67 engine dies when warm

- terribleted

- Posts: 4584

- Joined: Sun Apr 18, 2010 2:36 pm

- Location: Atlanta, GA

- Contact:

Re: 67 engine dies when warm

After reading this entire thread I did not see any suggestion to check for flooding. Check to see if either carb is flooding fuel into the engine. At idle with the air cleaners removed look down each carb throat (manually move the choke plate to vertical so you can see) and if you see any liquid fuel running or dripping in either carb then flooding is happening. If there is flooding then reset the float level in both carbs the 1 13/64" per the shop manuals. Bobs book specifies some smaller measurement, I think? At the factory setting flooding will generally no occur unless the fuel pressure is above 5-6PSI. Flooding at idle can cause the side that is flooding to get too rich to support combustion and a stall ensues. Be aware that one carb flooding if they are both adjusted the same means that once its float is adjusted to hold the valve closed better the flooding will generally move to the other carb since as soon as one floods the system fuel pressure drops so the other although set almost identically does not flood.

Corvair guy since 1982. I have personally restored at least 20 Vairs, many of them restored ground up.

Currently working full time repairing Corvairs and restoring old cars.

https://www.facebook.com/tedsautorestoration/

Located in Snellville, Georgia

Currently working full time repairing Corvairs and restoring old cars.

https://www.facebook.com/tedsautorestoration/

Located in Snellville, Georgia

Re: 67 engine dies when warm

I can only guess, but a popular safety to shut off the electric fuel pump was made up using the 1970's Chevrolet Vega oil pressure switch. It has two terminals, one for to the oil pressure warning lamp, and one to deactivate the fuel pump (usually via a relay). So when the engine is off it equals no oil pressure and fuel pumps shuts off. This was to shut off the electric fuel pump if the engine stalls, but the ignition key is on. HOWEVER how do you get power to the electric fuel pump when starting the engine (no oil pressure equals not electric fuel pump activation until the engine starts)? According to your picture of the starter solenoid, it has the factory two wire harness with additional wires. The PURPLE wire goes to the "S" labeled terminal. When the ignition key is turned to START electrical energy engages the solenoid to energize the starter. While the starter is energized electrical power from BIG RED cable is also connected to the small terminal opposite the "S" terminal that is labeled "R" (for resistance ballast wire by-pass).Martin wrote: ↑Sun Apr 09, 2023 1:47 am Thanks a lot!

I measured the white line to the coil and the whole setup (cable+coil) has now 2.6 ohms. Is that fine or not enough?

Also, here is the picture of the starter: https://ibb.co/GvDjjCc

I have an oil pressure safety switch with one cable going to the starter (-), one the the starter (+) (the new black and red cables) and one from the switch to the pump.

Do you see any problem here?

Best,

Martin

In you picture a RED wire was added to the "S" terminal with the PURPLE wire. So when the starter is solenoid is energized, then electrical power is supplied to the added RED wire. I guessing it is to activate the electric fuel pump while the starter is engaged.

A black wire is added to the "R" terminal which is only electrically energized while the starter is engaged. I have no idea what it's purpose is.

As for the 2.6 ohms. Due to the poor ohm resolution of most meters at that low a value it is difficult to say. You did not say if the wire measurement was done with the ballast wire isolated by disconnecting the wire from the coil "+" terminal and unplugging the big bulkhead connector. It is obvious someone has modified the wiring making a determination difficult. Isolating components for an ohmic measurement prevents loops in the circuit that compromise the ohm readings.

Just me, but whenever I modify a cars wiring I make up a schematic showing the changes and how they work. I make sure the owner of the car gets it so the next person doing repairs isn't confronted with wiring that the factory books don't show/explain. If/when you get this figured out please make up a diagram for future reference.

Re: 67 engine dies when warm

Good point Ted. Since Martin's car has an electric fuel pump, he was asked to use a fuel pressure gauge to check fuel pressure. His gauge starts at 3PSI and he indicted it did not rise above 3PSI. Not sure why. It's becoming obvious someone installed a fuel pump shut off circuit, but there are no diagrams to indicate exactly HOW it was done. I've run into this before and it usually involves a lot of work to trace wires to figure out what is going on.terribleted wrote: ↑Sun Apr 09, 2023 9:10 am After reading this entire thread I did not see any suggestion to check for flooding. Check to see if either carb is flooding fuel into the engine. At idle with the air cleaners removed look down each carb throat (manually move the choke plate to vertical so you can see) and if you see any liquid fuel running or dripping in either carb then flooding is happening. If there is flooding then reset the float level in both carbs the 1 13/64" per the shop manuals. Bobs book specifies some smaller measurement, I think? At the factory setting flooding will generally no occur unless the fuel pressure is above 5-6PSI. Flooding at idle can cause the side that is flooding to get too rich to support combustion and a stall ensues. Be aware that one carb flooding if they are both adjusted the same means that once its float is adjusted to hold the valve closed better the flooding will generally move to the other carb since as soon as one floods the system fuel pressure drops so the other although set almost identically does not flood.

Re: 67 engine dies when warm

Several posts ago I did mention something about black smoke or a black tailpipe regarding flooding. Problem was I forgot to hit "SUBMIT"  . Usually with flooding, the only way it will restart after quitting is to floor it, still, a simple check.

. Usually with flooding, the only way it will restart after quitting is to floor it, still, a simple check.

I'm glad someone else remembers those horrid Vega electric fuel pump safetys. My '73 with the Holley - Weber wannabe, well it seemd to leak down overnight. Then it had to crank forever to build oil pressure to activate the fuel pump and THEN long enough to fill the carb bowl (cure was a swap to the older Rochester carb and manifold)

The older Isuzus I have worked on a lot have a fuel pump safety where the alternator has an extra circuit that powers up the fuel pump relay. They also have a tier circuit that activates the fuel pump for a few seconds as soon as the key is switched on. Of course this is all for a 40 PSI fuel system, and the whole safety thing, like the Vegas was to kill the fuel pump in case of an accident where the engine stalled. I'm planning an electrical pump conversion for my convertible. I'm seriously planning to install the pump up front near the tank, and I do plan some kind of safety system. Dennis

I'm glad someone else remembers those horrid Vega electric fuel pump safetys. My '73 with the Holley - Weber wannabe, well it seemd to leak down overnight. Then it had to crank forever to build oil pressure to activate the fuel pump and THEN long enough to fill the carb bowl (cure was a swap to the older Rochester carb and manifold)

The older Isuzus I have worked on a lot have a fuel pump safety where the alternator has an extra circuit that powers up the fuel pump relay. They also have a tier circuit that activates the fuel pump for a few seconds as soon as the key is switched on. Of course this is all for a 40 PSI fuel system, and the whole safety thing, like the Vegas was to kill the fuel pump in case of an accident where the engine stalled. I'm planning an electrical pump conversion for my convertible. I'm seriously planning to install the pump up front near the tank, and I do plan some kind of safety system. Dennis

Re: 67 engine dies when warm

While I appreciate "creative wiring", and it's good at making work for automotive electrical technicians to fix, the easiest electric fuel pump control to install by most is the one by Revolution Electronics. I've never used one, but a few folks report they work well. They have a "fuel prime" delay so when you turn on the ignition key the electric fuel pump is turned on briefly and then off, unless it sees a pulse signal from the ignition coil "-" terminal. As long as it sees a pulse from the ignition coil it keeps the electric fuel pump on. If the engine stop, even with the ignition key on, the electric fuel pump is turned off. See https://www.revolutionelectronics.com/P ... _Pump.html.Dennis66 wrote: ↑Sun Apr 09, 2023 12:23 pm Several posts ago I did mention something about black smoke or a black tailpipe regarding flooding. Problem was I forgot to hit "SUBMIT". Usually with flooding, the only way it will restart after quitting is to floor it, still, a simple check.

I'm glad someone else remembers those horrid Vega electric fuel pump safetys. My '73 with the Holley - Weber wannabe, well it seemd to leak down overnight. Then it had to crank forever to build oil pressure to activate the fuel pump and THEN long enough to fill the carb bowl (cure was a swap to the older Rochester carb and manifold)

The older Isuzus I have worked on a lot have a fuel pump safety where the alternator has an extra circuit that powers up the fuel pump relay. They also have a tier circuit that activates the fuel pump for a few seconds as soon as the key is switched on. Of course this is all for a 40 PSI fuel system, and the whole safety thing, like the Vegas was to kill the fuel pump in case of an accident where the engine stalled. I'm planning an electrical pump conversion for my convertible. I'm seriously planning to install the pump up front near the tank, and I do plan some kind of safety system. Dennis

Re: 67 engine dies when warm

The safety switch that is installed is from Clarks ( C5607X ). I guess both cables from the starter should energize the pump while cranking (no oil pressure). However, sometimes I can hear the pump when only ignition is on (also no pressure). Maybe something is wrong with the wireing? Would you change something?

The FACET pump arrived today and I am going to test the fuel pressure of this guy next weekend. If this goes >3 PSI, we know that the AIRTEX is not providing enough pressure right?

I think flooding was a problem with the old carbs. There, one yould clearly see fuel on the inside of the carb. However, these carbs were in pretty bad shape and were missing a lot of seals etc. Therefore, swapped them to the Wolf Enterprise rebuild carbs. When these arrived, I took them apart to check for the hight of the floater and it was not in spec so I adjusted it to spec. After this, I have to admid, I never checked for flooding again, so good point! I will check next time.

If I remember correctly, it was 1.5 ohm for the cable using my ohm meter. Other cables hat something like 0.1-0.5 so there clearly is some ballast. You saif the overall ballast should be ~3 ohms (cable+coil) so I am asking myself, if 2.6 is fine. Adding a 1.6 ohm ballst into cable/coil, I measured 4 ohms. Do you think 4 ohms is better than 2.6 or is the resistance to high for the XR700 ignition system?

The FACET pump arrived today and I am going to test the fuel pressure of this guy next weekend. If this goes >3 PSI, we know that the AIRTEX is not providing enough pressure right?

I think flooding was a problem with the old carbs. There, one yould clearly see fuel on the inside of the carb. However, these carbs were in pretty bad shape and were missing a lot of seals etc. Therefore, swapped them to the Wolf Enterprise rebuild carbs. When these arrived, I took them apart to check for the hight of the floater and it was not in spec so I adjusted it to spec. After this, I have to admid, I never checked for flooding again, so good point! I will check next time.

If I remember correctly, it was 1.5 ohm for the cable using my ohm meter. Other cables hat something like 0.1-0.5 so there clearly is some ballast. You saif the overall ballast should be ~3 ohms (cable+coil) so I am asking myself, if 2.6 is fine. Adding a 1.6 ohm ballst into cable/coil, I measured 4 ohms. Do you think 4 ohms is better than 2.6 or is the resistance to high for the XR700 ignition system?

Re: 67 engine dies when warm

Martin --- A plain copper wire should have about 0.1 ohm resistance or less over a few feet. I mentioned before that "zero" out the meter by connecting the leads (the must be clean) together and taking a reading. That is the basic error (some meters have a "ZEROING" button to push when doing this). If the meter has no zeroing function, then write down the resistance of the lead to lead and subtract it from the ballast wire and coil measurement. The ballast wire is a metal alloy (looks silver, not copper colored) and should read about 1.8 ohms. You said you are using a new NGK coil at the shop manual rating (about 1.3 ohms - measure ohms from coil "+" to "-" terminal). So the total should be about 3.1 ohms. As Brad also mentioned, the XR-700 prefers a minimum 3.0 ohm resistance. Keep in mind only expensive laboratory ohm meters read accurately at these low values. I usually use a load and a current limiting bench power supply to verify low value ohmic ballast wires, but that is impractical for you. The voltage drop test (ignition coil "+" lead measured with volt meter positive lead and volt meter negative lead to chassis/engine ground then connect the coil "-" lead to ground) is a good test. With the coil "-" lead open measure the voltage, then briefly ground the coil "-" terminal. The voltage should drop to a value that is 41% to 44% of the reading of the coil "-" open.

Regarding the fuel pump control wiring. I must admit I cannot explain it without an in-person examination to see were all the wires are going.

You mentioned you purchased a new Facet electric fuel pump. What part number was it? They are sold in different PSI ratings.

Regarding the fuel pump control wiring. I must admit I cannot explain it without an in-person examination to see were all the wires are going.

You mentioned you purchased a new Facet electric fuel pump. What part number was it? They are sold in different PSI ratings.

- bbodie52

- Corvair of the Month

- Posts: 11956

- Joined: Mon Aug 06, 2012 12:33 pm

- Location: Lake Chatuge Hayesville, NC

- Contact:

Re: 67 engine dies when warm

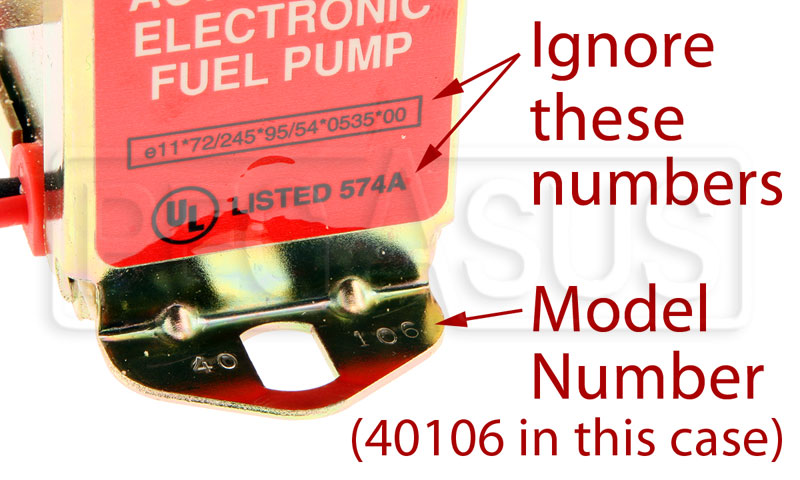

FAC-40105 Facet Cube 12v Fuel Pump, 1/8 NPT, 3-4.5 psi

I never knew that about the Facet cubic pumps... NOISY, I mean.terribleted wrote:Those square box diaphragm pumps are noisy as hell.

It appears that there are a lot of Facet CLONES, too!

terribleted wrote:The Airtex E8016S has been my choice for years now...

Brad Bodie

Lake Chatuge, North Carolina

1966 Corvair Corsa Convertible

1966 Corvair Corsa Convertible

Lake Chatuge, North Carolina

1966 Corvair Corsa Convertible

1966 Corvair Corsa ConvertibleRe: 67 engine dies when warm

Just hotwire the fuel pump to +12V for a quick engine run test to bypass issues with the safety switch & wiring.

I briefly considered such a switch. Worst case, you have low oil level and experience brief oil starvation during a turn. Ignition shuts off and you're DOA in the middle of a busy intersection.

I briefly considered such a switch. Worst case, you have low oil level and experience brief oil starvation during a turn. Ignition shuts off and you're DOA in the middle of a busy intersection.

Re: 67 engine dies when warm

I agree --- I've never been keen on the oil pressure fuel shut off switch.erco wrote: ↑Tue Apr 11, 2023 11:04 am Just hotwire the fuel pump to +12V for a quick engine run test to bypass issues with the safety switch & wiring.

I briefly considered such a switch. Worst case, you have low oil level and experience brief oil starvation during a turn. Ignition shuts off and you're DOA in the middle of a busy intersection.

The big concern is a fire after a severe accident due to broken fuel lines. Many have installed the FORD impact inertial switch (used on mid 1980's to mid 1990's FORD cars and mounted in the trunk) that shuts off the fuel pump after a severe impact (sometimes road pot holes trip them). Now cars use the computers and inertia/airbag sensors to shut off the fuel. Switch is inexpensive - See https://www.amazon.com/Ford-5L2Z-9341-5 ... B000NTI03C See earlier style with connector https://lmr.com/item/LRS-9341AK/mustang ... itch-83-89

If you are worried you won't shut off the ignition key when the engine stalls to prevent fuel flooding at the carburetor, then the Revolution unit is an easy install and has a timer to prime the carburetors when you turn on the ignition switch. It shuts off the fuel pump when there are no ignition pulses from the coil "-" terminal. See https://www.revolutionelectronics.com/P ... _Pump.html

Re: 67 engine dies when warm

Plenty of generic impact cutoff switches too, here's one for $12: https://www.amazon.com/Tickas-Inertia-S ... B08BZLBCKT

Re: 67 engine dies when warm

Did I miss something about IGNITION being wired through the oil pressure switch? I thought it was fuel pump, and if a cornering oil starvation situation came up and it was starved long enough to run the carbs empty, that must be some corner. The mains would probably be rattling long before the carbs ran dry. Dennis

P.S. I wasn't aware that there were "off the shelf" fuel safety switches, but it makes sense. Will I go that route? Probably not. I'm fully capable of designing, fabricating, and installing my own system.

Re: 67 engine dies when warm

You are correct Dennis, but I didn't want to point that out. The engine will run until the fuel bowl level drops after the electric fuel pump quits. So it is not immediate. That said, I still won't use the oil pressure sensor for fuel pump control or install one if other's ask.Dennis66 wrote: ↑Tue Apr 11, 2023 4:46 pmDid I miss something about IGNITION being wired through the oil pressure switch? I thought it was fuel pump, and if a cornering oil starvation situation came up and it was starved long enough to run the carbs empty, that must be some corner. The mains would probably be rattling long before the carbs ran dry. Dennis

P.S. I wasn't aware that there were "off the shelf" fuel safety switches, but it makes sense. Will I go that route? Probably not. I'm fully capable of designing, fabricating, and installing my own system.

On my first job as a kid my company car was a Vega and I tore a hole in it's oil pan going over some rail road tracks. The engine oil light came on, but it ran for another 1/8 mile! I knew starting the engine would prime the carburetor and it was 15F outside!!! So I did that a couple times until I got to a services station/garage. The guy at the garage pounded a broom handle into the oil pan hole and filled it with oil. I bought an extra 6 quarts and that got me back to the place I worked. Young and dumb, but it got me back to the shop without frostbite - LOL.

If you do fabricate you own circuit please make up schematics and give them to the next owner. I do that on the cars when I modify the wiring so the next owner has them. It avoids the issues Martin is now dealing with.

Re: 67 engine dies when warm

This is a really great and active discussion. Thank you so much for all of your involvement!!!

The Facet pump I recieved has the model number 40 105 so it seems to be the right one. I think for now, it might be the best to start with Dennis idea and just powering the pump independently from the safety switch to see if this is some kind of problem. I will also test the fuel pressure to check if its >3 PSI so higher, compared to the AIRTEX pump.

I have organized different multimeters since I assume the "auto" function of mine is just to slow to measure the voltage drop after briefly touching the ground. Maybe this helps. If I dont reach 6-7 V, I will go back to points for testing to save the FAST XR-700.

Last, I can only swap the left carb with one of my old ones to check for improvement. Additionally, I will check for flooding on the left side.

I hope this can give us more information on whats going on. I will try my luck on the weekend if the weather is not as bad as the last time.

Do you have any more suggestions what I can test or is this sufficient for the time?

The Facet pump I recieved has the model number 40 105 so it seems to be the right one. I think for now, it might be the best to start with Dennis idea and just powering the pump independently from the safety switch to see if this is some kind of problem. I will also test the fuel pressure to check if its >3 PSI so higher, compared to the AIRTEX pump.

I have organized different multimeters since I assume the "auto" function of mine is just to slow to measure the voltage drop after briefly touching the ground. Maybe this helps. If I dont reach 6-7 V, I will go back to points for testing to save the FAST XR-700.

Last, I can only swap the left carb with one of my old ones to check for improvement. Additionally, I will check for flooding on the left side.

I hope this can give us more information on whats going on. I will try my luck on the weekend if the weather is not as bad as the last time.

Do you have any more suggestions what I can test or is this sufficient for the time?

Re: 67 engine dies when warm

Brad's Facet pump pictures showed both a 40-105 and a 40-106. The 40-105 is the CORRECT pump. So you are good. The 40-105 is rated at a 4.5 - 3 PSI meaning it will be at 4.5 PSI for normal fuel flow volume. It only drops to 3 PSI at a huge flow volume (never happen with a Corvair expect briefly if the carburetors are dry). The 40-106 delivers 7 PSI, excessive for the Corvair. Brad did make a good point that the label number and stamped numbers are different and often vendors use the wrong numbers.Martin wrote: ↑Wed Apr 12, 2023 2:40 am This is a really great and active discussion. Thank you so much for all of your involvement!!!

The Facet pump I recieved has the model number 40 105 so it seems to be the right one. I think for now, it might be the best to start with Dennis idea and just powering the pump independently from the safety switch to see if this is some kind of problem. I will also test the fuel pressure to check if its >3 PSI so higher, compared to the AIRTEX pump.

I have organized different multimeters since I assume the "auto" function of mine is just to slow to measure the voltage drop after briefly touching the ground. Maybe this helps. If I dont reach 6-7 V, I will go back to points for testing to save the FAST XR-700.

Last, I can only swap the left carb with one of my old ones to check for improvement. Additionally, I will check for flooding on the left side.

I hope this can give us more information on whats going on. I will try my luck on the weekend if the weather is not as bad as the last time.

Do you have any more suggestions what I can test or is this sufficient for the time?

As per the good discussion about safety devices for fuel shut off. I don't use them. The only one I'd consider (and will install if I sell my Corvair) is the impact inertial switch that shuts off fuel in a severe accident were the driver could be "unresponsive". Just me, but I suggest tracing the added wires from the starter solenoid to find out if they go to a relay. At the moment I'd simplify things and disconnect those wires (including the one from the oil pressure switch) and run the electric fuel pump off the ignition power circuit. BTW -- The 1967 model fuse box wiring was revised. There is an "IGN. FUSED" terminal to connect the fuel pump power input wire to so it only runs when the ignition key is "ON", but not in the "ACC" position. The terminal is above the fuse for "BK-UP GAUGES". See page 12-4 of the 67 manual supplement Fig 6-Fuse Panel.

Also note the your BLACK wire from the starter solenoid "R" terminal is connected to the YELLOW wire from the coil "-" terminal and it may be loading down that circuit, depending on where the BLACK wire goes. This reminds me that when measuring the ballast wire make sure the ballast wire is NOT connected to the YELLOW wire at the coil "-" terminal. Normally it would not matter, but it occurred to me the added BLACK wire may be corrupting the circuit. So you've got some old fashioned wire tracing to do. Let me know what you find.

I can appreciate waiting for some better weather. I'm experiencing unusually damp and cool weather and it has my "garage" projects on hold.

Good luck.

Re: 67 engine dies when warm

Right you are, my bad, thanks for clarifying that, Dennis. It was me who briefly considered an ignition interruptor, not the OP. A fuel pump interruptor switch actually makes sense, assuming it can reliably handle the current.Dennis66 wrote: ↑Tue Apr 11, 2023 4:46 pm

Did I miss something about IGNITION being wired through the oil pressure switch? I thought it was fuel pump, and if a cornering oil starvation situation came up and it was starved long enough to run the carbs empty, that must be some corner. The mains would probably be rattling long before the carbs ran dry. Dennis