What type of intake to build?

What type of intake to build?

I just bought a 64 Monza Spyder. It does not have any of the original carb/turbo/intake parts. I know that there a multitude of approaches to replace or modify the original system, and I would like some input from the forums on what would be best. The goal is speed and performance in a street car that will last.

Oh--this is my first Corvair, and my first restoration/modification.

Troy in Albuquerque, NM

Oh--this is my first Corvair, and my first restoration/modification.

Troy in Albuquerque, NM

-

joelsplace

- Posts: 2019

- Joined: Wed Oct 13, 2010 12:51 pm

- Location: Northlake, TX

Re: What type of intake to build?

If you aren't going back stock then EFI and a modern turbo is best. Figure out a good place for the turbo outside the engine compartment so you aren't super heating the intake and cooling air with the turbo. You'll want to mill off the stock manifolds and make a 6 runner setup.

All the shrouding around the engine needs to be put back on also.

All the shrouding around the engine needs to be put back on also.

157 Corvairs, 5 Ultravans and counting

Northlake, TX

Northlake, TX

- bbodie52

- Corvair of the Month

- Posts: 11909

- Joined: Mon Aug 06, 2012 12:33 pm

- Location: Lake Chatuge Hayesville, NC

- Contact:

Re: What type of intake to build?

The 1964 engine was the first year of the longer stroke 164 CI engine. 1961-1963 engines had the same cylinder bore, but a shorter stroke, resulting in 145 CI displacement.

It appears that the 110 hp and 1965 140 hp engines shared the same camshaft that was used in the 1964 150 hp turbocharged engine. The bottom end of your engine should include a nitrided 164 CI long stroke crankshaft, and since it shares the same camshaft used in normally aspirated 110 and 140 hp engines, the bottom end would likely serve well as the basis for a solid normally-aspirated (non-turbocharged) engine (depending on the condition of the bearings, crankshaft, and camshaft and camshaft drive gear). (1965-66 180 hp turbocharged engines used a different camshaft).

You should note that the outside diameter of the 1964 cylinder barrels is only correct for 1964 and earlier cylinder heads, with an outside diameter of 3-3/4" (the portion that inserts into the head and mates with the head gasket). In 1965-1969 engines this outside diameter of the cylinder barrels increased to 3-13/16". Since the turbo heads have small valves and a low compression ratio (8.0:1), they are the equivalent of the low performance cylinder head. The 110 hp and later 140 hp heads provided a compression ratio of 9.0:1. I mention this because you might decide that a normally aspirated engine might be the best approach for your Corvair, since the turbo is missing. The bottom end is already configured as a solid basis for a good streetable performance engine, with a good crankshaft, connecting rods, and camshaft. A fresh set of pistons, rings, and 1965 and later cylinder barrels (3-13/16" outside diameter) would allow you to install a set of 1965-1969 110 hp small valve or 140 hp large valve cylinder heads. This would form a basis for either carburetors or an Electronic Fuel Injection (EFI) intake system and a dual exhaust system. A modern Stinger distributor would provide correct timing centrifugal advance, vacuum advance, and a modern breakerless electronic (magnetic trigger) ignition system. Rebuilding and reconfiguring the top end (cylinder barrels/pistons/rings and heads) would provide a good match for carburetors or EFI.

The post at the link below outlines the differences between the normally aspirated Corvair and the turbo engine...

viewtopic.php?f=55&t=15719&p=108787&hil ... es#p108787

viewtopic.php?f=55&t=15719&p=108787&hil ... es#p108787

HIGH PERFORMANCE FUEL INJECTION

HIGH PERFORMANCE FUEL INJECTION

http://www.corvair-efi.com/

http://www.corvair-efi.com/

http://www.corvair.com/user-cgi/catalog ... w_page=63B

http://www.corvair.com/user-cgi/catalog ... w_page=63B

https://www.perfvair.com/stinger-ignition-distributors/

https://www.perfvair.com/stinger-ignition-distributors/

It appears that the 110 hp and 1965 140 hp engines shared the same camshaft that was used in the 1964 150 hp turbocharged engine. The bottom end of your engine should include a nitrided 164 CI long stroke crankshaft, and since it shares the same camshaft used in normally aspirated 110 and 140 hp engines, the bottom end would likely serve well as the basis for a solid normally-aspirated (non-turbocharged) engine (depending on the condition of the bearings, crankshaft, and camshaft and camshaft drive gear). (1965-66 180 hp turbocharged engines used a different camshaft).

You should note that the outside diameter of the 1964 cylinder barrels is only correct for 1964 and earlier cylinder heads, with an outside diameter of 3-3/4" (the portion that inserts into the head and mates with the head gasket). In 1965-1969 engines this outside diameter of the cylinder barrels increased to 3-13/16". Since the turbo heads have small valves and a low compression ratio (8.0:1), they are the equivalent of the low performance cylinder head. The 110 hp and later 140 hp heads provided a compression ratio of 9.0:1. I mention this because you might decide that a normally aspirated engine might be the best approach for your Corvair, since the turbo is missing. The bottom end is already configured as a solid basis for a good streetable performance engine, with a good crankshaft, connecting rods, and camshaft. A fresh set of pistons, rings, and 1965 and later cylinder barrels (3-13/16" outside diameter) would allow you to install a set of 1965-1969 110 hp small valve or 140 hp large valve cylinder heads. This would form a basis for either carburetors or an Electronic Fuel Injection (EFI) intake system and a dual exhaust system. A modern Stinger distributor would provide correct timing centrifugal advance, vacuum advance, and a modern breakerless electronic (magnetic trigger) ignition system. Rebuilding and reconfiguring the top end (cylinder barrels/pistons/rings and heads) would provide a good match for carburetors or EFI.

The post at the link below outlines the differences between the normally aspirated Corvair and the turbo engine...

bbodie52 wrote:This will give you some idea of the differences between the 140 hp engine and the 110 hp engine.

140 hp vs. 110 hp...

140 hp Heads...

- Same high-performance camshaft on both 140 hp and 110 hp engines. Low performance camshaft in the 95 hp engine.

- Same 164 Cubic Inch displacement with same bore and stroke on all 1964-1969 engines.

- Stronger, nitrided crankshaft on the 140 hp and 180 hp turbocharged engines. (Nitriding is a heat treating process that diffuses nitrogen into the surface of a metal to create a case-hardened surface).

- On the 140 hp engine, a 4x1 carburetor arrangement, with two primary and 2 secondary 1-barrel carburetors, connected with a progressive linkage to open the secondary carburetors as you approach full throttle. (Equivalent to a 4 barrel carburetor on the 140 hp engine, vs. a 2 barrel carburetor (2x1) on the 110 hp and 95 hp engine).

- Dual muffler, dual exhaust with larger exhaust ports and larger exhaust manifolds on the 140 hp engine. Single exhaust on the 110 hp and 95 hp engine.

- 9.0:1 Compression Ratio in both 140 hp and 110 hp engines. 8.0:1 CR on the 95 hp engine.

It's all about better breathing at full throttle at the high RPM ranges. At lower RPM the big valves and dual exhaust don't make much difference, and the secondary carburetors are not open for business.

110 hp Heads...

HIGH PERFORMANCE FUEL INJECTION

HIGH PERFORMANCE FUEL INJECTION

Brad Bodie

Lake Chatuge, North Carolina

1966 Corvair Corsa Convertible

1966 Corvair Corsa Convertible

Lake Chatuge, North Carolina

1966 Corvair Corsa Convertible

1966 Corvair Corsa Convertible-

martyscarr

- Posts: 323

- Joined: Sun Dec 13, 2009 10:33 am

- Location: Eugene, OR

Re: What type of intake to build?

troy.w wrote: The goal is speed and performance in a street car that will last.

welcome to the forum

Are you planning on keeping the car turbocharged? There are 4 different turbochargers used on Corvairs.

62: 3817254

63: 3830651

64: 3840830

65-6: 3856709

The first 3 were for the 150 hp engines, the last for the 180 engine. You can make a hybrid turbo by taking the cold side of the late (F model turbo) and mate it to the hot side of the early (B model turbo) for more performance. There is also a larger compressor housing and impeller from the E model turbo that will fit for more flow.

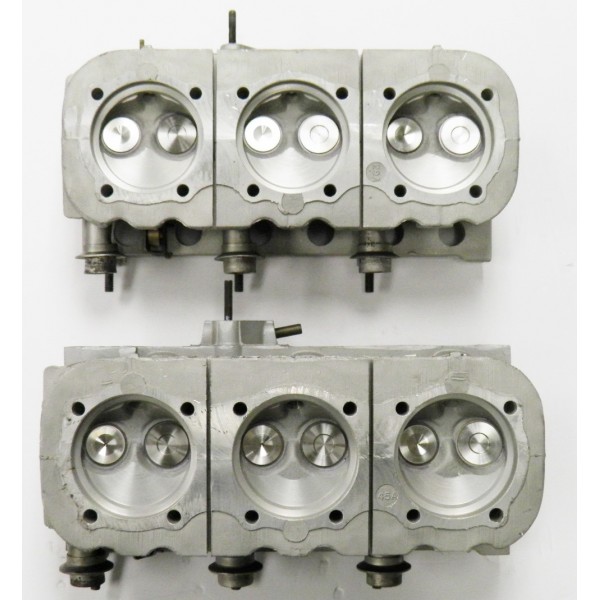

There are cylinder head mods that can also help with your goals. All Corvair engines except the 140HP engines have small valves. You can get turbo heads modified to have larger valves, or you can use 140 heads.

EFI is nice, I built a Megasquirt controller and put it on a Corvair. Fuel control is so much easier but performance gains will come from better ignition timing. Stock Corvair timing has lots of room for improvement. Best to map the timing on a dyno IMO

Restoring your 64 sounds like a good project, keep us posted.

Marty Scarr

welcome to the forum

Are you planning on keeping the car turbocharged? There are 4 different turbochargers used on Corvairs.

62: 3817254

63: 3830651

64: 3840830

65-6: 3856709

The first 3 were for the 150 hp engines, the last for the 180 engine. You can make a hybrid turbo by taking the cold side of the late (F model turbo) and mate it to the hot side of the early (B model turbo) for more performance. There is also a larger compressor housing and impeller from the E model turbo that will fit for more flow.

There are cylinder head mods that can also help with your goals. All Corvair engines except the 140HP engines have small valves. You can get turbo heads modified to have larger valves, or you can use 140 heads.

EFI is nice, I built a Megasquirt controller and put it on a Corvair. Fuel control is so much easier but performance gains will come from better ignition timing. Stock Corvair timing has lots of room for improvement. Best to map the timing on a dyno IMO

Restoring your 64 sounds like a good project, keep us posted.

Marty Scarr

Re: What type of intake to build?

Marty,

Where do I find what model turbo (A, B, C, D, E, F) went with what car? I like this idea of the hybrid turbo with the modifications you mention. Does EFI work with this mod? I don't know yet what heads are in this car (pulling the engine tonight hopefully) , but using the 140 heads is the goal. I also like the idea of a larger bore and slightly longer stroke than the stock 64 Spyder..

Where do I find what model turbo (A, B, C, D, E, F) went with what car? I like this idea of the hybrid turbo with the modifications you mention. Does EFI work with this mod? I don't know yet what heads are in this car (pulling the engine tonight hopefully) , but using the 140 heads is the goal. I also like the idea of a larger bore and slightly longer stroke than the stock 64 Spyder..

- bbodie52

- Corvair of the Month

- Posts: 11909

- Joined: Mon Aug 06, 2012 12:33 pm

- Location: Lake Chatuge Hayesville, NC

- Contact:

Re: What type of intake to build?

It is important for you to decide what type of Corvair you want to build. Do you want a moderately-tuned car that would suit a family as something of a fun, enjoyable and reliable daily driver? Or do you want a more-extreme and fun performance machine that may be somewhat temperamental and difficult to tune, but gives a thrill on a weekend drive? The more extreme the machine, the more-narrow focused it may be as a family car. This can also be true of more-extreme suspension modifications, which can be great for road racing or on the autocross competition course, but stiff and uncomfortable on the street. Turbocharged Corvairs can be a lot of fun, but a highly modified turbocharged engine can often be less reliable and/or expensive to build. The turbocharged engine that is driven hard will use greater quantities of expensive Premium fuel. Turbo Corvair engines are only meant to be "on the turbo" for relatively short bursts of acceleration. They can self-destruct if pushed too hard for long periods of high performance operation. (I drove my 1965 stock 180 hp turbo Corsa up a lengthy uphill highway grade one time — keeping the engine on the turbo continuously for several uphill miles. As I approached the top of the long uphill grade on a warm summer day, one of the pistons let go with a "hole in one". Apparently the engine started to experience detonation under the long period of turbo boost (which I failed to notice) and the result was a hole melted in the top of one of the pistons! Perhaps this is the reason that performance-tuned Corvairs intended for road racing seem to be normally aspirated (non-turbocharged), often sporting a pair of Weber 3-barrel carburetors mounted on a custom direct-port intake manifold, or some other variation of carburetion or fuel injection. Turbo Corvairs intended for racing or competition are more likely to be found at the drag strip, where maximum horsepower is only applied for short periods of time.

The attached booklets should answer some of your questions about Corvair turbochargers...

In addition to the factory shop manual, this book contains a great deal of performance information about the Corvair. As a teenager I read the earlier version of this book in 1970 and found it to be very valuable and informative. It is a personal favorite.

https://www.amazon.com/Performance-Corv ... +to+hotrod

I have attached a sample portion of this book for you to look at, to give yo an idea of the content of this valuable reference.

===========================================================================================

The books shown below made a lot of difference to me when I was starting out with working on Corvairs as a teen back in the late 1960s. I was trying to follow the shop manual, but there was still a gap in my basic knowledge that often prevented me from really grasping what was going on. I discovered this series of books that was published by the people who published Hot Rod Magazine. I really devoured the contents of each book, and as I did, the "light" came on for me in understanding how electrical systems, carburetion and ignition systems, etc. really were supposed to function. If you are interested, these books can often be purchased used on Amazon.com, eBay, etc. for only a few dollars. If you are willing to invest some reading time, you may find them to be helpful. The book series is old, but they match the technology found in vintage Corvairs and other older classic cars.

bbodie52 wrote:Classic cars had a different way of doing things in the 1950s, 1960s and earlier, when compared to modern techniques utilizing sensors and computer technology to control fuel injection and ignition systems. There was a series of books that were published in the 1960s and 1970s that focus on basic principles of automobile design and function. These books covered basics associated with carburetors, ignition systems, suspension and brakes systems, etc. When I was a teenager I read through many of these books and they gave me a good understanding of the principles and functional designs that were common in the cars that I was interested in, including the Corvair. Once I read through these books, the shop manuals made a lot more sense to me as I began to understand how things function and what I was trying to accomplish in working on my Corvair. This series was published long ago (1960s-1970s) by Petersen Publishing Company, which was also associated with Hot Rod Magazine. With titles like Petersen's Basic Cams, Valves and Exhaust Systems, Petersen's Basic Ignition and Electrical Systems, and Petersen's Basic Carburetion and Fuel Systems, I was a teenager that found myself devouring much of the series to teach myself the basics that could be applied to most 1970s and earlier vehicles. The material in those books are now somewhat dated because of the change to computer-controlled electronic fuel injection and other sophisticated technologies that have been introduced in the subsequent decades. But I do feel a Corvair owner or any classic car owner could benefit from the material in these books. Many of them are listed as available on Amazon.com. If you would like to consider the possibility of reading through some of this material, the following link may help you to find what you're looking for. The cost of these books is low, and the investment in time that you might make in reading them may help you to develop a foundation of knowledge that will help you to leap ahead in your DIY maintenance efforts on your Corvair.

https://www.amazon.com/s/ref=nb_sb_noss ... pany+basic

ebayhttps://www.ebay.com/sch/i.html?_odkw=b ... c&_sacat=0

The attached booklets should answer some of your questions about Corvair turbochargers...

- Attachments

-

- Corvair Rajay Turbocharger Primer.pdf

- Corvair Rajay Turbocharger Primer

- (1.78 MiB) Downloaded 37 times

-

- Corvair Rajay Turbocharger - Primer II - Generational Differences.pdf

- Corvair Rajay Turbocharger - Primer II - Generational Differences

- (2.14 MiB) Downloaded 40 times

Brad Bodie

Lake Chatuge, North Carolina

1966 Corvair Corsa Convertible

1966 Corvair Corsa Convertible

Lake Chatuge, North Carolina

1966 Corvair Corsa Convertible

1966 Corvair Corsa Convertible-

61SuperMonza

- Posts: 310

- Joined: Mon Apr 29, 2019 1:51 pm

Re: What type of intake to build?

The 64 spyder came with a b flow turbo. The hybrid turbo is a great modification. The big bore cylinders and larger stroke mods are big money. The machining alone will cost you around 3500 buck. If you are building a NA engine I would go with the big bore set up. The result with the VW jugs will be 3.1L. If you go with a turbo set up I would spend your money on big valve heads built for a turbo engine. You can go with 140 heads but you will have to have deep seats installed. The money spent on the machine work alone could be used for your turbo induction set up. To make a long story short if you do all the things that have been talked about you will have around 10 to 12000 in the engine alone. The machine work is costly. Good luck with the project.

First corvair in 1985

Have owned 4 corvairs since

65 Corsa coupe 180 turbo

66 Monza coupe 110 PG

66 Monza coupe 140 PG

61 Monza club coupe w/ 150 turbo

Anchorage,AK

Have owned 4 corvairs since

65 Corsa coupe 180 turbo

66 Monza coupe 110 PG

66 Monza coupe 140 PG

61 Monza club coupe w/ 150 turbo

Anchorage,AK

-

martyscarr

- Posts: 323

- Joined: Sun Dec 13, 2009 10:33 am

- Location: Eugene, OR

Re: What type of intake to build?

61SuperMonza is correct, your 64 would have come with a B flow turbo, part number 3840830.troy.w wrote: ↑Wed Apr 08, 2020 3:42 pm Marty,

Where do I find what model turbo (A, B, C, D, E, F) went with what car? I like this idea of the hybrid turbo with the modifications you mention. Does EFI work with this mod? I don't know yet what heads are in this car (pulling the engine tonight hopefully) , but using the 140 heads is the goal. I also like the idea of a larger bore and slightly longer stroke than the stock 64 Spyder..

EFI will work with the mods I mentioned, you can either adapt a throttle body to inject fuel before the turbo or after the turbo, at the heads. I mentioned Megasquirt, others have used the Simple Digital System unit and Haltech Fuel Injection among others.

For reliability, deep valve seat heads are used to prevent "dropping a seat", which is no fun. Here's one I dropped years ago Larger bores: Stock cylinders are often bored to .030 oversized, which is popular and still reliable IMO. VW cylinders have been adapted to Corvairs for decades. Popular are 92mm and 94mm piston/cylinder kits, the 92mm are available in a "thick wall" cylinder, which helps to keep the cylinder round during operation - a good thing with a turbo. You can read about this conversion at Kent Sullivan's site http://www.corvairkid.com/mm01.htm

There are only 2 factory stokes, the 2.6 and the 2.94, (yours should be 2.94) anything longer is custom. There are a few vendors that offer stroker cranks, or some folks have a stock crank modified.

HTH

-

martyscarr

- Posts: 323

- Joined: Sun Dec 13, 2009 10:33 am

- Location: Eugene, OR

Re: What type of intake to build?

troy.w I sent you a PM

Re: What type of intake to build?

Thanks all,

I have several Uncles that are machinists by trade. They tend to build large custom valves, flanges and other parts for chemical plants and refineries. The metals they use tend to be pretty unique and high grade because of the low reactivity (titanium, etc) I'm thinking about seeing if I can get the right billet material (and blueprints) I want for some custom parts, and seeing if that road might produce some parts without as much costs. It might be that it isn't feasible. This would be the crank, connecting rods, pistons, cams.

The heads on this car are in bad shape. Someone took the valve covers off eons ago, and the rockers etc have exposed to the southern New Mexico desert for who knows how long. Breaking the bolts loose has been difficult.

I like the three barrel Weber carbs. This might be the route I like best so far.

The application will be a street car that can get up and move when I feel like doing so. It will probably be driven one to two times a week for pleasure rather than a daily driver.

Troy

I have several Uncles that are machinists by trade. They tend to build large custom valves, flanges and other parts for chemical plants and refineries. The metals they use tend to be pretty unique and high grade because of the low reactivity (titanium, etc) I'm thinking about seeing if I can get the right billet material (and blueprints) I want for some custom parts, and seeing if that road might produce some parts without as much costs. It might be that it isn't feasible. This would be the crank, connecting rods, pistons, cams.

The heads on this car are in bad shape. Someone took the valve covers off eons ago, and the rockers etc have exposed to the southern New Mexico desert for who knows how long. Breaking the bolts loose has been difficult.

I like the three barrel Weber carbs. This might be the route I like best so far.

The application will be a street car that can get up and move when I feel like doing so. It will probably be driven one to two times a week for pleasure rather than a daily driver.

Troy