Valve noise

Valve noise

I have a '68 Corvair engine in my roadster which has been in there for 30 plus years. Over the last several years it would have an intermittent valve clatter for a while and then go away. It would only make noise under very light or no load at mid range to high rpm. Low rpm, accelerating or decelerating it's quiet. Recently the noise has decided to stay.

Thinking it was a valve out of adjustment I set them today (they seemed correct) and there was no change BUT one lifter would normalize almost immediately after the quarter turn on the nut rather than the usual few seconds of chuffing.

While I suspect the lifter is the culprit I wanted to check here and see if anyone had a similar experience before taking it all apart.

Thanks in advance!

Gary O

Thinking it was a valve out of adjustment I set them today (they seemed correct) and there was no change BUT one lifter would normalize almost immediately after the quarter turn on the nut rather than the usual few seconds of chuffing.

While I suspect the lifter is the culprit I wanted to check here and see if anyone had a similar experience before taking it all apart.

Thanks in advance!

Gary O

-

Jerry Whitt

- Posts: 887

- Joined: Thu Sep 26, 2013 2:42 pm

Re: Valve noise

You did not mention mileage on the engine after 30 plus years. If the mileage is pretty high, the thought of a new set of lifters comes to mind

right away.

right away.

Jerry Whitt

ASE CERTIFIED MASTER TECHNICIAN

Retired

Hemet, Callifornia

65 Monza, purchased new

65 Corsa convertible

ASE CERTIFIED MASTER TECHNICIAN

Retired

Hemet, Callifornia

65 Monza, purchased new

65 Corsa convertible

Re: Valve noise

That would have been good info wouldn't it? It had 40K on it when I put it in and have probably put another 40 K on it since then. I'm hesitant to change all of the lifters having heard horror stories about new lifters screwing up the cam. Credible?

-

Jerry Whitt

- Posts: 887

- Joined: Thu Sep 26, 2013 2:42 pm

Re: Valve noise

Camshafts and lifters do "wear in" to each other. If a new lifter is installed, the wear factor will be changed, and in turn the cam may very well not do well.

The solution is to go a bit further. All new lifters, and new cam. That is a lot of work. Not sure of your work experience. If you are a technical guy, and have tools available, might be a really good learning and freshening process.

The solution is to go a bit further. All new lifters, and new cam. That is a lot of work. Not sure of your work experience. If you are a technical guy, and have tools available, might be a really good learning and freshening process.

Jerry Whitt

ASE CERTIFIED MASTER TECHNICIAN

Retired

Hemet, Callifornia

65 Monza, purchased new

65 Corsa convertible

ASE CERTIFIED MASTER TECHNICIAN

Retired

Hemet, Callifornia

65 Monza, purchased new

65 Corsa convertible

-

64powerglide

- Posts: 1604

- Joined: Tue Mar 25, 2014 9:18 pm

- Location: Kalamazoo Mi..

Re: Valve noise

64Powerglide, Jeff Phillips

Kalamazoo, Mi..

Kalamazoo, Mi..

Re: Valve noise

It could also be indicative of a worn valve guide. This too can cause noise.

1966 Corsa turbo

1969 Monza convertible

1987 Buick Grand National

1969 Monza convertible

1987 Buick Grand National

- bbodie52

- Corvair of the Month

- Posts: 11974

- Joined: Mon Aug 06, 2012 12:33 pm

- Location: Lake Chatuge Hayesville, NC

- Contact:

Re: Valve noise

I must say that I've been working on Corvairs since the 1960s, but I have never disassembled and cleaned the hydraulic lifters on one yet. Now that you've started this, here are parts two and three...

Before tackling this complex and time-consuming procedure, read the section of the shop manual (copy attached) to familiarize yourself with the steps involved.

Here are some additional useful tips from one who knows....

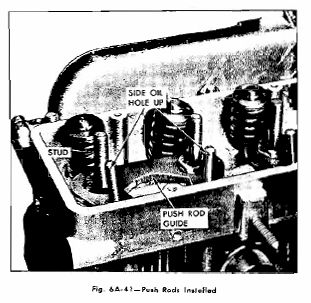

I've seen push rods inserted backward that resulted in a broken rocker arm. There is a small hole in the side of each push rod (one end only) that is there to spray oil on the rocker arm to lubricate it. If the push rod is inserted upside down, the side hole will be near the hydraulic lifter instead of the rocker, and the rocker arm may not be getting adequate lubrication!

If you are going to go through all this process to remove and clean your lifters, you should plan on replacing the rubber o-rings with new VITON o-rings. New valve cover gaskets might also be a good idea.

http://www.corvair.com/user-cgi/catalog.cgi?show_page=4

http://www.corvair.com/user-cgi/catalog.cgi?show_page=4

Part number C4314: O-RINGS-CLARK VITON PUSH TUBE & ROCKER ROCKER STUD=C4314A PUSH TUBE=C4314L

Weight: 0 lbs 4 oz

Catalog Pages(s): 4

Price:

1 - 1 $ 10.50

In my first rebuild effort in 1969 it seemed like the most difficult thing I ran into was getting the upper row of cylinder head nuts off. Although this procedure in the video does not involve removing the upper cylinder head nuts, re-torquing them should be done with a six-point socket. They are exposed to years of moisture, rust, dirt and high engine heat from the cylinder heads, which helps to soften the old nuts so they easily round off if the socket slips. Most are buried with limited access between the intake manifold casting and the valve cover mating surface area, so a damaged nut is difficult to get at to chisel or cut off. I found that sometimes I would be forced to use a hacksaw blade to cut the stud in the area around the cylinder barrel. The lower row (behind the rocker arms) is easier because they are cooled somewhat by oil, are larger, and are not exposed to rust or dirt on the threads. A deep six-point socket is all that is needed after removing the rocker arms.

A six-point socket usually gives a better grip on a bolt head than a 12-point socket.

Removing the push rod tubes with a pair of pliers can cause them to be crushed or damaged. Work carefully. Clark's even offers a special tool to accomplish this...

Before tackling this complex and time-consuming procedure, read the section of the shop manual (copy attached) to familiarize yourself with the steps involved.

Here are some additional useful tips from one who knows....

I've seen push rods inserted backward that resulted in a broken rocker arm. There is a small hole in the side of each push rod (one end only) that is there to spray oil on the rocker arm to lubricate it. If the push rod is inserted upside down, the side hole will be near the hydraulic lifter instead of the rocker, and the rocker arm may not be getting adequate lubrication!

If you are going to go through all this process to remove and clean your lifters, you should plan on replacing the rubber o-rings with new VITON o-rings. New valve cover gaskets might also be a good idea.

Part number C4314: O-RINGS-CLARK VITON PUSH TUBE & ROCKER ROCKER STUD=C4314A PUSH TUBE=C4314L

Weight: 0 lbs 4 oz

Catalog Pages(s): 4

Price:

1 - 1 $ 10.50

In my first rebuild effort in 1969 it seemed like the most difficult thing I ran into was getting the upper row of cylinder head nuts off. Although this procedure in the video does not involve removing the upper cylinder head nuts, re-torquing them should be done with a six-point socket. They are exposed to years of moisture, rust, dirt and high engine heat from the cylinder heads, which helps to soften the old nuts so they easily round off if the socket slips. Most are buried with limited access between the intake manifold casting and the valve cover mating surface area, so a damaged nut is difficult to get at to chisel or cut off. I found that sometimes I would be forced to use a hacksaw blade to cut the stud in the area around the cylinder barrel. The lower row (behind the rocker arms) is easier because they are cooled somewhat by oil, are larger, and are not exposed to rust or dirt on the threads. A deep six-point socket is all that is needed after removing the rocker arms.

A six-point socket usually gives a better grip on a bolt head than a 12-point socket.

Removing the push rod tubes with a pair of pliers can cause them to be crushed or damaged. Work carefully. Clark's even offers a special tool to accomplish this...

I pulled these illustrations from some earlier Corvair Forum posts...

Clark's sells these push rod tube removal tools...

http://www.corvair.com/user-cgi/catalog ... ge=TOOLS-3

Part number C1439: PUSH ROD TUBE REMOVER TOOL !!!NOTE- MANIFOLDS DO NOT NEED TO BE REMOVED

Weight: 1 lbs 0 oz

Catalog Pages(s): T-3

Price: $ 53.35

- Attachments

-

- 1965 Corvair Chassis Shop Manual - SECTION 6 - ENGINE PUSHROD TUBES AND O-RINGS and VALVE ADJUST.pdf

- 1965 Corvair Chassis Shop Manual - SECTION 6 - ENGINE PUSHROD TUBES AND O-RINGS and VALVE ADJUST

- (2.9 MiB) Downloaded 43 times

-

- 1965 Corvair Chassis Shop Manual - SECTION - SPECIFICATIONS.pdf

- 1965 Corvair Chassis Shop Manual - SECTION - SPECIFICATIONS

- (2.83 MiB) Downloaded 37 times

Brad Bodie

Lake Chatuge, North Carolina

1966 Corvair Corsa Convertible

1966 Corvair Corsa Convertible

Lake Chatuge, North Carolina

1966 Corvair Corsa Convertible

1966 Corvair Corsa Convertible-

64powerglide

- Posts: 1604

- Joined: Tue Mar 25, 2014 9:18 pm

- Location: Kalamazoo Mi..

Re: Valve noise

Brad, I didn't like the part two video. He tightens them down & lets them smooth out but I went by Motohead's cold adjustment then loosen them until you get some clatter then tighten them 1/2 turn. Mine are very quiet & the engine runs super. I also changed one exhaust tube, rusted bad. Anyway when I took the push rod tube out I lightly turned it with channel lock pliers, just enough pressure to grip without denting. Gave it just a little turn then grabbed it with my hand & it came right out. Maybe I was just lucky, cleaned the tube ends up oiled it & put it back in & have no leaks. I would say try the cleaning & readjusting cold & hot & see what that does before doing things that might not be needed.

64Powerglide, Jeff Phillips

Kalamazoo, Mi..

Kalamazoo, Mi..

Re: Valve noise

Boy Brad, you don't miss much. Thanks for the info!! Small block experience made me flip the push rods but a squeak got my attention. When I tracked down the noise I noticed the oil holes. DOH!!!!

I had 140 heads done and put them on my 110 engine. I have the 140 engine to go through at some future date so I really don't want to dig too far into this one. I'll watch those videos again and pull that lifter.

Thanks everyone for you valued input.

Gary O

I had 140 heads done and put them on my 110 engine. I have the 140 engine to go through at some future date so I really don't want to dig too far into this one. I'll watch those videos again and pull that lifter.

Thanks everyone for you valued input.

Gary O

- bbodie52

- Corvair of the Month

- Posts: 11974

- Joined: Mon Aug 06, 2012 12:33 pm

- Location: Lake Chatuge Hayesville, NC

- Contact:

Re: Valve noise

One useful trick I didn't mention is to discard and replace the original upper row of cylinder head nuts after carefully removing them with a six-point socket. Clark's offers new heat-treated flange nuts that protect the soft aluminum cylinder head mating surface without the need for a washer. They also suggest installing an acorn nut on top of each flange nut to cover and protect the remaining exposed threads of each stud to protect the threads from exposure to moisture, rust, and dirt. Clark's also mentions the use of anti-seize compound on the threads, but if you do use caution. It has been suggested that the use of this lubricant on the steel threads reduces friction and can result in over-torquing the nuts because of invalid torque wrench readings that can over-stress the pull on the stud and possibly cause the stud to be pulled out of the engine cases. The 1965 Corvair Chassis Shop Manual recommends 32-38 ft. lbs. for the cylinder head nuts and the valve rocker arm studs. The lower end of that range might be the safest bet. (To add to the confusion, the torque specification in the 1961 Shop Manual is lower: 27-33 ft. lbs.)

http://www.corvair.com/user-cgi/catalog ... IN&page=13

http://www.corvair.com/user-cgi/catalog ... IN&page=13

Part number C1089: NUTS-HEAD-SET 12 PLATED (SET 6=C4633) CHROME ACORN NUTS TO COVER END OF STUD =C3413

Weight: 0 lbs 6 oz

Catalog Pages(s): 13(69),20,181,OT-40

Price:

1 - 1 $ 6.10

2+ $ 5.50

Part number C3413: NUTS-12 CHROME ACORN-UPPER HEAD STUDS

Weight: 0 lbs 6 oz

Catalog Pages(s): 13(69),20,181

Price: $ 14.55

terribleted wrote:Sat Jun 19, 2010 12:12 am

Torque spec is 32-38 ft lbs. Pattern is as follows: XXX are upper nuts or rocker studs looking at the head from the valve cover side

-12--------8--------1--------4--------6--------10

XXX-----XXX-----XXX-----XXX-----XXX-----XXX

-11--------7-------3---------2--------5--------9

XXX-----XXX-----XXX-----XXX-----XXX-----XXX

Part number C1089: NUTS-HEAD-SET 12 PLATED (SET 6=C4633) CHROME ACORN NUTS TO COVER END OF STUD =C3413

Weight: 0 lbs 6 oz

Catalog Pages(s): 13(69),20,181,OT-40

Price:

1 - 1 $ 6.10

2+ $ 5.50

Part number C3413: NUTS-12 CHROME ACORN-UPPER HEAD STUDS

Weight: 0 lbs 6 oz

Catalog Pages(s): 13(69),20,181

Price: $ 14.55

Brad Bodie

Lake Chatuge, North Carolina

1966 Corvair Corsa Convertible

1966 Corvair Corsa Convertible

Lake Chatuge, North Carolina

1966 Corvair Corsa Convertible

1966 Corvair Corsa Convertible