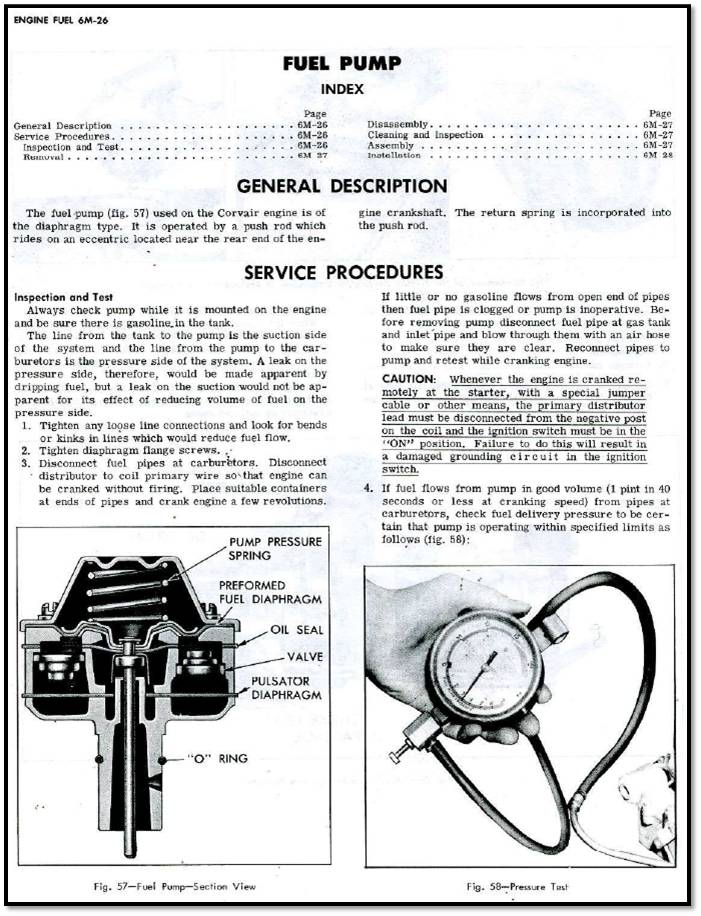

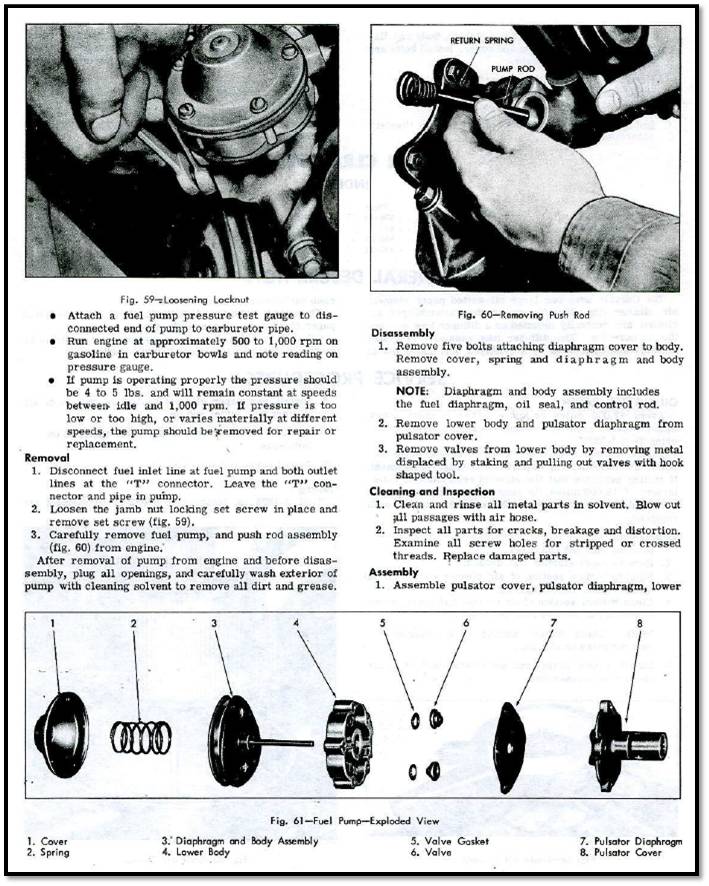

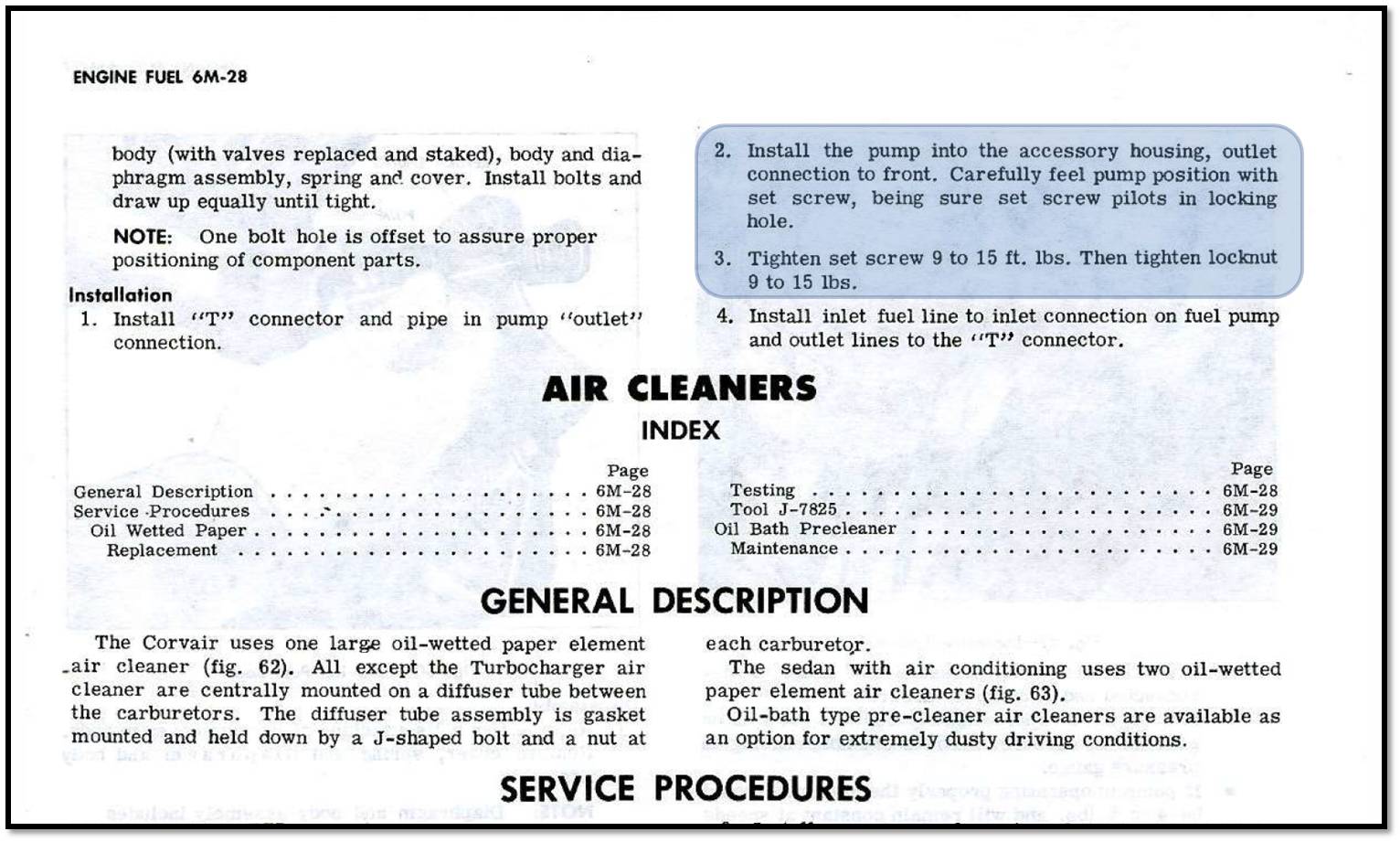

According to the shop manual pages below, the correct fuel pump output pressure should be about 4-5 psi. (3 psi should be sufficient). The volume of fuel being delivered should be about 1 pint in about 40 seconds. Many electric fuel pumps do not do a very good job of pulling fuel long distances from the fuel tank, so the installation instructions usually recommend mounting the electric pump close to the tank outlet, so that gasoline will be gravity-fed to the pump inlet. Then the electric pump can pressurize the fuel and push it long distances to the engine compartment. Unlike most electric pumps, the Corvair mechanical pump was designed to PULL the fuel from the tank at the other end of the vehicle, and then pump it only a short distance to the carburetors.

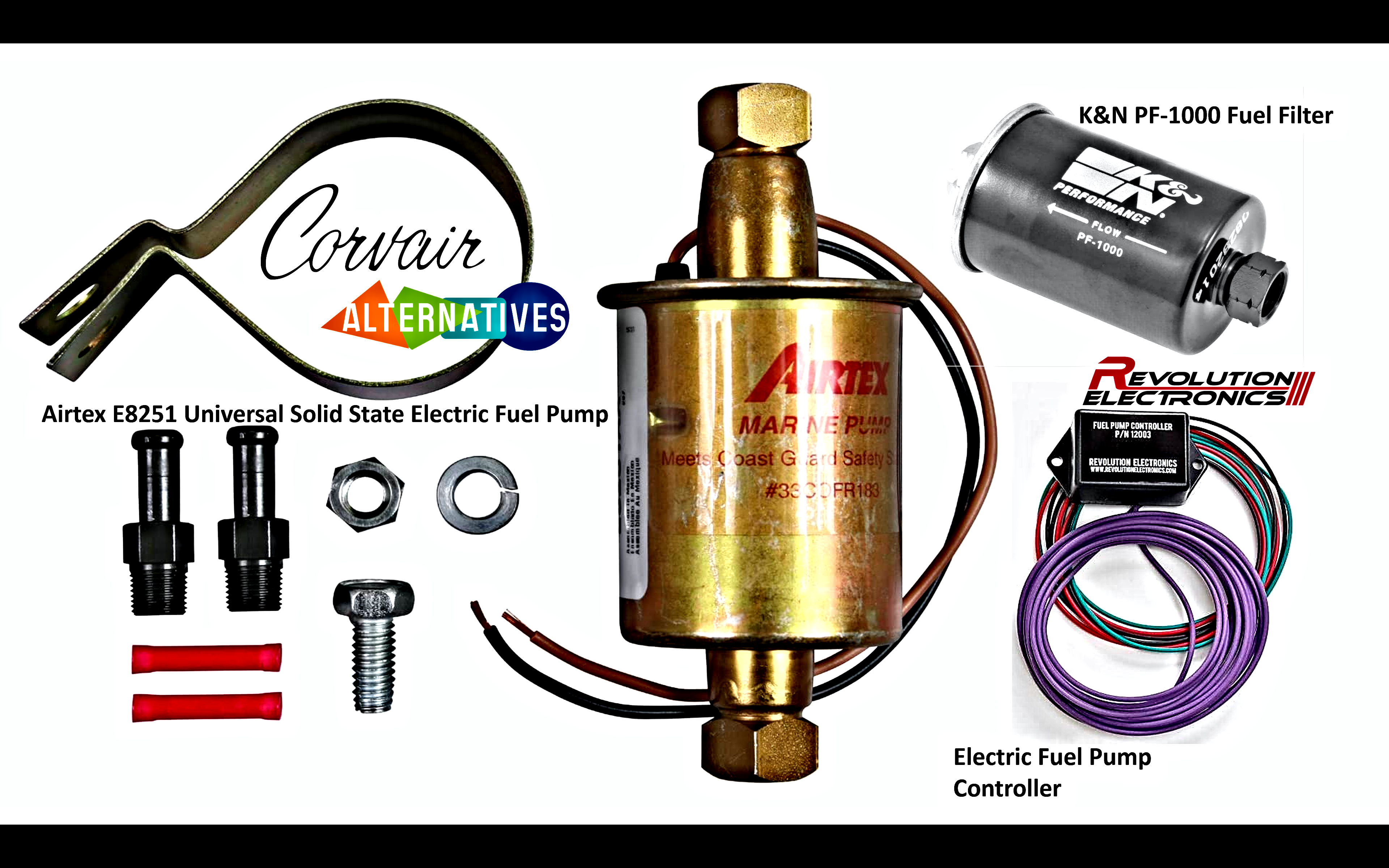

The Airtex E8251 I selected delivers the correct fuel pressure and fuel volume for the Corvair engine. It is also a fuel pump designed to support marine installations in boats, and because of this the pump also does a good job of pulling fuel long distances. It can be installed near the engine compartment on the Corvair, and does not need to be close to the fuel tank. UNFORTUNATELY IT APPEARS TO HAVE BEEN DISCONTINUED AND IS GENERALLY NO LONGER AVAILABLE. So most electric pumps will require an installation close to the fuel tank. Check the installation instructions for the electric pump you are considering.

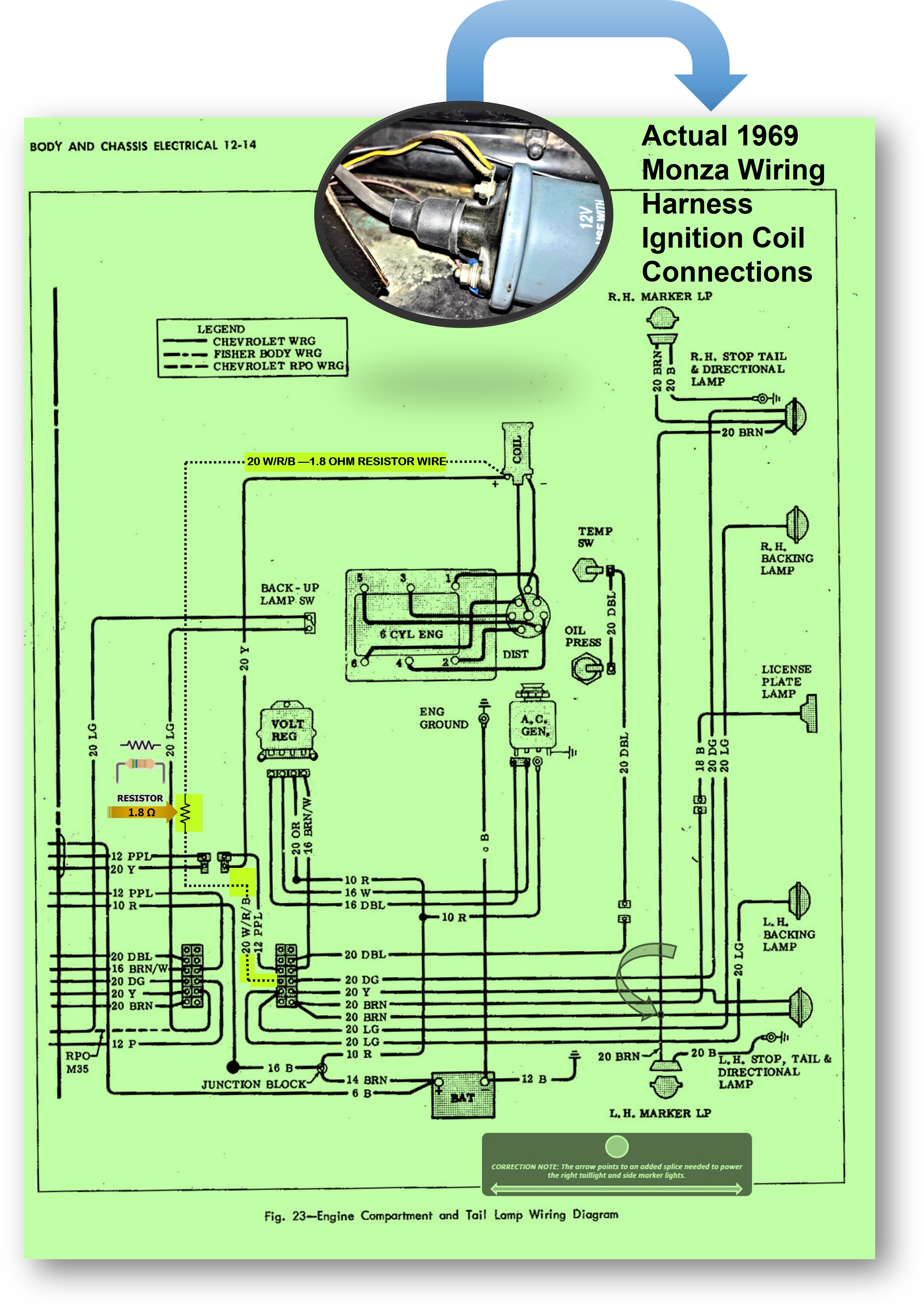

The first diagram below shows two separate wires leading to the ignition coil positive terminal. The wire labeled "20Y" is connected to the starter solenoid. Unless the starter is engaged to crank the engine, this wire is not active and carries no voltage to the ignition coil. It only applies full battery voltage (12.5 VDC) to the ignition coil when the key is rotated to START to crank the engine. This temporarily boosts the voltage feeding the ignition coil to full battery voltage to increase the coil output to the spark plugs to assist in starting the slowly turning cold engine with getting started. When the engine starts the driver releases the key and it returns to the ON position. With the starter solenoid disengaged the higher voltage fed to the ignition coil from the starter solenoid is disconnected, leaving only the lower voltage fed to the coil from the resistor wire (approximately 7VDC). This reduced voltage allows the coil to run at a lower internal temperature, which prolongs the life of the coil. (The reduced voltage produces a weaker spark to the spark plugs, but the weaker spark is sufficient for normal engine operation. The lower voltage also prolongs the life of ignition points switch contacts).

- 1965 Corvair Monza Full Schematic (Rev. E)

Left-click the image to enlarge it for better viewing or "Pan & Scan"...

While some electronic ignition system designs, like the Pertronix Ignitor, are designed to require a full 12VDC to properly power the electronic circuitry, the engineers who designed the FAST XR700 engineered it to operate properly on the normally reduced 7VDC found on factory installations with a resistor wire or ballast resistor in the circuit. Their intent was to simplify the installation process for the average home mechanic/installer, by allowing the installer to connect the XR700 power wire directly to the ignition coil positive (+) connection, which is already running on a 7VDC power source because of the ballast resistor in the circuit. (If the FAST XR700 required a full 12VDC power source, the installer would have to find a 12VDC power source that was switched on only with the key ON. The XR700 power wire would have to be extended farther from the distributor to connect to a point BEFORE the resistor wire or ballast resistor. Instead, because the XR700 can run on the reduced 7VDC found at the ignition coil, the XR700 power wire can be connected directly to the ignition coil positive terminal, which is near the distributor. HOWEVER, if the ballast resistor wire has been removed or bypassed, a full 12 VDC may be the source voltage found at the ignition coil (sometimes required with the installation of aftermarket high performance coils). The FAST XR700 may initially function with a full 12VDC powering it, but after a short period of overpowered operation the XR700 will likely overheat and will begin to malfunction when powered by 12VDC, instead of the required reduced 7VDC found at the end of a ballast wire circuit.

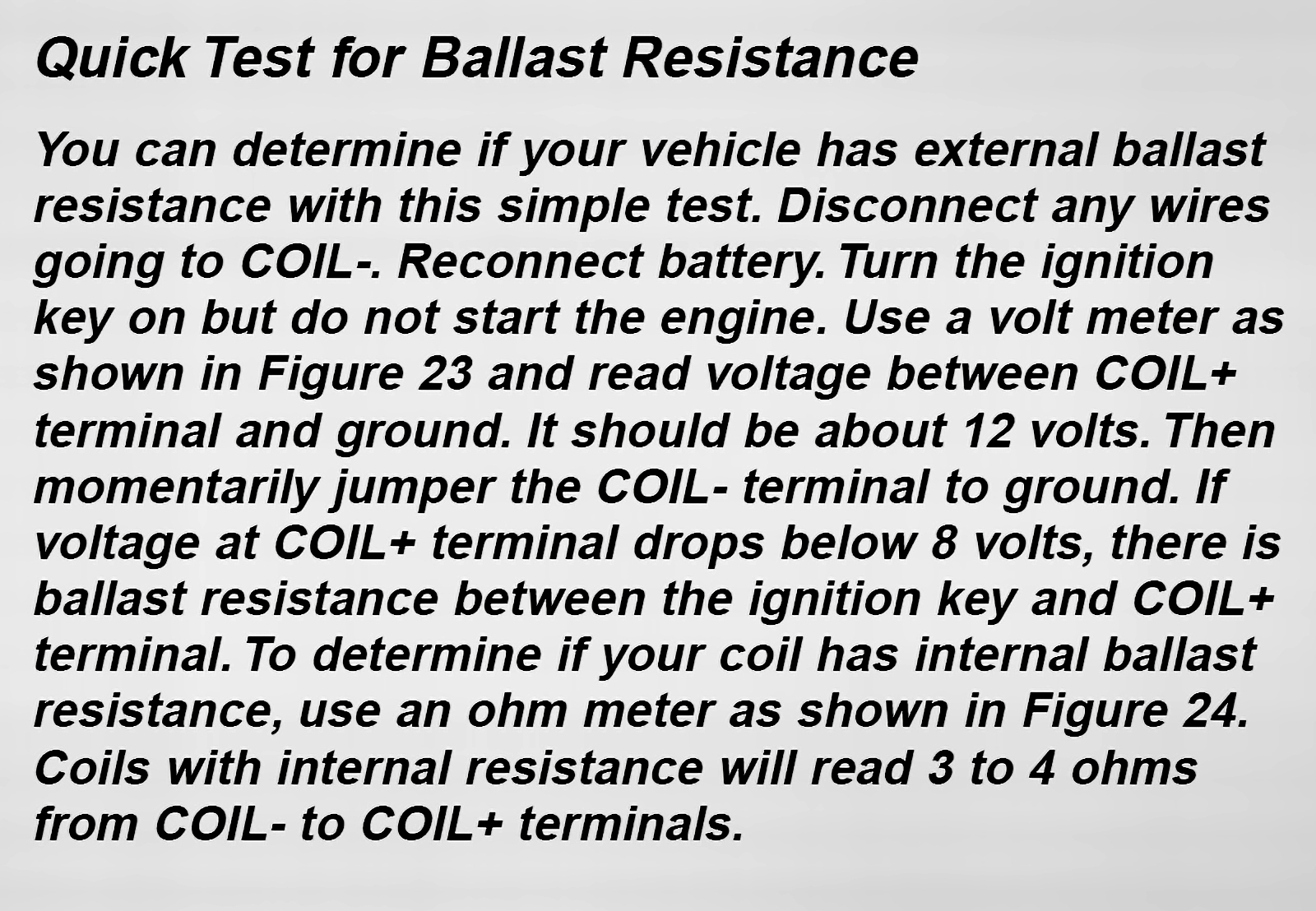

To test and measure the ACTUAL voltage fed to the coil with the key ON, electrical current must be passing through the coil. This only occurs with the ignition points closed, which grounds the negative coil terminal and energizes the coil primary winding (with the key ON). A test of the actual voltage feeding the coil at the positive terminal with the key ON can be done by temporarily grounding the negative coil terminal, turning the key to the ON position, and then measuring the voltage present at the coil positive terminal (the coil must be grounded and conducting electricity through the primary winding to permit an accurate test of the voltage present at the positive terminal. With the key ON, the effect of the ballast resistor wire can only be measured while the coil is grounded and conducting electrical current. When the coil is grounded, the voltage should read the reduced 7VDC voltage caused by the resistor wire in the circuit. If the coil negative terminal is not grounded, no current will be flowing and the voltage at the positive terminal will read a full battery voltage (12VDC).

1966 Corvair Corsa Convertible

1966 Corvair Corsa Convertible