Neither of these work.

The C shape device has two problems. The upper part of the C leg hits the head on every valve accept the two ends. It's too flimsy and runs out of thread before compressing a spring enough.

The tubular unit - I don't have the strength to compress nor how many times I hit it with a hammer per instructions do the keepers come off.

Got any recommendations?

Edit - I was using the tubular one wrong - figured it out. I am managing now. Got some worn valve guides - damn!

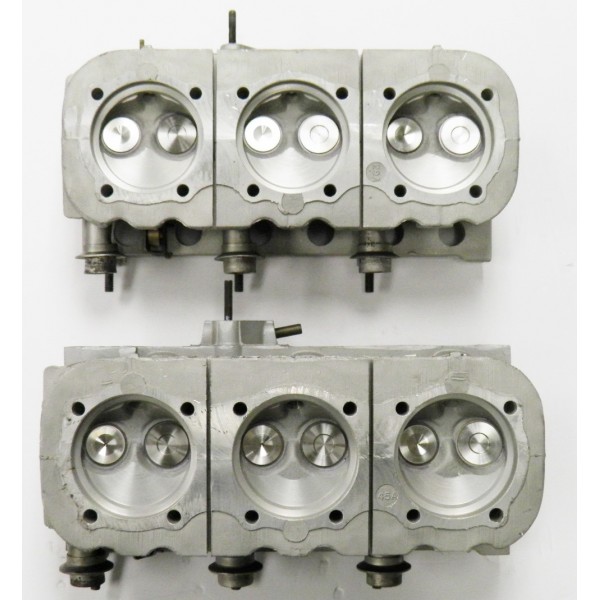

I admit I've lost track of which head is passenger side 1/3/5 and which is drivers side 2/4/6. I had incorrectly assumed they were unique and mirror imaged. Nope they are the same.

Does it matter then which side they go back on?

If so, is there some visually distinguishing difference between the two?

1966 Corvair Corsa Convertible

1966 Corvair Corsa Convertible