1963 engine ticking

1963 engine ticking

Hi all,

I purchased a 1963 Monza that needed some work to get running again. I rebuilt the carbs, cleaned up the engine bay, and replaced the seals and gaskets up there. I also installed new air and fuel filters and changed the oil. Started it up today and there is a ticking noise. Here is a link to a short video:

https://photos.app.goo.gl/fvjbumk9tFEt4LZW7

Thinking this could be a lifter or rocker issue?

I was hoping to drive it a bit before doing anything else, but it seems like this issue should be addressed first. The noise goes away when given throttle.

I have never owned a corvair and am a diy mechanic with limited so any help or pointers is appreciated. What do you guys think?

Thanks,

Nate

I purchased a 1963 Monza that needed some work to get running again. I rebuilt the carbs, cleaned up the engine bay, and replaced the seals and gaskets up there. I also installed new air and fuel filters and changed the oil. Started it up today and there is a ticking noise. Here is a link to a short video:

https://photos.app.goo.gl/fvjbumk9tFEt4LZW7

Thinking this could be a lifter or rocker issue?

I was hoping to drive it a bit before doing anything else, but it seems like this issue should be addressed first. The noise goes away when given throttle.

I have never owned a corvair and am a diy mechanic with limited so any help or pointers is appreciated. What do you guys think?

Thanks,

Nate

- bbodie52

- Corvair of the Month

- Posts: 12141

- Joined: Mon Aug 06, 2012 12:33 pm

- Location: Lake Chatuge Hayesville, NC

- Contact:

Re: 1963 engine ticking

"Ticking" is a term usually describing valve train noise. Your noise sounds a lot more like possibly something in the fan belt rotating mass. If you temporarily remove the fan belt and run the engine for a few seconds without it, does the noise go away? If it does, shut down the engine and check each individual rotating mass for interference or looseness in a bearing assembly or component.

If the noise is not related to the fan belt drive, is your car fitted with a Powerglide automatic transmission? I was thinking something loose in the torque converter attachment. If a manual transmission car, does the sound change when you depress the clutch??

If a manual transmission car, does the sound change when you depress the clutch??

A mechanic's stethoscope may help you to localize the noise source.

If the noise is not related to the fan belt drive, is your car fitted with a Powerglide automatic transmission? I was thinking something loose in the torque converter attachment.

A mechanic's stethoscope may help you to localize the noise source.

Brad Bodie

Lake Chatuge, North Carolina

1966 Corvair Corsa Convertible

1966 Corvair Corsa Convertible

Lake Chatuge, North Carolina

1966 Corvair Corsa Convertible

1966 Corvair Corsa ConvertibleRe: 1963 engine ticking

Thanks for the help. It's a manual. I borrowed a scope and it sounded louder on the transaxle. Pressing the clutch made the noise much better, but it did not go away completely. Looks like we need to drop everything to investigate, so I need to figure that out. Thanks for getting me on the right track.

- bbodie52

- Corvair of the Month

- Posts: 12141

- Joined: Mon Aug 06, 2012 12:33 pm

- Location: Lake Chatuge Hayesville, NC

- Contact:

Re: 1963 engine ticking

The stock Corvair flywheel is riveted to a plate that bolts to the crankshaft. over time those rivets become loose and a rattling sound is heard while the idling engine spins in Neutral. Pressing the clutch pedal slightly brings the throw-out bearing into contact with the pressure plate diaphragm spring, which has a damping effect on the rattling, loose flywheel and quits the rattling sound somewhat. Releasing the clutch pedal allows the idling loose flywheel to begin rattling again. Yours sounds particularly bad.

If it is a worn-out flywheel, the only cure is rebuilding the clutch. This requires removing the powertrain and separating the engine from the transaxle. All clutch components are examined and worn parts are replaced. There is no easy answer, and requires significant work.

https://ssl.corvair.com/user-cgi/catalo ... w_page=108

https://ssl.corvair.com/user-cgi/catalo ... w_page=108

See catalog page 108 and applicable subsequent pages.

This attachment may help. The 1961 Shop Manual and appropriate supplement is needed. If there is a local CORSA club chapter, the members may be able to guide and assist. Lots of useful assistance can be found here on the Corvair Forum, too!

If it is a worn-out flywheel, the only cure is rebuilding the clutch. This requires removing the powertrain and separating the engine from the transaxle. All clutch components are examined and worn parts are replaced. There is no easy answer, and requires significant work.

Clark's Corvair Parts wrote:Bad Flywheels: Stock flywheels are riveted together. They are usually good for 50,000 to 110,000 miles, then they start to rattle and later also vibrate badly. If yours has over 75,000 miles and you are replacing a clutch disc, I would replace the flywheel. Be sure to replace all seaIs and gaskets.

See catalog page 108 and applicable subsequent pages.

This attachment may help. The 1961 Shop Manual and appropriate supplement is needed. If there is a local CORSA club chapter, the members may be able to guide and assist. Lots of useful assistance can be found here on the Corvair Forum, too!

Brad Bodie

Lake Chatuge, North Carolina

1966 Corvair Corsa Convertible

1966 Corvair Corsa Convertible

Lake Chatuge, North Carolina

1966 Corvair Corsa Convertible

1966 Corvair Corsa ConvertibleRe: 1963 engine ticking

Thanks Brad! I have the '61 shop manual so I'll review that as well. I'll separate the engine from the transaxle and take a look and let you know what I find. I bought this car to learn and it looks like I'm getting thrown in the deep end right away. I love how user friendly working on the Corvair has been so far, hopefully all goes well. I'll let you know what I find.

- bbodie52

- Corvair of the Month

- Posts: 12141

- Joined: Mon Aug 06, 2012 12:33 pm

- Location: Lake Chatuge Hayesville, NC

- Contact:

Re: 1963 engine ticking

Balancing the heavy engine and transaxle on a floor jack is somewhat unnerving, and can be dangerous. I did it by myself for the first time at age 16 in 1969. I did not drop the powertrain, fortunately. A transmission jack or a jack with a large cradle can provide a more-steady platform. A few experienced assistants (if a nearby CORSA club chapter is available) may also be useful.

Once the powertrain is out of the car, use caution when separating the transaxle from the engine.

TIP: The first time I lowered a powertrain from the car (car supported level using four jack stands) I had the engine/transaxle balanced on the small floor jack round lifting head and a small sheet of plywood to protect the aluminum engine components and the oil pan. Side to side balance was not hard to figure. The balance point at the center is near the oil pan drain plug. But front to back balance is a little difficult to ascertain. You can check for proper front to back balance when you slowly begin to lower the powertrain on the floor jack. If it comes down off of the three engine mounts evenly, you are probably OK. But if the rear comes down first, or the front (transmission end) comes down before the rear end, your powertrain balance is either front or rear-heavy. If this imbalance is detected, raise the powertrain back up onto the three engine mounts and temporarily reinstall the engine mount nuts. You can then adjust the jack position slightly and try again after removing the engine munt nuts. When the powertrain comes down evenly off of the three engine mounts, you can continue to slowly lower it down and wheel the jack out from under the car so that you can set the engine on some stacks of 2x4s or similar support.

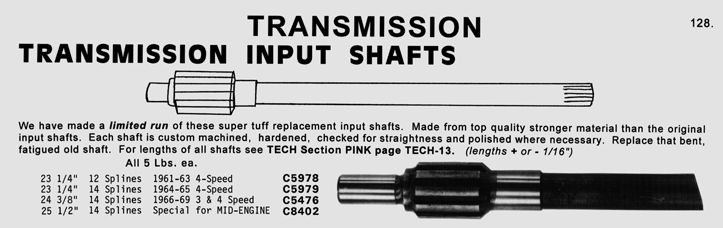

Separating the transaxle from the engine is best done with the floor jack under the differential and with the help of an assistant, so that the heavy transmission and differential can be pulled evenly straight back and away from the engine clutch housing. Once the splined input shaft pulls completely free of the clutch disc, or out of the transaxle, you no longer have to worry about the input shaft pressing on a side of the "snout" that supports the throw-out bearing and possibly damaging the "snout".

This picture was taken from page 10 of the attached Corvair and Corvair 95 Power Train Removal & Installation booklet, It helps to illustrate the powertrain balance point.

Once the powertrain is out of the car, use caution when separating the transaxle from the engine.

bbodie52 wrote:Most likely it is a loose flywheel. The Corvair flywheel is a two-piece affair with the mounting plate riveted to the flywheel. As the components age, the rivets begin to loosen, and the rattle is most-often heard when the engine is idling with the clutch not under load. The slow rotation with the transmission in NEUTRAL allows the loose flywheel components to rattle.

When you hear the rattling sound, try pressing slightly on the clutch pedal. There is normally a small gap between the throw-out bearing and the metal fingers on the diaphragm clutch pressure plate. When you push slowly on the clutch pedal, the throw-out bearing comes into contact with the diaphragm clutch spring. When it does, the physical contact and slight pressure on the diaphragm clutch spring is enough to dampen the vibration, which will quiet the rattling sound if a loose flywheel is the problem and the source of the noise. The noise will usually restart the moment you release the clutch pedal. The vibration you noticed when you come off-idle is usually associated with "clutch chatter" as the worn clutch slips and engages intermittently instead of smoothly slipping as it transitions from being disengaged to being fully-engaged.kevinpreston wrote:There seems to be pretty good vibration when you first come off idle, is that normal?

Unfortunately, the only fix is to remove the powertrain from the vehicle, separate the engine from the transaxle, and replace the worn-out flywheel. Since accessing the clutch assembly is a big job, it is usually a good idea to inspect the pressure plate, clutch disc, throw-out bearing, pilot bushing, and input shaft and crankshaft seals at the same time, and then order any needed replacement components and rebuild the clutch. It is usually a good idea to inspect the clutch cable and associated pulleys (and the parking brake cable and pulleys) to check and service the entire system.

https://www.youtube.com/user/davemotohead1/videos

https://ssl.corvair.com/user-cgi/catalo ... w_page=109

If you find that you need a clutch job on your Corvair, and you get to the point where you are ready to separate the transaxle from the engine, be cautious so that you do not damage the transaxle "snout" when pulling the two components apart.

The differential "snout" should be inspected for cracks or damage, as this is a cast machined part and is subject to damage if the input shaft is allowed to press laterally against it while separating the transaxle from the engine (the long input shaft is splined at both ends, and the shaft can pull out of the transaxle while remaining embedded in the clutch while separating the engine from the transaxle. If you allow the weight of one heavy component to lever against the shaft, it may press against the "snout" and crack it. Replacing this part of the differential requires completely dismantling the differential, as the "snout" has to be removed from the inside of the differential housing.

TIP: The first time I lowered a powertrain from the car (car supported level using four jack stands) I had the engine/transaxle balanced on the small floor jack round lifting head and a small sheet of plywood to protect the aluminum engine components and the oil pan. Side to side balance was not hard to figure. The balance point at the center is near the oil pan drain plug. But front to back balance is a little difficult to ascertain. You can check for proper front to back balance when you slowly begin to lower the powertrain on the floor jack. If it comes down off of the three engine mounts evenly, you are probably OK. But if the rear comes down first, or the front (transmission end) comes down before the rear end, your powertrain balance is either front or rear-heavy. If this imbalance is detected, raise the powertrain back up onto the three engine mounts and temporarily reinstall the engine mount nuts. You can then adjust the jack position slightly and try again after removing the engine munt nuts. When the powertrain comes down evenly off of the three engine mounts, you can continue to slowly lower it down and wheel the jack out from under the car so that you can set the engine on some stacks of 2x4s or similar support.

Separating the transaxle from the engine is best done with the floor jack under the differential and with the help of an assistant, so that the heavy transmission and differential can be pulled evenly straight back and away from the engine clutch housing. Once the splined input shaft pulls completely free of the clutch disc, or out of the transaxle, you no longer have to worry about the input shaft pressing on a side of the "snout" that supports the throw-out bearing and possibly damaging the "snout".

This picture was taken from page 10 of the attached Corvair and Corvair 95 Power Train Removal & Installation booklet, It helps to illustrate the powertrain balance point.

Brad Bodie

Lake Chatuge, North Carolina

1966 Corvair Corsa Convertible

1966 Corvair Corsa Convertible

Lake Chatuge, North Carolina

1966 Corvair Corsa Convertible

1966 Corvair Corsa ConvertibleRe: 1963 engine ticking

Thanks again Brad! That information is very helpful. My dad is in town for a while so he is working with me. We got everything ready to drop last night, but it got late so we called it a day. We will get to it today and I'll let you know what we find.

- bbodie52

- Corvair of the Month

- Posts: 12141

- Joined: Mon Aug 06, 2012 12:33 pm

- Location: Lake Chatuge Hayesville, NC

- Contact:

Re: 1963 engine ticking

It was probably best to knock off when you were tired... that is when mistakes are made!

I was 16 and working alone when I removed my first Corvair powertrain.

I was 16 and working alone when I removed my first Corvair powertrain.

I was nervously sweating like a pig in fear of dropping that heavy powertrain, but I managed to remove and lower it successfully!

The first time I ever separated a manual transaxle from a Corvair engine, well, I didn't exactly approach it correctly. I had the engine resting upon some stacks of two by fours. I removed the starter, and I unbolted the transaxle from the engine. Being young (17), overconfident, and healthy I decided that I could simply lift the heavy transaxle away from the engine and set it on the garage floor!

If you can picture this...

I straddled the transaxle and bent over and cupped my hands under it — cradling all of its weight in my hands as I was completely bent over and expecting to walk away with this heavy transaxle between my legs! That was when I discovered the issue with the long input shaft that inevitably remains embedded in the clutch disc. I was confronted with this very awkward moment (working alone, of course) when I had to try to figure out how to keep the alignment between the face of the differential and the clutch housing while balancing all of that weight in my hands, between my legs. I managed to take a whole series of very small backward steps while desperately trying to maintain the necessary alignment so that I would not damage the input shaft. That input shaft seemed soooooo long! But the small splined end finally came out of the differential and I was able to set the transaxle on the floor. I think I simply went into the house after that to lay down for awhile.

I was 16 and working alone when I removed my first Corvair powertrain.

I was 16 and working alone when I removed my first Corvair powertrain.I was nervously sweating like a pig in fear of dropping that heavy powertrain, but I managed to remove and lower it successfully!

The first time I ever separated a manual transaxle from a Corvair engine, well, I didn't exactly approach it correctly. I had the engine resting upon some stacks of two by fours. I removed the starter, and I unbolted the transaxle from the engine. Being young (17), overconfident, and healthy I decided that I could simply lift the heavy transaxle away from the engine and set it on the garage floor!

If you can picture this...

I straddled the transaxle and bent over and cupped my hands under it — cradling all of its weight in my hands as I was completely bent over and expecting to walk away with this heavy transaxle between my legs! That was when I discovered the issue with the long input shaft that inevitably remains embedded in the clutch disc. I was confronted with this very awkward moment (working alone, of course) when I had to try to figure out how to keep the alignment between the face of the differential and the clutch housing while balancing all of that weight in my hands, between my legs. I managed to take a whole series of very small backward steps while desperately trying to maintain the necessary alignment so that I would not damage the input shaft. That input shaft seemed soooooo long! But the small splined end finally came out of the differential and I was able to set the transaxle on the floor. I think I simply went into the house after that to lay down for awhile.

Brad Bodie

Lake Chatuge, North Carolina

1966 Corvair Corsa Convertible

1966 Corvair Corsa Convertible

Lake Chatuge, North Carolina

1966 Corvair Corsa Convertible

1966 Corvair Corsa ConvertibleRe: 1963 engine ticking

Ha ha. That's a good story. We got it down and separated with no issues other than a little stress. Decided to order new flywheel, clutch, and pressure plate. The pressure plate had some riveted repairs that were loose so that could have been the noise. Flywheel looked ok but could be past it's lifespan.

The clutch had some wear and was oil soaked. There was a lot of oil in the bell housing so I also ordered new seals and gaskets for both sides. I also ordered trans gaskets from Clark's because there looked to be a leak. Is there anything else we should address while everything out? How do we check if the axle bearings are good? They seem ok but I'm not sure. Throw out bearing seems good. Thanks again for all the help and entertaining stories. So far working on the Corvair has been manageable and fun. I'm glad my dad decided to come help!

The clutch had some wear and was oil soaked. There was a lot of oil in the bell housing so I also ordered new seals and gaskets for both sides. I also ordered trans gaskets from Clark's because there looked to be a leak. Is there anything else we should address while everything out? How do we check if the axle bearings are good? They seem ok but I'm not sure. Throw out bearing seems good. Thanks again for all the help and entertaining stories. So far working on the Corvair has been manageable and fun. I'm glad my dad decided to come help!

- bbodie52

- Corvair of the Month

- Posts: 12141

- Joined: Mon Aug 06, 2012 12:33 pm

- Location: Lake Chatuge Hayesville, NC

- Contact:

Re: 1963 engine ticking

With the transaxle out, you might consider emptying the transmission and differential lube and replacing it with fresh gear lube. Many Corvair transaxles lack a good way to drain the differential and transmission, but with them out of the car you might find it easier to do. Always use GL-4 gear lubricant in both, and stay away from GL-5, which can damage the "yellow metal" synchros in the transmission. The gear lube is shared between the transmission and differential. Because of the difficulty in draining the old fluid, changing the aging transaxle fluid is often ignored or overlooked. The aging gears need to be treated well, so don't neglect replacing the transaxle fluid with fresh, high-quality gear lubricants.

Inspect and service or replace the universal joints with good-quality universal joints that include grease (Zerk) fittings. I have seen them ignored to the point where the needle bearings break and disintegrate and turn into rusty powder!

https://ssl.corvair.com/user-cgi/catalo ... w_page=167

https://ssl.corvair.com/user-cgi/catalo ... w_page=167

https://ssl.corvair.com/user-cgi/catalo ... w_page=165

https://ssl.corvair.com/user-cgi/catalo ... w_page=165

https://ssl.corvair.com/user-cgi/catalo ... w_page=166

https://ssl.corvair.com/user-cgi/catalo ... w_page=166

Inspect and service or replace the universal joints with good-quality universal joints that include grease (Zerk) fittings. I have seen them ignored to the point where the needle bearings break and disintegrate and turn into rusty powder!

Clark's Corvair Parts wrote:REAR AXLE (WHEEL) BEARINGS

1960-64 CARS & 1961-65 VANS

The rear axle bearings are probably the most dangerous part of the whole car. It is not uncommon for the axle shaft to pull right out. In some cases the axle shaft just worked out and in others the bearing has failed. The 1965-69 style fixed this but people with the earlier style should not ignore any possible bearing noises! ANY NEW OLD STOCK BEARINGS SHOULD BE REPACKED WITH GREASE AS THE OLD GREASE IS USUALLY HARD. NOTE: The 1960-62 (stamped steel housing) will fit 63-64 (although it is not as snug in the lower a-frame opening). The 1963-64 (cast iron housing) will not fit 1960-62 opening without considerable grinding.

BobWitt » Sun Sep 04, 2016 9:56 am

Steve - I made 4x guide pins from 5 or 6" bolts, I had the engine on a cart and used the floor jack to manage the trans...

Although it is somewhat pricey, I have come to believe that these Royal Purple motor oil and gear lube products are a good match for the Corvair engine and manual transaxle.

HIGH PERFORMANCE ENGINE OIL (WITH SYNERLEC®)

HPS is recommended for use in gasoline and diesel automotive, commercial fleet and stationary industrial engines. Royal Purple® HPS® Series motor oil is specifically formulated to maximize performance and meet the demands of high performance and modified engines. HPS is recommended for vehicles no longer under manufacturer warranty and for those seeking a higher level of performance and protection. Royal Purple HPS oils are fortified with a high level of zinc / phosphorus anti-wear additive and a generous dose of Royal Purple’s proprietary Synerlec® additive technology. These unique formulations enable HPS oils to outperform leading synthetic and conventional lubricants in both gasoline and diesel engines.

PERFORMANCE ADVANTAGES

- Exceptionally high film strength for dramatic reductions in engine wear and reduced engine heat to extend the life of your engine

- Improved sealing between the piston ring and cylinder wall maximizes horsepower and torque and optimizes fuel economy

- Exceptional oxidation stability extends oil life and allows for more miles driven between oil changes saving you time and money

- Advanced synthetic solvency reduces engine deposits and keeps engines clean

- Outstanding wear protection for valve train components, including performance roller lifter and high lift flat tappet camshafts and lifters

- Superior corrosion protection

https://www.royalpurple.com/product/hps ... motor-oil/

This synthetic gear lubricant appears to support both hypoid differentials and, unlike GL-5 lubricants, is safe for "yellow metal" synchros.

Special gear oils are required for hypoid gears found in Corvair differentials because the sliding action requires effective lubrication under extreme pressure between the teeth. ... They are considerably stronger in that any load is conveyed through multiple teeth simultaneously. By contrast, bevel gears are loaded through one tooth at a time. Hypoid gear oil is formulated with extreme-pressure (EP) additives to protect and operate effectively with hypoid gears.

EP additives which contain phosphorus/sulfur compounds are corrosive to yellow metals such as the copper and/or brass used in bushings and synchronizers.

Richard Widman wrote:A traditional GL-4 gear oil of any given viscosity has about ½ of the level of sulfur/phosphorous additive that would be in the GL-5 product, so the bond is not as strong, and therefore can be peeled off without peeling a layer of brass (or less brass). This means that the GL-4 product provides a little less extreme pressure protection, so in the differential of a high-powered car, it would not be the ideal product in the differential. To understand this need we should be aware of the fact that the differential is where the final torque is applied to the wheels (in most applications)...

---Some cars (including later Corvairs) came with military specs instead of API gear oil specs. So we should consider that MIL-L-2105B is an equivalent to GL-4, and MIL-L-2105C, 2105D, and 2105E are GL-5 gear oil lubricants.Basically, Corvair transaxles share the lubricant in the transmission portion and the differential portion. So it is necessary to compromise and select a gear lube that will protect the hypoid gears in the differential and not harm the "yellow metal" synchronizer components in the manual transmission. A good quality GL-4 Hypoid gear lubricant (SAE 75W-90) in your Corvair manual transaxle is the way to go.66vairguy wrote:Tue Nov 07, 2017 11:32 am

... DO NOT USE Redline MT-90 in a Corvair transaxle. Redline's site specifically states that MT-90 is NOT approved for hypoid gears (differential). So it is NOT acceptable for use in a Corvair transaxle since protection for the ring and pinion differential gears is inadequate. Redline does make a modified GL-5 lube that is suppose to work with brass synchronizers called - 75W90 NS GL-5 and states it's approved for transaxles with brass parts. NOTE: Redline NS GL-5 is different vs. their GL-5 which is NOT approved for transaxle use.

HIGH PERFORMANCE GEAR OIL (WITH SYNERLEC®)

Max Gear is recommended for truck and automotive differentials, outboard motor lower units or in rear axles or manual transmissions requiring an API fluid. Max Gear is a high performance automotive gear oil designed to provide maximum protection to heavily loaded gears while increasing power throughput through the drive train. Max Gear virtually eliminates both gear and bearing wear—even under severe squeeze film conditions caused by extremely high loads, sudden shock loads or low RPMs. Slippery, synthetic molecules not only reduce wear and friction but significantly increase Max Gear’s cold weather fluidity and lubricity, making it the ideal choice for vehicles operating in cold climates. Gears run smoother, quieter, cooler and longer without overhauls. It is noncorrosive to both ferrous and nonferrous metals.

PERFORMANCE ADVANTAGES

- Maximizes horsepower

- Extends gear and bearing life

- Reduces operating temperature

- Lower coefficient of friction

- Superior corrosion protection

- Separates rapidly from water

- For use with open, limited-slip and locking differential

- Contains limited-slip friction modifier

https://www.royalpurple.com/product/max_gear/

Brad Bodie

Lake Chatuge, North Carolina

1966 Corvair Corsa Convertible

1966 Corvair Corsa Convertible

Lake Chatuge, North Carolina

1966 Corvair Corsa Convertible

1966 Corvair Corsa ConvertibleRe: 1963 engine ticking

We drained the trans and dif before dropping because there were drain plugs  . The trans had an inch or so of thick gloop I had to poke at before any fluid came out. Thanks for the oil tips, I had not gotten around to looking into that yet. Making alignment pins from bolts seems like a good idea. We have the motor and the transaxle on bases with wheels so with shims we should be able to join them again with alignment and evenly without those I think. Waiting on parts at this point and working on other aspects of the car until they arrive. The gasket between the trans and diff seems good. I was not going to mess with the diff at all other than the fluid change. I just want to make sure to address any common issue areas before putting it back in. Thanks for all your helpful input!

. The trans had an inch or so of thick gloop I had to poke at before any fluid came out. Thanks for the oil tips, I had not gotten around to looking into that yet. Making alignment pins from bolts seems like a good idea. We have the motor and the transaxle on bases with wheels so with shims we should be able to join them again with alignment and evenly without those I think. Waiting on parts at this point and working on other aspects of the car until they arrive. The gasket between the trans and diff seems good. I was not going to mess with the diff at all other than the fluid change. I just want to make sure to address any common issue areas before putting it back in. Thanks for all your helpful input!

Re: 1963 engine ticking

Thanks for all the great info. I think I have the same problem. With care in neutral and clutch released it rattles away and as soon as I touch the clutch all sounds normal. What is the worst that could happen if I don't get to fixing this right away?

-

coppertop666

- Posts: 35

- Joined: Thu Dec 18, 2014 9:40 am

- Location: Centerport, NY

Re: 1963 engine ticking

Hey Garth,

I'm having the same issue with my 64 and I should be getting to the repair in the next few weeks.

From what I've read, it can eventually break the starter nose and/or worse if its continually driven. Also since the flywheel is out of balance, it can be hard on the main bearings, which is not good for the engine.

I'm having the same issue with my 64 and I should be getting to the repair in the next few weeks.

From what I've read, it can eventually break the starter nose and/or worse if its continually driven. Also since the flywheel is out of balance, it can be hard on the main bearings, which is not good for the engine.

Matt

Centerport, NY

64 Monza Conv.

110 / 4 speed

Lagoon Aqua

Centerport, NY

64 Monza Conv.

110 / 4 speed

Lagoon Aqua

Re: 1963 engine ticking

Yes use GL-4, but I didn't see anybody mention viscosity. Many use Sta-Lube GL-4 85-90 since it's relatively inexpensive. It works in warm climates, but is too thick for cool climates since it's 85-90. The Corvair transaxle requires GL-4 80-90, NOT 85-90. Unfortunately 80-90 is harder to find and can be expensive from some of the "boutique" oil companies. BTW our club transaxle expert likes to say "The main cause of transmission and differential failure is nobody ever changes the gear oil!!" If you change the gear lube every 30,000 miles and drive resonably, you can expect a Corvair transaxle to go well over 100,000 miles without issue, except maybe seals.

Years ago a fellow suggested Brad-Penn GL-4 80-90. It's available on Amazon and other sites. Now it's called Penn Grade. My 66's like it as they shift better vs. using the Sta-lube GL-5 85-90.

See https://www.amazon.com/Brad-Penn-023-77 ... 143&sr=8-2

or https://www.ebay.com/itm/284342970919?h ... R5by2ZbgYQ

Years ago a fellow suggested Brad-Penn GL-4 80-90. It's available on Amazon and other sites. Now it's called Penn Grade. My 66's like it as they shift better vs. using the Sta-lube GL-5 85-90.

See https://www.amazon.com/Brad-Penn-023-77 ... 143&sr=8-2

or https://www.ebay.com/itm/284342970919?h ... R5by2ZbgYQ