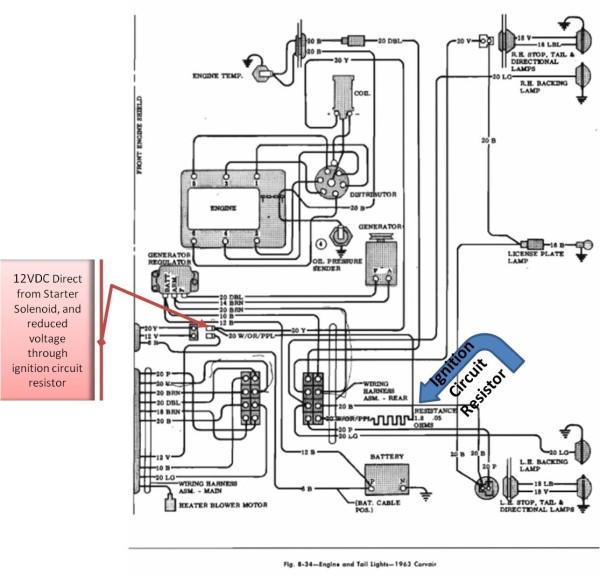

The original Delco coil primary resistance value of 1.28-1.42 ohms was likely chosen to match with the 1.8 ohm ballast resistor wire value to produce about 3 ohms of total resistance for the Delco coil Primary to manage heat buildup within the coil. At the same time, the voltage divider circuit was designed to reduce arcing and burning of the points contacts by minimizing the voltage as much as possible during normal engine operation, but this made the coil secondary output too weak to get the cold engine started reliably during engine cranking, so the starter solenoid was used to momentarily compromise the voltage divider resistor circuitry to promote engine starting.

The GM design engineers integrated all of these features into the ignition circuitry to optimize the system for initial startup, and for continued running, and to get the longest life with acceptable reliability out of the system. In other words, they looked at the whole system and designed it using available technology and components to cover the changing environment during engine startup and operation.

When the ignition switch is turned to the ON position, voltage is routed back to the engine compartment to power the ignition coil. This voltage is normally routed through a ballast resistor wire to reduce the 12 VDC provided by the battery and charging system to only about 7 VDC. This lower voltage reduced the electrical current flowing through the ignition coil and ultimately through the ignition points to GROUND. The points are simply an ON/OFF switch that turns the current through the ignition coil PRIMARY winding on and off as the points are actuated by the cam inside the distributor. WHEN THE POINTS CLOSE, CURRENT FLOWS THROUGH THE COIL PRIMARY WINDING. WHEN THE POINTS OPEN THEMAGNETIC FIELD IN THE COIL PRIMARY COLLAPSES, WICH INDUCES A HIGH VOLTAGE THROUGH THE SECONDARY WINDING TO SEND A SPARK VOLTAGE TO A SPARK PLUG. (The rotor and cap determine which spark plug gets the high voltage).

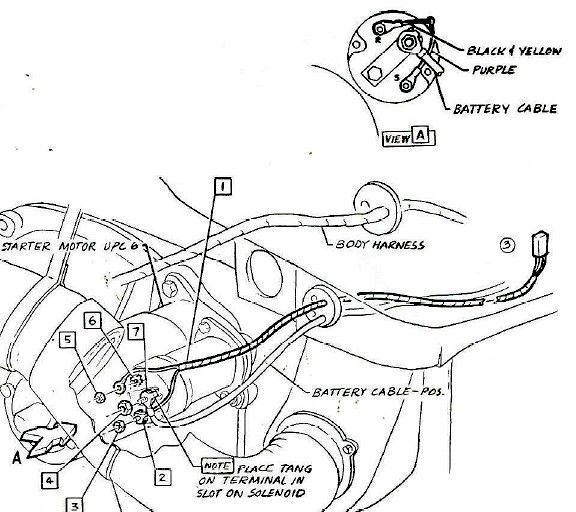

Ig you watch the starter activity in the diagram below, you will see the solenoid physically moves the starter drive gear to engage it with th large ring gear on the clutch or torque convertor, to rotate the engine for starting. AT THE SAME TIME THE DRIVE GER ENGAGES THE ENGNE RING GEAR, A LARGE DISC ON THE LEFT END OF THE SOLENOID CONNECTS THE THICK BATTERY CABLE TO THE STARTER MOTOR, TO ACTIVATE THE MOTOR TO TURN THE ENGINE.

That same disc that feeds a large amount of current to the motor simultaneously connects with another terminal connection on the back of the solenoid. This routes electricity to the electrical connector that is spliced to the resistor wire that normally feeds the coil and points. WHILE THE RESISTOR WIRE NORMALLY REDUCES THE IGNITION SWITCH VOLTAGE FROM 12.5 VDC TO ABOUT 7 VDC, THE 12.5 VDC THAT IS ADDED AT THE SPLICE CONNECTION FROM THE SOLENOID SUPERCEDES THE 7 VDC, AND THE HIGHER VOLTAGE TEMPORARILY TAKES OVER — FEEDING THE HIGHER BATTERY VOLTAGE DIRECTLY TO THE COIL POSITIVE TERMINAL. (The 7 VDC from the ignition switch/resistor wire is still there, but since 12.5 VDC is electrically spliced in to the same wire, the voltage from the starter solenoid connection supersedes the lower resistor wire voltage. This results in a "hotter" spark plug voltage from the coil, but only as long as the starter is cranking the engine. The "hotter" spark from the coil helps the cold, slowly cranking engine to get started. At the moment the engine starts, the driver releases the key, which disengages the purple wire voltage to the solenoid. which allows the solenoid to relax and simultaneously stop the starter motor while the drive gear disengages from the ring gear. This action also stops the added voltage from connecting to the ignition coil, so the coil only gets what is left — 7 VDC coming from the ballast resistor wire. The spark plug voltage coming form the coil is then reduced, but is still deemed to be high enough to keep the engine running.

The 3.0 ohm aftermarket coil is designed to be powered by a full 125 VDC battery voltage all the time. Its internal 3 ohm Primary produces a good spark plug voltage, and the coil will not overheat because of the internal current-limiting resistance of the 3 ohm primary winding. This also limits the amount of current running through the points, to protect the points. IF THE BALLAST RESISTOR WIRE HAD BEEN LEFT IN THE CIRCUIT, THE TOTAL CIRCUIT RESISTANCE WOULD BE TOO MUCH, AND WOLD SERIOUSLY WEAKEN THE COIL OUTOUT TO THE SPARK PLUGS. For this reason, the external ballast resistor must be bypassed to properly power the aftermarket ignition coil. The new ignition coil gets 12.5 VDC all the time — whenever the key is in the ON position. The extra yellow wire coming form the solenoid would no longer have any affect on the ignition circuit.

The circuitry that GM used for decades was designed ONLY to prolong the life of the ignition points contacts. The use of a mechanical switch (POINTS) was the only method they had during those years to switch the coil on and off at such a rapid pace. The engineers also determined that a stronger spark plug voltage was needed to get the cold engine running, so they came up with the external ballast resistor (integrated wire or ceramic resistor) to permit the starter solenoid to determine the amount of voltage feeding the coil while cranking the engine, or with the engine running. The newer design of the aftermarket 3.0 ohm coil still protects the points by limiting the current flowing across the points contacts. At the same time, the coil internal redesign produces a strong spark to start the car, and continues with the same spark output for normal engine operation. WITH THE 3.0 OHM COIL IN OPERATION, THE EXTERNAL BALLAST RESISTOR WIRE MUST BE PERMANENTLY BYPASSED FOR THE COIL TO BE POWERED PROPERLY.

1966 Corvair Corsa Convertible

1966 Corvair Corsa Convertible