Welcome to the Corvair Forum!

jdflight wrote:... I am new to the forum and in the process of finding my first Corvair, trying to avoid the rust not having any luck. This will be my first project car have many years experience working on aircooled porsches but really love the Corvair body especially the 66 and up models.

Part of the difficulty in answering your questions is that we know little about you. Here is an opener that I have posted several times to try to help out new prospective Corvair owners a little. Hopefully you will find some useful information below. At the end I also posted some contact information for a local Dallas area club chapter of CORSA (Corvair Society of America). Members may be aware of decent Corvairs in your area that might interest you, and their experience with Corvairs may also help you as you evaluate possibilities.

As you will read below, owning a classic Corvair as a daily driver is certainly a possibility. I have been doing it all over the USA and in Germany since the 1960's, and at age 62 my wife and I are still plugging along with enjoying Corvair ownership and driving it regularly.

The cars are certainly capable — they have been

survivairs as daily drivers with owners all over the USA and Canada, and we have Corvair Forum members who drive them regularly in South Africa, many European countries, Australia, South America, Japan, etc. The cars survive because the owners generally take the time to become DIY mechanics and hobbyists. It requires some monetary investment, but not nearly as much as many other classic car breeds. In that sense it is still something of an economy car. They can be a money pit if the body and sheet metal are in poor shape, so it is important that the car is carefully inspected so that cars suffering from extensive body rot and rust, and perhaps many patches with plastic body filler will be avoided. A DIY "shade tree mechanic" can master almost any mechanical repair. Parts suppliers are good, and generally make all things possible on the mechanical end. Local parts sources are not a reality for most people, as few auto parts supply stores can support Corvairs adequately. But Corvair specialists like Clark's Corvair Parts have been highly successful supplying Corvair owners for decades. Without them most Corvairs would have disappeared from the road long ago. The supply is good and the prices are reasonable.

As I mentioned, the other side of the coin is the Corvair body. It is of unibody construction and subject to rust and body rot — especially if the car has been driven extensively in Winter months in areas that use road salt. Few body parts are bolt-on in nature, so welding and sheet metal skills are essential for Corvair body repair. Owners who have adequate body repair skills are relatively rare, and it is an art form that is difficult to master. You really should try to start with a Corvair that is in good physical condition.

Anyway, what follows is a somewhat lengthy broadside that covers Corvair configurations, maintainability, ownership, and personal commitment. You will have to realistically assess your own abilities, financial and time commitment, etc. While a Corvair can certainly be a good daily driver, you should have a backup plan if something breaks — since even a minor breakdown can mean several days awaiting delivery of replacement part(s).

Since there is a local CORSA (Corvair Society of America) club chapter near you, members may be willing to help you to assess any Corvair you are considering. Their experience with Corvairs can help you by identifying issues you might not notice. Alternately, posting a quantity of detailed photos here on the Corvair Forum can help Corvair Forum members to potentially spot issues and to provide you with useful recommendations.

Joining CORSA (Corvair Society of America) — if you are not already a member — and a local Corvair club chapter is another good way to see and to learn more about Corvairs. You might check out the CORSA chapter in your area. Contacting a local club and making Corvair-knowledgeable friends can often be a big help.

CORSA (Corvair Society of America) Chapter Locator

Locating a local CORSA chapter near you can be very helpful, and attending meetings, parties, Corvair shows, etc. can greatly add to the enjoyment of your Corvair

NOTE: Information on the CORSA Chapter Locator is generally badly out of date. Names, phone numbers, email addresses, etc. are often inaccurate. Your best bet is to find the nearest club chapter on the list, and then use the chapter website link to move on to the club website. Contact information on the actual club website is often much-more accurate and up to date!

CORSA (Corvair Society of America) Chapter Locator

Locating a local CORSA chapter near you can be very helpful, and attending meetings, parties, Corvair shows, etc. can greatly add to the enjoyment of your Corvair

NOTE: Information on the CORSA Chapter Locator is generally badly out of date. Names, phone numbers, email addresses, etc. are often inaccurate. Your best bet is to find the nearest club chapter on the list, and then use the chapter website link to move on to the club website. Contact information on the actual club website is often much-more accurate and up to date!

https://www.corvair.org/index.php?optio ... crmSID=3_u

https://www.corvair.org/index.php?optio ... crmSID=3_u

I would like to encourage you to expand on your initial post and tell us more about yourself, the Corvair you are considering, and your goals for that Corvair. If you can describe your personal assessment of your mechanical skills and abilities, that would help a lot. Members of the Corvair Forum love to be helpful in assisting other Corvair owners with technical support and advice, but it helps a lot if we have some understanding of your technical background and mechanical abilities, Corvair-related knowledge, etc. Helping us to know more about you and the Corvair will help us to write comments to you that are tailored to your needs and experience. Pictures are great too, because pictures of your Corvair will help us to visualize where you are with your Corvair and its condition at the present time. Knowing your location is also useful, because knowing where you live can sometimes suggest possibilities to resolve some issues or problems.

The Corvairs are vintage 1960s technology and design — easy to learn and easy to maintain. I would say that learning to work on a Corvair is analogous to an experienced home DIY "shade tree" car mechanic learning to work on a motorcycle. The concepts and procedures are very similar, but the details and the way it is put together is a little different. With the Corvair engine (like a motorcycle) you are dealing with a lot of aluminum. The metal is soft when compared to steel and cast iron, so the use of a torque wrench, anti-seize compound and carefully avoiding cross-threading becomes more important. Also, (like some motorcycles) you are dealing with multiple carburetors so tuning procedures are a little different. The use of Corvair shop manuals and supplements, other technical guides, and information sources like the Corvair Forum, and perhaps joining a CORSA (Corvair Society of America) club chapter can help you to quickly learn about Corvairs. Information resources, like good Corvair parts suppliers, are plentiful if you know where to look. Suppliers like Clark's Corvair Parts have been well-respected and extremely supportive since 1973, and suppliers like that make Corvair ownership more practical and much-more possible. I taught myself how to remove a Corvair powertrain, overhaul the engine, and rebuild the Powerglide transmission during my summer vacation in 1969, when I was sixteen years old. I was working alone (my father had been transferred by Lockheed from northern California to southern California, and we had not yet moved to join him). I had a shop manual and a garage full of tools. There was no Internet, no Corvair Forum, no CORSA club — I was pretty-much on my own. Yet I learned and was successful (in 1972 that engine carried me and my new bride on our wedding day and on our honeymoon).

So you should be able to master working on Corvairs without too much trouble — except watch out for rust and body rot! The Corvair is of unibody construction, so most body repair involves cutting and welding. The doors, trunk lid (in the front)

, and engine compartment lid (in the back)

and maybe the gas filler door are the only bolt-on body components. Everything else is cut and weld, and the body serves as the main chassis frame. So unless you are a master body repair technician, you need to select your Corvair carefully and avoid excessive hidden rust or a "Bondo bucket". The door frame areas, fenders, floor pan, the bottom of the trunk, lower windshield and battery area often rust and rot.

What follows is an attempt at introducing new prospective Corvair Owners to Corvairs and some of the issues involved. Food for thought, before you take the plunge. This is a copy of something I wrote earlier, but I think it may be helpful in your quest for the "right" Corvair...

bbodie52 wrote:I will try to provide a quick summary of the 1960-1969 Corvair lineup, and will also try to provide some answers regarding the use of a Corvair as a "daily driver".

EARLY MODEL: 1960 - 1964 Corvairs were the first generation. Their body style emulated other Chevrolet body styles from the early 1960s. The rear suspension was a swing-axle design that was similar to the Volkswagen "Beetle". The 1960 model year was the only year with a 140 cubic inch engine, and there were some characteristics that were unique to that model year only. A number of refinements were implemented in the following year, including some restyling of the front end and an increase in displacement to 145 cubic inches (CI). A manual choke was used in 1961, and this was changed to an automatic choke design in 1962 that remained with the car through 1969. A turbocharged 150 hp Spyder was introduced in 1962, and the Spyder name remained with the turbocharged engine through 1964. In 1964 the engine displacement in all Corvair engines increased from 145 CI to 164 CI. There were also some suspension refinements, including a front anti-sway bar and a rear transverse leaf spring to improve handling in all 1964 Corvairs. Here are a few pictures of Early Model (EM) 1960-1964 Corvairs...

LATE MODEL:

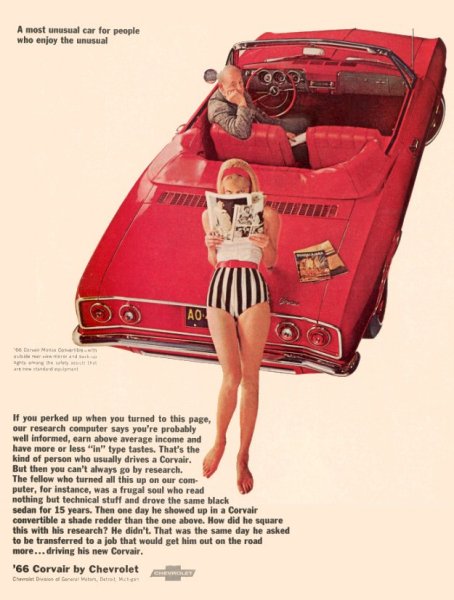

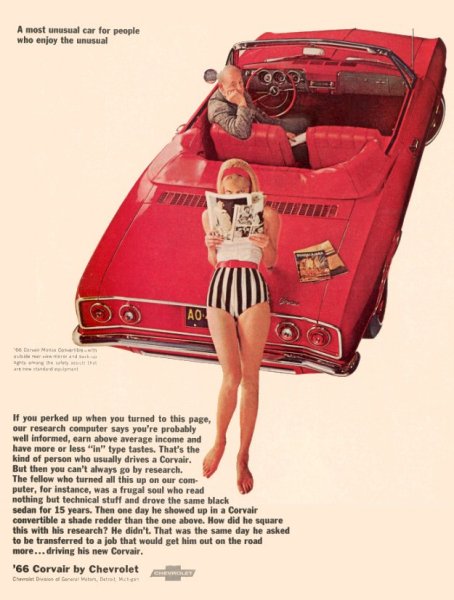

LATE MODEL:The 1965 Corvair introduced a completely new body style, that was also seen later in similar styles in the Camaro and Pontiac Firebird. The drum brake size was increased, and the swing-axle rear suspension design used in EM Corvairs was abandoned. The new rear suspension was a design lifted from the Corvette Stingray.

1965 and 1966 Corvairs were nearly identical. In 1967-69 the top of the line Corsa was dropped, leaving the Monza and economy 500 until production was discontinued in the spring of 1969. During the 1967-69 production period, there were minor safety changes, such as a dual master brake cylinder in place of the single unit used in 1960-1966. Interior seats and trim changed somewhat, paralleling the items used in Camaros and some other GM products during that period.

All 1965-66 Corsas came with a standard 4-carburetor 140 hp engine, and an optional 180 hp turbocharged engine. The 140 hp engine remained optional in the rest of the lineup. Other engine options in the Monza and 500 were 110 hp and 95 hp dual carburetor engines. All engines could be had with a manual 4-speed or 3-speed transmission, or with a 2-speed Powerglide automatic (with the exception of the 1965-66 turbocharged 180 hp engine, which was available with the Corsa only, and only with a 4-speed manual transmission).

Air conditioning was a rare option, but can be found in the 1965-1967 lineup, and some of the EM Corvairs as well. The following link will provide you with some air conditioned Corvair background and history...

http://www.corvair.org/chapters/airvairs/

http://www.corvair.org/chapters/airvairs/

The brakes, front and rear suspension, transaxle and body were essentially identical in the Corsa, Monza, and 500. The primary differences in the cars were the instrument panel (the Corsa had more gauges), trim details, and the engine option.

The late model Corvairs were available in a 2-door Coupe, 2-door Convertible, and 4-door Sedan. In 1968, the four-door hardtop was discontinued, leaving three models—the 500 and Monza Hardtop Coupes and the Monza Convertible. Air conditioning was dropped as an option. The weight of the cars was very similar in all configurations.

bbodie52 wrote:Here is something I wrote over a year ago — Brad's Admonition, or some words of advice — based on over 50 years of exposure to Corvair ownership — that I wrote to try to give new Corvair buyers some idea of the issues involved. I'm sure you have some idea already, but I also think this is worth considering...

Since you are new to Corvairs, I want to give you some information that I have written to other new prospective first-time Corvair owners. I have been involved with Corvairs since I was nine years old, when my parents bought our first Corvair – a brand new 1961 Monza 2-door coupe, white on red with a 4-speed transmission. I now own Corvair number ten, which I purchased in June 2012. (If you want to read a brief personal biography that outlines my family background and our experiences with Corvairs, go to

CORVAIR FORUM > Introductions > New from Lake Chatuge North Carolina.

viewtopic.php?f=13&t=4032 ) I want to encourage your enthusiasm in developing your plans to buy your first Corvair, but at the same time I want to help you to think through just what you are getting into. So please read and consider these comments below...

I have listened to many potential Corvair first-time owners. Many have no prior experience with owning

any classic car, and many have never driven a Corvair at all, or have not driven one in decades. Some are motivated by childhood memories of a family Corvair. They typically describe the desire to locate a perfect, restored, ultra-clean example, and look to the Corvair Forum Corvair enthusiasts and aficionados to tell them what to do.

The first thing I think that needs to be done is to try to set-aside the usual emotion-based enthusiasm that any car buyer might feel when visiting a dealer and gazing with emotional eagerness at the vast array of new cars displayed in the showroom, on the car lot, and in factory brochures and advertisements. There is an extreme difference between owning a 40+ year-old Chevrolet that was likely engineered, designed and built with pre-planned obsolescence in mind — a car that GM only envisioned having a life-span of ten years or so. Many of the potential Corvair buyers are captivated with the exciting idea of owning something different — something not normally seen on the road — something that your neighbor will not buy! Certainly that is the case with a Corvair, but owning a Corvair and enjoying that ownership demands a certain dose of reality before you "buy-in". Many are unprepared for the maintenance and upkeep demands of a Corvair. "Where can I find a good Corvair mechanic?" is a common question — often displaying an inability or unwillingness to do some mechanical work and maintain that car yourself. Yet qualified Corvair mechanics can be distant, expensive, inconvenient, and all-too rare. At a time when finding even a spark plug, fan belt, or oil filter for a Corvair often means an Internet or mail-order purchase, finding local support may be unlikely or impossible. Even searching automobile junk yards will often not help, because these cars are so rare and infrequently found that they have all but disappeared from the scrap yards too. Even locating and buying a used part is a mail-order proposition. And even if you spend $15,000-$20,000 for a fully-restored Corvair in mint condition, it still comes "as-is", with no warranty and little in the way of a local support system — far different than what most car buyers are used to expecting! These are the realities of owning an older classic car.

Corvairs are popular and affordable classic cars, and enjoy a good infrastructure of maintenance supporters, owner's clubs, and parts suppliers — and that REALLY helps! But I suspect that most happy Corvair owners are something of "shade-tree mechanics" and hobbyists who are prepared to deal with the risks and problems related to Corvair ownership. It requires a long-term commitment and a dose of reality to happily own a classic Corvair. The "first date" infatuation with the attractiveness and uniqueness of a Corvair will not sustain you in a long-term relationship with a Corvair. It is far-better to have a realistic idea of just what you are getting into before you "take the plunge" and buy your dream car.

A cautious, knowledgeable and educated search for your dream Corvair is a great start, and a careful and realistic analysis of your own mechanical talents, skills and abilities is also useful. If you plan to have a mechanic do most of the work for you, the availability of a Corvair-skilled mechanic and the associated costs involved must be taken into account in your financial planning to own a Corvair.

I try to not be too negative, but I have worked with others who came to realize that Corvair ownership was more than they could handle. I just feel that new prospective Corvair owners come here to this forum to learn from others who have more experience, and we are not doing them any favors by "candy coating" the issues involved. If they pass the "sanity check" and still want to pursue buying a Corvair, then GREAT! This Forum and perhaps some local Corvair club members can potentially help them pursue that dream. But it should be a realistic dream, and not a frustrating "nightmare" experience. Better to make a clear-headed, informed decision early in the game!

I hope that these comments are useful to you. I know I get "long-winded", but I also know you are trying to make an important decision, and I hope all of these comments will help you.

Corvairs can suffer from rust and body rot problems, especially in areas that use a lot of road salt in the wintertime. While you may be able to learn and successfully attack most mechanical issues as a DIY effort, body decay can be much-more difficult, time-consuming, intimidating, and expensive to correct. So look for hidden rust or rot problems that may have been covered up with plastic filler, and be cautious in your Corvair selection.

A Corvair can serve well as a daily driver. But I would recommend a backup car or other alternatives, since ANY breakdown can put the car out of service for days until replacement parts can be obtained (if needed). If you have the skills and ability to work on the car yourself, repairs can often be completed fairly quickly. But if you have to rely on professional mechanics, downtime can be long and possibly expensive — if you can find a good mechanic to do the work for you.

Let us know how you wish to proceed. If you have good prospects, I urge you to seek opinions from experienced Corvair enthusiasts before you commit to a purchase. Good luck!

Finally, one or two pairs of experienced "Corvair eyes" can tell you a lot. If you are inclined to join the local CORSA (Corvair Society of America) club chapter, I would encourage you to do so. You might be able to enlist some Corvair aficionados to join you in your Corvair hunt. Their opinions could be very helpful. Here is some contact information.

I must say that this club chapter appears to be very well organized with excellent member participation, based on the content of their website. Membership in this club could really add to your enjoyment of Corvair ownership.

CORSA Chapter Locator - North Texas Corvair Association

CORSA Chapter Locator - North Texas Corvair Association

Chapter ID: 750

Organization Name: North Texas Corvair Association

Street Address (Primary): North Texas Corvair Association, P.O. Box 170796, Irving, Texas 75017-0796

CHAPTER OFFICERS FOR 2015

President: Fred Rehders, 972-272-0049,

fred@thepegasus.us

Vice President: Tommy Wright, 972-345-3449,

twmotorcraft@msn.com

Secretary: Bob Gill, 214-686-0289,

recycled.roadkill@verizon.net

Treasurer: Susan Wright, 972-438-6209,

txbluegrass95@yahoo.com

Activities Coordinator: Mike Boyle, 817-909-7874,

txboyle@sbcglobal.net

Director 1: Tom Fricker, 817-821-5094,

tomcat.vair35@gmail.com

Director 2: Sam Baker, 214-636-2207,

sam.baker101@verizon.net

Director 3: Nick Raeber, 469-863-4416,

nraeber@gmail.com

Newsletter Editor: Gail Fricker, 817-821-5094,

ntcanews@live.com

Newsletter Name:

Transaxle Telegraph

Sample Newsletter:

Website:

http://www.northtexascorvair.org

Email (Primary):

contactsmu@yahoo.com

Next Meeting: NTCA September Meeting

♦ Saturday, September 5, 2015, 2:00 PM

♦ Regular Meeting

♦ Presentation to be announced

September 5, 2015, Saturday - 2 p.m.

Meeting Program: To be announced

Regular Monthly Meeting at the Senter East building, 228 Chamberlain St.

Regular Monthly Meeting. Meet at the Senter East building, 228 Chamberlain St

Visitors and guests are always welcome. Come and join the fun!

Visitors and guests are always welcome. Come and join the fun!