66vairguy wrote:Sat Apr 06, 2024 12:34 pm

Brad - I do us dielectric grease on contacts, but I'm reluctant to use it on the dimmer rheostat wire as it is nichrome wire and it can get warm, ever hot. That said I've never measured the wire temperature with the lights dimmed. Not sure how warm the wire gets, but the wire is in a cerarmic holder!

Anybody ever bench tested the switch to see how warm the rheostat gets?

The rheostat contained in the Corvair light switch serves to dim the illumination from between 5 to 8 small 3 watt instrument panel light bulbs (the total number varies between the Monza, Spyder, and Corsa instrument panels, plus the heater control and the Powerglide transmission shift lever control, if any). With a maximum current drawn by these bulbs no more than 24 watts, which calculates out to a total current draw of approximately 2 amps. A thin coating of dielectric grease would not be expected to have much insulating properties, and such a small capacity rheostat would be unlikely to get warm as it restricted a small portion of the current flowing to 8 or fewer small 3 watt illumination bulbs.

Dielectric grease is not an automotive necessity like oil or coolant, but it’s a popular product used in garages across the country. Most commonly applied on spark plug boots, lightbulbs, and battery terminals, dielectric grease is, in theory, a protectant like car wax. It’s not required, but it could help extend and maintain the life and quality of your vehicle and its parts.

Dielectric grease is not an automotive necessity like oil or coolant, but it’s a popular product used in garages across the country. Most commonly applied on spark plug boots, lightbulbs, and battery terminals, dielectric grease is, in theory, a protectant like car wax. It’s not required, but it could help extend and maintain the life and quality of your vehicle and its parts.

Dielectric grease is just one of the numerous types of lubricants found in and around your automobile, and each one has a specific purpose. If you choose to pick up some dielectric grease, you can’t use it interchangeably with wheel bearing grease, or vice versa.

The Drive’s greasy editors are here to explain what dielectric grease is, isn’t, and how it’s supposed to work. Let’s start with the basics.

What Is Dielectric Grease?

Dielectric, sometimes referred to as tune-up grease, is a viscous non-conductive waterproof substance used to protect electrical connections from corrosion and dirt.

What Is Dielectric Grease Made of?

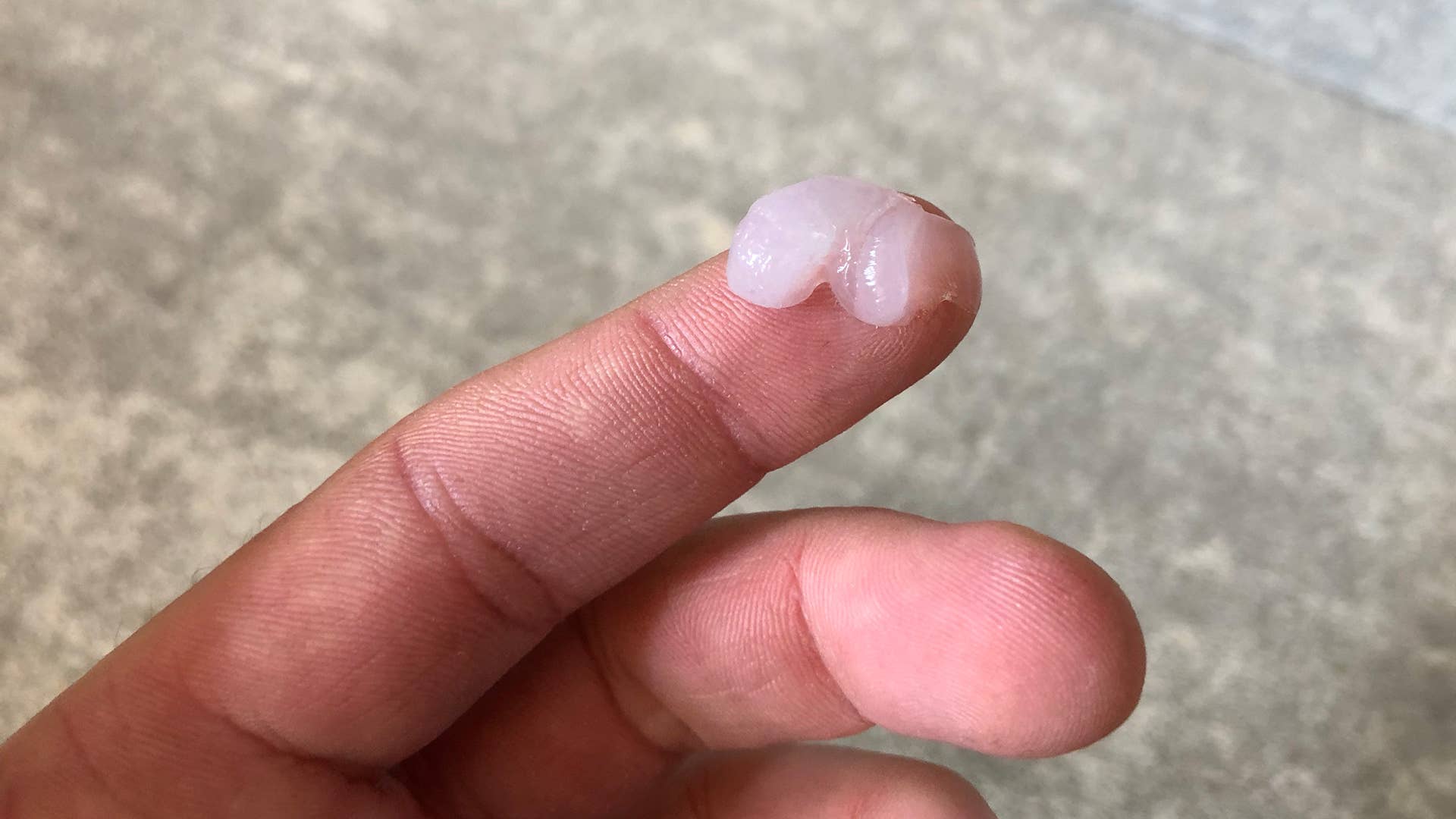

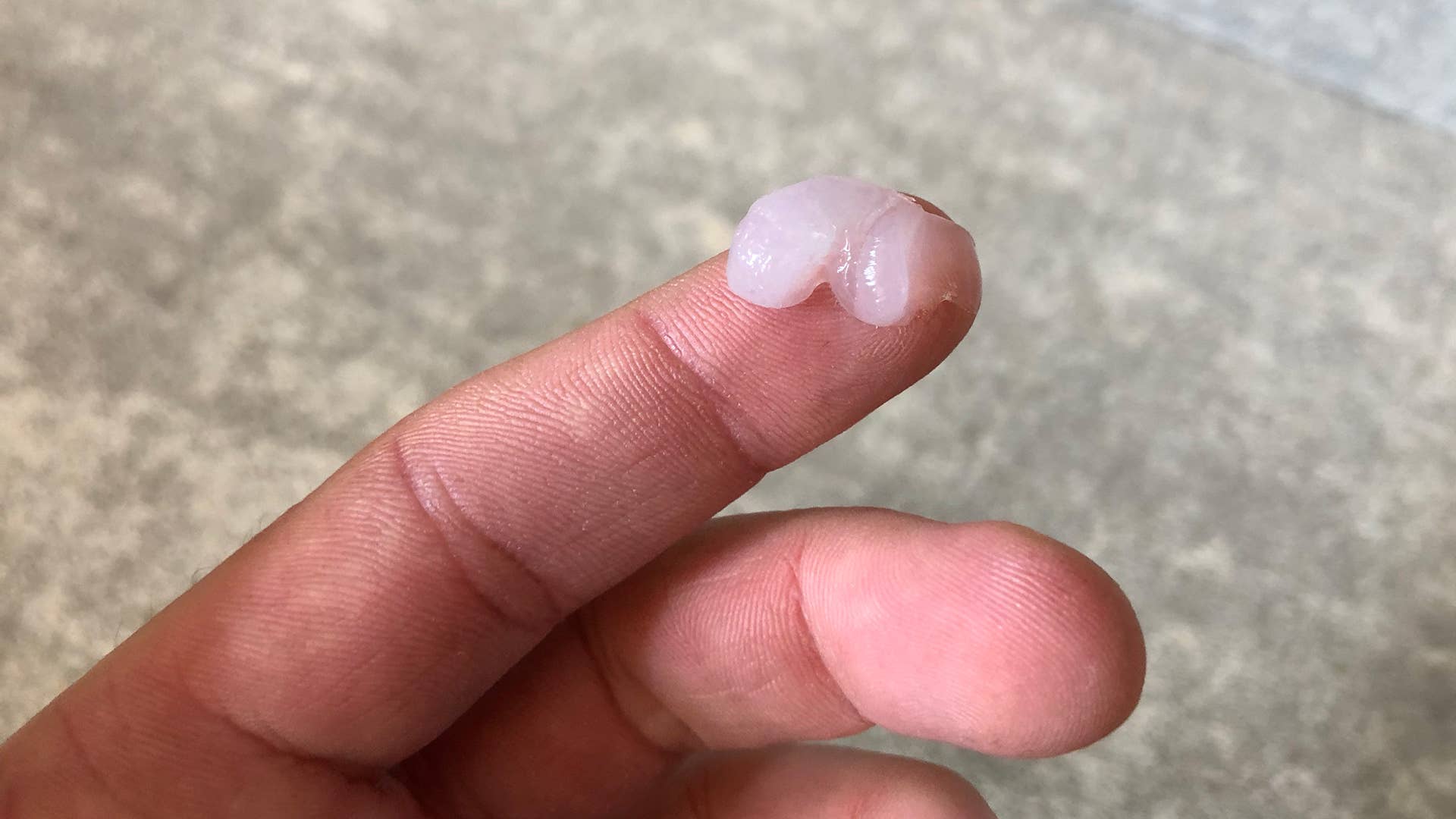

Dielectric grease is most commonly made of a silicone base and a thickener. It typically has a slightly translucent grayish or milky clear color. Permatex dielectric grease lists polydimethylsiloxane and silicone dioxide.

Although the dielectric grease does insulate the metal and wiring from external invaders, the contacts are tight enough to still maintain a connection, the grease is just displaced. That said, you do not need to squirt huge globs of dielectric grease into your connectors as you see in some videos out there.

Will Dielectric Grease Worsen a Connection?

There is a myth floating around that putting dielectric grease into electrical connections can cause them to fail because the grease gets between the metal. That’s not true.

When To Use Dielectric Grease

Dielectric grease acts as a lubricant, a sealant, an insulator, and a protectant when lightly used on these applications.

- Battery terminals

- Spark plug boots

- Bulb sockets

- Trailer connectors

- General electrical connections

- General plastic or rubber lubrication

Q: So Does Dielectric Grease Improve a Connection?

A: No, dielectric grease is not conductive, so it does not improve connectivity. It helps maintain a good connection, though.

https://www.thedrive.com/maintenance-re ... ric-grease

https://www.thedrive.com/maintenance-re ... ric-grease

https://www.amazon.com/Permatex-22058-D ... hdGY&psc=1

https://www.thedrive.com/maintenance-re ... ric-grease

1966 Corvair Corsa Convertible

1966 Corvair Corsa Convertible