PCV valve

PCV valve

I’m a new owner of a 1963 Monza Coupe, 102hp with a little over 44,000 miles. As I was just looking around the car, trying to get familiar with it, I noticed the PCV valve and corresponding hoses look like they’ve been changed. At least from what I’ve seen on the forum, manual and Facebook photos. Any insight on this?

(Hopefully the pics upload)

(Hopefully the pics upload)

1963 Monza Club Coupe

Western North Carolina

Catawba County

Western North Carolina

Catawba County

- toms73novass

- Posts: 223

- Joined: Sat Mar 04, 2017 6:58 am

- Location: Grand Island NY

Re: PCV valve

Does not look right.

Upon further looking at it, it might be ok. It depends if the PCV valve has the proper size orifice.

It is definitely not stock

Upon further looking at it, it might be ok. It depends if the PCV valve has the proper size orifice.

It is definitely not stock

1962 700 Wagon

1963 Spyder convertable

1965 Monza

1967 UltraVan 211

1963 Spyder convertable

1965 Monza

1967 UltraVan 211

Re: PCV valve

Yeah, I was going to replace it, or at least check it, when I noticed it definitely wasn’t the valve that shows up when I try to order one. Then I wondered if maybe the last time it was changed whoever did it just had this one on hand and changed the hose to fit it.

1963 Monza Club Coupe

Western North Carolina

Catawba County

Western North Carolina

Catawba County

Re: PCV valve

The correct size hose might help too. Dennis

Re: PCV valve

Yeah, I think I’m going to buy the correct valve, new section of hose and put it back the way it was.

1963 Monza Club Coupe

Western North Carolina

Catawba County

Western North Carolina

Catawba County

- bbodie52

- Corvair of the Month

- Posts: 11974

- Joined: Mon Aug 06, 2012 12:33 pm

- Location: Lake Chatuge Hayesville, NC

- Contact:

Re: PCV valve

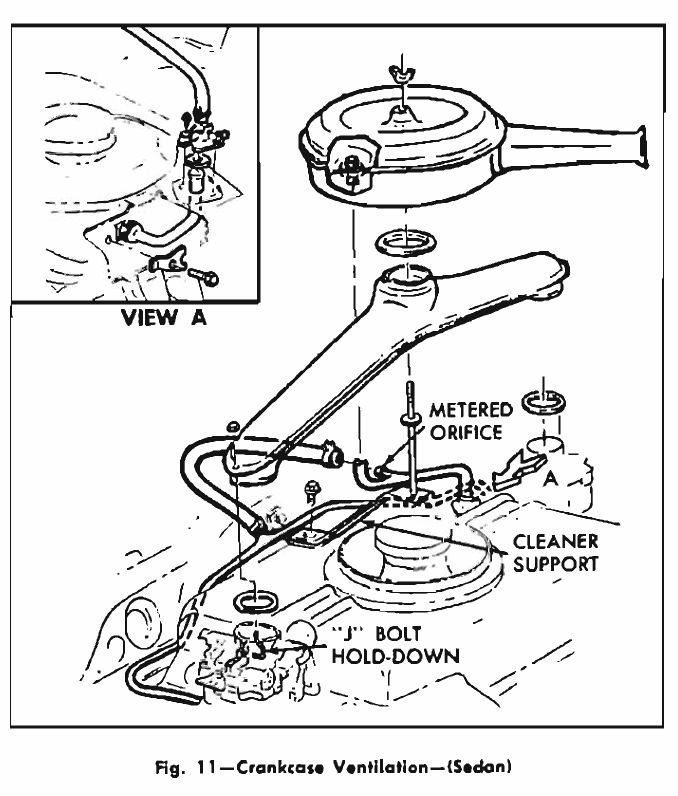

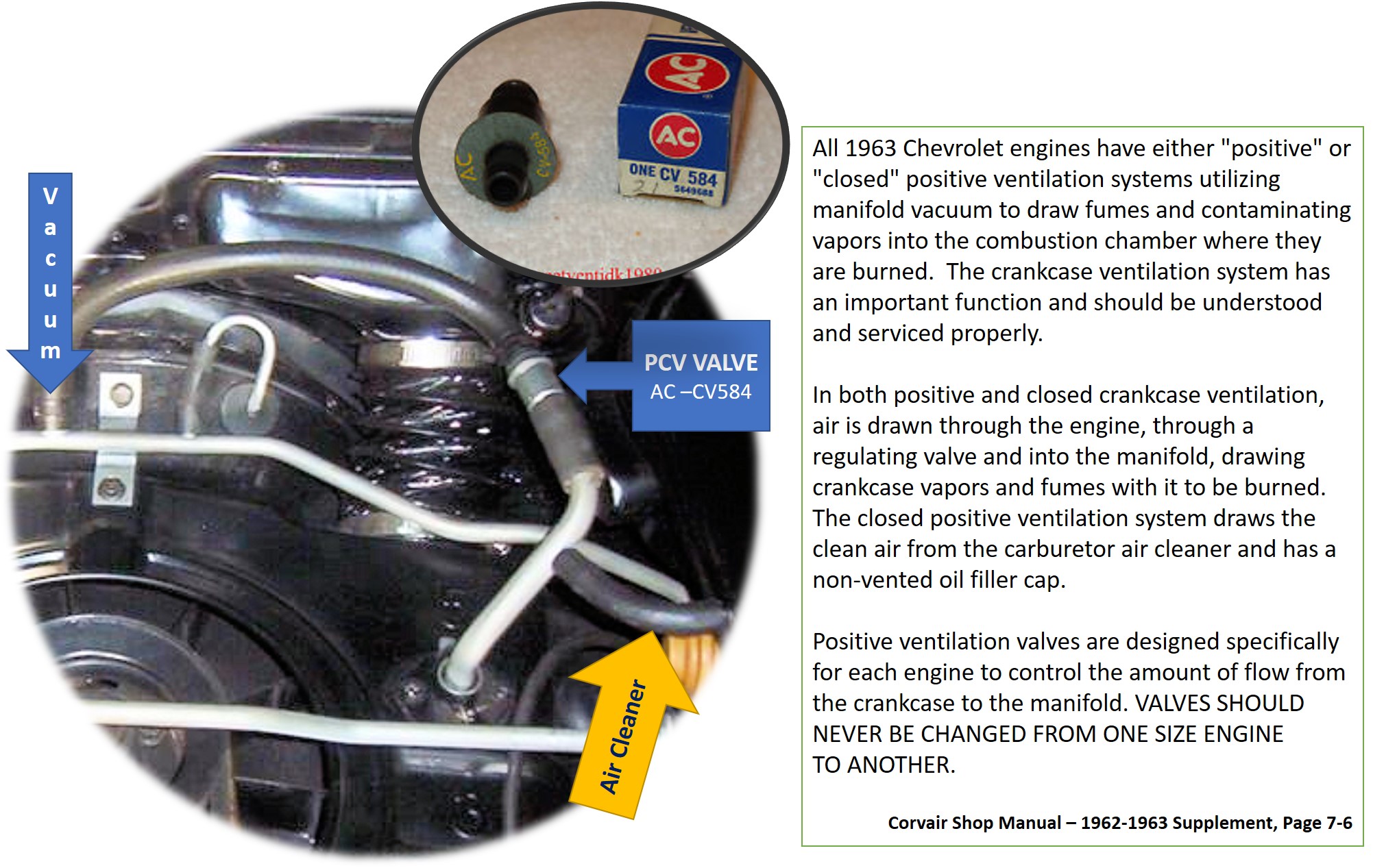

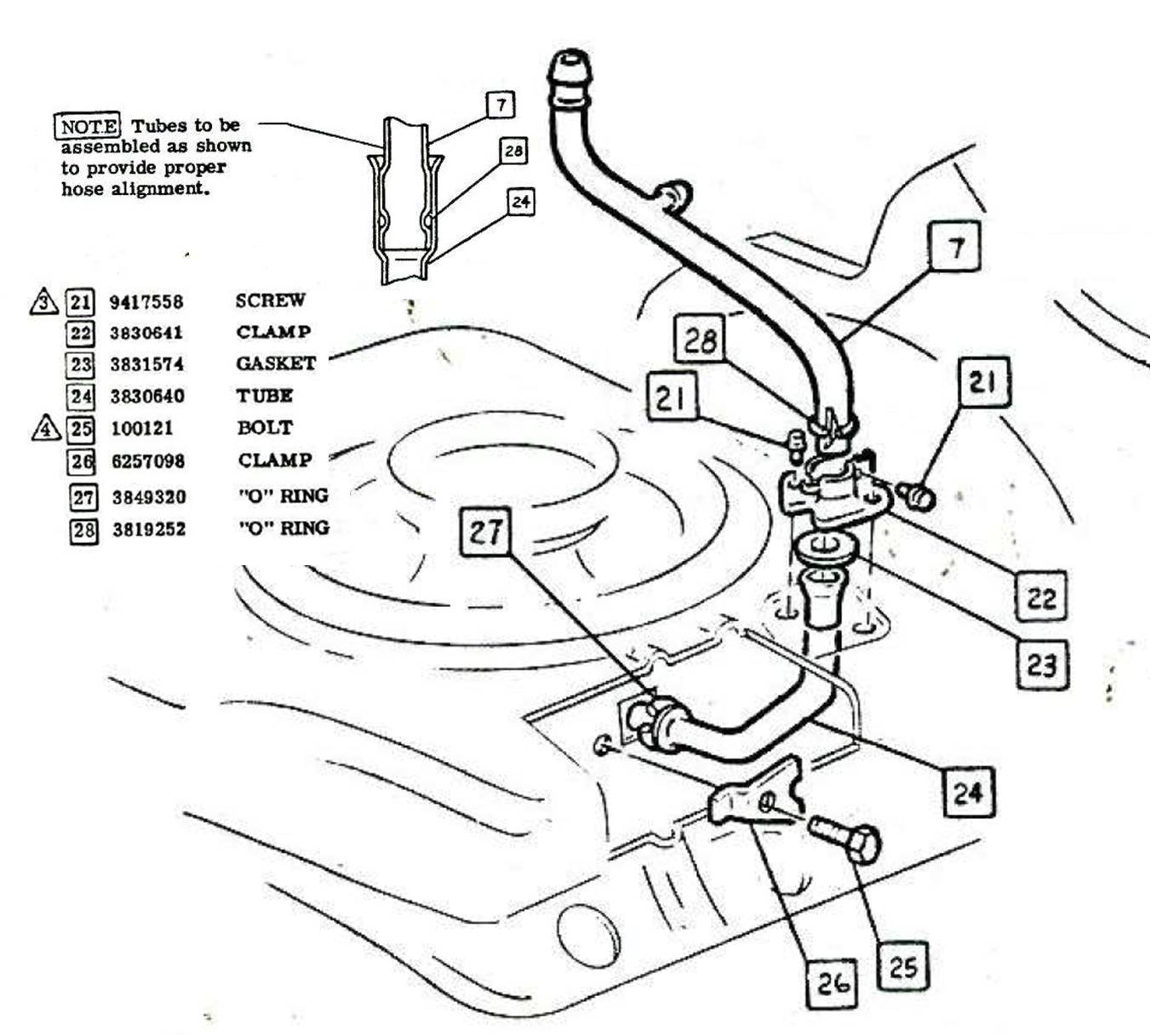

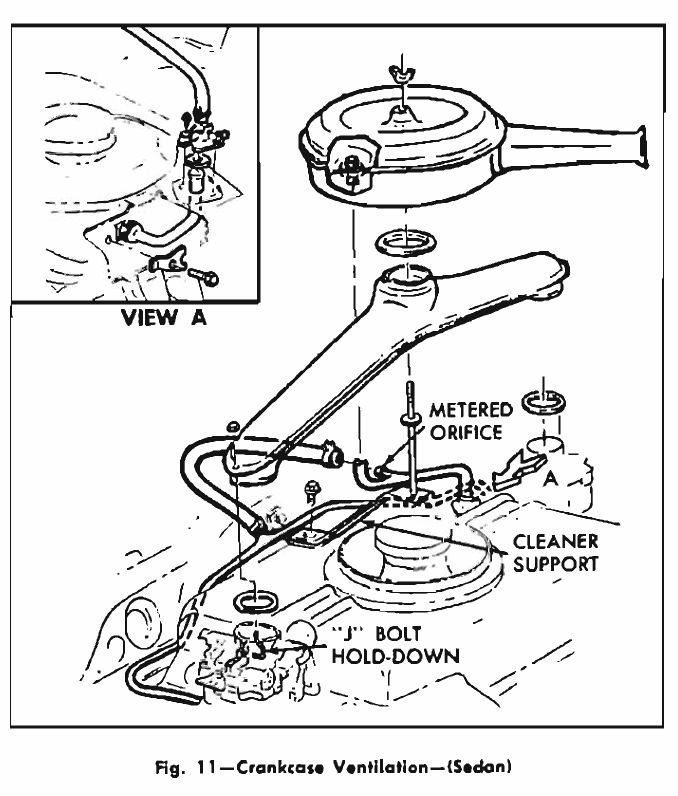

I have copied a couple of my previous posts and their associated illustrations to try to provide you with a detailed description of the Corvair Positive Crankcase Ventilation (PCV) systems as they replaced the 1960-1962 road draft tube with a variety of crankcase ventilation configurations. In all cases the PCV system has two crankcase breathing subsystems, to provide adequate, and essential crankcase ventilation from low RPM, partial throttle operation to high RPM, open throttle operation.

At low RPM, closed throttle (idle), or low throttle settings, the intake manifold vacuum is relatively high — because the closed carburetor throttle butterfly valves essentially seal the intake manifolds to produce a relatively high vacuum as available air is drawn into each of the six cylinders during the intake strokes. As the throttles open, the engine RPM increases, and the initial high vacuum levels inside the intake manifolds transitions to low vacuum levels, substituting high airflow volume levels as increasing amounts of a fuel/air mixture flows into the cylinders. During this high engine speed operation,there is little vacuum in the vacuum balance tube, but a lot of airflow through each carburetor air cleaner and throat. Crankcase pressure produced by piston blowby also increases. and the bulk of the crankcase fume volume is then drawn directly into the air cleaner assembly and down the throats of the carburetors, to be drawn into the cylinders, and then reburned at the power stroke in each cylinder, and then forced out through the exhaust system.

IN THIS ILLUSTRATION, THE PCV CONNECTIONS ARE INCORRECTLY REVERSED — PERMITTING TOO MUCH CRANKCASE AIR TO BE PULLED DIRECTLY INTO THE INTAKE MANIFOLDS VIA THE BALANCE TUBE. THE PCV VALVE HAS ALSO BEEN LEFT OUT OF THE SYSTEM. (The PCV VALVE functions as an airflow restriction, which prevents a lean fuel-air mixture

that may otherwise be caused by too much air leaking into the vacuum balance tube. The PCV valve is a one-way valve attached to the crankcase that holds motor oil and produces gasses when your engine burns fuel. A PCV valve's main job is to control gas emissions and reroute any gas produced by the crankcase back into your engine's combustion chambers).

The Corvair Positive Crankcase Ventilation (PCV) system operates differently at different engine speeds and various throttle opening settings. At closed/partial throttle the engine intake manifold vacuum is relatively high, so the vacuum level in the balance tube is high. At these engine settings the engine can draw crankcase fumes though the 0.062" metered orifice in the side of the crankcase breather tube (or the PCV valve, in some models), where the fumes are pulled through the vacuum balance tube and down to the base of the carburetors, into the intake manifolds — to be recycled through the combustion chambers and reburned and passed out of the exhaust system.

At engine speeds where the throttle settings are opened wide, intake manifold vacuum decreases, but air velocity through the carburetor intakes increases. As the engine transitions from partial throttle to open throttle, less vacuum is available to pull the fumes through the vacuum balance tube. However, open throttles and high RPM produce more crankcase pressure with increased blowby past the piston rings. Increased airflow through the air filter and carburetor throats permits crankcase fumes to be drawn through the larger breather tube and into the carburetor intakes, where the crankcase fumes again make their way through the intake manifolds and back into the combustion chambers, to again be reburned and pumped out of the exhaust system.

Because the PCV system is engineered to offer two separate paths back through the engine combustion chambers (each path to compensate for a range of engine operating speeds and throttle openings), both paths must be connected to the intake manifold. The slow RPM path is through the vacuum balance tube, while the high RPM open throttle path is through the carburetor air cleaner.

The smaller side tube connection should have a small hole (fixed orifice, or metered orifice) that restrict airflow. THIS METERED ORIFICE REPLACED THE PCV VALVE, WHICH GENERALLY APPEARED ONLY IN THE 1963 CORVAIRS. The metered orifice, or the PCV valve, should be connected to the vacuum balance tube so that a small amount of air will be drawn through the PCV valve, or the small fixed orifice hole at the side of the PCV tube.

The tube with a larger diameter that is essentially unrestricted is supposed to be connected to the carburetor main intake, via the air filter connection at the top of one (or both) carburetors. This connection brings crankcase fumes into the main airflow via the carburetor throat, which draws those fumes from the crankcase back into the carburetor intake(s) at throttle settings where the airflow into the carburetor throat is greater, due to open throttle and higher engine RPM speeds.

The two PCV connections handle low-RPM, partial throttle (high intake manifold vacuum) operation, and also at open throttle levels when airflow through the main carburetor throat increases. The side tube metered orifice limits airflow directly into the intake manifold so that the fuel/air mixture provided by each carburetor does not become unbalanced (too lean) because of too much air from the PCV system mixing with the fuel/air ratio controlled by the carburetor systems. This restricted airflow is deemed sufficient because engine RPM speeds are low, so the volume of crankcase pressure due to piston blowby is relatively low. At higher engine speeds, piston blowby into the crankcase increases, and the crankcase fumes shift to entering the intake manifold via the main carburetor (top) intake(s). (Note that a connection to only one air cleaner is sufficient to recycle the crankcase blowby fumes). This allows the carburetors to continue to manage the overall fuel/air mixture, while still providing a path for the crankcase blowby fumes to be recycled back into the combustion chambers.

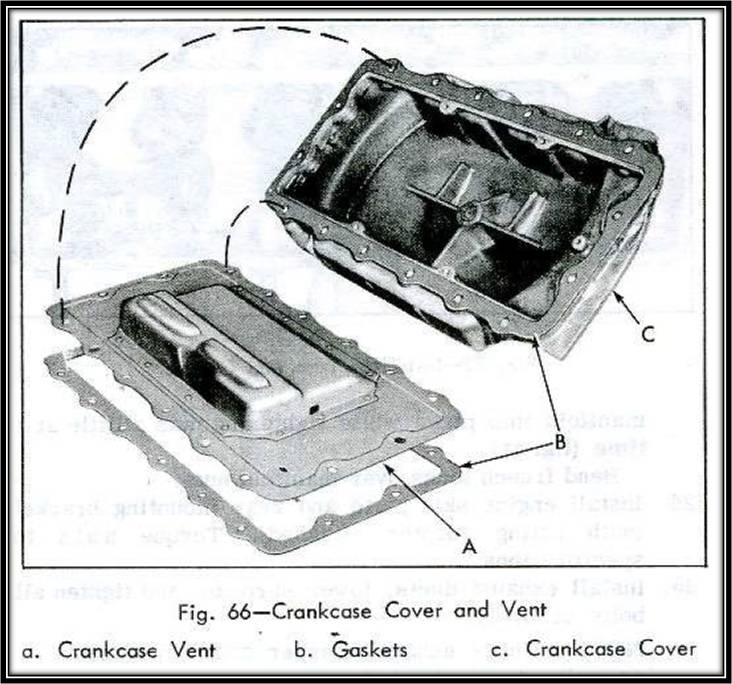

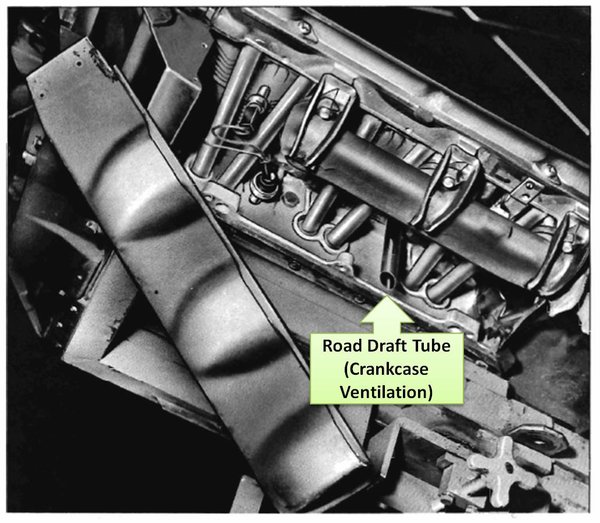

1962 and earlier Corvair with Road Draft Tube and Oil Pressure Warning Switch down below.

Introductory Year with a Positive Crankcase Ventilation (PCV) System that utilized a 1963 PCV Tube with separate PCV Valve.

1964 and Later PCV Tube with Vacuum Airflow Restriction Fixed Orifice (Eliminated the Separate PCV Valve)

To summarize... the Positive Crankcase Ventilation (PCV) system has TWO ventilation paths between the engine crankcase and the engine INTAKE MANIFOLD. Two paths are needed to allow the PCV system to function at low RPM (closed or partial throttle) settings, when intake manifold vacuum is relatively high, and at open throttle settings, when intake manifold vacuum is low, but air velocity through the carburetor throat (venturi) is high. Piston ring blowby can occur at all engine speeds and allows some fuel/air mixture to leak into the crankcase, building crankcase pressures with contaminated fuel/air vapors. At low engine speeds the high intake manifold vacuum sucks these crankcase vapors through the fixed (metered) orifice or PCV valve and recycles those fumes back through the intake manifold, to be burned in normal combustion chamber activity and sent out of the tail pipe. As engine RPM increases with open throttle action, intake manifold vacuum decreases, so the crankcase fumes take the secondary path via the air cleaner and down the carburetor throat — ultimately ending up in the same place: back in the combustion chamber — to be burned and sent out through the exhaust system.

The piston ring seal in each cylinder is never perfect, so there will always be some blowby past the pistons and into the crankcase. If that blowby is allowed to linger in the crankcase, oil contamination and heat can produce harmful sludge. All the PCV system does is to effectively put the blowby gases back where they belonged in the first place... the combustion chambers! The PCV-routed gases are mixed in small quantities with the normal fuel/air mixture, and the spark plugs set off the burning process and the exhaust system takes care of the rest!

ROAD DRAFT TUBE systems were around for many years. They were not very efficient or effective at removing piston blowby contaminants from the engine crankcase and valve train area. As a result, engine oil would become badly contaminated if it was not changed very frequently. Engines would develop harmful sludge. The unburned contaminants that did escape into the atmosphere via the road draft tube contributed greatly to the SMOG content in the air. The development of the PVC system was a huge advancement in pollution reduction and engine protection. while causing almost no degradation in engine power, performance, or drivability.

An example of extreme engine sludge buildup due to oil contamination from crankcase fumes.

SLUDGE https://www.google.com/search?q=engine+ ... e&ie=UTF-8

https://www.google.com/search?q=engine+ ... e&ie=UTF-8

At low RPM, closed throttle (idle), or low throttle settings, the intake manifold vacuum is relatively high — because the closed carburetor throttle butterfly valves essentially seal the intake manifolds to produce a relatively high vacuum as available air is drawn into each of the six cylinders during the intake strokes. As the throttles open, the engine RPM increases, and the initial high vacuum levels inside the intake manifolds transitions to low vacuum levels, substituting high airflow volume levels as increasing amounts of a fuel/air mixture flows into the cylinders. During this high engine speed operation,there is little vacuum in the vacuum balance tube, but a lot of airflow through each carburetor air cleaner and throat. Crankcase pressure produced by piston blowby also increases. and the bulk of the crankcase fume volume is then drawn directly into the air cleaner assembly and down the throats of the carburetors, to be drawn into the cylinders, and then reburned at the power stroke in each cylinder, and then forced out through the exhaust system.

IN THIS ILLUSTRATION, THE PCV CONNECTIONS ARE INCORRECTLY REVERSED — PERMITTING TOO MUCH CRANKCASE AIR TO BE PULLED DIRECTLY INTO THE INTAKE MANIFOLDS VIA THE BALANCE TUBE. THE PCV VALVE HAS ALSO BEEN LEFT OUT OF THE SYSTEM. (The PCV VALVE functions as an airflow restriction, which prevents a lean fuel-air mixture

that may otherwise be caused by too much air leaking into the vacuum balance tube. The PCV valve is a one-way valve attached to the crankcase that holds motor oil and produces gasses when your engine burns fuel. A PCV valve's main job is to control gas emissions and reroute any gas produced by the crankcase back into your engine's combustion chambers).

The Corvair Positive Crankcase Ventilation (PCV) system operates differently at different engine speeds and various throttle opening settings. At closed/partial throttle the engine intake manifold vacuum is relatively high, so the vacuum level in the balance tube is high. At these engine settings the engine can draw crankcase fumes though the 0.062" metered orifice in the side of the crankcase breather tube (or the PCV valve, in some models), where the fumes are pulled through the vacuum balance tube and down to the base of the carburetors, into the intake manifolds — to be recycled through the combustion chambers and reburned and passed out of the exhaust system.

At engine speeds where the throttle settings are opened wide, intake manifold vacuum decreases, but air velocity through the carburetor intakes increases. As the engine transitions from partial throttle to open throttle, less vacuum is available to pull the fumes through the vacuum balance tube. However, open throttles and high RPM produce more crankcase pressure with increased blowby past the piston rings. Increased airflow through the air filter and carburetor throats permits crankcase fumes to be drawn through the larger breather tube and into the carburetor intakes, where the crankcase fumes again make their way through the intake manifolds and back into the combustion chambers, to again be reburned and pumped out of the exhaust system.

Because the PCV system is engineered to offer two separate paths back through the engine combustion chambers (each path to compensate for a range of engine operating speeds and throttle openings), both paths must be connected to the intake manifold. The slow RPM path is through the vacuum balance tube, while the high RPM open throttle path is through the carburetor air cleaner.

The smaller side tube connection should have a small hole (fixed orifice, or metered orifice) that restrict airflow. THIS METERED ORIFICE REPLACED THE PCV VALVE, WHICH GENERALLY APPEARED ONLY IN THE 1963 CORVAIRS. The metered orifice, or the PCV valve, should be connected to the vacuum balance tube so that a small amount of air will be drawn through the PCV valve, or the small fixed orifice hole at the side of the PCV tube.

The tube with a larger diameter that is essentially unrestricted is supposed to be connected to the carburetor main intake, via the air filter connection at the top of one (or both) carburetors. This connection brings crankcase fumes into the main airflow via the carburetor throat, which draws those fumes from the crankcase back into the carburetor intake(s) at throttle settings where the airflow into the carburetor throat is greater, due to open throttle and higher engine RPM speeds.

The two PCV connections handle low-RPM, partial throttle (high intake manifold vacuum) operation, and also at open throttle levels when airflow through the main carburetor throat increases. The side tube metered orifice limits airflow directly into the intake manifold so that the fuel/air mixture provided by each carburetor does not become unbalanced (too lean) because of too much air from the PCV system mixing with the fuel/air ratio controlled by the carburetor systems. This restricted airflow is deemed sufficient because engine RPM speeds are low, so the volume of crankcase pressure due to piston blowby is relatively low. At higher engine speeds, piston blowby into the crankcase increases, and the crankcase fumes shift to entering the intake manifold via the main carburetor (top) intake(s). (Note that a connection to only one air cleaner is sufficient to recycle the crankcase blowby fumes). This allows the carburetors to continue to manage the overall fuel/air mixture, while still providing a path for the crankcase blowby fumes to be recycled back into the combustion chambers.

Shop Manual — 1964 Supplement, Page 7-6 wrote:All 1964 Chevrolet engines have either "positive" or "closed" positive ventilation systems utilizing manifold vacuum to draw fumes and contaminating vapors into the combustion chamber where they are burned. The crankcase ventilation system has an important function and should be understood and serviced properly.

1962 and earlier Corvair with Road Draft Tube and Oil Pressure Warning Switch down below.

Introductory Year with a Positive Crankcase Ventilation (PCV) System that utilized a 1963 PCV Tube with separate PCV Valve.

1964 and Later PCV Tube with Vacuum Airflow Restriction Fixed Orifice (Eliminated the Separate PCV Valve)

To summarize... the Positive Crankcase Ventilation (PCV) system has TWO ventilation paths between the engine crankcase and the engine INTAKE MANIFOLD. Two paths are needed to allow the PCV system to function at low RPM (closed or partial throttle) settings, when intake manifold vacuum is relatively high, and at open throttle settings, when intake manifold vacuum is low, but air velocity through the carburetor throat (venturi) is high. Piston ring blowby can occur at all engine speeds and allows some fuel/air mixture to leak into the crankcase, building crankcase pressures with contaminated fuel/air vapors. At low engine speeds the high intake manifold vacuum sucks these crankcase vapors through the fixed (metered) orifice or PCV valve and recycles those fumes back through the intake manifold, to be burned in normal combustion chamber activity and sent out of the tail pipe. As engine RPM increases with open throttle action, intake manifold vacuum decreases, so the crankcase fumes take the secondary path via the air cleaner and down the carburetor throat — ultimately ending up in the same place: back in the combustion chamber — to be burned and sent out through the exhaust system.

The piston ring seal in each cylinder is never perfect, so there will always be some blowby past the pistons and into the crankcase. If that blowby is allowed to linger in the crankcase, oil contamination and heat can produce harmful sludge. All the PCV system does is to effectively put the blowby gases back where they belonged in the first place... the combustion chambers! The PCV-routed gases are mixed in small quantities with the normal fuel/air mixture, and the spark plugs set off the burning process and the exhaust system takes care of the rest!

ROAD DRAFT TUBE systems were around for many years. They were not very efficient or effective at removing piston blowby contaminants from the engine crankcase and valve train area. As a result, engine oil would become badly contaminated if it was not changed very frequently. Engines would develop harmful sludge. The unburned contaminants that did escape into the atmosphere via the road draft tube contributed greatly to the SMOG content in the air. The development of the PVC system was a huge advancement in pollution reduction and engine protection. while causing almost no degradation in engine power, performance, or drivability.

An example of extreme engine sludge buildup due to oil contamination from crankcase fumes.

SLUDGE

Brad Bodie

Lake Chatuge, North Carolina

1966 Corvair Corsa Convertible

1966 Corvair Corsa Convertible

Lake Chatuge, North Carolina

1966 Corvair Corsa Convertible

1966 Corvair Corsa ConvertibleRe: PCV valve

Thanks, Brad for all the detailed info. The valve currently in-line on my car is not of the design of the CV584. It is black plastic and much larger on one side, hence the add-on larger hose (roughly twice the diameter of the other end. I want to make sure I have the correct set up and I have no information from the previous owner as to why it was changed to the current configuration.

1963 Monza Club Coupe

Western North Carolina

Catawba County

Western North Carolina

Catawba County

- Frank DuVal

- Posts: 548

- Joined: Wed Dec 09, 2009 4:58 pm

Re: PCV valve

The tube that comes out of the top shroud (Turkey Roaster in Corvair slang), if you take that large hose off of it, can you turn it so it points to the bracket on the air cleaner cross over tube? If so, that is the right PVC tube out of the shroud and all you need is the right (or close to right) PCV valve, new hose from that tube to the PCV valve, new hose from the PCV valve to the balance tube, and a shorter piece of hose from the "T" nipple to the air cleaner nipple. That hose should just be on a 90° turn, not the double 90s in your picture.

Frank DuVal

Fredericksburg, VA

Hey look, blue background!

Fredericksburg, VA

Hey look, blue background!

Re: PCV valve

Frank, thank you. Yes, if I take the clamp off the large hose, the tube will move to line up with the (now empty) bracket on the crossover tube, pointing towards the transmission dipstick. I found a shorter, 90 degree hose laying on the spare tire deck. Maybe that’s where someone tossed it when they redid this whole thing.

1963 Monza Club Coupe

Western North Carolina

Catawba County

Western North Carolina

Catawba County

Re: PCV valve

Nice post.

Just to clarify, all 1964 and 1965 engines with dual air cleaner setup (FCs, Cars with C64 Air Conditioning, Cars with K47 first style Oil Bath PreCleaner) also use the 1963 style PCV system with PCV valve.

To complicate the situation a bit further, 1964-65 Cars with both C64 and K47 also use a PCV valve, but they use a different upper crankcase vent tube and hose routing in order to get around the modified intake tube.

You can read more about Oil Bath Precleaners here: https://stock.corvair.org/wordpress/201 ... -cleaners/

Click on the photos below to see them in full resolution and proper orientation. Use your browser "Back" button to return to this post after viewing the photo

Just to clarify, all 1964 and 1965 engines with dual air cleaner setup (FCs, Cars with C64 Air Conditioning, Cars with K47 first style Oil Bath PreCleaner) also use the 1963 style PCV system with PCV valve.

To complicate the situation a bit further, 1964-65 Cars with both C64 and K47 also use a PCV valve, but they use a different upper crankcase vent tube and hose routing in order to get around the modified intake tube.

You can read more about Oil Bath Precleaners here: https://stock.corvair.org/wordpress/201 ... -cleaners/

Click on the photos below to see them in full resolution and proper orientation. Use your browser "Back" button to return to this post after viewing the photo

- Attachments

Bill Hubbell

President, Stock Corvair Group

President, Stock Corvair Group

Re: PCV valve

If I recall correctly, Jim Brandberg was stocking up on the OEM parts for the ‘63 pcv setup… that’s what I have and it’s the best arrangement in my opinion.

Rick Macdonald

1963 700 4dr

Eastern Massachusetts

1963 700 4dr

Eastern Massachusetts

Re: PCV valve

Got it all apart and put back to “normal” today. In the process I pulled all the air filters, assemblies, gaskets etc. cleaned the assemblies and replaced gaskets and elements with new. A couple gaskets were missing according to the shop manual. Found the fresh air hose was in pieces. It resembled oily black lace. Got it all off, and cleaned clamps and shrouds. Put new weatherstripping on hood. Have to get new fresh air hose piece now. Pics coming.

1963 Monza Club Coupe

Western North Carolina

Catawba County

Western North Carolina

Catawba County

Re: PCV valve

"Fresh air hose". Is this the hose that goes from the right front of your engine shroud to the firewall? If that hose is damaged, disconnected, or missing, you would do best to remove the hose adapter from the right front of the shroud (3 bolts, 5/16 head IIRC). Trace the flange onto a piece of sheet metal, cut it out, make the holes, and bolt this block off plate over the hole. Running with no hose, damaged hose, or disconnected hose can cause the #5 cylinder to run hot resulting in possible valve or other damage.

The hose is normally sealed by the damper door in your heater duct. Often, with age, sealing rubber pad on this door is missing or falling apart. Repair may involve gluing a thin foam rubber like pad on the door. Probably requires heater duct removal. Dennis

The hose is normally sealed by the damper door in your heater duct. Often, with age, sealing rubber pad on this door is missing or falling apart. Repair may involve gluing a thin foam rubber like pad on the door. Probably requires heater duct removal. Dennis

- Frank DuVal

- Posts: 548

- Joined: Wed Dec 09, 2009 4:58 pm

Re: PCV valve

Great information, Dennis. On every Corvair I work on I make a plate to cover the hole in the shroud, just like Dennis, trace onto thin sheet metal, holes, black paint, reinstall. On an early I go ahead and put the hose adapter and hose back on since it is so short and looks stock. On lates I just use the blocking plate, no adapter and no hose, since the hose is so long and pricey. Except if the person wants the stock look, then I sandwich the block off plate and install a hose for looks.

Frank DuVal

Fredericksburg, VA

Hey look, blue background!

Fredericksburg, VA

Hey look, blue background!