Page 1 of 1

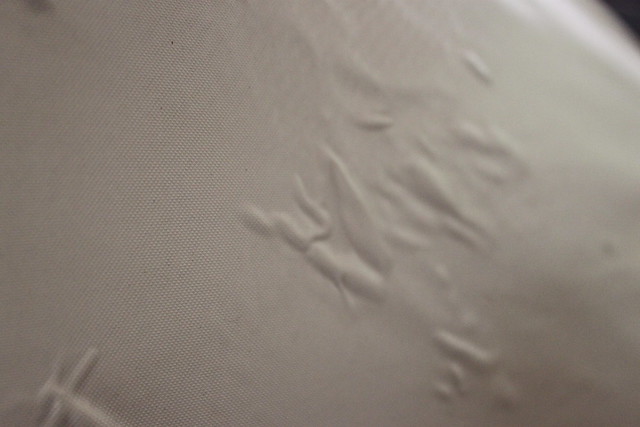

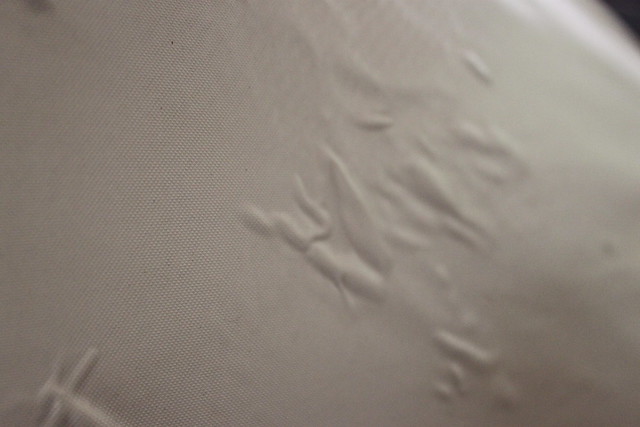

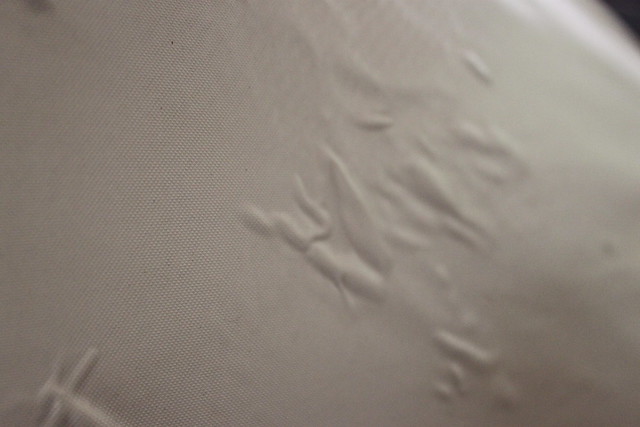

'64 convertible top material separation

Posted: Wed Nov 29, 2017 7:56 pm

by AZScott

I am in the process of restoring a ’64 convertible. The top is in overall good condition, has no tears and the rear window is excellent shape. However, on each side of the top between the rear window and the back seat window, where the top folds, I have delimitation. It looks like the outside material separates from the inside material and creates a bubble. I was thinking of injecting some kind of flexible adhesive and pressing it to together, but thought I would ask if others have had this problem and if there is a fix someone has tried and recommends.

Below are a couple of photos of the problem.

IMG_6916

IMG_6916 by

AZScott, on Flickr

IMG_6917

IMG_6917 by

AZScott, on Flickr

Re: '64 convertible top material separation

Posted: Wed Nov 29, 2017 8:22 pm

by Jerry Whitt

With the top up, the latches as tight as possible, a portable steamer might allow the material to flatten out. The steamer I use is actually for taking

wrinkles out of clothes but seems like it might work for this project. The steam is not likely to cause any damage.

If you do this, let us know how it worked.

Re: '64 convertible top material separation

Posted: Thu Nov 30, 2017 7:44 am

by AZScott

Thanks Jerry I will try that. I do have a portable steamer. I will let you know how that works. I still think I may need some sort of an adhesive to bond the two layers, and it would need to be flexible so that the top can fold in those locations. I am experimenting around with different adhesives.

Re: '64 convertible top material separation

Posted: Thu Nov 30, 2017 7:47 am

by GriffinGuru

So from my experimentation on this subject I'm at a loss as to what I would do in a similar circumstance. From what I know of the material from cutting and gluing pieces to hold my separated window apart is that it is two layers. The top vinyl layer is adhered onto the cloth-like inner layer, but to complicate matters, that cloth inner layer is a little bit fuzzy between the layers. As such, the fuzzy surface makes for a poor glue surface.

Your delamination will likely spread since once the vinyl peels, it will peel easily from the cloth layer once started. My gut instinct tells me that you should inject something into it, but whatever you inject will likely create a hard spot in the top. Also. most glues are too thick to inject.

Suppose you cut the cloth side of the bubble out from the inside, and then glue a sheet of some cloth material over the area you cut out from the inside? Spread the glue thoroughly over the cut out area and into the remaining edges of the delamination. For the patch to glue tight though you need to clamp it so the cloth is tight together and flat with itself... perhaps use some stereo magnets on either side of the top as a clamp?

Just throwing some ideas out, but I can't guarantee how well it will work or how easily it can be clamped given the location.

IMG_6916 by AZScott, on Flickr

IMG_6916 by AZScott, on Flickr IMG_6917 by AZScott, on Flickr

IMG_6917 by AZScott, on Flickr IMG_6916 by AZScott, on Flickr

IMG_6916 by AZScott, on Flickr IMG_6917 by AZScott, on Flickr

IMG_6917 by AZScott, on Flickr