Big Day at the garage

This entire suspension thing has really been holding me down. After the first major failure, everything has been thought to death. We think about what to.........we talk about what to do......someone else gets in the conversation and we talk and think about it some more. I was just about ready to go up on the roof with a magnum and start picking off people in the neighborhood just to show my frustration

............We finally decided on what we were going to do. First we stocked up on some thick wall (.156 ) tubing. We cut a couple of small pieces of tubing to make spacers. We added some washers to the ends to make them 2.750 wide. These will be the basis for the Camber adjustment units on the bottom of the trailing arm. We got our heim joint and some brackets together to make our center pivot. We made our center pivot mount out of 3 nuts which we welded together.....more on this in a minute

Here are the bits and pieces

Next came the arms. We welded nuts to the end of the thick wall arms and used 1/2" X 1/2" heim joints as rod ends. Laying next to the arms is another piece which slides on the spacers. The tube and tab are chormemolly . The arms will bolt to the tabs.

Here are those pieces

Once we made sure the concentric was centered, we could start the assembly process. Here is how the arm bolts to the slider

REASONING !!!

REASONING !!!

As the trailing arm moves up and down, the length of arm will need to change. The slider over the bushing will allow the change to the needed rod length. We have only a small amount of travel ( 2 inches up, 3 inches down from ride height ) on the trailing arm. This slider should only need about 3/16 of an inch of total travel. We gave it a total of 5/8 inch of travel.

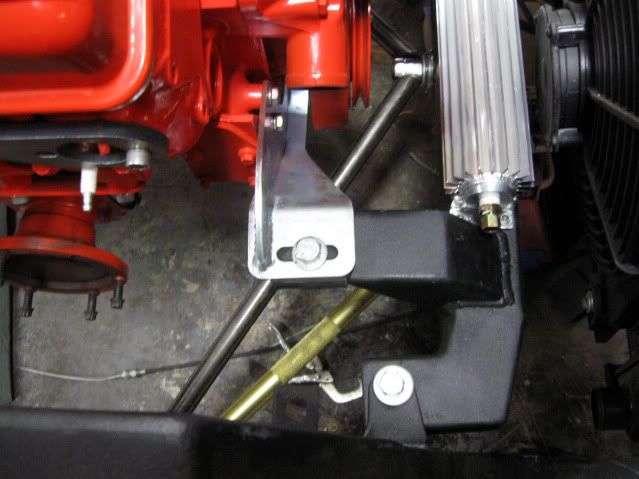

The arms attach to a center pivot. The pivot is attached to the main cross member. Even with the uneven mounts, we have no binding in the travel of the arm. If we had more travel in the arm, this might not have worked. Here is the center pivot mount

And of course from above

Once the final welding has been done and the mount brackets are fully welded, We can put the suspension to rest. We have toe in/out adjustment as well as full camber adjustment. Time to build the axles.......woohoo !!

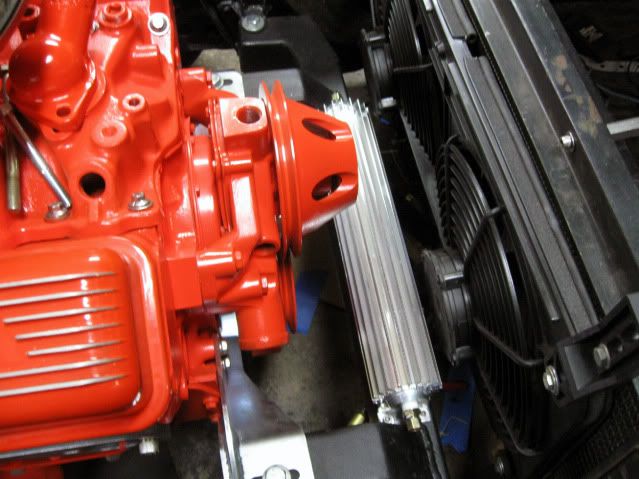

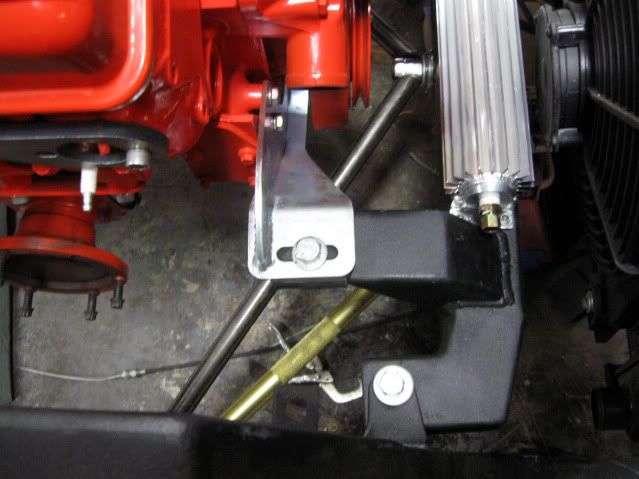

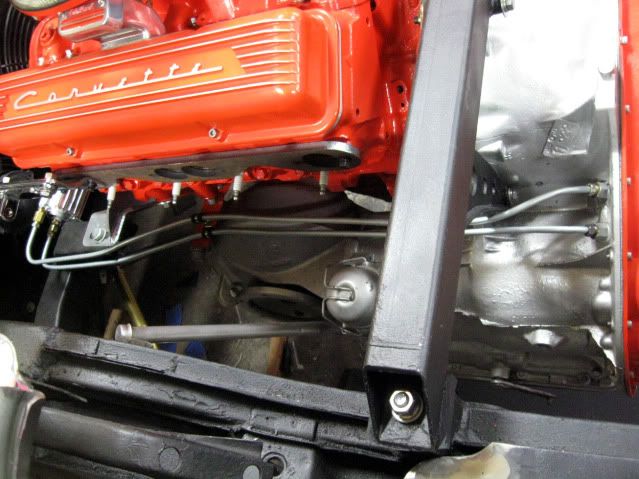

Saturday will be the beginning of the header build as well as the trans cooler plumbing...............getting there