2bbl carb set up

2bbl carb set up

I have a center mount manifold for a 110 hp corvair engine . I was wondering if anyone has any leads to where i can acquire the linkages for a rochester 2gc carb or a holley 2bbl carb set up. They were available from IECO performance parts years ago.

- bbodie52

- Corvair of the Month

- Posts: 11956

- Joined: Mon Aug 06, 2012 12:33 pm

- Location: Lake Chatuge Hayesville, NC

- Contact:

Re: 2bbl carb set up

I believe that most Holley 2bbl carburetors are rated at approximately 350-500 CFM airflow with both barrels opening simultaneously via mechanical linkage. These 2-barrel carburetors generally targeted an engine with 300+ Cubic Inch displacement. Most center-mounted Corvair intake manifolds were designed to be mounted on a 164 CI engine with 140 hp large valve heads, with dual exhaust, 4 intake ports, etc. that add up to better breathing capacity for the Corvair engine. The recommended 4-barrel carburetor usually had a total airflow capacity of 390-450 CFM, and that airflow is divided between two primary barrels and 2 secondaries that open later with a progressive secondary linkage that only brings on the second half of the carburetor at higher engine speeds that better match the full carburetor airflow capacity. A 110hp engine usually has the same camshaft as the 140hp engine, but it has much smaller valves, two carburetor mounts and a single muffler exhaust system. I think that opening up all of that airflow capacity divided between only two carburetor barrels would likely overwhelm the 110hp engine airflow capacity and would almost stall the airflow passing through the 2-barrel venturis, which may produce a poor fuel/air atomization. It may add up to a difficult engine with poor street drivability. The total airflow capacity of the 110hp engine may not be a good match for a center-mounted large capacity 2-barrel.

How many CFM is a Rochester 2GC carburetor?

All two-barrel carburetors had a cfm range of 285 to 450 cfm, and the original 2G used a manifold-mounted thermal-spring assembly that connected to the choke via a linkage rod.

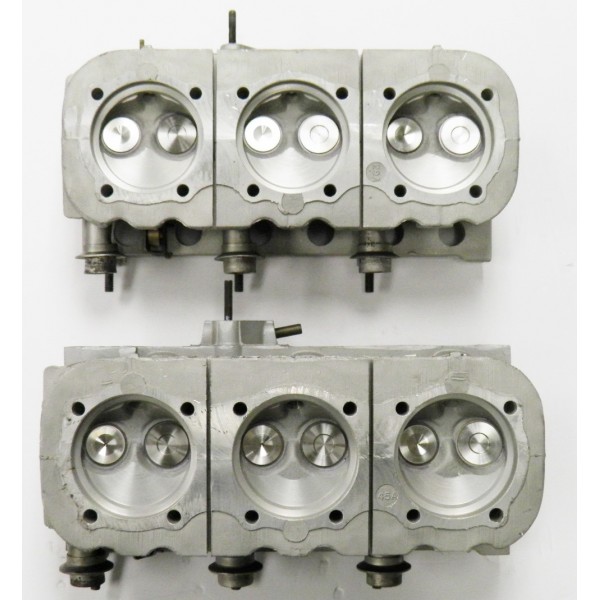

This will give you some idea of the differences between the 140 hp engine and the 110 hp engine.

140 hp vs. 110 hp...

- Same high-performance camshaft on both 140 hp and 110 hp engines. Low performance camshaft in the 95 hp engine.

- Same 164 Cubic Inch displacement with same bore and stroke on all 1964-1969 engines.

- Stronger, nitrided crankshaft on the 140 hp and 180 hp turbocharged engines. (Nitriding is a heat treating process that diffuses nitrogen into the surface of a metal to create a case-hardened surface).

- On the 140 hp engine, a 4x1 carburetor arrangement, with two primary and 2 secondary 1-barrel carburetors, connected with a progressive linkage to open the secondary carburetors as you approach full throttle. (Equivalent to a 4 barrel carburetor on the 140 hp engine, vs. a 2 barrel carburetor (2x1) on the 110 hp and 95 hp engine).

- Dual muffler, dual exhaust with larger exhaust ports and larger exhaust manifolds on the 140 hp engine. Single exhaust on the 110 hp and 95 hp engine.

- 9.0:1 Compression Ratio in both 140 hp and 110 hp engines. 8.0:1 CR on the 95 hp engine.

It's all about better breathing at full throttle at the high RPM ranges. At lower RPM the big valves and dual exhaust don't make much difference, and the secondary carburetors are not open for business.

110 hp Heads...

When GM engineers introduced the 140hp engine, the not only doubled the carburetor airflow capacity with a 4x1 carburetor configuration, but they also redesigned the heads with greater intake and exhaust valve capacity, added dual exhaust, and included a progressive throttle linkage that only opened the two secondary carburetors at higher throttle openings with higher engine RPM speeds that could take advantage of the extra carburetors when the engine was ready for it. If you over-carburate your 110hp engine with too much airflow the engine may be difficult to drive.

A turbocharger or a properly-sized Electronic Fuel Injection (EFI) system (using two throttle bodies) can produce a more-tractable and enjoyable street Corvair with improved top-end performance as well. However, EFI is a pretty expensive upgrade!

Corvair Electronic Fuel Injection (EFI)

Corvair Electronic Fuel Injection (EFI)I hope you will include some pictures of your Corvair (including the engine compartment). Please tell us more about yourself, your mechanical experience, and your Corvair background and goals/objectives for your Corvair. Where are you located?

Brad Bodie

Lake Chatuge, North Carolina

1966 Corvair Corsa Convertible

1966 Corvair Corsa Convertible

Lake Chatuge, North Carolina

1966 Corvair Corsa Convertible

1966 Corvair Corsa ConvertibleRe: 2bbl carb set up

I used one of these with a Rochester 2 bbl on a '65 95hp 500 back in '66. It worked well in the summertime in the lush Willamette valley of Oregon. However when the weather turned cold and humid it tended to ice up the carb since I did not have a way to heat the manifold. The manifold had 2 threaded holes to fashion heat riser tubes from the exhaust but the engineering was beyond the ability and resources of a 17 y.o. kid. I wish I still had some of those parts I could send you but that was a lifetime and many moves ago. Don't remember the linkage to be anything fancy and someone should be able to fabricate something to work. Good luck! Thanks bbodie52 for the pics of 140 hp heads. Didn't know the intake valves are so gargantuan!

Last edited by Benergy on Mon Jan 08, 2024 7:56 pm, edited 2 times in total.

- Phil Dally

- Posts: 910

- Joined: Thu Dec 10, 2009 4:47 am

Re: 2bbl carb set up

To answer the original posters question those IECO parts will be impossible to find.

You could get lucky at a swap meet...but why not build your own linkage set up?

I used this set up in my racecar with a 500 and SU mounted in both directions.

Using a six foot Morse cable and tie it into the stock bell crank in the tunnel.

Everything is available from Summit and the cable runs through stock holes.

You could get lucky at a swap meet...but why not build your own linkage set up?

I used this set up in my racecar with a 500 and SU mounted in both directions.

Using a six foot Morse cable and tie it into the stock bell crank in the tunnel.

Everything is available from Summit and the cable runs through stock holes.

- Attachments

-

- morse3.jpg (64.81 KiB) Viewed 449 times

-

- morse2.jpg (85.63 KiB) Viewed 449 times

-

- su1.jpg (87 KiB) Viewed 449 times

-

- morse.jpg (63.53 KiB) Viewed 449 times

CA Central Coast

Vairy V8 Rides Again.

LA Angels fan since 1978

World Series Champs 2002

Only Own 10 Corvairs Today

Been Associated With Fifty!!

Vairy V8 Rides Again.

LA Angels fan since 1978

World Series Champs 2002

Only Own 10 Corvairs Today

Been Associated With Fifty!!