Page 1 of 2

Weber upgrade advise and build thread

Posted: Sat Dec 06, 2014 6:40 am

by 72BBNova

I've decided to start my own thread on this subject instead of high jacking someone else's.

A quick history on the car. This was my dads car that him and I spent 5-1/2 years restoring, he pasted away in Feb of 2013 so now it's mine. I'm upgrading some things on it to kind of make it my own.

I've never had a turbo motor so my ignorance will show it self a lot, I'm smart enough to know that I'm ignorant about turbo's so I'm going to be asking a lot of questions so be patient with me.

Here's what I know of the engine, 304 cam, stock compression (heads done by Michael LeVeque), turbo is an EM exhaust and LM comp and carb (please explain the different flow's, B,E,F don't know what I have), stock exhaust and an HEI distributor (also by Michael LeVeque). That's all that I can think of right now.

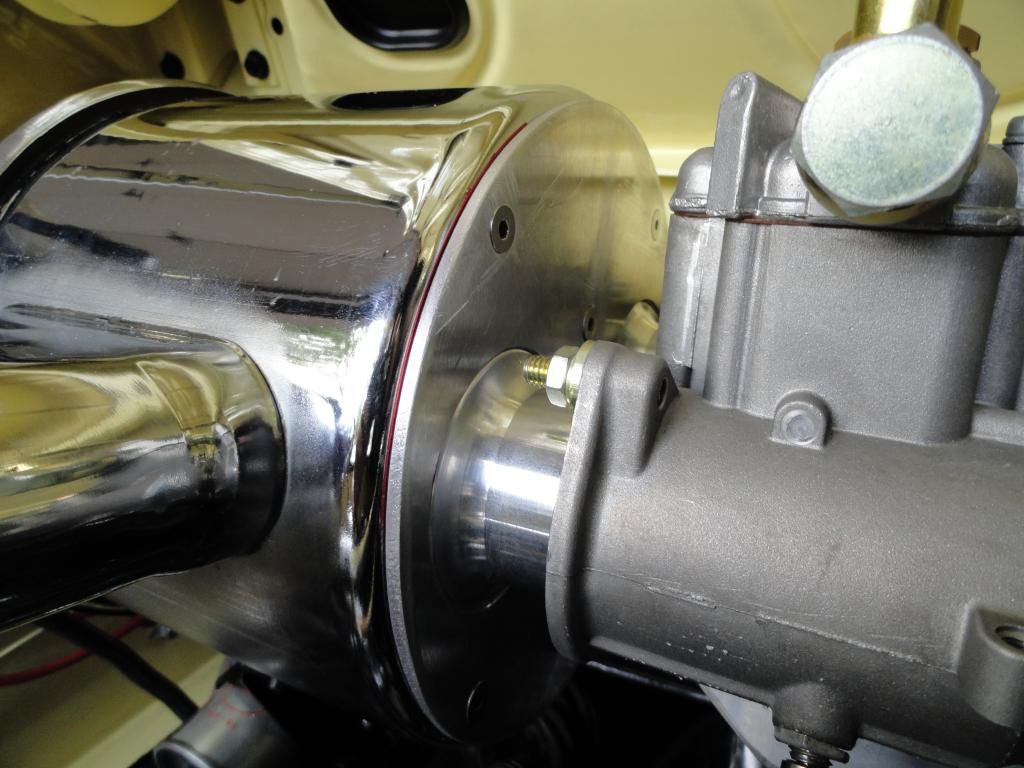

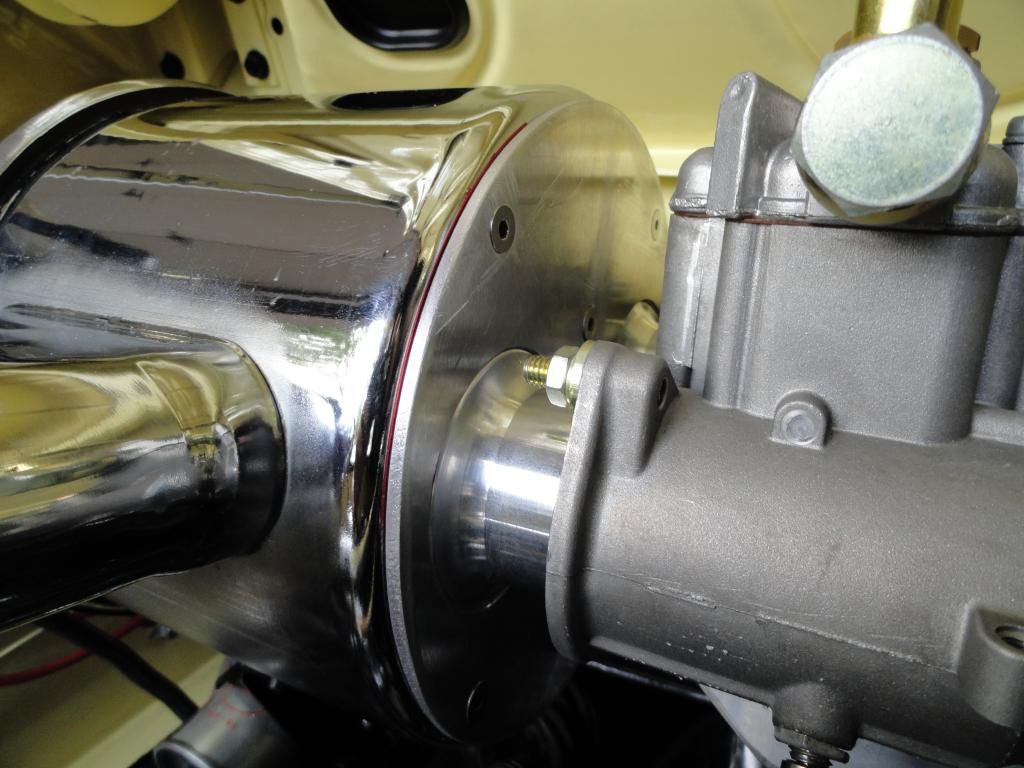

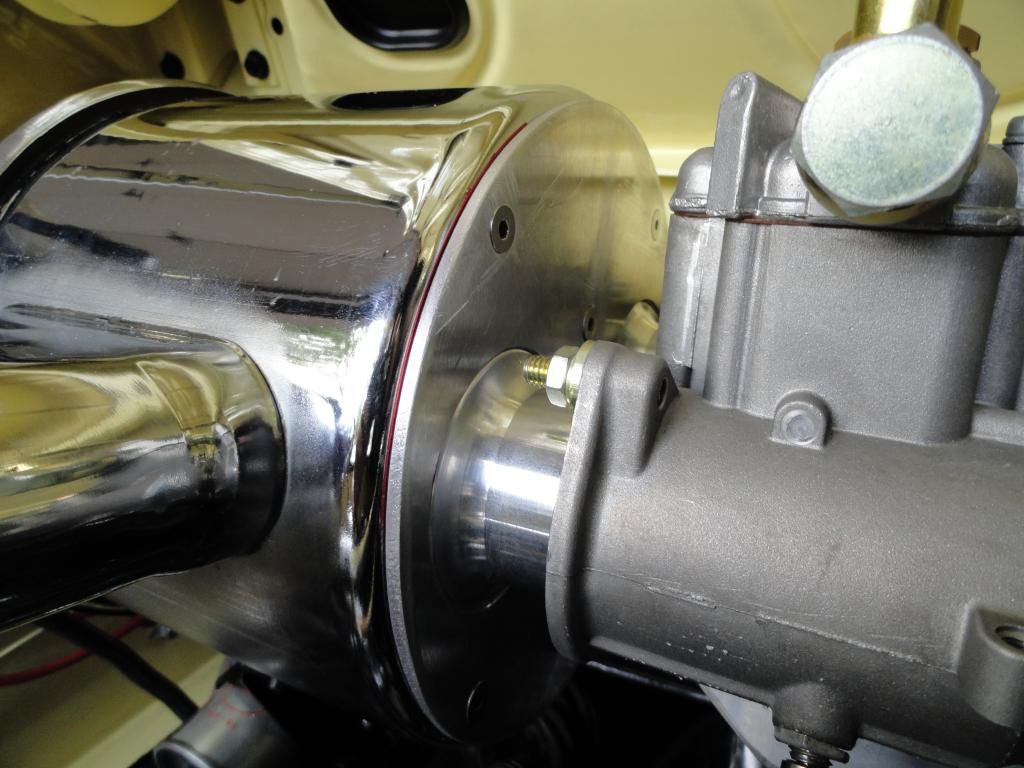

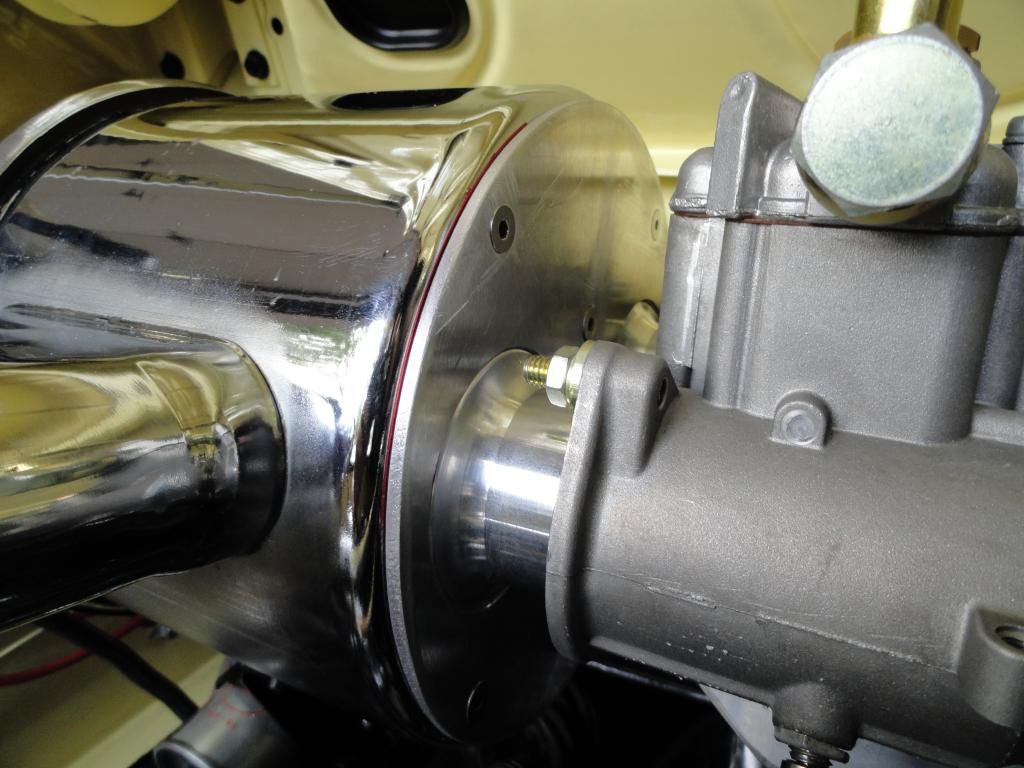

Here are the upgrades that I'm planning this winter, a Weber 40DCOE (already have and modified by Warren LeVeque), a water/meth system (custom tank being built now), MSD digital programmable 6AL-2 ignition and coil, a wideband O2 sensor (already have thanks for the advise Lee aka "notched") a 140 amp alternator and now it's looking like a wastegate is added to the list. I'm thinking about taking the exhaust manifolds off and polishing them up to help flow (just smooth them out) and possibly fab a new stainless steel exhaust.

I've started this thread to get advise from guys that have more experience with these turbo motors than I do. I understand the basic's of them, exhaust gases go in, turn's a turbine which turns a compressor and builds boost and the fun begins.

Since I already have the weber I would like to here from guys that are running a 40DCOE on there cars, how it's setup, pro's and con's, do's and don'ts "real world experience". Advise on water/meth system's, where to install the nozzle, before carb, after carb & before turbo, after turbo but in the housing, in the cross over tube right above the heads, in other words "the best place". Also what kind of pump and solenoid to use. Advise on ignitions, I want to keep my distributor so that's why I'm looking at the MSD ignition's and I think the programmable type is the way to go in this situation, a lot more versatile, and yes I'll be contacting MSD very soon to discuss this. Advise on wastegates, I know nothing about them so brands to look at and stay away from, how to set them up and where to install one. Where's the best place to install the bung for my wideband sensor to get the best reading's? I'd like to put under the car to keep it out of sight. Any custom exhaust systems that anybody might have. I want lots of pictures of everything that you guys have, I can understand something a lot better when I can see it. Other things to do this winter/early spring is to finish my rear disc brake conversion and new master cylinder and maybe new coil springs and shocks. I've posted pictures of my carb installed using a factory air cleaner that I modified when I was doing some mock up work. I will be posting progress pictures on everything I do to it this winter. I appreciate any pictures, advise, boot in the A$$ that you guy's can give me. Thanks Jeff

Re: Weber upgrade advise and build thread

Posted: Sat Dec 06, 2014 8:41 am

by notched

Jeff, I use the Tial MVR 44 but you can also use a Precision 46. Is one better than the other? No; people argue over them like they argue Chevy vs Ford.

Both of these are MORE than enough to control anything you would throw at a Corvair engine. I prefer the V band flange units just for installation simplicity and no gaskets being needed. Plus they look cool :)

I have mine mounted on the inlet pipe just below the turbo.

You will want the wide band bung about 6 inches out from the turbine housing outlet. Did you see mine?

I spray my methanol right into the compressor housing discharge right above the clamp that attaches it to the cross over. Reason for this is that the compressed air is not hot from being compressed so mixing it right at the discharge is one way to potentially cool it off. Others spray it into the turbo inlet but there are the stories of it causing erosion of the compressor.

Re: Weber upgrade advise and build thread

Posted: Sat Dec 06, 2014 9:43 am

by flat6_musik

Let me just jump in here and compliment you guys on your creative and beautiful upgrades here in these pics......wow, very nice!

Re: Weber upgrade advise and build thread

Posted: Sat Dec 06, 2014 9:57 am

by 72BBNova

Ok Lee you need to send me a link or more pics of your exhaust, that looks really nice, nice smooth bends nothing real sharp from what I can see.

Thanks for the complement flat6, but I can't take the credit for it, I saw a picture online of this and just copied it. I have that air cleaner and the aluminum plate at the chrome shop being plated now and hoping to get it back in a week or two, I'll post pictures when I get it back. Jeff

Re: Weber upgrade advise and build thread

Posted: Sat Dec 06, 2014 10:33 am

by Scott V

notched wrote:I spray my methanol right into the compressor housing discharge right above the clamp that attaches it to the cross over. Reason for this is that the compressed air is not hot from being compressed so mixing it right at the discharge is one way to potentially cool it off.

edit for notched - Reason for this is that the compressed air is *hot* from being compressed so mixing it right at the discharge is one way to potentially cool it off.

-Scott V.

Re: Weber upgrade advise and build thread

Posted: Sat Dec 06, 2014 10:37 am

by notched

Thank you Scott.

Re: Weber upgrade advise and build thread

Posted: Sat Dec 06, 2014 10:39 am

by notched

Some more exhaust pictures for you.

Re: Weber upgrade advise and build thread

Posted: Sat Dec 06, 2014 10:43 am

by Scott V

72BBNova wrote:turbo is an EM exhaust and LM comp and carb (please explain the different flow's, B,E,F don't know what I have)

b=150 turbo

f=180 turbo

e=larger than 180.

you have whats called a b/f hybird. you get fast spool w/the smaller 150 exhaust & more boost w/the 180 comp. its a nice setup.

-Scott V.

Re: Weber upgrade advise and build thread

Posted: Sat Dec 06, 2014 9:19 pm

by Alexrobic604

Has anyone with a turbo done a duel exhaust, what type of muffler are you running and what kinda note.

Re: Weber upgrade advise and build thread

Posted: Sun Dec 07, 2014 4:27 am

by 72BBNova

Scott V wrote:72BBNova wrote:turbo is an EM exhaust and LM comp and carb (please explain the different flow's, B,E,F don't know what I have)

b=150 turbo

f=180 turbo

e=larger than 180.

you have whats called a b/f hybird. you get fast spool w/the smaller 150 exhaust & more boost w/the 180 comp. its a nice setup.

-Scott V.

Thanks for clarifying that up.

Re: Weber upgrade advise and build thread

Posted: Sun Dec 07, 2014 4:59 pm

by Scott V

Alexrobic604 wrote:Has anyone with a turbo done a duel exhaust, what type of muffler are you running and what kinda note.

what kind of dual exhaust? a muffler on each side or two mufflers on 1 side?

i saw 1 w/a muffler on each side. it was kind of funky & kind of doesnt make sense w/a turbo. the guy used a glasspak that was welded to the outlet pipe w/a crossover like a regular non turbo vair.

-Scott V.

Re: Weber upgrade advise and build thread

Posted: Mon Dec 08, 2014 6:05 pm

by 72BBNova

Lee can you give some details on your exhaust, size of tubing, where you got the flanges at, exhaust logs, etc. The pipe and fittings aren't going to be to much of a problem for me being a plumber, we've probably got most of that stuff in our shop, have to do some digging. Jeff

Re: Weber upgrade advise and build thread

Posted: Mon Dec 08, 2014 8:48 pm

by BIGTWIN

You Go Guys! Those are both a thing of beauty. Good luck Jeff, I hope it screams for you.

Re: Weber upgrade advise and build thread

Posted: Mon Dec 08, 2014 8:55 pm

by notched

My heads have been modified and have 140 exhaust tubes and I use stock 140 exhaust manifolds. The cross over I believe is 1 5/8" and the inlet to the turbo is 2". The outlet/down pipe is 2.5" inch. We made the flanges where the donut gaskets that seal to the front of the manifold. My buddy has a steel mandrel to swage pipe with so that was done in a press and it was 2 pieces (an outer portion that was swaged and a straight inner portion that the donut gasket fits over).

The V band flanges came from Ebay. The cross over has a slip joint in the middle to allow it to expand and contract. The inlet pipe below the turbo has one as well so that if I need to work on the engine I can unbolt the turbo and pull the flange with part of the inlet pipe up and off without spending an hour trying to separate them under the car. The flange that the turbo mounts to was cut off a rusted out OEM inlet pipe. I ended up setting it up in the mill and working the weld joint off with an end mill and then belt sanded both sides flat again.

The triangular outlet flange is stainless and I made that from a rough blank. The flange for the donut gasket at the turbo to outlet pipe was made the same way as the ones at the cross over.

Re: Weber upgrade advise and build thread

Posted: Tue Dec 09, 2014 3:01 am

by 72BBNova

Nice job on the exhaust. How does the expansion joint's not leak with out some kind of a clamp? Jeff

Re: Weber upgrade advise and build thread

Posted: Tue Dec 09, 2014 4:42 am

by notched

Thank's Jeff. I can't take credit for all of it. My friend Keith did the cutting and welding. I did the smaller stuff and had some of the ideas.

The slip joints are tight when cold. When engine gets hot the inner pipe expands intake the outer pipe. No leaks. Fabricators do the same thing with the slip on collectors on a lot of V8 headers. The only clamp that I have is on the inlet pipe and where the muffler slips on.

Since I already have the weber I would like to here from guys that are running a 40DCOE on there cars, how it's setup, pro's and con's, do's and don'ts "real world experience". Advise on water/meth system's, where to install the nozzle, before carb, after carb & before turbo, after turbo but in the housing, in the cross over tube right above the heads, in other words "the best place". Also what kind of pump and solenoid to use. Advise on ignitions, I want to keep my distributor so that's why I'm looking at the MSD ignition's and I think the programmable type is the way to go in this situation, a lot more versatile, and yes I'll be contacting MSD very soon to discuss this. Advise on wastegates, I know nothing about them so brands to look at and stay away from, how to set them up and where to install one. Where's the best place to install the bung for my wideband sensor to get the best reading's? I'd like to put under the car to keep it out of sight. Any custom exhaust systems that anybody might have. I want lots of pictures of everything that you guys have, I can understand something a lot better when I can see it. Other things to do this winter/early spring is to finish my rear disc brake conversion and new master cylinder and maybe new coil springs and shocks. I've posted pictures of my carb installed using a factory air cleaner that I modified when I was doing some mock up work. I will be posting progress pictures on everything I do to it this winter. I appreciate any pictures, advise, boot in the A$$ that you guy's can give me. Thanks Jeff

Since I already have the weber I would like to here from guys that are running a 40DCOE on there cars, how it's setup, pro's and con's, do's and don'ts "real world experience". Advise on water/meth system's, where to install the nozzle, before carb, after carb & before turbo, after turbo but in the housing, in the cross over tube right above the heads, in other words "the best place". Also what kind of pump and solenoid to use. Advise on ignitions, I want to keep my distributor so that's why I'm looking at the MSD ignition's and I think the programmable type is the way to go in this situation, a lot more versatile, and yes I'll be contacting MSD very soon to discuss this. Advise on wastegates, I know nothing about them so brands to look at and stay away from, how to set them up and where to install one. Where's the best place to install the bung for my wideband sensor to get the best reading's? I'd like to put under the car to keep it out of sight. Any custom exhaust systems that anybody might have. I want lots of pictures of everything that you guys have, I can understand something a lot better when I can see it. Other things to do this winter/early spring is to finish my rear disc brake conversion and new master cylinder and maybe new coil springs and shocks. I've posted pictures of my carb installed using a factory air cleaner that I modified when I was doing some mock up work. I will be posting progress pictures on everything I do to it this winter. I appreciate any pictures, advise, boot in the A$$ that you guy's can give me. Thanks Jeff