1965 Corvair Corsa Convertible 140hp 4x1 - Spring 1980 - Base Housing - Hanscom AFB, MA

Is there any chance that you turned the IDLE MIXTURE SCREW clockwise, possibly getting it mixed up with the idle speed screw? Turning the idle speed screw clockwise on each carburetor would open the throttle butterfly valves (associated with the throttle linkage) and would increase the idle speed. If you mistakenly turned the idle mixture screws in 1½ turns, you would be cutting-off the fuel from the idle mixture, causing the idle mixture to be very lean.ahhhoo wrote: » Mon Apr 29, 2024 5:28 am

Thank you Brad.. We just picked up the car Saturday. Drove it home 30 miles to Belchertown Ma (our location). Next day, cleaning out the barn, the car just would idle choppy and would stall out at idle. Pushing the gas kept the engine running, but once off the accelerator, the engine would quit. To get the car moving again and moved into shelter, because of the rain last night, I turned each idle screw (without the syncing carb tool, its ordered.) 1.5 turns clockwise. The idle went up on the engine, but boy did it run rough!!! We limped it into the barn on where it sits now.

bbodie52 wrote:There is no simple, or compressed method to tune and troubleshoot a Corvair engine. A certain amount of knowledge or understanding is essential for the person doing the tune-up to interpret the results and then to be able to make logical adjustments accordingly. I would encourage you to do your homework, ask questions for clarification when needed. and follow the guidance below and in the shop manual to ultimately get the desired results with your Corvair.

bbodie52 wrote:Here is a fair amount of tune-up info, but if you can work your way through it the explanations may help with your understanding of how the various subsystems interact with each other, and why the proper sequence should be followed so you don't end up adjusting one area improperly to compensate for another area that isn't functioning properly.

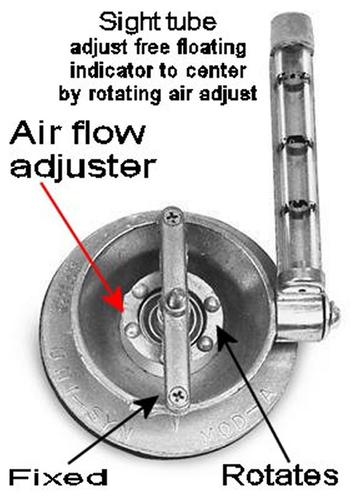

The dwell tachometer and timing light are the most common items thought of when working with an older engine in a classic car. As previously mentioned, however, there are ways to work around the lack of these tools. Adjusting the ignition points gap with a flat feeler gauge is a substitute for having a dwell tachometer. Setting the dwell with an electronic instrument is more accurate, however. The tachometer portion is needed to measure idle speeds and possibly to perform other tests where engine speed measurement is needed. It is possible to static-time your ignition system with a strip of paper placed between the ignition points. The engine timing mark can be manually positioned to the desired setting on the crankshaft pulley, and the distributor can be slowly rotated until the points just start to open and release the strip of paper. The distributor is then tightened and the mechanic has established an initial static timing setting. Of course, having a timing light makes things much easier, improves accuracy, and permits visual confirmation that the centrifugal advance is functioning. A vacuum gauge can be used for carburetor synchronization and other carburetor tests, and most vacuum gauges also double as a pressure gauge for measuring fuel pump output pressure. A UniSyn gauge, as shown below, measures airflow through each carburetor throat, and is an accurate way for synchronizing multiple carburetors at idle speeds and at partial throttle. A multimeter is a useful tool for troubleshooting and diagnosing electrical and charging system problems.

Many ignition systems in Corvairs have been upgraded by fitting an electronic ignition system to the distributor. These electronic ignition systems eliminate ignition points and condenser, which makes engine tuning somewhat easier and eliminates the need to periodically replace worn ignition points. The breakerless ignition system utilizes an optical or magnetic trigger to control the ignition coil. The system eliminates the need for a dwell meter or flat feeler gauge for ignition points adjustments. (A wire-type feeler gauge is needed for adjusting spark plug gaps). The tachometer portion of a dwell-tachometer, however, is still useful.

Learning to work with the two Rochester primary carburetors on the Corvair really isn't all that difficult. But you should take the time to review the shop manuals and other attached manuals to get a better feel for what you are trying to accomplish. It is important to perform tuning steps in the right sequence, as outlined in the shop manuals and in the video below. Many of the tuning steps can impact the results found in other steps. There is a logical progression in tuning a Corvair engine, and skipping around or tuning components in a random order can only serve to confuse the outcome. The Delco Rochester service manual that I have attached is a good supplement to the Corvair shop manual. About half of the manual is dedicated to explaining the various subsystems and components of the Rochester HV carburetor. To some extent these carburetors perform as you would expect a computer-controlled fuel injection system and ignition system to operate — but they were designed at a time when computer-controlled systems that were designed to respond to sensor input throughout the car would only have been a dream. The various carburetor and ignition subsystems respond to engine temperature, engine speed, airflow and vacuum changes, etc. much like a modern engine — but without all of the sophisticated electronics and sensors. Engineers were attempting to accomplish the things we do now, but with much less sophistication — but still making changes as engine speed, throttle position, engine vacuum, and fluid and air flow characteristics varied. If you take the time to read through the Delco Rochester manual, you might come to understand how the choke system functions, what an accelerator pump does and why it exists, and how the distributor is designed to adjust timing at low engine speeds and at higher engine speeds using both a vacuum advance and a centrifugal advance to provide the correct timing at various engine speeds and load settings. A good understanding of how these systems work and what they are supposed to do can be a great help when tuning and troubleshooting your engine.

The links, videos, and attachments below should help you to understand how to work with a dual carburetor engine. Try not to be intimidated by two physically separated carburetors. They really function very much like a single two-barrel carburetor, but are physically separated from each other out of necessity due to the layout of the flat air cooled engine with cylinders opposed to each other. The Corvair engine layout is in many ways similar to many motorcycle engine configurations. It usually takes an experienced automobile mechanic a little adjustment time to get used to the way things are done on a motorcycle. The aluminum, air cooled flat six Corvair engine often is seen as a challenge to an automobile mechanic, who is not used to the "strange configuration" found in a Corvair.

http://www.corvairforum.com/forum/viewt ... 875#p90875

The entire shop manual and many other Corvair technical references can be downloaded at no cost using the following link...

Common and Useful Corvair Websites

http://www.corvairforum.com/forum/viewt ... 225&t=6007

Watching the video presentations below helps to provide insight and understanding about proper sequencing of the tuneup steps and procedures. Skipping around can insert obstacles and problems with getting the engine properly tuned.

The portion of the first video segment toward the end (Part 1, 5:10) and at the beginning of the second segment discusses throttle linkage adjustments and carburetor synchronization.

Tuning the Corvair Engine — Part 1

Tuning The Corvair Engine — Part 2

bbodie52 wrote: The Uni-Syn Carburetor Balancing Instrument is a tool that I remember as far back as the 1950s and 1960s. It was designed for use in multi-carburetor automobiles, motorcycles, etc. that were initially common in European vehicles, but were later found in American vehicles like the Corvair.

The Uni-Syn is an airflow gauge that must be calibrated to match the specific engine airflow moving through the carburetor throat. The flow control in the center of the Uni-Syn is mounted on a threaded pin. Rotating the flow control raises or lowers it, which increases/decreases the air gap, which impacts the air velocity passing the oriface that allows some airflow to pass through the gauge. With the Uni-Syn held firmly on the carburetor intake with the engine idling, the flow control is adjusted so that the plastic float is approximately centered in the glass sight tube. Once calibrated, the Uni-Syn can be moved back and forth between the two primary carburetors to compare airflow at idle. The goal is to play with the idle speed screws to get an even airflow level that matches between both carburetors, and at the same time produces the desired idle speed. Before fine-tuning this idle balance with a Uni-Syn, the ignition system, idle speed and idle mixture should have been adjusted following the standard procedures as described in the factory shop manual. The balancing step with the Uni-Syn gauge is added at the end of the tuning procedure to measure actual airflow though both carburetors at idle, and balancing that airflow using the airflow meter as a measuring tool, rather than simply relying on a physical balanced "calibration" using a strip of paper to detect initial contact between the idle speed adjustment screws and the carburetor linkage, followed by counting the screw turns needed to obtain the desired idle speed (and ensuring that the same number of screw turns are applied to each screw). That procedure achieves a fairly close initial setup. The use of the Uni-Syn airflow gauge as a final step ensures balance between the two carburetors by measuring actual airflow.

Once the balanced idle airflow and desired idle speed have been achieved, a similar procedure can be used to synchronize the airflow when the carburetors are held open at a faster engine speed by the throttle linkage. Again, the shop manual procedure can be used to set the initial mechanical balance between the two sides of the throttle linkage. The linkage segment connecting the accelerator pedal to the cross-linkage between the two carburetors is temporarily disconnected, and a turnbuckle is temporarily attached to hold the throttle opened against the pull of the throttle return spring.

The turnbuckle can be adjusted to hold the throttle open at approximately 1500 RPM. The Uni-Syn center flow control is readjusted to re-calibrate the float to a position somewhere in the center travel of the sight tube, based on the increased airflow through the carburetors at the higher steady RPM maintained by the turnbuckle arrangement. As with the idle synchronization procedure, the re-calibrated Uni-Syn is used to measure the airflow moving through the two carburetors. The goal is to fine-tune the threaded portion of the carburetor actuation linkage so that the same airflow reading is attained on each carburetor, but this time with the throttles held open by a pull on the throttle linkage, instead of by the setting of the idle speed screws. When the airflow has been balanced using the throttle linkage adjustment, the balancing procedure has been completed and the normal accelerator pedal throttle linkage can be reconnected.

TIPS & CLARIFICATION...

With the engine at idle, you want to open the Uni-Syn flow control as much as possible, but still keep the float in the sight glass at about mid-level. Then check the other carburetor, which you want to read the same flow rate. You may have to adjust the flow control a few times as you adjust the carburetor settings. Just remember to check each carburetor with the flow control set at the same point, and to keep the sight glass in the vertical to prevent the float from hanging up in the tube.

The wheel in the Uni-Syn venturi controls the flow through the tube, or in other words how high the bead is in the cylinder for a given engine speed. You need enough flow to not strangle the engine, and the bead works just as well in the lower third (which still lets good air flow through). Make sure the idle speed doesn't drop when you place the tool on the carb: if it does, open it up.

Before setting the carbs, make sure that the ignition is right: points and timing set, good wires and plugs. Poor running is often blamed on carbs when in fact it's a weak, retarded spark. Check the throttle shafts: loose ones let in air and lean the mixture, raising idle speed, as well as throw off the linkage action. Check the linkage that connects the carburetors. if it's loose, one will open before the other. Make sure there are no vacuum leaks.

With a twin carburetor set up, disconnect the linkage that connects one carburetor to the other. Set the idle speed with the linkage screws first. Use the Uni-Syn to check that each carburetor is drawing equally at idle. This may take a few tries until you get both drawing equally at the speed you want. Blip the throttle to see if they come back to those settings (worn throttle shafts can fool you). Set the idle mixture screws in accordance with the shop manual instructions. Check the balance again. Hook the linkage back up. If one carburetor now draws more, adjust the linkage until it's back to roughly equal.

Once the carburetors are drawing equally at idle, hold an engine speed: at about 1500 RPM. This checks that the mechanical linkage is pulling equally. You'll need to open up the Uni-Syn center wheel to draw more air and bring the bead down in the tube. If both carburetors are within a bead's thickness of each other, that's good. If one is definitely off from the other, the higher flow carburetor's linkage is being pulled more than the other. You'll need to figure out why that's happening mechanically to rectify it.

You need to backtrack a little...

The goal is normally to try to match the left and right carburetors as closely as possible. Rebuilding or replacing one carburetor while neglecting to do the same on the other side encourages something of a mismatch.

After checking for vacuum leaks (don't forget the Powerglide transmission vacuum modulator as a possibility), disconnect and plug the vacuum advance line that is coming from the right carburetor. (Make sure that the rubber hose is connected to the vertical vacuum tube on the right carburetor, and NOT the horizontal vacuum tube, which should be connected to the choke mechanism vacuum break unit on each carburetor). Temporarily readjust the carburetor idle speed screws to get the engine idle slowed down to about 700 rpm in NEUTRAL. This will ensure that the centrifugal advance mechanism in the distributor is not affecting the timing. Then recheck the points (dwell) with a dwell-tachometer and then the base timing setting with a timing light, and set them correctly for your engine, using the specs in the shop manual.

See Vacuum gauge viewtopic.php?f=225&t=10563

At this point, you will have confirmed that there are no vacuum leaks, and that the ignition system settings (dwell and timing) are correct. Reconnect the vacuum advance tube between the right carburetor and the distributor vacuum advance mechanism.

Following the procedures in the shop manual, the base (starting point) idle settings on each carburetor are to be established. With the throttle linkage at both carburetors disconnected from the cross linkage between the two carburetors, a narrow strip of paper is used like a feeler gauge by placing it between the idle speed adjusting screw and the carburetor throttle linkage. With the throttle closed, the idle speed screw is slowly backed away until it just releases its grip on the strip of paper. This establishes its point of contact with the throttle linkage. Then carefully turn the screw clockwise an a additional 1-1/2 turns to establish the idle speed preset. Perform this same procedure on the other carburetor. Then perform the idle mixture preset on both carburetors by gently turning the idle mixture screws all the way in so they just bottom-out in the carburetor. Then back each screw out counterclockwise 1-1/2 turns.

With the engine running, the correct idle speed for your engine must be established. With a manual transmission-based engine, the idle speed is set to the speed designated in the shop manual. This can be a starting point with the automatic transmission-based engine as well. Any adjustment made to increase or decrease the idle speed must be duplicated at both carburetors, so that the carburetor settings remain in sync on both sides. (A uni-syn gauge, or a vacuum gauge, if available, can be used to more-accurately synchronize the two carburetors so that they are each contributing an equal amount of airflow to the engine idle). With a Powerglide-based engine, the final idle speed must be set with the transmission in DRIVE, to load the engine with the resistance provided by the fluid coupling (torque converter). The goal is to achieve a slow, smooth and steady idle speed in DRIVE.

With the carburetor idle settings in sync, and the correct idle speed established in DRIVE, the last step is to reconnect the main throttle linkage between the two carburetors, and then the throttle linkage connection to the accelerator pedal. These procedures are described in the shop manual. There is an adjustment point in the linkage on the left side. The goal is to have both carburetors connected to the cross-linkage, without the linkage binding or holding either carburetor throttle open or impacting the idle speed. The link on the left carburetor is adjusted so that bot the right and left carburetor connections slip into the cross linkage. Finally, the adjustable link and throttle return spring is adjusted to slip into the cross link without changing the idle speed, so that the gas pedal permits opening the throttle fully but also allows the throttle to return fully to the idle setting.

1966 Corvair Corsa Convertible

1966 Corvair Corsa Convertible