67 engine dies when warm

67 engine dies when warm

Hey community,

after starting my 67 corvair it runs pretty good. However, after ~2min when warmed up a bit, the engine slows down and finally dies.

I checked so far:

Ignition (changed to FAST); Coil, Spark plugs and cables changed.

Fuel pump changed to electric pump (Airtex) and after the engine dies, the accelerator pump still works fine, so I guess fuel is no problem.

Tank vantilation is also tested. Carbs are rebuild by Wolf enterprises. No vacuum leaks.

I really cant come up with any explanation, why the engine runs so good when cold, but stops working when warm..

I would be extremely thankful for any advice. Maybe someone already had this problem.

Best,

Martin

after starting my 67 corvair it runs pretty good. However, after ~2min when warmed up a bit, the engine slows down and finally dies.

I checked so far:

Ignition (changed to FAST); Coil, Spark plugs and cables changed.

Fuel pump changed to electric pump (Airtex) and after the engine dies, the accelerator pump still works fine, so I guess fuel is no problem.

Tank vantilation is also tested. Carbs are rebuild by Wolf enterprises. No vacuum leaks.

I really cant come up with any explanation, why the engine runs so good when cold, but stops working when warm..

I would be extremely thankful for any advice. Maybe someone already had this problem.

Best,

Martin

Re: 67 engine dies when warm

Does it start back up? or crank and not start? Is this a new problem, or since all the work was done? This could be as simple as a carb idle adjustment, or it could be something else. More info needed. Dennis

Re: 67 engine dies when warm

That's a tough one, but usually it's fuel or ignition.You didn't mention if the engine runs with the chokes closed, but won't idle when the chokes are open. The choke has a fast idle cam and when the choke opens the throttle lever rests on the adjustable stop. First I'd try to adjust the idle speed with the choke off. You didn't mention if your car is an automatic or manual transmission. The other issue is the timing. It has to be set to spec. AT THE CORRECT ENGINE IDLE SPEED. I find Corvairs that won't idle or have little power due to the static timing being too retarded because the static timing was adjusted at a high RPM that caused the centrifugal advance to advance the timing. Depending on the year, engine, transmission the timing specification requires an RPM below were it starts to advance.Martin wrote: ↑Sat Mar 18, 2023 2:52 pm Hey community,

after starting my 67 corvair it runs pretty good. However, after ~2min when warmed up a bit, the engine slows down and finally dies.

I checked so far:

Ignition (changed to FAST); Coil, Spark plugs and cables changed.

Fuel pump changed to electric pump (Airtex) and after the engine dies, the accelerator pump still works fine, so I guess fuel is no problem.

Tank vantilation is also tested. Carbs are rebuild by Wolf enterprises. No vacuum leaks.

I really cant come up with any explanation, why the engine runs so good when cold, but stops working when warm..

I would be extremely thankful for any advice. Maybe someone already had this problem.

Best,

Martin

That's a start. There could be other issues.

Re: 67 engine dies when warm

Hey both thanks for your input. First, I forgit to mention, that its an automatic transmission.

If the engine is warm, it wont run anymore until its cold.

When the engine runs, the chokes are closed when it dies, they are ~40-50% open.

The idle adjustment on the carbs was done exactly like its stated in the shop manual. Regarding the timing, this could be a problem here but I tried a lot. Since the engine wont run with low idle, its hard to set the timing like that. I tried to initially set it it to TDC and than checkt with a light by using the starter. Through this, the engine rund pretty good the first minutes and changing the timing here will lead to worse idle.

What could be a problem with the fuel? Since the accelerator pumps work fine after the engne stops, I would say this means that I have enough fuel during the run as well.

I hope this gives more information to you.

Best,

Martin

If the engine is warm, it wont run anymore until its cold.

When the engine runs, the chokes are closed when it dies, they are ~40-50% open.

The idle adjustment on the carbs was done exactly like its stated in the shop manual. Regarding the timing, this could be a problem here but I tried a lot. Since the engine wont run with low idle, its hard to set the timing like that. I tried to initially set it it to TDC and than checkt with a light by using the starter. Through this, the engine rund pretty good the first minutes and changing the timing here will lead to worse idle.

What could be a problem with the fuel? Since the accelerator pumps work fine after the engne stops, I would say this means that I have enough fuel during the run as well.

I hope this gives more information to you.

Best,

Martin

Re: 67 engine dies when warm

Much better description of your problem. What you're going to have to do is run it until it quits. Get an extra spark plug or a spark tester, and see if you have spark after it dies (my guess is you won't have spark). If it turns out to be an ignition issue, trouble shooting will have to proceed from there. I had to look up the FAST ignition system (another electronic conversion). Did you do the conversion? Do you still have the installation instructions? Ignitions can be temperature sensitive. This can come from engine compartment temperature, and it can come from internal temperature from the components themselves. Hopefully, we'll get it all sorted out. Dennis

Re: 67 engine dies when warm

Great instructions. Need to know the FAST model, but most likely it requires the Corvair inline wire ballast and stock coil, or a combo that is at least 3 ohms. Otherwise the FAST will overheat. If the ignition is fine, then let us know -- I know of another issue with the 66-67 carburetors, but for now -- one thing at a time. Check for ignition spark, BUT DO NOT remove the spark plug wires while the engine is running, that will damage the FAST unit.Dennis66 wrote: ↑Sun Mar 19, 2023 4:40 am Much better description of your problem. What you're going to have to do is run it until it quits. Get an extra spark plug or a spark tester, and see if you have spark after it dies (my guess is you won't have spark). If it turns out to be an ignition issue, trouble shooting will have to proceed from there. I had to look up the FAST ignition system (another electronic conversion). Did you do the conversion? Do you still have the installation instructions? Ignitions can be temperature sensitive. This can come from engine compartment temperature, and it can come from internal temperature from the components themselves. Hopefully, we'll get it all sorted out. Dennis

Re: 67 engine dies when warm

Thanks a lot both! Really good description.

Just a quick add on the history. My fuel pump leaked fuel into the engine, therefore I switched to an electrical pump and this forum recommended the Airtex pump. To exclude, that my points are the reason for engine failure, I swapped to an electric ignition system and the FAST was also recommended in this forum. That also means that the problem was also present when I had a points system. However, I will still try your suggestion.

Regarding the cable ballast I have already read that there is a 3 Ohm resistance in the cable. Is there any way I can measure this? The reason is that my corvair had a new cable harness when I got it. Maybe the resistance is wrong? Could this be a reason?

The box of the FAST ignition is currently outside the engine bay so overheating could only come from the FAST itself.

Just a quick add on the history. My fuel pump leaked fuel into the engine, therefore I switched to an electrical pump and this forum recommended the Airtex pump. To exclude, that my points are the reason for engine failure, I swapped to an electric ignition system and the FAST was also recommended in this forum. That also means that the problem was also present when I had a points system. However, I will still try your suggestion.

Regarding the cable ballast I have already read that there is a 3 Ohm resistance in the cable. Is there any way I can measure this? The reason is that my corvair had a new cable harness when I got it. Maybe the resistance is wrong? Could this be a reason?

The box of the FAST ignition is currently outside the engine bay so overheating could only come from the FAST itself.

Re: 67 engine dies when warm

It sounds like you eliminated the ignition as an issue. The Corvair (and most Chevies of the era) use a 1.8 ohm ballast wire and the coil was about 1.3 ohms for a total of about 3.1 ohms. The FAST requires a minimum of 3.0 ohms per instructions on most of their units.Martin wrote: ↑Sun Mar 19, 2023 10:40 am Thanks a lot both! Really good description.

Just a quick add on the history. My fuel pump leaked fuel into the engine, therefore I switched to an electrical pump and this forum recommended the Airtex pump. To exclude, that my points are the reason for engine failure, I swapped to an electric ignition system and the FAST was also recommended in this forum. That also means that the problem was also present when I had a points system. However, I will still try your suggestion.

Regarding the cable ballast I have already read that there is a 3 Ohm resistance in the cable. Is there any way I can measure this? The reason is that my corvair had a new cable harness when I got it. Maybe the resistance is wrong? Could this be a reason?

The box of the FAST ignition is currently outside the engine bay so overheating could only come from the FAST itself.

How to check the ballast wire? Most affordable meters cannot accurately measure less than10 ohms. Without an oscilliscope you can't check the stepping voltage with the engine running.

There is a simple test. Remove the wire from the distributor to the coil "-" terminal. Connect a DMM (Digital multi meter or any volt meter) to the coil "+" terminal and turn on the ignition key (DON'T START THE ENGINE). The DMM should read battery voltage - about 12.4 - 13.0 VDC. Next - BRIEFLY connect the coil "-" terminal to ground and the DMM should read 5-6VDC. That indicates electrical current through the ballast wire to the coil results in a voltage drop from about 12.5 to about 5.5 VDC. If the voltage does not drop, or very little, then the ballast wire has been by-passed, or the coil resistance is incorrect. If all is well, then post here and I'll write up how to check the INFAMOUS 66-67 idle circuit for a problem. Also why I use model year 1965 carburetors on my 66 cars.

Re: 67 engine dies when warm

NOTE: AirTex sold out to some offshore company in Asia and they replaced the AirTex pump with a unit folks are complaining about (still uses the same AirTex part number, but it is NOT the old AirTex pump many of us used).

I would check the fuel pressure. The manual spec. is 4 to 5 PSI. If the pump is an issue. I have the Facet pump number that many have used on Corvairs and claim it is a good unit without issues.

- terribleted

- Posts: 4584

- Joined: Sun Apr 18, 2010 2:36 pm

- Location: Atlanta, GA

- Contact:

Re: 67 engine dies when warm

Sounds like possibly the idle speed when warm is simply too low to keep the engine running. How fast is the idle speed when the chokes are on and it is cold? Should be between say 1500 and 2250RPM maybe. I might try turning up the idle speed pretty high to see if the engine will run once the chokes come off. Are you sure both carbs are operating at idle. Just because they are rebuilt does not mean they are working correctly. If you cover the top of each carb in turn they should suck your hand down with equal force. If not the one with no or a lot less force likely has an issue (maybe a plugged idle circuit). Have the carbs been properly balanced? Balancing the carbs to each other is necessary for proper operation. It is possible that if they have not been balanced that one could have so little idle speed vs the other that it is not contributing to the engine running at idle. This would present as the same symptom as a plugged idle circuit like I mentioned above. To me it sounds like a tuning issue or a carb fault as long as spark and fuel are present.

Corvair guy since 1982. I have personally restored at least 20 Vairs, many of them restored ground up.

Currently working full time repairing Corvairs and restoring old cars.

https://www.facebook.com/tedsautorestoration/

Located in Snellville, Georgia

Currently working full time repairing Corvairs and restoring old cars.

https://www.facebook.com/tedsautorestoration/

Located in Snellville, Georgia

Re: 67 engine dies when warm

Martin -- you didn't mention if the car won't idle in neutral, or if it quits when you put it in drive.

The RPM should be set for about 900 RPM in neutral or it will stall when you put it in Drive.

The RPM should be set for about 900 RPM in neutral or it will stall when you put it in Drive.

- bbodie52

- Corvair of the Month

- Posts: 11947

- Joined: Mon Aug 06, 2012 12:33 pm

- Location: Lake Chatuge Hayesville, NC

- Contact:

Re: 67 engine dies when warm

The final conclusions above are probably correct. Your car idles when cold because it is still idling using the choke fast-idle cam. When the engine warms up, the choke disengages and the fast-idle cam no longer is in operation. Your normal idle speed screws are set too low. The engine idles in Neutral, but stalls when loaded with the transmission in DRIVE. You must increase the idle speed setting on each carburetor to support the engine when loaded by the Powerglide torque converter when in DRIVE or REVERSE.

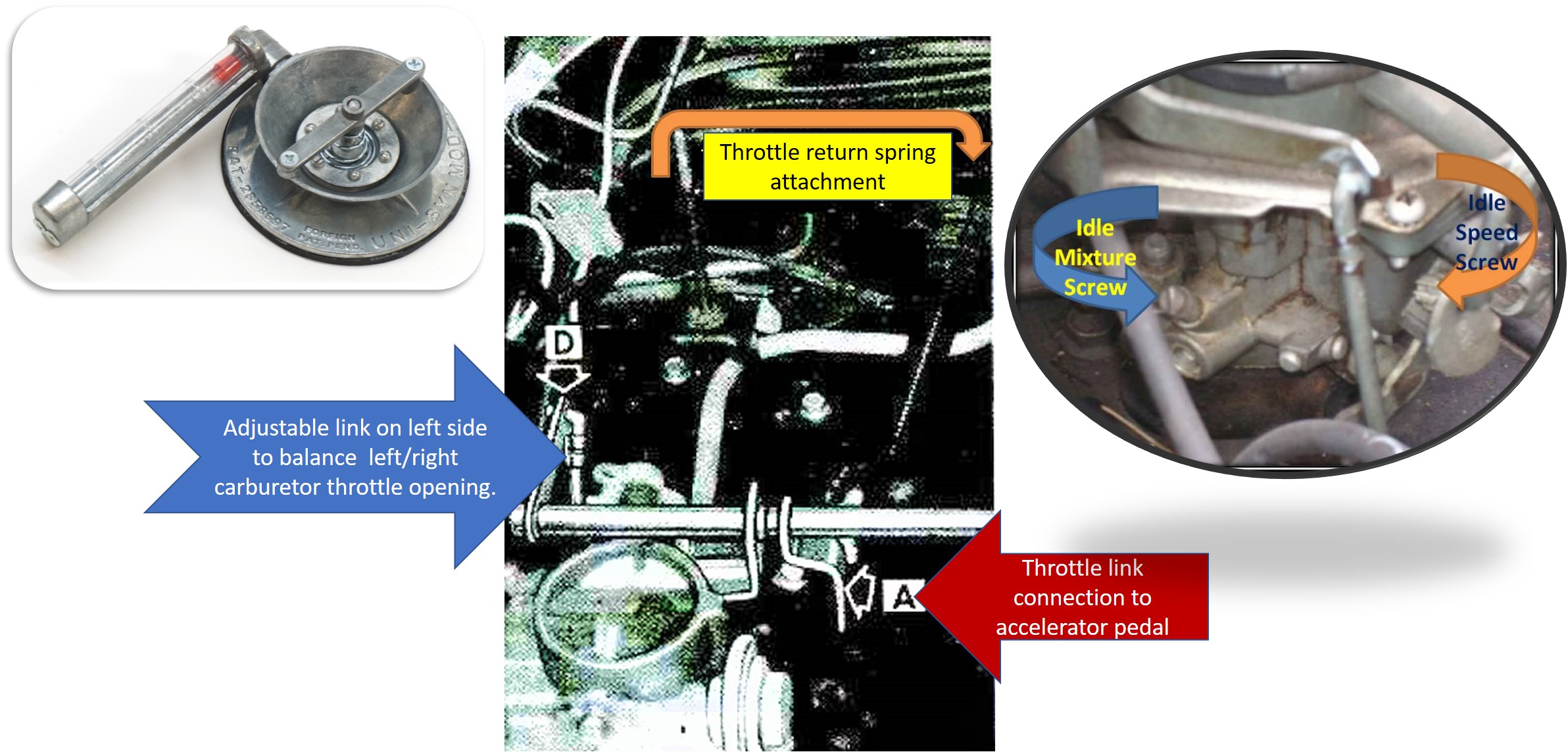

With a twin carburetor set up, disconnect the linkage that connects one carburetor to the other. Set the idle speed with the linkage screws first. Use the Uni-Syn to check that each carburetor is drawing equally at idle. This may take a few tries until you get both drawing equally at the speed you want. Blip the throttle to see if they come back to those settings (worn throttle shafts can fool you). Set the idle mixture screws in accordance with the shop manual instructions. Check the balance again. Hook the linkage back up. If one carburetor now draws more, adjust the linkage until it's back to roughly equal.

Once the carburetors are drawing equally at idle, hold an engine speed: at about 1500 RPM. This checks that the mechanical linkage is pulling equally. You'll need to open up the Uni-Syn center wheel to draw more air and bring the bead down in the tube. If both carburetors are within a bead's thickness of each other, that's good. If one is definitely off from the other, the higher flow carburetor's linkage is being pulled more than the other. You'll need to figure out why that's happening mechanically to rectify it.

With a twin carburetor set up, disconnect the linkage that connects one carburetor to the other. Set the idle speed with the linkage screws first. Use the Uni-Syn to check that each carburetor is drawing equally at idle. This may take a few tries until you get both drawing equally at the speed you want. Blip the throttle to see if they come back to those settings (worn throttle shafts can fool you). Set the idle mixture screws in accordance with the shop manual instructions. Check the balance again. Hook the linkage back up. If one carburetor now draws more, adjust the linkage until it's back to roughly equal.

Once the carburetors are drawing equally at idle, hold an engine speed: at about 1500 RPM. This checks that the mechanical linkage is pulling equally. You'll need to open up the Uni-Syn center wheel to draw more air and bring the bead down in the tube. If both carburetors are within a bead's thickness of each other, that's good. If one is definitely off from the other, the higher flow carburetor's linkage is being pulled more than the other. You'll need to figure out why that's happening mechanically to rectify it.

Brad Bodie

Lake Chatuge, North Carolina

1966 Corvair Corsa Convertible

1966 Corvair Corsa Convertible

Lake Chatuge, North Carolina

1966 Corvair Corsa Convertible

1966 Corvair Corsa ConvertibleRe: 67 engine dies when warm

Do tell, I'm rebuilding a '66 AFAIK carb now. I recently discovered that I had mismatched primaries, only one had the '66 upper idle air bleed that Larry Claypool described in his great carb video. I found another '66 base in my pile o' parts so I'm cleaning that out.

Related, the PEV was stuck, even after soaking in carb cleaner overnight. Just varnished in place by old gas. I was able to pull it out using a #20 drill bit (0.161") as an extractor, going slowly & carefully by hand. Sharp-eyed viewers will notice that the base pictured was bored out by previous owner.

So the other carb without an upper idle air bleed is a '65?

Re: 67 engine dies when warm

First -- let me make it clear that the 66 model year carburetor works fine IF the idle circuit is in good shape.erco wrote: ↑Tue Mar 21, 2023 12:42 pmDo tell, I'm rebuilding a '66 AFAIK carb now. I recently discovered that I had mismatched primaries, only one had the '66 upper idle air bleed that Larry Claypool described in his great carb video. I found another '66 base in my pile o' parts so I'm cleaning that out.

Related, the PEV was stuck, even after soaking in carb cleaner overnight. Just varnished in place by old gas. I was able to pull it out using a #20 drill bit (0.161") as an extractor, going slowly & carefully by hand. Sharp-eyed viewers will notice that the base pictured was bored out by previous owner.

So the other carb without an upper idle air bleed is a '65?

As noted in Bob Helt's Rochester book the model year 66 carburetors have a revised cluster idle jet hole and an additional hole in the carburetor throat ABOVE the idle transition slot (the transition slot is above the idle mixture screw hole). This design produces an emulsion that results in a more uniform gasoline spray from the idle mixture hole for a smoother idle with a leaner adjustment. Good for emissions, spark plugs, and the engine.

So what's the problem? I've rebuilt a few 66 carburetors that would NOT hold a steady idle. After consulting with a few knowledgeable folks we discovered the inner body idle passages from the cluster to the idle mixture screw hole were CORRODED. No amount of cleaning would smooth the passages and we concluded this seems to upset the idle circuit mixture. Now if you are thinking you can remove the plugs from the original passages and just drill bigger passages to get rid of the pitting --- well I've been told by the knowledgeable folks NO! It seems the passage size is critical. Note the 65 carburetors (without the extra air bleed hole above the idle transition slot) can have this corrosion problem, but unless it is severe, it doesn't seem to be an issue. This has resulted in a demand for the 65 carburetor to replace the 66 and newer carburetors.

As for you PEV needle valve. Make sure the needle tip and seat in the carburetor are smooth. Some have reported that if the needle valve does not seat well, then you get dribbling from the main cluster at idle - and yes they lowered the float bowl fuel level per Bob Helt's recommendation which did NOT fix the dribble issue. To verify the plugged up the PEV circuit and the cluster stopped dribbling.

Conclusion --- crusty and corroded carburetors are probably not good candidates for rebuilding.

Re: 67 engine dies when warm

Thanks for that info. No corrosion on this base, just some varnish buildup which comes off with some elbow grease. I have a variety of tiny wires to probe passages and no clogging found.

I'm using a new gallon soak can w/parts basket of GUNK carb cleaner. Much different than 20 years ago, oilier and greener I suppose. Doesn't evaporate much at all, fewer aromatics. Works more slowly than the old stuff, which would dissolve anything (fingers included) in a matter of minutes.

I'm using Evaporust on steel parts, which also works slowly but does a great job of removing surface rust from throttle & choke plates, levers and screws.

I'm using a new gallon soak can w/parts basket of GUNK carb cleaner. Much different than 20 years ago, oilier and greener I suppose. Doesn't evaporate much at all, fewer aromatics. Works more slowly than the old stuff, which would dissolve anything (fingers included) in a matter of minutes.

I'm using Evaporust on steel parts, which also works slowly but does a great job of removing surface rust from throttle & choke plates, levers and screws.

Re: 67 engine dies when warm

The OLD carburetor cleaner was effective, although it could ruin a carburetor if you left it in the solution for too long. Also it could burn you skin!erco wrote: ↑Tue Mar 21, 2023 2:51 pm Thanks for that info. No corrosion on this base, just some varnish buildup which comes off with some elbow grease. I have a variety of tiny wires to probe passages and no clogging found.

I'm using a new gallon soak can w/parts basket of GUNK carb cleaner. Much different than 20 years ago, oilier and greener I suppose. Doesn't evaporate much at all, fewer aromatics. Works more slowly than the old stuff, which would dissolve anything (fingers included) in a matter of minutes.

I'm using Evaporust on steel parts, which also works slowly but does a great job of removing surface rust from throttle & choke plates, levers and screws.

Years ago a few folks suggested using blasting soda on carburetors (or aluminum and pot metal). It removes all the crud without damaging the metal. Then to get all the soda out of the passages I use Simple Green as it doesn't doesn't discolor aluminum, pot metal, or magnesium IF you don't soak the metal for too long.