Since I had never installed or used an electric fuel pump in a car, I did not know of a weakness in electric fuel pumps that limits their installation to distances that are close to the fuel tank. It would be easy to assume that, when replacing a mechanical fuel pump with an electric fuel pump, the physical layout and configuration used with the mechanical fuel pump installation would be similar to that needed by the electric fuel pump. Apparently this is not true! The functional purpose may be the same, but the installation requirements are not.

Airtex Fuel PumpsAirtex Fuel Pumps wrote:Be sure to pick a location within 2-3 feet of the fuel tank!

Airtex Fuel TV

=============== BACKGROUND INFORMATION THAT MAY BE HELPFUL ================Mine has mechanical fuel pump how can I convert it into a electric?

Reply ·

Airtex Fuel Pumps --

There are many steps to this process depending on vehicle type, engine size, pump placement, etc. We address some of these issues in our video. If you need more detailed help on your application please call our free Tech Support Hotline 800-424-7839 & we'd be happy to walk you through it. Thanks.

I recently did a comparison between standard Corvair mechanical fuel pumps and aftermarket electric fuel pumps for another Corvair Forum member. I thought that you would find that material informative, so I have included it here.

Replacement mechanical fuel pumps are reliable and relatively inexpensive. A good electric pump, with proper safety switching can cost many times the price of a new mechanical pump. Corvair mechanical fuel pumps have been widely tested in hundreds of thousands of Corvairs for 40-50 years, and they are a proven product with good reliability. They are also easy to remove and replace. I would suggest reading and following the shop manual to properly test and diagnose a suspected fuel pump problem.

If you feel that the fault is a bad fuel pump, replace it. But I would recommend against a conversion to an electric fuel pump. It is not worth the expense. You could purchase two mechanical pumps and keep one in the trunk as part of a spares kit, and still spend significantly less than the cost of an electric pump conversion. An electric fuel pump is not inherently more reliable than the standard Corvair mechanical pump. It simply substitutes an electric motor for the engine to provide the power source to pump the fuel. The electric fuel pump, including the safety devices to ensure its operation only when the engine is running, adds complexity which can actually increase the possibility of a system failure.

The material below will provide you with good information.

http://www.corvairunderground.com/fuelpump.htm

http://www.corvairunderground.com/pumpleaks.htmLet's Talk About

Corvair FUEL PUMPS

This is always a controversial subject amongst Corvair owners. But a great deal of the controversy is self inflicted. Mechanical or electric fuel pumps? Let's try and sort this out.

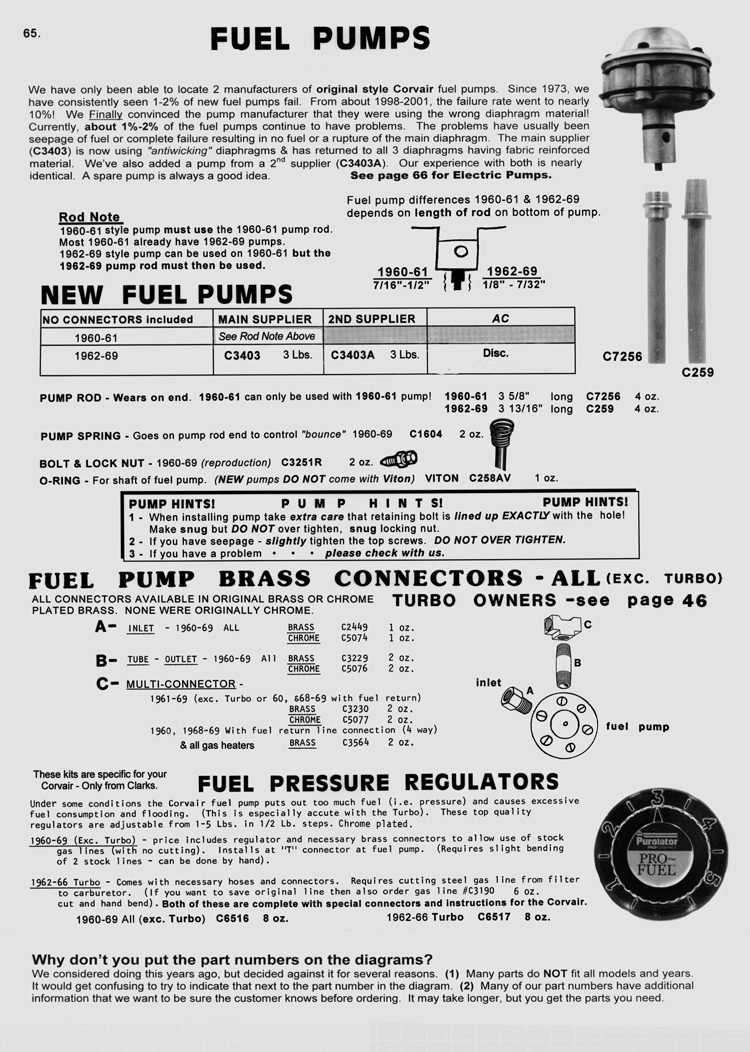

MECHANICAL FUEL PUMPS - These are the pumps that came standard with all Corvairs from the factory. The mechanical pump is a simple diaphragm type that is operated by a push rod which rides on an eccentric on the crankshaft. The pump develops suction which draws gas from the fuel tank and distributes it to the carburetors.

It would be simple to say that all mechanical Corvair pumps are the same - but alas, that is not the case. The original 1960 models had a pump that appears to be the same but has a longer rod exiting the bottom of the pump. In turn a shorter pump pushrod was obviously used. This design was carried over into 1961 models for an uncertain period of time. This is why if you own a 1960 or 1961 you should always measure the overall length of your pushrod before you replace the pump.

In that same vein I would highly suggest that if you find you have one of these earlier pumps you should convert it to the 62-69 type. Why? because it's easy and cheap to do and there is never a question in the future as to which pump you're using. If you should be unlucky enough to find an NOS earlier pump do not be tempted to use it!

These 60-61 pumps were last produced well over 30 years ago and that pump will be too old to reply on. To make the conversion simply get one of our part number U-481 pump pushrods.

Now let's go back 18 years ago to 1992. One of the largest makers of Corvair fuel pumps got a defective batch of diaphragms. THIS HAPPENED ONCE and only in 1992. But the repercussions have lasted ever since. The problem was corrected within a few months BUT because this manufacturer sold to many different retailers it made it appear that numerous manufacturers were putting defective pumps on the market. To make matters worse, some of those retailers moved very few Corvair pumps, so for years (even to the present) some "brands" (labels, really) still sell defective Corvair pumps - all ones made in that original batch 18 years ago.

Well, bad enough you say. Oh it can always get worse - and it did. Back in the early 90's a small parts vendor saw an opportunity. Because everyone at the time was in a virtual panic this vendor saw an opportunity to promote their fuel pumps. An abnormal amount of negative advertising and outright nonesense permeated the Corvair grapevine. The claim, of course, was that this vendors fuel pumps were perfect while everyone elses were bad. But there was an irony here.

As time went on it became more than apparent that the vendors fuel pumps were actually worse than everyone elses. Where their pumps came from were anyone's guess, but by hundreds of defective pumps and 3 different, but failing, revisions later the matter was dropped.

But that wasn't enough. During this timeframe numerous Corvair experts (some real some self-proclaimed) wrote articles that only clouded the issue even worse.

Some claimed that rebuild kits were the only answer. Ironic again, because the few remaining rebuild kits also suffered from the diaphragm problem, possibly because they had been the original supplier for this part from the beginning. Some claimed that certain visible features could warn you of doom. Visible reinforcement fibers in the diaphragm, the type of screws holding the pump body together, even the precise length of the lower diaphragm rod were all to be worshipped. While it's true that some of these identities sometimes had validity none of them were absolute. The issue of the diaphragm rod length was especially absurd.

It's true that the rod length has to fall within certain parameters, but the miniscule measuring of this rod was misleading overkill. The amount the rod protrudes from the pump casting can still vary up to at least 1/4 of an inch and still be within specs.

Take all of the above and horsewhip it to death from 1992 to the present and what can you expect? If you study the psychology of panics most of them look a lot like our fuel pump example. An issue can be twisted and confused so much for so long there is no way to untangle it.

Then we have to think that many people quit driving their Corvairs? No, a "white knight" came to some owners rescue. The electric fuel pump is used on nearly all modern cars. Electric pumps are generally reliable, and are readily available. So why isn't that the end of the story?

I have said since Day One that I would never talk a happy electric fuel pump owner out of their pump. That has never really been the issue. The issue are new Corvair owners and what they should feel compelled to do. I think it's irresponsible to tell a new owner that he has to get rid of a perfectly functioning mechanical pump and replace it with an electric.

Electric fuel pumps cost more than mechanical pumps, especially when set up safely, take a bit of work and knowledge to retrofit and have their own problems (as do all mechanical devices). Bottom line - they are unnecessary, but if you really WANT one (as opposed to being convinced that you MUST have one) then that's your decision.

But what if your mechanical pump has failed?

FIRST - Make sure it HAS failed. I believe that many fuel pump "failures" have nothing directly to do with the pump. The most common of these is when you develop an air leak in the incoming fuel line. Spots to look for trouble include the rubber connecting line just behind the firewall (old cracked hose or loose fittings are the culprit) and make sure the fittings where the incoming line connect to the pump are good. These air leaks can be transient or very specific and repeatable - all related to ambient temperature. If you think your fuel pump has quit pumping check these spots first.

And then there's leaks, both internal and external. Of course the biggest boogeyman is the internal leak that pumps gas into your crankcase causing everything from noisy lifters all the way to a trashed engine. This can be serious and I have seen it happen - with both mechanical AND electric fuel pumps - but it isn't so common that you have to spend every day immersed in paranoia about it.

External leaks can happen but they are usually the result of incorrect installation or other misuse of the pump OR you may have purchased one of the brands of pumps that never got sent back from the 1992 recall.

One important point about electric pumps is that if you chose to use one make sure to remember that the incoming line system was not designed to be pressurized.

CLARK'S CORVAIR PARTS MECHANICAL FUEL PUMP OPTION (Page 65)Our own mechanical fuel pump "horror" stories....

As I've mentioned before, I have nearly 2 million miles of Corvair driving on mechanical fuel pumps. I believe them to be totally reliable.

Never the less, we do no one a service by ignoring actual issues. Rather, it's better to get them out in the open and try to analyze them. Here are the ones I have experienced firthand.

Once my stepson and I were driving his 1969 up to a Corvair event in northern Washington. He hadn't put many miles on the new engine but everything was running well. We had stopped at a Wendy's to eat lunch. The 69 was parked on a pretty steep space where the engine was on the downhill side.

After eating we came out and started the 69 up. It was running fine but I was sure I smelled gas. Went to the back of the car and gas was POURING out of the back of the fuel pump. We immediately stopped the engine and pondered our options (I had brought a new spare fuel pump with us - I carry a spare tire and fan belt too).

Because I couldn't explain why the pump was suddenly "leaking" I asked my stepson to start the motor up for just a few seconds so I could see exactly where the gas was coming from. SURPRISE! Gas wasn't coming out of the pump any more. I was baffled.

We watched the pump for about 10 minutes. Not a drop of gas. We proceeded (cautiously) the further 100 miles to the show. No leaks. Then drove home (about 300 miles) no leaks. In fact, this was 10 years ago and the car still has the same fuel pump on it. Not a drop since.

What exactly was going on? I have my theories, but maybe you have an idea.

Another leak story involves my Ultravan. Because it usually sat for months at a time when it came time to start up for a new season I'd have the engine lid off to watch for problems. The last time it had been started was about 9 months before. This time on startup there was a massive fuel pump leak.

I shut the van down and went inside to ponder the situation. About 10 minutes later I went out, restarted the Ultravan, and of course, no leak. The "leak" never came back - even 4 years and 5000 plus miles later.

Our last example is interesting because it just happened to me 2 days ago (August 30th). I had my daily driver 64 Greenbrier down for about 3 weeks while I rebuilt the carbs, distributor, and alternator.

When all the work was done I did the initial startup and SURPRISE the fuel pump that had been serving faithfully for over 60,000 miles was leaking. But this time I thought I'd just shut down for a few minutes and then restart.

Of course the "leak" was gone. And it hasn't come back.

In all the cases above I DID NOT tighten the screws on the pump - In these circumstances many people retighten the pump cap screws and lay the "leak" on the need to do that. But note that, at the same time, there was a short waiting period between "leaking" and not leaking. I'm certain it was the waiting period - NOT the screw tightening that fixed the problem.

But why is it happening? (Even if just occasionally) It appears that modern fuel dries out the rubber diaphragm between extended intervals of operation. Sometimes (but not usually) the diaphragm material will shrink causing a leak at startup. BUT, once the material is re-exposed to the fuel it "swells up" and re seals.

If you have other ideas let me know.

The last example is what I believe to be very typical. Linda and I drove our 67 out to southern Utah for a Corvair event back in 2000. We had already driven 900+ miles without incident but after meeting up with the Bonneville Corvair club we stopped for lunch (At a Wendys again - hmmmmm I wonder...).

As we left we all drove back onto the freeway and the 67 died out. No fuel. Everyone thought it was a failed pump. But I was suspicious. I went back and checked everything over and noticed that the incoming gas line fitting was loose. Upon tightening it up we had fuel pressure again and finished our trip, including a barren 300 mile return across HWY 50 in Northern Nevada (The world's loneliest highway).

Vacuum leaks anywhere in the incoming line can cause the pump to quit drawing fuel. These leaks can be effected by temperature and other factors. Check these things first , before you assume the pump has failed.

http://www.corvair.com/user-cgi/catalog ... IN&page=65

Part number C3403A: 62-69 FUEL PUMP REBUILD KITS ARE NOT AVAILABLE

Weight: 2 lbs 4 oz

Catalog Pages(s): 65

Price:

1 - 1 $ 78.45

2+ $ 74.55

==========================================================================

ADDITIONAL ITEMS - Any products listed below are possible alternate choices:

Part number C3403 (Regular): NON-GM FUEL PUMP-62-69 WILL FIT 60-61 IF ORDER C259 ROD

Weight: 2 lbs 4 oz

Catalog Pages(s): 65

Price:

1 - 1 $ 59.10

2+ $ 57.35

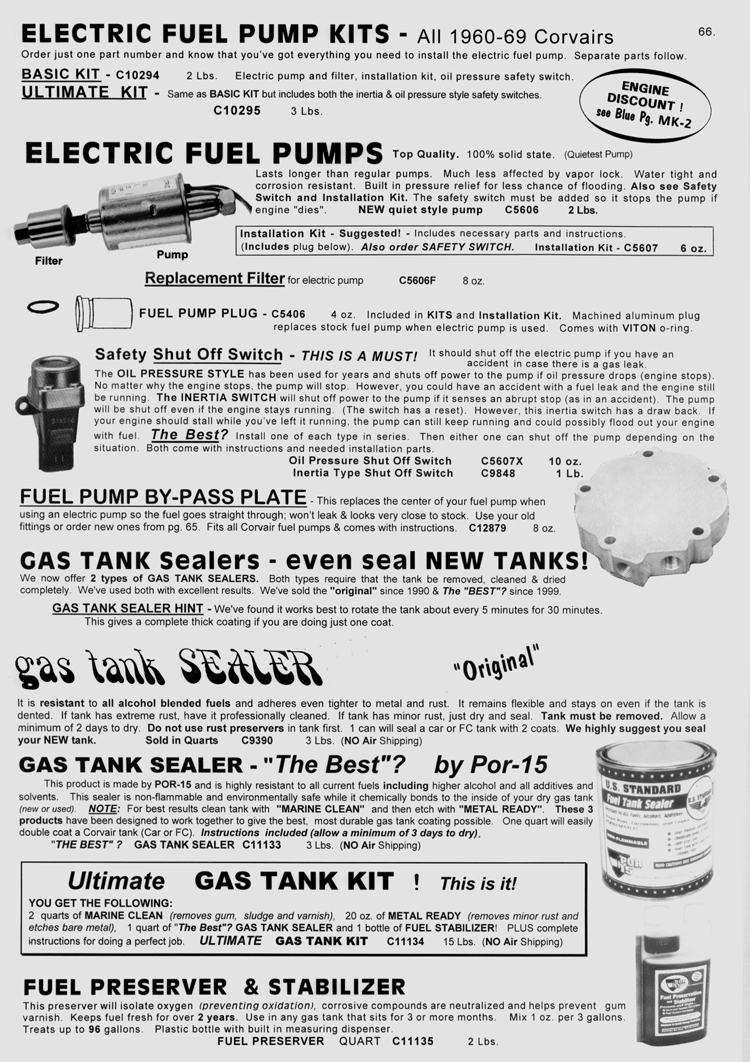

CLARK'S CORVAIR PARTS ELECTRIC FUEL PUMP OPTION (Page 66)

http://www.corvair.com/user-cgi/catalog ... IN&page=66

Part number C10295: ULTIMATE ELECTRIC FUEL PUMP KIT INCLUDES BOTH STYLES OF SAFETY SWITCHES

This part is a Multi Kit, which contains the following parts:

Part Number C5606: 1 x ELECTRIC FUEL PUMP & FILTER -ALSO ORDER

Part Number C5607: 1 x ELECTRIC FUEL PUMP INSTALLATION KIT *

Part Number C5607X: 1 x SAFETY SHUT-OFF SWITCH WITH FITTINGS TO

Part Number C9848: 1 x FUEL SAFETY INERTIA SWITCH

Weight: 2 lbs 8 oz

Catalog Pages(s): 66

Price: $ 241.60

1966 Corvair Corsa Convertible

1966 Corvair Corsa Convertible