this is due to the change in refining beginning with "no lead" gasoline to boost octane after the lead additives were banned.

The "turkey baster" routine works, but ALWAYS INSTALL THE AIR CLEANER BEFORE STARTING THE CAR. Occasionally you'll get a back fire pop up through the carburetor. A buddy set himself on fire trying to dribble fuel and start the engine. He survived and won't do that again.

Yes a reliable name brand fuel preservative for ethanol blended fuels does help, but read up on the limit for gasoline preservation/storage. I won't use fuel, even with treatment, after four months! Yes the carburetors will dry out during storage and it's possible the carb accelerator pump cups will harden and may need replacing. Same for the fuel pump diaphragm. You can install an electric pulse pump like an Airtex or Facet to prime the system during storage. Those pumps will not interfere with fuel flow to the mechanical fuel pump when they are off. Many have done this. The other option is to just delete the mechanical fuel pump. After years of mechanical fuel pump problems I went electric and have had no issues. Only problems seem to be poor installations, wrong pump type, counterfeit fuel pumps bought online.

The "turkey baster" routine works, but ALWAYS INSTALL THE AIR CLEANER BEFORE STARTING THE CAR. Occasionally you'll get a back fire pop up through the carburetor. A buddy set himself on fire trying to dribble fuel and start the engine. He survived and won't do that again.

Yes a reliable name brand fuel preservative for ethanol blended fuels does help, but read up on the limit for gasoline preservation/storage. I won't use fuel, even with treatment, after four months! Yes the carburetors will dry out during storage and it's possible the carb accelerator pump cups will harden and may need replacing. Same for the fuel pump diaphragm. You can install an electric pulse pump like an Airtex or Facet to prime the system during storage. Those pumps will not interfere with fuel flow to the mechanical fuel pump when they are off. Many have done this. The other option is to just delete the mechanical fuel pump. After years of mechanical fuel pump problems I went electric and have had no issues. Only problems seem to be poor installations, wrong pump type, counterfeit fuel pumps bought online.

- Bruins_Fan

- Corvair of the Month

- Posts: 377

- Joined: Wed Aug 08, 2012 9:45 am

- Location: North Shore, MA

Re: Noob Questions

Thanks for the replies, guys. Very helpful!

'66 Monza Convertible 110hp Powerglide

-

Flagon_15T

- Posts: 5

- Joined: Wed Nov 28, 2018 11:58 pm

- Location: Russia/Kansas

Re: Noob Questions

Thanks for the thorough explanations, that forum definitely is a gold mine! My grandfather mentioned having trouble starting the engine after a couple days without using the car (he was getting old at this point and didn't drive as often as he used to do) and I now have an idea of where it came from... I'll make sure to follow your advice and install a small electric pump.

- Gregory_Miller

- Corvair of the Month

- Posts: 921

- Joined: Tue Feb 23, 2010 1:54 pm

Re: Noob Questions

I use an electric pump with the safety cut-out that allows it to run for a few seconds with the engine not turning to allow the bowls to fill. If that isn't long enough, one can shut off the key and turn it back on for another few seconds of run time with the engine not cranking. That is usually long enough to overcome fuel bowl evaporation. I bypassed the mechanical pump completely with the Clark's bypass plate that replaces the guts of the old fuel pump and looks stock. Still need to plug off the hole the push rod used to pass through to keep it from slinging oil up and it dripping where you don't want it to.

Re: Noob Questions

I have an electric one, by the tank, that I can flip a toggle w/o turning the key to activate. However, 8 to 10 seconds seems to be enough to fire it up. Then turn it off. First Crank! I then run on the mechanical fuel pump. Iffin the mechanical pump goes out on the side of the road, (Been there, Done that!)...I still have the toggle for the electric to get me HOME!Gregory_Miller wrote: ↑Fri Nov 30, 2018 4:06 pm I use an electric pump with the safety cut-out that allows it to run for a few seconds with the engine not turning to allow the bowls to fill. If that isn't long enough, one can shut off the key and turn it back on for another few seconds of run time with the engine not cranking. That is usually long enough to overcome fuel bowl evaporation. I bypassed the mechanical pump completely with the Clark's bypass plate that replaces the guts of the old fuel pump and looks stock. Still need to plug off the hole the push rod used to pass through to keep it from slinging oil up and it dripping where you don't want it to.