Flywheel noise

-

MORTUNDEAD

- Posts: 35

- Joined: Sat Mar 23, 2013 10:48 pm

Flywheel noise

Almost everything is finished on my '62 monza 900. However, it still has a horrible rattly flywheel. How big of an issue is this? Can i just replace the rivets with bolts? Or is it even a big deal? If the main issue is just the sound, i can deal with that. But i need the car to be reliable, so if this flywheel needs replacement i will do it.

1962 Chevrolet Corvair Monza 4-speed 80 h.p. over a million documented miles !

- bbodie52

- Corvair of the Month

- Posts: 12140

- Joined: Mon Aug 06, 2012 12:33 pm

- Location: Lake Chatuge Hayesville, NC

- Contact:

Re: Flywheel noise

The problem you described is most likely a loose flywheel. The Corvair flywheel is riveted to a flex plate when it was manufactured by Chevrolet. Over the years these rivets can loosen as the car is driven, producing a loose flywheel attachment. This produces a rattling sound when the engine idles with the transmission in neutral. Applying any pressure on the clutch pedal moves the throw out bearing into contact with the diaphragm spring on the clutch assembly pressure plate. This has a dampening effect on the assembly, and usually silences the rattling sound that you hear. The sound will resume immediately when the driver removes his foot from the clutch pedal. Unfortunately, there is no easy solution. The only way to fix this is to remove the powertrain from the car and separate the engine from the transaxle to allow the flywheel to be removed and replaced.

Do the symptoms I described match the symptoms in your Corvair? Repairing a loose flywheel in your Corvair is not a small job, so you want to be absolutely certain when troubleshooting the problem that the symptoms are from a loose flywheel and not from some other source. If you perform the repair you should completely examine the clutch assembly for excess wear or other problems. The condition of the pressure plate, clutch disc, and throw out bearing should also be checked, and any worn components should be replaced. The input shaft seal should also be replaced, and the crankshaft seal should be checked for oil leaks. The throw out bearing shaft that protrudes from the differential should be carefully examined for cracks or damage, as damage to these components can occur, and the crack can result in an oil leak from the differential. If you are doing this work yourself, be very careful when separating the transaxle from the engine. The input shaft is long and may remain embedded in the clutch disc as you separate the two components. If this happens the other end of the splined input shaft may pull free from the transmission. When the two components are separated by several inches you may be able to reach between them and pull the input shaft from the clutch assembly. It is important to maintain the alignment of the engine and transaxle so that the input shaft does not act like a lever against the differential throw out bearing shaft, because such leverage against the throw out bearing shaft could potentially cause damage to the throw out bearing shaft or to the input shaft if it is bent. A damaged throw out bearing shaft can only be replaced by completely dismantling the differential.

I have attached a Chevrolet guide that explains procedures for removing the transaxle from the car. Removing the transaxle is usually done with a service station type hydraulic floor jack. I usually use a sheet of three-quarter inch plywood to protect the underside of the powertrain from the lifting surface of the floor jack. Once the powertrain has been lowered to the ground the engine can be separated from the transaxle. If you're going to do this job please review all of the procedures in the factory shop manual prior to starting the work. It is always a good idea to have one or two assistants with you to help you to carefully lower the powertrain from the car.

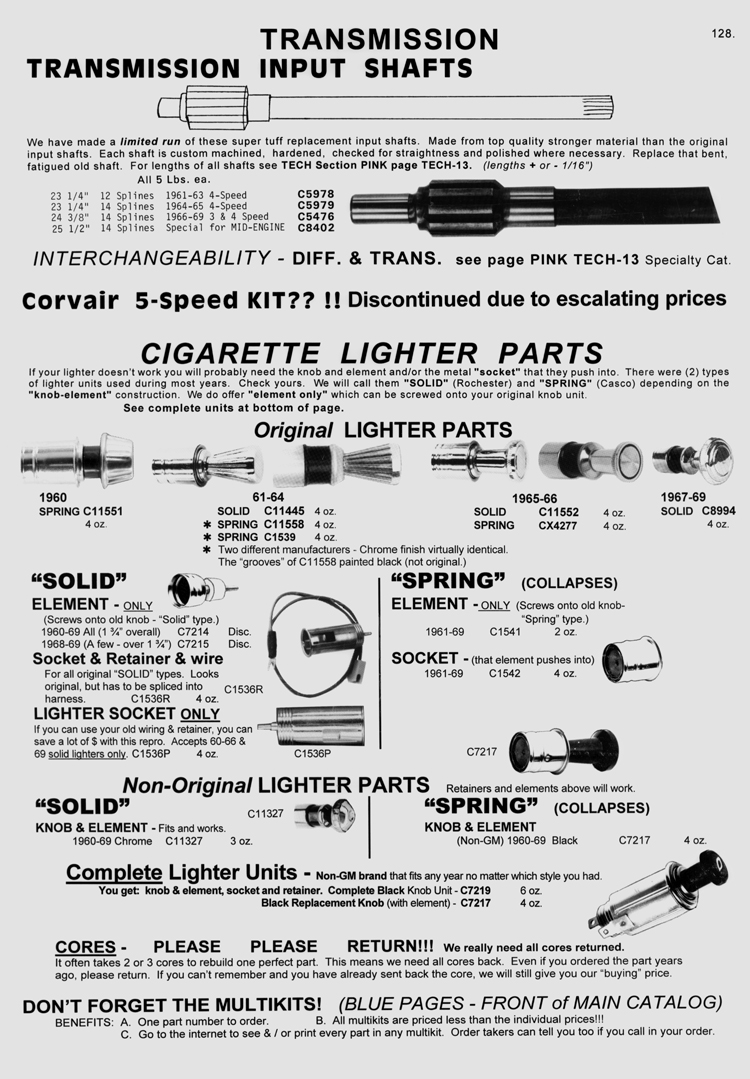

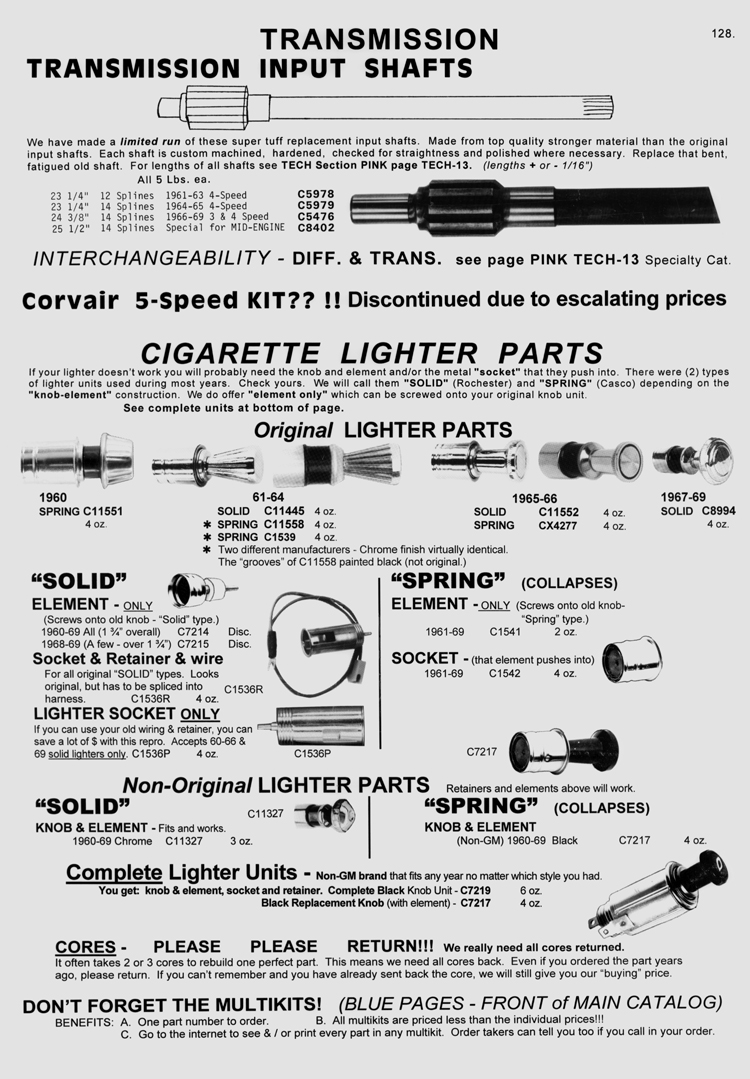

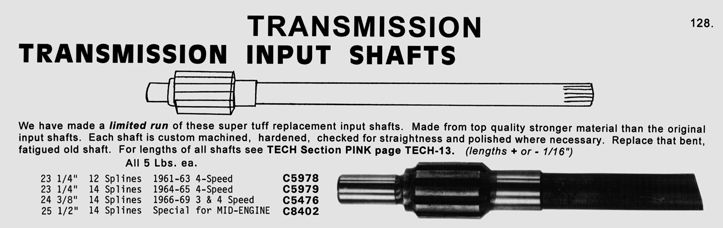

Here are some pages from the Clark's Corvair Parts online catalog. These pages explain the rattling sound you hear from your Corvair clutch. They also list several replacement part options. The last two pages illustrate the input shaft and throw out bearing shaft.

Simply click on the URL displayed above each image to go to the actual website. Clicking on any part number will display costs and availability.

http://www.corvair.com/user-cgi/catalog ... N&page=109

http://www.corvair.com/user-cgi/catalog ... N&page=110

http://www.corvair.com/user-cgi/catalog ... N&page=124

http://www.corvair.com/user-cgi/catalog ... N&page=128

From Corvair Underground http://www.corvairunderground.com/

Do the symptoms I described match the symptoms in your Corvair? Repairing a loose flywheel in your Corvair is not a small job, so you want to be absolutely certain when troubleshooting the problem that the symptoms are from a loose flywheel and not from some other source. If you perform the repair you should completely examine the clutch assembly for excess wear or other problems. The condition of the pressure plate, clutch disc, and throw out bearing should also be checked, and any worn components should be replaced. The input shaft seal should also be replaced, and the crankshaft seal should be checked for oil leaks. The throw out bearing shaft that protrudes from the differential should be carefully examined for cracks or damage, as damage to these components can occur, and the crack can result in an oil leak from the differential. If you are doing this work yourself, be very careful when separating the transaxle from the engine. The input shaft is long and may remain embedded in the clutch disc as you separate the two components. If this happens the other end of the splined input shaft may pull free from the transmission. When the two components are separated by several inches you may be able to reach between them and pull the input shaft from the clutch assembly. It is important to maintain the alignment of the engine and transaxle so that the input shaft does not act like a lever against the differential throw out bearing shaft, because such leverage against the throw out bearing shaft could potentially cause damage to the throw out bearing shaft or to the input shaft if it is bent. A damaged throw out bearing shaft can only be replaced by completely dismantling the differential.

I have attached a Chevrolet guide that explains procedures for removing the transaxle from the car. Removing the transaxle is usually done with a service station type hydraulic floor jack. I usually use a sheet of three-quarter inch plywood to protect the underside of the powertrain from the lifting surface of the floor jack. Once the powertrain has been lowered to the ground the engine can be separated from the transaxle. If you're going to do this job please review all of the procedures in the factory shop manual prior to starting the work. It is always a good idea to have one or two assistants with you to help you to carefully lower the powertrain from the car.

Here are some pages from the Clark's Corvair Parts online catalog. These pages explain the rattling sound you hear from your Corvair clutch. They also list several replacement part options. The last two pages illustrate the input shaft and throw out bearing shaft.

Simply click on the URL displayed above each image to go to the actual website. Clicking on any part number will display costs and availability.

http://www.corvair.com/user-cgi/catalog ... N&page=109

http://www.corvair.com/user-cgi/catalog ... N&page=110

http://www.corvair.com/user-cgi/catalog ... N&page=124

http://www.corvair.com/user-cgi/catalog ... N&page=128

From Corvair Underground http://www.corvairunderground.com/

Corvair Underground wrote:THE ENGINE MAKES A HORRIBLE RATTLING NOISE - yes, I realize that you think you have rod bearings going out but this is rarely the case. First, remove the fan belt and run for a short period of time. If the rattle goes away you can be pretty sure that the blower bearing is bad. That not being the case the next thing to suspect is a bad flywheel. A positive test is to let the engine idle in neutral and slightly depress the clutch pedal - if the rattle goes away or changes then you have bad rivets in your flywheel and it must be replaced with a new bolted unit Sometimes there is no rattling but a lot of vibration.

Brad Bodie

Lake Chatuge, North Carolina

1966 Corvair Corsa Convertible

1966 Corvair Corsa Convertible

Lake Chatuge, North Carolina

1966 Corvair Corsa Convertible

1966 Corvair Corsa ConvertibleRe: Flywheel noise

Good plan on replacing the flywheel. Somethings it's better to get it done right.

Jeremy (cad-kid)

Kronenwetter, WI (Central Wisconsin)

SOLD 9-2016 65 Monza 4spd/140

My 65 Monza thread

My YouTube page

My YouTube page

Kronenwetter, WI (Central Wisconsin)

SOLD 9-2016 65 Monza 4spd/140

My 65 Monza thread

-

MORTUNDEAD

- Posts: 35

- Joined: Sat Mar 23, 2013 10:48 pm

Re: Flywheel noise

Yes im sure the flywheel is the issue. Has exactly the symptoms of a loose one. Is it bad to just replace the rivets with bolts? I've seen it done before with decent results...

1962 Chevrolet Corvair Monza 4-speed 80 h.p. over a million documented miles !

- bbodie52

- Corvair of the Month

- Posts: 12140

- Joined: Mon Aug 06, 2012 12:33 pm

- Location: Lake Chatuge Hayesville, NC

- Contact:

Re: Flywheel noise

If you look at the first two pages that I posted from Clark's, you will see numerous options discussed and offered there, including stock, re-riveted, bolted, solid, and tapered bolt, as well as DIY bolt kits. As to which is best or most-economical? I could not say, since I only had to replace one loose flywheel, and that was back in 1980.

Brad Bodie

Lake Chatuge, North Carolina

1966 Corvair Corsa Convertible

1966 Corvair Corsa Convertible

Lake Chatuge, North Carolina

1966 Corvair Corsa Convertible

1966 Corvair Corsa ConvertibleRe: Flywheel noise

On mine i just took an air chisel and pushed the rivits out and put in a grade 8 bolt and red locktight and prick punched the ends, do this one rivit at a time and you should be good, unless the holes are elongated

Drive it like you stole it

65 Turbo Monza Coupe

64 monza convertible 4 spd

Grand Ledge, Michigan

65 Turbo Monza Coupe

64 monza convertible 4 spd

Grand Ledge, Michigan

Re: Flywheel noise

If you are trying to save some money and you have the time , go ahead and try it .Is it bad to just replace the rivets with bolts? I've seen it done before with decent results...

Not really much to lose except time if you have to redo it.

- Attachments

-

- aa05824.jpg (53.12 KiB) Viewed 3373 times

Kevin Willson

1965 Monza 3.1

Juneau Alaska

1965 Monza 3.1

Juneau Alaska

-

BobFarrell

- Posts: 12

- Joined: Tue Jul 01, 2014 7:16 pm

- Location: Goodyear, AZ

Re: Flywheel noise

I am afraid I may have a similar issue but would like confirmation from the experts before I begin the repair process.

My fan belt broke (unbeknownst to me) and I suspect I drove between 10-20 miles this way before getting home. I changed the oil (as it smelt burnt) an installed a new belt. Upon my next start-up, I heard a terrible rattle that is only there upon idle. With some gas, it goes away. Obviously, this is something I want to correct before placing any additional miles on the car.

I disconnected the fan belt to see if it was the fan bearing. No such luck as the noise is still there. My issue with the explanation for the others is that my car is an automatic. Therefore I do not have a manual clutch. Any recommendations on a 62 Convertible automatic (with a 65 engine)???

Thanks!

Bob

Goodyear, AZ

My fan belt broke (unbeknownst to me) and I suspect I drove between 10-20 miles this way before getting home. I changed the oil (as it smelt burnt) an installed a new belt. Upon my next start-up, I heard a terrible rattle that is only there upon idle. With some gas, it goes away. Obviously, this is something I want to correct before placing any additional miles on the car.

I disconnected the fan belt to see if it was the fan bearing. No such luck as the noise is still there. My issue with the explanation for the others is that my car is an automatic. Therefore I do not have a manual clutch. Any recommendations on a 62 Convertible automatic (with a 65 engine)???

Thanks!

Bob

Goodyear, AZ

- Grandpacorvair

- Posts: 111

- Joined: Fri Apr 06, 2012 5:39 pm

Re: Flywheel noise

Have you had any luck with this?

IF it weren't for the 10-20 mile drive with no belt and the resultant burnt oil smell, the sound you are hearing MIGHT be a broken flex plate..

However given the circumstances I suspect you may have done some significant damage to the engine...A compression test MIGHT give a hint as to the engines present condition but a tear down may be the best way to go....

Best of luck,

Kerry

IF it weren't for the 10-20 mile drive with no belt and the resultant burnt oil smell, the sound you are hearing MIGHT be a broken flex plate..

However given the circumstances I suspect you may have done some significant damage to the engine...A compression test MIGHT give a hint as to the engines present condition but a tear down may be the best way to go....

Best of luck,

Kerry

Kerry Borgne

1963 Spyder Convertible

Birmingham, Michigan

1963 Spyder Convertible

Birmingham, Michigan

-

BobFarrell

- Posts: 12

- Joined: Tue Jul 01, 2014 7:16 pm

- Location: Goodyear, AZ

Re: Flywheel noise

Thanks. However as stated above, the issue with the noise was 2 loose bolts on the flywheel and accessed by removing the rear engine shroud. Upon tightening these bolts, the noise disappeared.

I was concerned about possible engine damage. I checked compression (as you also recommended). There was no significant difference in any cylinder.

I am absolutely certain I was VERY lucky in this circumstance.....

Thanks for your suggestions and participation on this site.

Bob

I was concerned about possible engine damage. I checked compression (as you also recommended). There was no significant difference in any cylinder.

I am absolutely certain I was VERY lucky in this circumstance.....

Thanks for your suggestions and participation on this site.

Bob

Re: Flywheel noise

This might be confusing to anyone new to Corvairs so I'm replying in order to clarify since there are two different noise problems presented within this thread (Manual vs. Automatic)BobFarrell wrote:Thanks. However as stated above, the issue with the noise was 2 loose bolts on the flywheel and accessed by removing the rear engine shroud. Upon tightening these bolts, the noise disappeared.

Bob,

More correctly it sounds like you fixed the problem by tightening two of the three bolts that connnect the flex plate to the torque converter. An automatic does not have a flywheel so the solutions offered above to MORTUNDEAD about fixing flywheels with hot rivets or special bolt sets do not apply to anyone with a flexplate.

How about the original poster (MORTUNDEAD) in this thread? Did you get your flywheel problem fixed? I dropped the power pack in my 65 Corsa yesterday because of this same issue. It still has the original flywheel and rattles like mad when the clutch is not depressed and is really noisy when the clutch is out with the tranny in neutral. I've got a new (old) Dale repair flywheel ready to install.

Dave W. from Gilbert, AZ

66 Corsa 140/4 Yenko Stinger Tribute

66 Corsa 140 Coupe w/factory A/C

65 Monza 4DR 140/PG w/factory A/C

65 Monza 4DR EJ20T/5

64 Greenbrier 110/PG, Standard 6-Door

66 Corsa 140/4 Yenko Stinger Tribute

66 Corsa 140 Coupe w/factory A/C

65 Monza 4DR 140/PG w/factory A/C

65 Monza 4DR EJ20T/5

64 Greenbrier 110/PG, Standard 6-Door

Re: Flywheel noise

I have a post on here somewhere, basically I had all the bad flywheel and clutch symptoms. I looked at parts piece by piece, but my end goal was to put some miles on this car. In the end I went ahead and ordered Clarks deluxe kit. Seems pricey, but you get directions with all the tips and tricks attached to each piece and they give you money for your old parts. The best part is all the parts are there and go together with no hassle, and my car has been trouble free in that department for 7200 miles. If you want to do it o ce that is the investment I would make.

- bbodie52

- Corvair of the Month

- Posts: 12140

- Joined: Mon Aug 06, 2012 12:33 pm

- Location: Lake Chatuge Hayesville, NC

- Contact:

Re: Flywheel noise

When replacing your clutch, I would caution you to be careful when separating the engine from the transaxle.

The problem with the manual transaxle is that the long input shaft (23-24 inches) tends to remain embedded in the pilot bushing and clutch disc, while the other (smaller) end of the splined shaft pulls free from the transmission. As the two heavy components separate, any misalignment that is permitted risks leverage being applied by the input shaft against the throwout bearing shaft, which can fracture this machined casting. Replacing a damaged throwout bearing shaft requires dismantling the differential.

The problem with the manual transaxle is that the long input shaft (23-24 inches) tends to remain embedded in the pilot bushing and clutch disc, while the other (smaller) end of the splined shaft pulls free from the transmission. As the two heavy components separate, any misalignment that is permitted risks leverage being applied by the input shaft against the throwout bearing shaft, which can fracture this machined casting. Replacing a damaged throwout bearing shaft requires dismantling the differential.

Even if you remove the powertrain as an assembly, use caution when separating the heavy transaxle from the engine. If the input shaft remains embedded in the clutch, you must pull the transaxle straight back about 24 inches until the other end clears the transaxle. If you have an assistant, the assistant may be able to reach between the differential face and the bell housing to grab the input shaft and pull it free from the clutch assembly — reducing the risk of damaging the input shaft, clutch disc, or throwout bearing shaft.

With the engine and transaxle separated, be sure to inspect the throwout bearing shaft completely for cracks or fractures. The input shaft seal should be replaced when doing a clutch job, to ensure that no gear lube will leak onto the clutch assembly during operation. Also, when prying the input shaft retaining ring and seal out, be careful not to apply levarage against the end of the throwout bearing shaft, as excess leverage with a screwdriver or similar tool could conceivably cause a crack to form on the throwout bearing shaft.

Even if you remove the powertrain as an assembly, use caution when separating the heavy transaxle from the engine. If the input shaft remains embedded in the clutch, you must pull the transaxle straight back about 24 inches until the other end clears the transaxle. If you have an assistant, the assistant may be able to reach between the differential face and the bell housing to grab the input shaft and pull it free from the clutch assembly — reducing the risk of damaging the input shaft, clutch disc, or throwout bearing shaft.

With the engine and transaxle separated, be sure to inspect the throwout bearing shaft completely for cracks or fractures. The input shaft seal should be replaced when doing a clutch job, to ensure that no gear lube will leak onto the clutch assembly during operation. Also, when prying the input shaft retaining ring and seal out, be careful not to apply levarage against the end of the throwout bearing shaft, as excess leverage with a screwdriver or similar tool could conceivably cause a crack to form on the throwout bearing shaft.

Brad Bodie

Lake Chatuge, North Carolina

1966 Corvair Corsa Convertible

1966 Corvair Corsa Convertible

Lake Chatuge, North Carolina

1966 Corvair Corsa Convertible

1966 Corvair Corsa ConvertibleRe: Flywheel noise

I ran a broken snout (chunk missing) for years and never knew it. The seal and retainer inside was still in place and I had no clue it was broken until I did a clutch job years later. I suspect the previous owner was the culprit as I never found the missing chunk when I took it all apart. I guess they took the risk that it would be okay and put it back together that way. Seems they got away with it too.bbodie52 wrote:When replacing your clutch, I would caution you to be careful when separating the engine from the transaxle.

Dave W. from Gilbert, AZ

66 Corsa 140/4 Yenko Stinger Tribute

66 Corsa 140 Coupe w/factory A/C

65 Monza 4DR 140/PG w/factory A/C

65 Monza 4DR EJ20T/5

64 Greenbrier 110/PG, Standard 6-Door

66 Corsa 140/4 Yenko Stinger Tribute

66 Corsa 140 Coupe w/factory A/C

65 Monza 4DR 140/PG w/factory A/C

65 Monza 4DR EJ20T/5

64 Greenbrier 110/PG, Standard 6-Door