Oil puke out dipstick

Oil puke out dipstick

Car: 1963 Turbo

Issue: Oil spewing out dipstick tube (I think).

My 63 Turbo was bought with unknown history and unknown true mileage. It ran OK, but felt tired. Brakes were shot, now replaced and upgraded to dual master. I decided to help the motor out a little. First came electronic ignition from Clarks, the one recommended for turbo motors. Huge difference, ran smoother and stronger. But at full throttle near redline only had a couple pounds boost showing, so I decided to get a rebuilt carb and turbo from a well known rebuilder, in fact the turbo has 150 inlet but 180 outlet so it will spool up faster. The exhaust also looked almost ready to rust through so I got all new exhaust including manifolds because the old ones were very crusty.

After the test drive post ignition install, I noticed quite a bit of oil on the top shroud. It looked like it mostly had come out the dipstick tube. I was taking the whole intake and exhaust off anyway so I took off the top shroud. The crankcase vent tube was very loose with no o-ring where it enters the top case. I put a proper fit on o-ring on it and the clamp held it very well. I put the whole new exhaust, including new cooling door thermostats, and new (rebuilt) intake on and while I had a bit of trouble lining up the turbo outlet to the intake inlet, asfter doing as the shop manual suggests, loosening the band on the turbo and lining those up first, then tightening everything down, I got all the parts fitted and it didntvappear there would be any leaks.

I test started the motor and it started and ran fine, indeed no leaks, oil or gas. I also added a advance/retard module to the distributor and retuned the motor at 18 degrees at idle per Clark’s.

I took the car out for a test drive and noticed great vacuum at low rpm, but at high rpm, near redline, zero on the gauge, no apparent boost. I thought the rebuilt turbo may be bad, and started for home. Partway home the motor started to idle rough, and oil pressure light started to come on at idle, but I thought it might be that the idle stop needed adjustment so used my right heel to keep the motor running at stops. I began to smell oil burning and saw white smoke out the right side vents. I was nearly home so continued. Cylinder head temp was approaching 500. When I got home to my shop oil smoke was drifting up through the right side hood vents. I opened the hood and there was a large amount of oil all over the right side of the top shroud, and much of it really seemed to have come from the dipstick tube.

I mentioned this to a tech and he said I may have a bad cylinder, so the turbo really couldn’t turbo, all the pressure would leak past the bad cylinder and pressurize the crankcase which would cause the crankcase vent to be overwhelmed and oil out the dipstick tube. He suggested a compression check.

Here is what I have:

1-130, 2-128, 3-127, 4-125, 5-117, 6-133.

Crankcase vent is clear and patent.

Turbo oil drain is clear and patent.

Cooling flapper doors open via thermostats correctly.

So what is causing this oil to push out the dipstick? Or could it be coming up somewhere else that can get the top shroud full of oil including the dipstick rubber boot?

What else causes increased crankcase pressure? Could the one low cylinder (117) be the leak? 117 doesn’t seem that bad to me.

Why is the car running hotter than it used to? Does the electronic ignition giv e that much hotter of a spark?

Why doesn’t the turbo charge?

Thanks in advance for the help!

Issue: Oil spewing out dipstick tube (I think).

My 63 Turbo was bought with unknown history and unknown true mileage. It ran OK, but felt tired. Brakes were shot, now replaced and upgraded to dual master. I decided to help the motor out a little. First came electronic ignition from Clarks, the one recommended for turbo motors. Huge difference, ran smoother and stronger. But at full throttle near redline only had a couple pounds boost showing, so I decided to get a rebuilt carb and turbo from a well known rebuilder, in fact the turbo has 150 inlet but 180 outlet so it will spool up faster. The exhaust also looked almost ready to rust through so I got all new exhaust including manifolds because the old ones were very crusty.

After the test drive post ignition install, I noticed quite a bit of oil on the top shroud. It looked like it mostly had come out the dipstick tube. I was taking the whole intake and exhaust off anyway so I took off the top shroud. The crankcase vent tube was very loose with no o-ring where it enters the top case. I put a proper fit on o-ring on it and the clamp held it very well. I put the whole new exhaust, including new cooling door thermostats, and new (rebuilt) intake on and while I had a bit of trouble lining up the turbo outlet to the intake inlet, asfter doing as the shop manual suggests, loosening the band on the turbo and lining those up first, then tightening everything down, I got all the parts fitted and it didntvappear there would be any leaks.

I test started the motor and it started and ran fine, indeed no leaks, oil or gas. I also added a advance/retard module to the distributor and retuned the motor at 18 degrees at idle per Clark’s.

I took the car out for a test drive and noticed great vacuum at low rpm, but at high rpm, near redline, zero on the gauge, no apparent boost. I thought the rebuilt turbo may be bad, and started for home. Partway home the motor started to idle rough, and oil pressure light started to come on at idle, but I thought it might be that the idle stop needed adjustment so used my right heel to keep the motor running at stops. I began to smell oil burning and saw white smoke out the right side vents. I was nearly home so continued. Cylinder head temp was approaching 500. When I got home to my shop oil smoke was drifting up through the right side hood vents. I opened the hood and there was a large amount of oil all over the right side of the top shroud, and much of it really seemed to have come from the dipstick tube.

I mentioned this to a tech and he said I may have a bad cylinder, so the turbo really couldn’t turbo, all the pressure would leak past the bad cylinder and pressurize the crankcase which would cause the crankcase vent to be overwhelmed and oil out the dipstick tube. He suggested a compression check.

Here is what I have:

1-130, 2-128, 3-127, 4-125, 5-117, 6-133.

Crankcase vent is clear and patent.

Turbo oil drain is clear and patent.

Cooling flapper doors open via thermostats correctly.

So what is causing this oil to push out the dipstick? Or could it be coming up somewhere else that can get the top shroud full of oil including the dipstick rubber boot?

What else causes increased crankcase pressure? Could the one low cylinder (117) be the leak? 117 doesn’t seem that bad to me.

Why is the car running hotter than it used to? Does the electronic ignition giv e that much hotter of a spark?

Why doesn’t the turbo charge?

Thanks in advance for the help!

Re: Oil puke out dipstick

One more thing to add: the plugs I use are AC 44 FF, and all 6 are burning very light mocha color, no oil on the plugs.

Should I use a colder plug?

Should I use a colder plug?

-

joelsplace

- Posts: 2118

- Joined: Wed Oct 13, 2010 12:51 pm

- Location: Northlake, TX

Re: Oil puke out dipstick

Some engines tend to push oil up the dipstick tube from what I've read. I've never had one do it. I've heard various fixes from pulling the tube out and cutting it shorter to drilling a hole in the side of it just after it enters the crankcase.

Are you sure it's getting hot? Maybe it's just oil burning from being leaked all over?

Turbo engines are really picky about exhaust leaks. If you have leaks it won't boost.

Overheating can be caused by various things but a hot spark is not one of them. It can be caused by blocked cooling fins on the heads, cylinders or oil cooler. The head castings were pretty sloppy so you'll need to de-flash them if it hasn't already been done.

I wouldn't worry about the plugs just yet. When you get it boosting you may need to go to some colder plugs but not before. Hot plugs will make it detonate which will cause overheating but if it isn't pinging then you aren't there yet.

Are you sure it's getting hot? Maybe it's just oil burning from being leaked all over?

Turbo engines are really picky about exhaust leaks. If you have leaks it won't boost.

Overheating can be caused by various things but a hot spark is not one of them. It can be caused by blocked cooling fins on the heads, cylinders or oil cooler. The head castings were pretty sloppy so you'll need to de-flash them if it hasn't already been done.

I wouldn't worry about the plugs just yet. When you get it boosting you may need to go to some colder plugs but not before. Hot plugs will make it detonate which will cause overheating but if it isn't pinging then you aren't there yet.

157 Corvairs, 5 Ultravans and counting

Northlake, TX

Northlake, TX

- bbodie52

- Corvair of the Month

- Posts: 11981

- Joined: Mon Aug 06, 2012 12:33 pm

- Location: Lake Chatuge Hayesville, NC

- Contact:

Re: Oil puke out dipstick

If oil is being forced out of the dipstick tube, it sounds like you either have a problem with excessive crankcase pressures caused by excessive blow-by that leaks past the pistons and piston rings into the crankcase, or you may have a problem with your Positive Crankcase Ventilation (PCV) system. The engine crankcase is a sealed chamber. It is normal for a certain amount of combustion chamber gases to escape past the piston rings and into the engine crankcase. Those fumes are expected and on 1963-1969 Corvair engines they are vented from the crankcase and drawn back into the intake system via a vacuum tube and a tube that connects to the air cleaner. This system is designed to properly ventilate the sealed crankcase during all engine operating conditions and speeds. If the PCV system becomes clogged, or if the piston rings and cylinders become excessively worn, the crankcase pressure buildup may exceed the ability of the PCV system to properly vent the engine crankcase. Under these circumstances the pressure buildup will seek a path out of the crankcase. The only path readily available is often the oil dipstick tube. As the pressure pushes its way through the oil dipstick tube, engine oil is often siphoned from the oil reservoir at the bottom of the crankcase and pushed up through the dipstick tube. A small volume of oil siphoned in this way would exit the top of the dipstick tube and likely drain back the outside of the engine and create a mess around the right exhaust manifold. If pressures become too great oil may be forced out of the dipstick tube at such a rate that it will be spraying around the engine compartment and making a mess in that area.

What follows is an explanation of the PCV system, and the variation of that PCV system that should be installed on your turbocharged engine. I would suggest starting by a examining the PCV system and cleaning it as necessary to ensure that it is fully functional. If cleaning your PCV system and confirming that it is properly connected to your turbocharger and air cleaner does not resolve the problem, you may need to perform a compression check of all cylinders to check the condition of the seal that should exist in each cylinder. A proper seal is affected by the condition of the pistons and cylinder walls, piston rings, intake and exhaust valves, and cylinder head gasket. If you find one or more cylinders that fails the compression test, a more advanced cylinder leak down test can be performed to try to determine the specific cause of the low cylinder pressure. Hopefully a simple cleaning and servicing of the PCV system will resolve your problem. A failure of a cylinder compression test and/or leak down test could point to the need for a more extensive engine overhaul or repair.

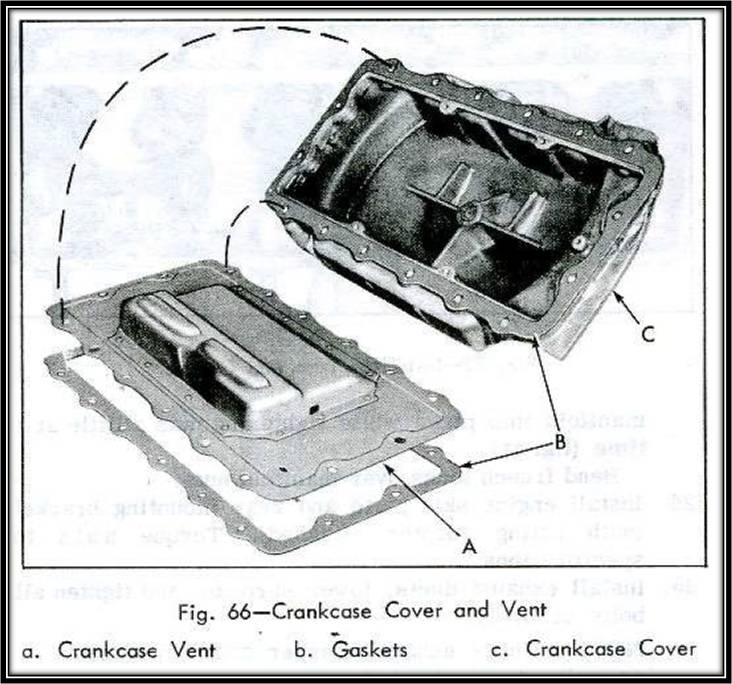

The Positive Crankcase Ventilation (PCV) system was designed by engineers to deal with crankcase ventilation requirements in a wide range of engine operating conditions — full throttle, closed throttle, partial throttle, high RPM, low RPM, and everything in-between. The baffle plate and vents, the PCV tube, the PCV valve or fixed vacuum orifice that is connected to the engine intake, and the PCV breather connected to the air cleaner, are all part of a dynamic system design that is intended to function continuously during all engine operating conditions.

1962 and earlier Corvair engines did not have a PCV system. Like most earlier engines, they were fitted instead with a simple road draft tube.

When road draft tubes were used, they were simple unfiltered tubes that routed from the Corvair crankcase cover directly downward, where they vented through a hole in the sheet metal cover under the right side of the engine, adjacent to the oil pan. There was never a tee on it that connected via an orifice to manifold vacuum at that time. The first stage of Positive Crankcase Ventilation that appeared around 1963 utilized an appropriately-sized vent restriction (PCV valve design AC-CV584) that limited the amount of crankcase fumes and air that could be drawn into the vacuum balance tube that connected at the base of the carburetors to the intake manifold. This was essentially a "vacuum leak" that was engineered into the system to draw some of the crankcase fumes into the intake manifolds to be burned as they passed through the combustion chambers and ultimately out through the engine exhaust system.

Part of the main vent tube is ALSO CONNECTED TO THE AIR CLEANER. This allows those excess crankcase pressures that cannot be completely drawn through the PCV valve and into the intake manifold to be managed by instead having them drawn through the air cleaner assembly and into the carburetor intake throats. The secondary vent path into the air cleaner assembly allows for excess crankcase pressures that routinely occur at higher engine speeds and that would also routinely overwhelm the limitations of the PCV valve vent path. (This necessary connection also allows air that is filtered by the air cleaner air filter to access the engine crankcase, providing a balancing effect for the crankcase so that crankcase vacuum and pressure can be maintained at approximately normal atmospheric pressure). Without the connection to the air cleaner assembly, the sealed crankcase has no way to "breathe", because half of the normal PCV system design would have been omitted.

The fixed orifice only became a part of the PCV system in 1964-1969. The use of a fixed orifice was not a part of the 1964 system in Forward Control (FC) vehicles and in air conditioned cars, because of clearance limitations in the van and truck engine compartments and in cars equipped with air conditioning. Those vehicles retained the earlier design of the air cleaner assembly with its associated PCV valve design (AC-CV584).

All PCV systems have connection between the main vent tube and the air cleaner, which is necessary for proper crankcase ventilation. With the use of custom individual air cleaners, you can replicate the portion of the PCV system that is missing by installing a connection to the right air cleaner. The custom air cleaner can be modified to provide a hose connection at its base.

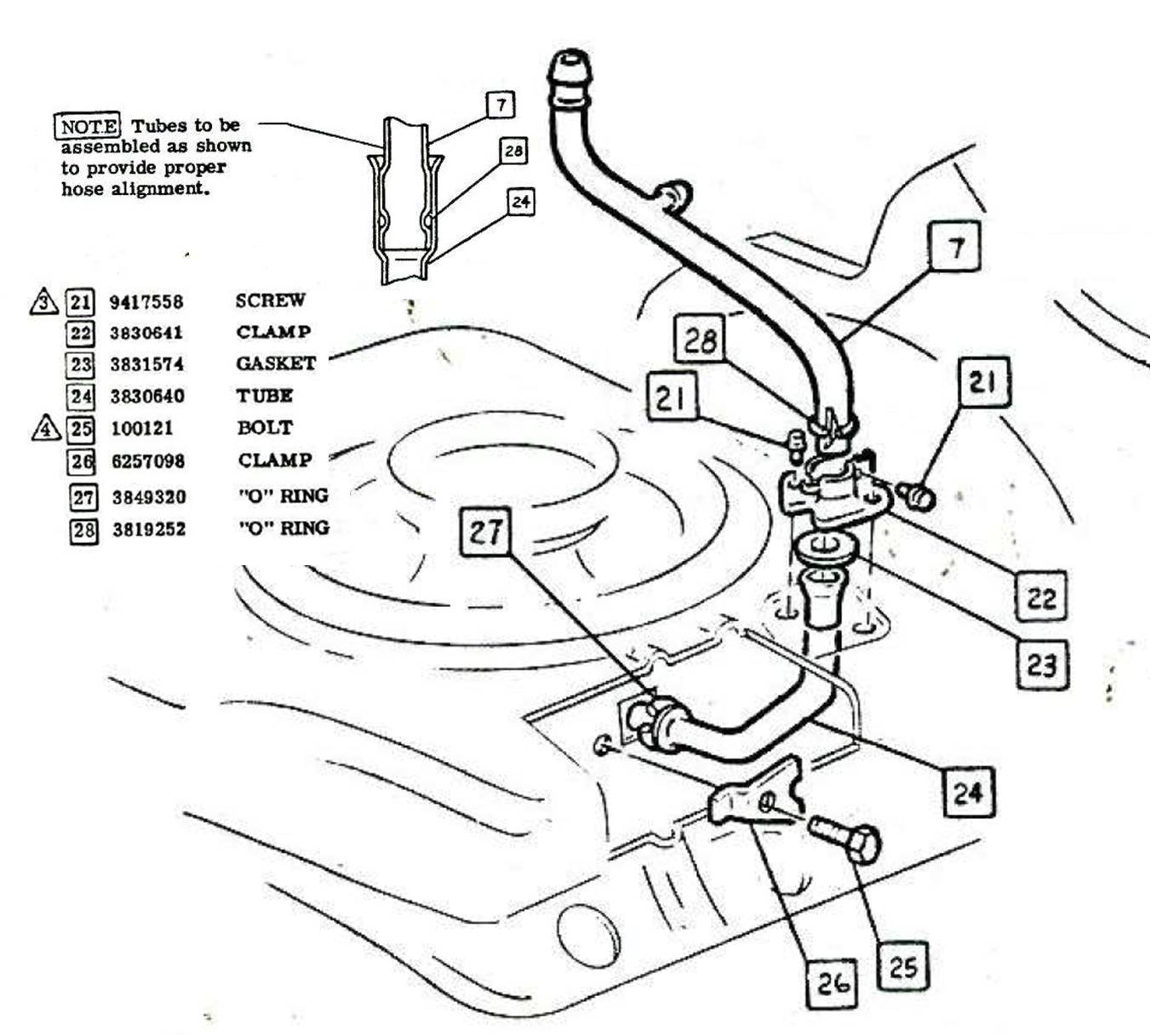

The illustration below shows the proper configuration for the turbocharged Corvair PCV system. The illustration was taken from the Corvair shop manual.

The turbocharged Corvair PCV system is functionally the same as that used on non-turbocharged, normally aspirated Corvairs. A short tube from the metered orifice is connected directly to the turbocharger intake at the base of the carburetor. This would be the correct connection point since it would always be a source of unpressurized intake vacuum. The other portion of the PCV tube connects to the air cleaner, as it does on the normally aspirated Corvairs.

Perhaps you should consider a cylinder leak down test so that you can determine which way the air is bleeding from the cylinder. It requires some special tools and a large capacity air compressor to perform...

A cylinder leak down test is a more advanced diagnostic procedure, and little more difficult to perform, because it requires some fabricated plumbing or a special test instrument, and a large capacity air compressor. Each cylinder to be tested is set at Top Dead Center (TDC) on the compression stroke (both valves closed). External air pressure is applied through the spark plug hole, and the percentage of leakage is evaluated. The source of the leakage (intake valve, exhaust valve, cylinder head gasket, or piston/cylinder seal) can be determined using an automotive stethoscope to listen for the leakage path (intake manifold, exhaust manifold, or crankcase). This test is performed on each cylinder, to determine the mechanical seal and condition of each cylinder. A video demonstration of this process (in this case, using a Volkswagen engine) is shown below.

There are many leak down testers available on Amazon.com. An example is shown below...

OTC 5609 Cylinder Leakage Tester Kit

4½ Stars out of 5 with 498 customer reviews | 53 answered questions

Price: $69.88 & FREE Shipping.

http://www.amazon.com/s/ref=sr_st_revie ... eview-rank

http://www.amazon.com/s/ref=sr_st_revie ... eview-rank

A decent mechanic's stethoscope can be had for about $15.00...

Also helps to locate noisy idler bearings, blower bearings, etc.

OF COURSE, A PURCHASE OR A RENTAL WILL DO YOU NO GOOD IF YOU DON'T HAVE ACCESS TO A DECENT AIR COMPRESSOR WITH ADEQUATE CAPACITY.

What follows is an explanation of the PCV system, and the variation of that PCV system that should be installed on your turbocharged engine. I would suggest starting by a examining the PCV system and cleaning it as necessary to ensure that it is fully functional. If cleaning your PCV system and confirming that it is properly connected to your turbocharger and air cleaner does not resolve the problem, you may need to perform a compression check of all cylinders to check the condition of the seal that should exist in each cylinder. A proper seal is affected by the condition of the pistons and cylinder walls, piston rings, intake and exhaust valves, and cylinder head gasket. If you find one or more cylinders that fails the compression test, a more advanced cylinder leak down test can be performed to try to determine the specific cause of the low cylinder pressure. Hopefully a simple cleaning and servicing of the PCV system will resolve your problem. A failure of a cylinder compression test and/or leak down test could point to the need for a more extensive engine overhaul or repair.

The Positive Crankcase Ventilation (PCV) system was designed by engineers to deal with crankcase ventilation requirements in a wide range of engine operating conditions — full throttle, closed throttle, partial throttle, high RPM, low RPM, and everything in-between. The baffle plate and vents, the PCV tube, the PCV valve or fixed vacuum orifice that is connected to the engine intake, and the PCV breather connected to the air cleaner, are all part of a dynamic system design that is intended to function continuously during all engine operating conditions.

1962 and earlier Corvair engines did not have a PCV system. Like most earlier engines, they were fitted instead with a simple road draft tube.

When road draft tubes were used, they were simple unfiltered tubes that routed from the Corvair crankcase cover directly downward, where they vented through a hole in the sheet metal cover under the right side of the engine, adjacent to the oil pan. There was never a tee on it that connected via an orifice to manifold vacuum at that time. The first stage of Positive Crankcase Ventilation that appeared around 1963 utilized an appropriately-sized vent restriction (PCV valve design AC-CV584) that limited the amount of crankcase fumes and air that could be drawn into the vacuum balance tube that connected at the base of the carburetors to the intake manifold. This was essentially a "vacuum leak" that was engineered into the system to draw some of the crankcase fumes into the intake manifolds to be burned as they passed through the combustion chambers and ultimately out through the engine exhaust system.

Part of the main vent tube is ALSO CONNECTED TO THE AIR CLEANER. This allows those excess crankcase pressures that cannot be completely drawn through the PCV valve and into the intake manifold to be managed by instead having them drawn through the air cleaner assembly and into the carburetor intake throats. The secondary vent path into the air cleaner assembly allows for excess crankcase pressures that routinely occur at higher engine speeds and that would also routinely overwhelm the limitations of the PCV valve vent path. (This necessary connection also allows air that is filtered by the air cleaner air filter to access the engine crankcase, providing a balancing effect for the crankcase so that crankcase vacuum and pressure can be maintained at approximately normal atmospheric pressure). Without the connection to the air cleaner assembly, the sealed crankcase has no way to "breathe", because half of the normal PCV system design would have been omitted.

The fixed orifice only became a part of the PCV system in 1964-1969. The use of a fixed orifice was not a part of the 1964 system in Forward Control (FC) vehicles and in air conditioned cars, because of clearance limitations in the van and truck engine compartments and in cars equipped with air conditioning. Those vehicles retained the earlier design of the air cleaner assembly with its associated PCV valve design (AC-CV584).

All PCV systems have connection between the main vent tube and the air cleaner, which is necessary for proper crankcase ventilation. With the use of custom individual air cleaners, you can replicate the portion of the PCV system that is missing by installing a connection to the right air cleaner. The custom air cleaner can be modified to provide a hose connection at its base.

The illustration below shows the proper configuration for the turbocharged Corvair PCV system. The illustration was taken from the Corvair shop manual.

The turbocharged Corvair PCV system is functionally the same as that used on non-turbocharged, normally aspirated Corvairs. A short tube from the metered orifice is connected directly to the turbocharger intake at the base of the carburetor. This would be the correct connection point since it would always be a source of unpressurized intake vacuum. The other portion of the PCV tube connects to the air cleaner, as it does on the normally aspirated Corvairs.

Perhaps you should consider a cylinder leak down test so that you can determine which way the air is bleeding from the cylinder. It requires some special tools and a large capacity air compressor to perform...

A cylinder leak down test is a more advanced diagnostic procedure, and little more difficult to perform, because it requires some fabricated plumbing or a special test instrument, and a large capacity air compressor. Each cylinder to be tested is set at Top Dead Center (TDC) on the compression stroke (both valves closed). External air pressure is applied through the spark plug hole, and the percentage of leakage is evaluated. The source of the leakage (intake valve, exhaust valve, cylinder head gasket, or piston/cylinder seal) can be determined using an automotive stethoscope to listen for the leakage path (intake manifold, exhaust manifold, or crankcase). This test is performed on each cylinder, to determine the mechanical seal and condition of each cylinder. A video demonstration of this process (in this case, using a Volkswagen engine) is shown below.

There are many leak down testers available on Amazon.com. An example is shown below...

OTC 5609 Cylinder Leakage Tester Kit

4½ Stars out of 5 with 498 customer reviews | 53 answered questions

Price: $69.88 & FREE Shipping.

A decent mechanic's stethoscope can be had for about $15.00...

Also helps to locate noisy idler bearings, blower bearings, etc.

OF COURSE, A PURCHASE OR A RENTAL WILL DO YOU NO GOOD IF YOU DON'T HAVE ACCESS TO A DECENT AIR COMPRESSOR WITH ADEQUATE CAPACITY.

Brad Bodie

Lake Chatuge, North Carolina

1966 Corvair Corsa Convertible

1966 Corvair Corsa Convertible

Lake Chatuge, North Carolina

1966 Corvair Corsa Convertible

1966 Corvair Corsa Convertible-

Jerry Whitt

- Posts: 887

- Joined: Thu Sep 26, 2013 2:42 pm

Re: Oil puke out dipstick

One simple cure that is sometimes missed. The oil level is too high.

Drain the oil and measure the amount that comes out. With the filter full, the total amount should be close to 5 quarts. If more than that, you have located the problem.

Drain the oil and measure the amount that comes out. With the filter full, the total amount should be close to 5 quarts. If more than that, you have located the problem.

Jerry Whitt

ASE CERTIFIED MASTER TECHNICIAN

Retired

Hemet, Callifornia

65 Monza, purchased new

65 Corsa convertible

ASE CERTIFIED MASTER TECHNICIAN

Retired

Hemet, Callifornia

65 Monza, purchased new

65 Corsa convertible

Re: Oil puke out dipstick

I had a similar problem with my ‘66 CORSA although not as bad as you described. After I rebuilt my turbo engine I kept finding oil on the right side shroud and tins. I had no idea where that was coming from. It turned out that the nut and compression fitting which connects the turbo drain tube to the turbo oil outlet fitting was bad. The compression fitting wasn’t sealing properly and oil was leaking onto the shroud. Tightening the nut didn’t help. Replacing the compression fitting and nut fixed the problem.

Alec Carlson

Dahlonega, GA

1965 Regal Red Corsa 4 Speed Turbo Convertible

Restoration "In Progress"...

Dahlonega, GA

1965 Regal Red Corsa 4 Speed Turbo Convertible

Restoration "In Progress"...

-

playerpage

- Posts: 34

- Joined: Tue Jan 11, 2011 9:14 pm

- Location: From Delta Junction, AK to Provo, UT to Los Angeles, CA, to Sunbury, PA, now Porterville, CA

- Contact:

Re: Oil puke out dipstick

This sounds exactly like what is going on with me! My thing is, though I think my PCV is incorrectly installed, and I don't have the parts. Does anyone out there have a complete PCV setup I could use?

Then:

1967 Monza 140 Red

1966 500 110 Black

1965 Monza 110 Yellow

Now:

1966 Corsa 180 Turbo Rust Project

"Chevrolet's Corvair was a maverick machine, a rear-engined renegade born out of spite and genius." - Sports Car Graphic, August 1969

1967 Monza 140 Red

1966 500 110 Black

1965 Monza 110 Yellow

Now:

1966 Corsa 180 Turbo Rust Project

"Chevrolet's Corvair was a maverick machine, a rear-engined renegade born out of spite and genius." - Sports Car Graphic, August 1969

- terribleted

- Posts: 4584

- Joined: Sun Apr 18, 2010 2:36 pm

- Location: Atlanta, GA

- Contact:

Re: Oil puke out dipstick

I just going to type this.Jerry Whitt wrote: ↑Wed Feb 13, 2019 12:07 am One simple cure that is sometimes missed. The oil level is too high.

Drain the oil and measure the amount that comes out. With the filter full, the total amount should be close to 5 quarts. If more than that, you have located the problem.

Verify the oil level by first verifying that your dipstick is the correct length (people swap dipsticks and sometimes they are not correct). Corvair dipsticks are all interchangeable. Length measurement is 12 1/8"+- a hair from the full mark up to the point which stops the stick when pushed onto the dipstick tube (some sticks use a flat washer like seal others use a thimble shaped cup that pushes down onto the tube a little, For the cupped ones you are measuring to the point where the tube stops up inside the cup). Oil capacity like Jerry said is almost right at 5 quarts (usually a slight bit less) unless there is an aftermarket oil pan or non stock oil filter installed, Or other mods like external oil coolers etc.

Corvair guy since 1982. I have personally restored at least 20 Vairs, many of them restored ground up.

Currently working full time repairing Corvairs and restoring old cars.

https://www.facebook.com/tedsautorestoration/

Located in Snellville, Georgia

Currently working full time repairing Corvairs and restoring old cars.

https://www.facebook.com/tedsautorestoration/

Located in Snellville, Georgia

-

joelsplace

- Posts: 2118

- Joined: Wed Oct 13, 2010 12:51 pm

- Location: Northlake, TX

Re: Oil puke out dipstick

You can run a good half qt over without issues.

157 Corvairs, 5 Ultravans and counting

Northlake, TX

Northlake, TX