Revisiting the topic for a newbie - - - HIGH IDLE SPEED

Revisiting the topic for a newbie - - - HIGH IDLE SPEED

Well, here we go again . . . HIGH IDLE SPEED . . . after reading most all of the previous forum posts here and on the Corvair Center "Phorum", I am still unable to get the idle, after initial warm up, below 1500.

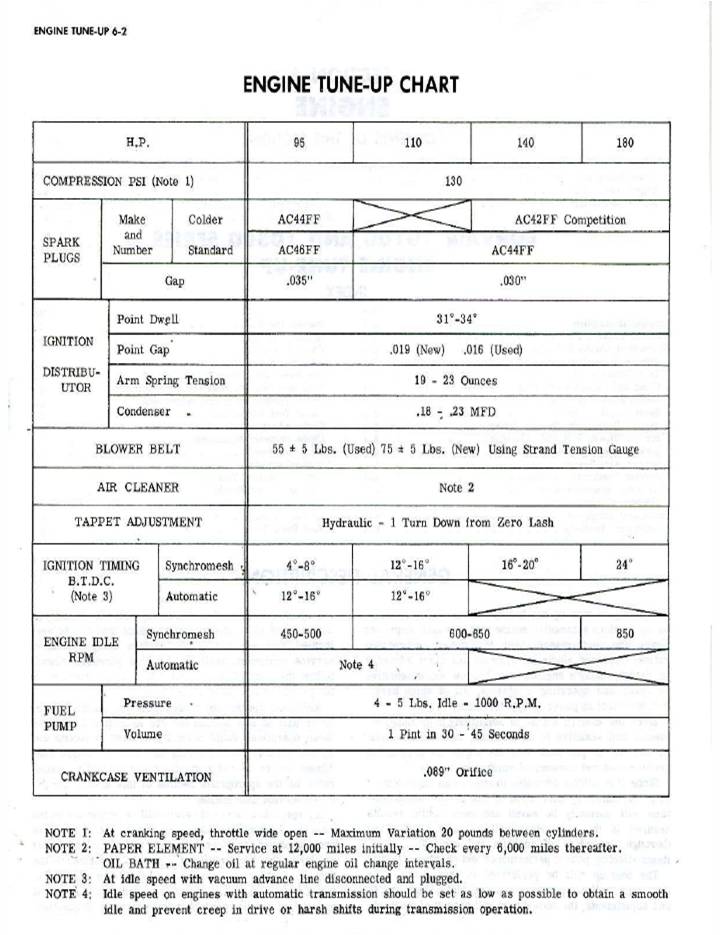

I have a 1966 Monza, 110hp, 4-speed. Carburetors both recently rebuilt and set up according to shop manual, new electric fuel pump, dwell, spark plugs, valves set according to shop manual. I have adjusted and then re-adjusted the timing to 14 degrees. I am still (at warm engine) seeing an idle speed of 1548. That is better than the 1758 I had two weeks ago . . but a loooong way from the 500 - 700 rpm noted in the carb balancing tutorial seen below or the 600-650 seen in the '65 shop manual and the '66 supplement - page 6-2.

After seeing bbodie52 post the photo of a degree wheel (attachment below) and knowing that the engine turns in a counterclockwise direction, I assume I have the timing set correctly at a position halfway between the expressed "16" and the first hash line to the left (12)?

Today, I played with again turning the distributor cap to see if I could lower the idle. It did . . but then, again with my new timing light, the setting on the motor casting was just about what is seen in the photo - approximately 2. The idle had come down to 848 but that 2 is so far from 14 I re-adjusted to 14 and left it there with the higher idle speed.

Having seen forum discussions of "carburetors out of sync" as being a potential cause for high idle I looked at the Corvair Center FAQ and found this:

Basics of Carburetor Balancing

You need 6 good cylinders! Do a Compression Check!

You need the TIMING / point gap-dwell SET correctly BEFORE attempting

note: timing must be set BELOW 800 rpm! with Vacuum Advance hose plugged!

You need to DISCONNECT the driver's side linkage!!!

You need 2 GOOD CARBS! [ test by opening just ONE carb at a time to see if engine runs the same for both!].

You need TIGHT linkage..do what is necessary to stop side movement in the cross shaft and slop in any of the holes…BUT make sure linkage is not binding!

You need the engine fully warmed up AND make sure the CHOKES are fully opened! [ VERTICAL!!!]

If using a UniSyn, or other device ON TOP of the carbs....make sure the Choke plate is not hitting the device!

You need 2 good carb bodies! If the Choke shaft hole[s] are worn...AIR LEAK! [ apply thick grease to plug temporarily!]

If you are using the carbs for the 1st time / engine startup, etc., hold the choke open, back out idle SPEED screw until throttle is totally closed......slowly screw in until you feel / see the throttle just start to move..than 4 turns more! Idle MIXTURE screws should be 2 turns out from seated [ closed fully ].

NOTE: TO BALANCE THE CARBS…..YOU ARE ADJUSTING AIRFLOW ONLY/ IDLE SPEED SCREWS!!! NOT THE IDLE MIXTURE SCREWS.

ONLY AFTER GETTING THE AIRFLOW BALANCED, AND IDLE SPEED DOWN LOW [ 500-700 RPMS] DO YOU THEN ADJUST IDLE MIXTURE SCREWS TO MAKE THE IDLE SMOOTHER!!!!

A great easy to follow writing . . and after the above there is a good tutorial on how to to the job . . . IF you are at the mentioned 500 - 700 rpm!!

I feel that I am running in circles chasing an ever illusive lower idle speed that is always one step out of my grasp. So much information and many helpful hints . . . BUT . . . I could really use a definitive; "DO THIS . . Step 1 . . . then Step 2 . . . then VOILA . . you have a 635 idle speed!!! YAY.

It all seems a bit "by guess, by golly" . . . you really just have to have a feel for it?!

Help? Please!

THANK YOU

I have a 1966 Monza, 110hp, 4-speed. Carburetors both recently rebuilt and set up according to shop manual, new electric fuel pump, dwell, spark plugs, valves set according to shop manual. I have adjusted and then re-adjusted the timing to 14 degrees. I am still (at warm engine) seeing an idle speed of 1548. That is better than the 1758 I had two weeks ago . . but a loooong way from the 500 - 700 rpm noted in the carb balancing tutorial seen below or the 600-650 seen in the '65 shop manual and the '66 supplement - page 6-2.

After seeing bbodie52 post the photo of a degree wheel (attachment below) and knowing that the engine turns in a counterclockwise direction, I assume I have the timing set correctly at a position halfway between the expressed "16" and the first hash line to the left (12)?

Today, I played with again turning the distributor cap to see if I could lower the idle. It did . . but then, again with my new timing light, the setting on the motor casting was just about what is seen in the photo - approximately 2. The idle had come down to 848 but that 2 is so far from 14 I re-adjusted to 14 and left it there with the higher idle speed.

Having seen forum discussions of "carburetors out of sync" as being a potential cause for high idle I looked at the Corvair Center FAQ and found this:

Basics of Carburetor Balancing

You need 6 good cylinders! Do a Compression Check!

You need the TIMING / point gap-dwell SET correctly BEFORE attempting

note: timing must be set BELOW 800 rpm! with Vacuum Advance hose plugged!

You need to DISCONNECT the driver's side linkage!!!

You need 2 GOOD CARBS! [ test by opening just ONE carb at a time to see if engine runs the same for both!].

You need TIGHT linkage..do what is necessary to stop side movement in the cross shaft and slop in any of the holes…BUT make sure linkage is not binding!

You need the engine fully warmed up AND make sure the CHOKES are fully opened! [ VERTICAL!!!]

If using a UniSyn, or other device ON TOP of the carbs....make sure the Choke plate is not hitting the device!

You need 2 good carb bodies! If the Choke shaft hole[s] are worn...AIR LEAK! [ apply thick grease to plug temporarily!]

If you are using the carbs for the 1st time / engine startup, etc., hold the choke open, back out idle SPEED screw until throttle is totally closed......slowly screw in until you feel / see the throttle just start to move..than 4 turns more! Idle MIXTURE screws should be 2 turns out from seated [ closed fully ].

NOTE: TO BALANCE THE CARBS…..YOU ARE ADJUSTING AIRFLOW ONLY/ IDLE SPEED SCREWS!!! NOT THE IDLE MIXTURE SCREWS.

ONLY AFTER GETTING THE AIRFLOW BALANCED, AND IDLE SPEED DOWN LOW [ 500-700 RPMS] DO YOU THEN ADJUST IDLE MIXTURE SCREWS TO MAKE THE IDLE SMOOTHER!!!!

A great easy to follow writing . . and after the above there is a good tutorial on how to to the job . . . IF you are at the mentioned 500 - 700 rpm!!

I feel that I am running in circles chasing an ever illusive lower idle speed that is always one step out of my grasp. So much information and many helpful hints . . . BUT . . . I could really use a definitive; "DO THIS . . Step 1 . . . then Step 2 . . . then VOILA . . you have a 635 idle speed!!! YAY.

It all seems a bit "by guess, by golly" . . . you really just have to have a feel for it?!

Help? Please!

THANK YOU

- bbodie52

- Corvair of the Month

- Posts: 11949

- Joined: Mon Aug 06, 2012 12:33 pm

- Location: Lake Chatuge Hayesville, NC

- Contact:

Re: Revisiting the topic for a newbie - - - HIGH IDLE SPEED

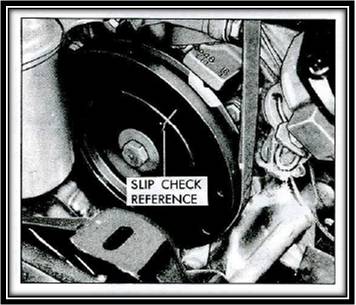

You should have a harmonic balancer. It is a component of all 1964 and later Corvair engines, with the single exception of the low-horsepower 95hp engine. It is a good idea to inspect the harmonic balancer for slippage. Does the harmonic balancer appear to be intact without any signs of outer ring slippage? The balancer is a 3-piece assembly consisting of a center hub, an outer ring, and a rubber ring component pressed between the inner and outer metal components. As the harmonic balancer ages, slippage can occur between the inner and outer pieces. If this occurs, the harmonic balancer must be replaced, as it will ultimately fail and come apart. There is usually a slip-check reference mark, as shown below, to assist with verifying that the balancer is intact. If any slippage has occurred, the timing mark on the outer ring will no longer be accurate. You should check the harmonic balancer to confirm the accuracy of the timing mark BEFORE you check and adjust the timing with a timing light.

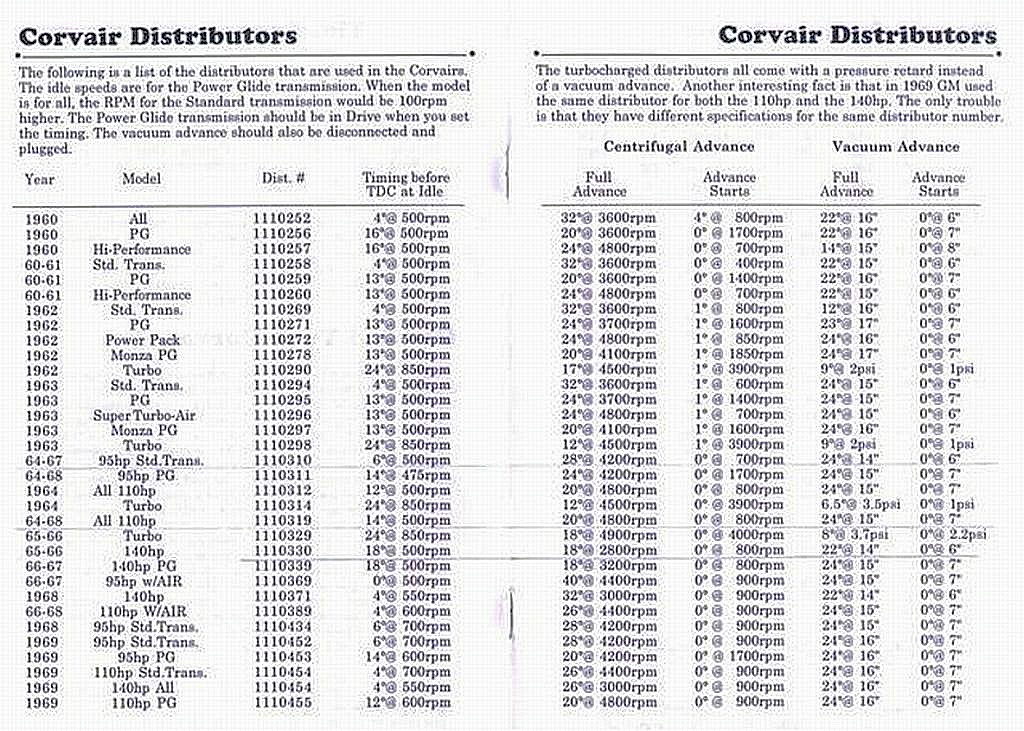

Again, assuming that your engine is a 110hp engine, the timing should be set to 12°-16° BTDC with the engine warmed up and off of the automatic choke fast idle. When checking the timing, it is important that the vacuum advance hose be disconnected and plugged, to insure that there is no vacuum advance affecting the timing at idle. Also, the engine speed should be about 600 RPM at idle, to ensure that the centrifugal advance mechanism inside the distributor is not affecting the base timing setting. (The internal centrifugal advance mechanism inside the 110hp engine distributor begins to advance the timing at about 800 RPM).

What is the make and model of your timing light?

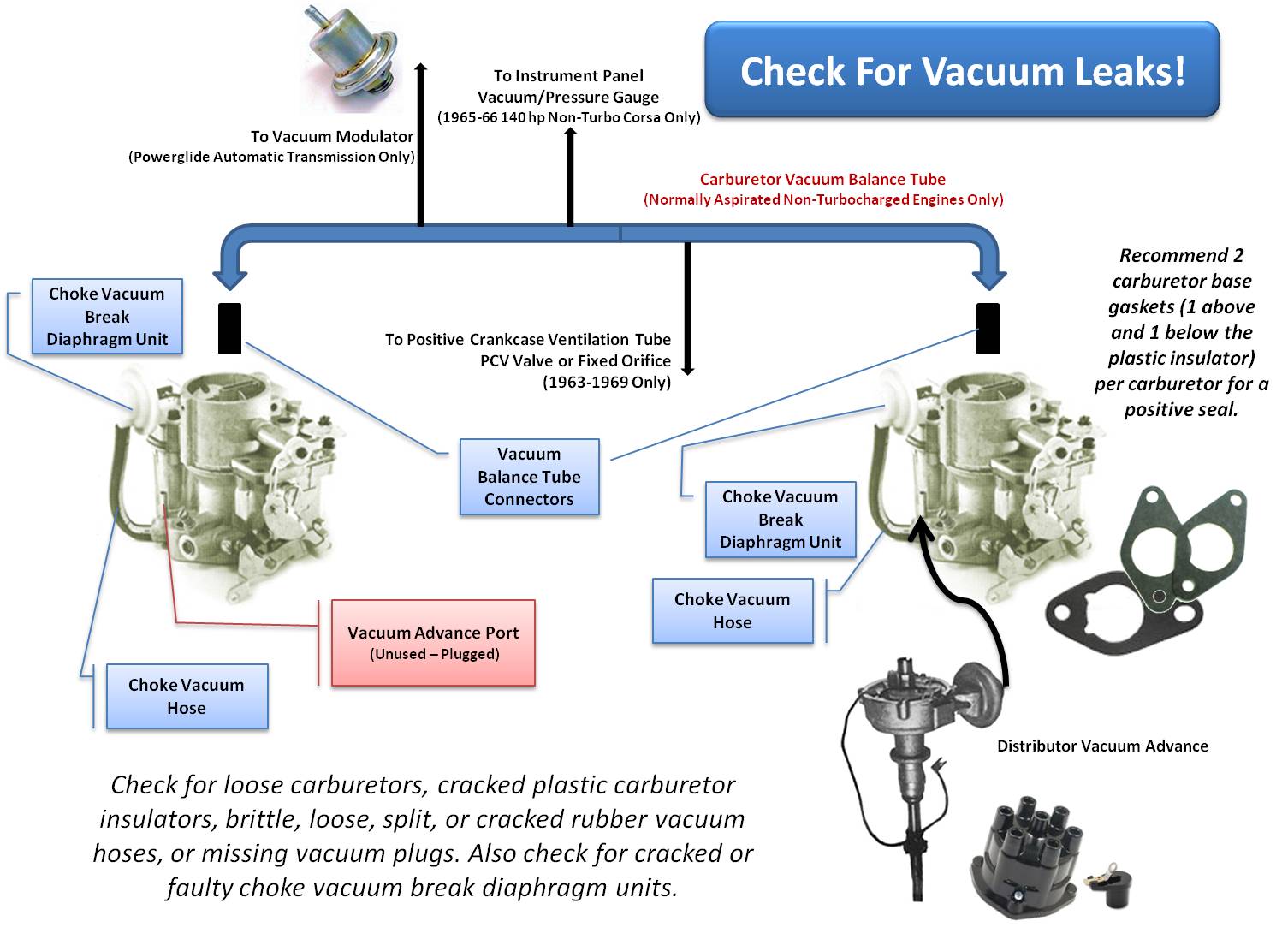

Just to confirm, you are setting the timing with the vacuum advance disconnected from the distributor vacuum advance and plugged? Once the timing has been set to 14 degrees BTDC @ 500-600 rpm, the vacuum hose must be reconnected from the VERTICAL vacuum tube (spark port) on the right carburetor (not the horizontal vacuum tube, which is reserved for the automatic choke vacuum break on each carburetor. The vertical tube on the left carburetor should always be plugged.

The difference between the vertical "spark port" and the horizontal manifold vacuum port is that the horizontal intake manifold vacuum port has continuous access to full intake manifold vacuum, while the spark port's access to manifold vacuum is regulated by the position of the carburetor throttle butterfly valve. The "Spark Port" is accessing the manifold vacuum from a position that is ABOVE the throttle, so it only provides vacuum as the throttle is opened to expose it to intake manifold vacuum. In this way the throttle position regulates distributor vacuum advance at low engine speeds.

Again, assuming that your engine is a 110hp engine, the timing should be set to 12°-16° BTDC with the engine warmed up and off of the automatic choke fast idle. When checking the timing, it is important that the vacuum advance hose be disconnected and plugged, to insure that there is no vacuum advance affecting the timing at idle. Also, the engine speed should be about 600 RPM at idle, to ensure that the centrifugal advance mechanism inside the distributor is not affecting the base timing setting. (The internal centrifugal advance mechanism inside the 110hp engine distributor begins to advance the timing at about 800 RPM).

What is the make and model of your timing light?

Just to confirm, you are setting the timing with the vacuum advance disconnected from the distributor vacuum advance and plugged? Once the timing has been set to 14 degrees BTDC @ 500-600 rpm, the vacuum hose must be reconnected from the VERTICAL vacuum tube (spark port) on the right carburetor (not the horizontal vacuum tube, which is reserved for the automatic choke vacuum break on each carburetor. The vertical tube on the left carburetor should always be plugged.

The difference between the vertical "spark port" and the horizontal manifold vacuum port is that the horizontal intake manifold vacuum port has continuous access to full intake manifold vacuum, while the spark port's access to manifold vacuum is regulated by the position of the carburetor throttle butterfly valve. The "Spark Port" is accessing the manifold vacuum from a position that is ABOVE the throttle, so it only provides vacuum as the throttle is opened to expose it to intake manifold vacuum. In this way the throttle position regulates distributor vacuum advance at low engine speeds.

According to the chart below, the centrifugal timing advance in the distributor begins to affect timing at 800 rpm. It reaches full advance of 20 degrees at approximately 4800 rpm. Your engine must be idling at less than 800 rpm with the vacuum advance disconnected to set the engine base timing with a timing light without the centrifugal advance affecting the timing.

Brad Bodie

Lake Chatuge, North Carolina

1966 Corvair Corsa Convertible

1966 Corvair Corsa Convertible

Lake Chatuge, North Carolina

1966 Corvair Corsa Convertible

1966 Corvair Corsa Convertible- terribleted

- Posts: 4584

- Joined: Sun Apr 18, 2010 2:36 pm

- Location: Atlanta, GA

- Contact:

Re: Revisiting the topic for a newbie - - - HIGH IDLE SPEED

Ok you adjust idle speed with the idle speed screws on both carbs. Disconnect the throttle rod coming from the trans from the carb cross shaft and reinstall the spring to hold the cross shaft toward idle position. Set timing and then balance the carbs. Once the carbs are balanced adjust both idle speed screws the same amount up or down to attain the desired idle speed. Recheck timing and adjust if necessary. Perhaps you needed to change the timing and the idle speed changed. If so, readjust both carbs idle speed screws the same amount (so they stay in balance) again to attain desired idle speed. Reinstall the throttle rod while keeping the cross shaft moved to idle and the carbs hitting their idle speed screws. If the rod will not reinsert in this position without moving the cross shaft then the throttle linkage is out of adjustment. Adjust the linkage per the manual. If the car is an automatic idle speed must be adjusted idling in drive to the lowest possible idle where the idle is still smooth. This will vary but will generally be between 650 and about 850RPM

Things that can cause high idle. Throttle linkage misadjusted and not allowing carbs to return to idle position where throttle levers sit against the idle speed screws, binding somewhere in carbs or linkage that keep the carbs from returning idle position, or vacuum leaks, minor flooding, vacuum advance active (vacuum advance becomes active at about 800-1000 RPM depending on vacuum advance number). vacuum advance can get stuck every now and then (rare) but stuck (or active ....worn out and weak?), vacuum advance active will keep idle speed higher also. Make sure the throttle plates in the carbs are not installed upside down as this can cause a high idle (vacuum leak). The plates are machined at an angle on the edges and must be installed so the flat of the angle on the edge sits against the sides of the carb throat not the sharp edge.

Things that can cause high idle. Throttle linkage misadjusted and not allowing carbs to return to idle position where throttle levers sit against the idle speed screws, binding somewhere in carbs or linkage that keep the carbs from returning idle position, or vacuum leaks, minor flooding, vacuum advance active (vacuum advance becomes active at about 800-1000 RPM depending on vacuum advance number). vacuum advance can get stuck every now and then (rare) but stuck (or active ....worn out and weak?), vacuum advance active will keep idle speed higher also. Make sure the throttle plates in the carbs are not installed upside down as this can cause a high idle (vacuum leak). The plates are machined at an angle on the edges and must be installed so the flat of the angle on the edge sits against the sides of the carb throat not the sharp edge.

Corvair guy since 1982. I have personally restored at least 20 Vairs, many of them restored ground up.

Currently working full time repairing Corvairs and restoring old cars.

https://www.facebook.com/tedsautorestoration/

Located in Snellville, Georgia

Currently working full time repairing Corvairs and restoring old cars.

https://www.facebook.com/tedsautorestoration/

Located in Snellville, Georgia

Re: Revisiting the topic for a newbie - - - HIGH IDLE SPEED

THANKS . . I'll try to answer your questions . . .

Post by bbodie52 » Wed Mar 02, 2022 10:34 pm

You should have a harmonic balancer. It is a good idea to inspect the harmonic balancer for slippage. Does the harmonic balancer appear to be intact without any signs of outer ring slippage?

The harmonic balancer was replaced by the previous owner "a couple years ago", I have the old one in the Clark's box from the new one. Even though the old ones rubber looks dried, the marks still align. I just checked again and the one on the car is aligned correctly.

Again, assuming that your engine is a 110hp engine, the timing should be set to 12°-16° BTDC with the engine warmed up and off of the automatic choke fast idle. When checking the timing, it is important that the vacuum advance hose be disconnected and plugged, to insure that there is no vacuum advance affecting the timing at idle. Also, the engine speed should be about 600 RPM at idle, to ensure that the centrifugal advance mechanism inside the distributor is not affecting the base timing setting. (The internal centrifugal advance mechanism inside the 110hp engine distributor begins to advance the timing at about 800 RPM).

I plugged the vacuum hose. "the engine speed should be about 600 RPM at idle" . . . is exactly my issue here!!

Could I be having an issue with the distributor centrifugal advance mechanism?

Just to confirm, you are setting the timing with the vacuum advance disconnected from the distributor vacuum advance and plugged?

Correct, it was plugged. Port on 2nd carb was plugged, as always.

From the diagram concerning vacuum leaks:

Choke Vacuum Brake Diaphragm Units . . . BOTH new with carb rebuild kits.

Vacuum Balance Tube Connectors . . . BOTH new with carb rebuild kits.

Carburetor gaskets (2) and plastic insulators . . . All new with carb rebuild kits. One gasket each above and below plastic insulator.

Choke Vacuum Hoses . . . BOTH new with carb rebuild kits.

Vacuum Advance Port - left carb . . . New tube cover supplied with carb rebuild kit always in place.

Carburetors loose? . . . NO, new washers and flange nuts secured tightly.

Note: I have the air cleaner apparatus removed, top of carbs are open while doing this work.

Here is the Tune Up Chart I am using from the '66 Supplement to the '65 Shop Manual:

Similar but showing 14 degrees BTDC.

Post by bbodie52 » Wed Mar 02, 2022 10:34 pm

You should have a harmonic balancer. It is a good idea to inspect the harmonic balancer for slippage. Does the harmonic balancer appear to be intact without any signs of outer ring slippage?

The harmonic balancer was replaced by the previous owner "a couple years ago", I have the old one in the Clark's box from the new one. Even though the old ones rubber looks dried, the marks still align. I just checked again and the one on the car is aligned correctly.

Again, assuming that your engine is a 110hp engine, the timing should be set to 12°-16° BTDC with the engine warmed up and off of the automatic choke fast idle. When checking the timing, it is important that the vacuum advance hose be disconnected and plugged, to insure that there is no vacuum advance affecting the timing at idle. Also, the engine speed should be about 600 RPM at idle, to ensure that the centrifugal advance mechanism inside the distributor is not affecting the base timing setting. (The internal centrifugal advance mechanism inside the 110hp engine distributor begins to advance the timing at about 800 RPM).

I plugged the vacuum hose. "the engine speed should be about 600 RPM at idle" . . . is exactly my issue here!!

Could I be having an issue with the distributor centrifugal advance mechanism?

Just to confirm, you are setting the timing with the vacuum advance disconnected from the distributor vacuum advance and plugged?

Correct, it was plugged. Port on 2nd carb was plugged, as always.

From the diagram concerning vacuum leaks:

Choke Vacuum Brake Diaphragm Units . . . BOTH new with carb rebuild kits.

Vacuum Balance Tube Connectors . . . BOTH new with carb rebuild kits.

Carburetor gaskets (2) and plastic insulators . . . All new with carb rebuild kits. One gasket each above and below plastic insulator.

Choke Vacuum Hoses . . . BOTH new with carb rebuild kits.

Vacuum Advance Port - left carb . . . New tube cover supplied with carb rebuild kit always in place.

Carburetors loose? . . . NO, new washers and flange nuts secured tightly.

Note: I have the air cleaner apparatus removed, top of carbs are open while doing this work.

Here is the Tune Up Chart I am using from the '66 Supplement to the '65 Shop Manual:

Similar but showing 14 degrees BTDC.

Re: Revisiting the topic for a newbie - - - HIGH IDLE SPEED

Post by terribleted » Thu Mar 03, 2022 9:50 am

Ok you adjust idle speed with the idle speed screws on both carbs.

So this is done no matter what the idle speed after getting the timing set to the specified 14 degrees BTDC?

Disconnect the throttle rod coming from the trans from the carb cross shaft and reinstall the spring to hold the cross shaft toward idle position. Set timing and then balance the carbs.

I thought this could only be done with a 600 - 650 rpm range first? I am above 1500 with timing set at 14 degrees.

Things that can cause high idle. Throttle linkage misadjusted and not allowing carbs to return to idle position where throttle levers sit against the idle speed screws, binding somewhere in carbs or linkage that keep the carbs from returning idle position,

I have installed new throttle shafts and the spring loaded O-rings to seal any potential air leaks. Everything "seems" smooth and working properly. I will re-look at all pieces.

or vacuum leaks,

In answering bbodie52 I noted that all rubber hoses were replaced when the carbs were recently rebuilt.

minor flooding,

My flooding issues were recently corrected by installation of an electric fuel pump.

vacuum advance active (vacuum advance becomes active at about 800-1000 RPM depending on vacuum advance number). vacuum advance can get stuck every now and then (rare) but stuck (or active ....worn out and weak?), vacuum advance active will keep idle speed higher also.

The Vacuum Control Assembly seemed to be working properly . . perhaps I should replace this old item just in case? I do not know if it was replaced by the previous owner?

Make sure the throttle plates in the carbs are not installed upside down as this can cause a high idle (vacuum leak). The plates are machined at an angle on the edges and must be installed so the flat of the angle on the edge sits against the sides of the carb throat not the sharp edge.

During my 2nd carb rebuild last month while working on flooding problems I double checked the throttle plate and also the orientation of the small "notch" for alignment with the off idle slot. Both were judged as correct. I will re-check!

Ok you adjust idle speed with the idle speed screws on both carbs.

So, this says that, no matter what the idle is after setting the timing to the designated 14 degrees, these screws are the only way to lower the idle? Also, the initial setting of idle adjustment screw to a 0.003" clearance and then an additional 1-1/2 turns inward (clockwise) is just a starting point?

Appreciate your time and help with my lack of understanding . . .

Ok you adjust idle speed with the idle speed screws on both carbs.

So this is done no matter what the idle speed after getting the timing set to the specified 14 degrees BTDC?

Disconnect the throttle rod coming from the trans from the carb cross shaft and reinstall the spring to hold the cross shaft toward idle position. Set timing and then balance the carbs.

I thought this could only be done with a 600 - 650 rpm range first? I am above 1500 with timing set at 14 degrees.

Things that can cause high idle. Throttle linkage misadjusted and not allowing carbs to return to idle position where throttle levers sit against the idle speed screws, binding somewhere in carbs or linkage that keep the carbs from returning idle position,

I have installed new throttle shafts and the spring loaded O-rings to seal any potential air leaks. Everything "seems" smooth and working properly. I will re-look at all pieces.

or vacuum leaks,

In answering bbodie52 I noted that all rubber hoses were replaced when the carbs were recently rebuilt.

minor flooding,

My flooding issues were recently corrected by installation of an electric fuel pump.

vacuum advance active (vacuum advance becomes active at about 800-1000 RPM depending on vacuum advance number). vacuum advance can get stuck every now and then (rare) but stuck (or active ....worn out and weak?), vacuum advance active will keep idle speed higher also.

The Vacuum Control Assembly seemed to be working properly . . perhaps I should replace this old item just in case? I do not know if it was replaced by the previous owner?

Make sure the throttle plates in the carbs are not installed upside down as this can cause a high idle (vacuum leak). The plates are machined at an angle on the edges and must be installed so the flat of the angle on the edge sits against the sides of the carb throat not the sharp edge.

During my 2nd carb rebuild last month while working on flooding problems I double checked the throttle plate and also the orientation of the small "notch" for alignment with the off idle slot. Both were judged as correct. I will re-check!

Ok you adjust idle speed with the idle speed screws on both carbs.

So, this says that, no matter what the idle is after setting the timing to the designated 14 degrees, these screws are the only way to lower the idle? Also, the initial setting of idle adjustment screw to a 0.003" clearance and then an additional 1-1/2 turns inward (clockwise) is just a starting point?

Appreciate your time and help with my lack of understanding . . .

Re: Revisiting the topic for a newbie - - - HIGH IDLE SPEED

bbodie52 . . .

Forgot to answer one of your questions:

My timing light is a Bosch Inductive Timing Light, Model # FIX7527 purchased new on September 30 2021 . . this is it's first usage. I like Bosch products.

Forgot to answer one of your questions:

My timing light is a Bosch Inductive Timing Light, Model # FIX7527 purchased new on September 30 2021 . . this is it's first usage. I like Bosch products.

- terribleted

- Posts: 4584

- Joined: Sun Apr 18, 2010 2:36 pm

- Location: Atlanta, GA

- Contact:

Re: Revisiting the topic for a newbie - - - HIGH IDLE SPEED

The initial curb idle setting of the carbs is made when you adjust the fast idle cam setting the throttle lever on the second highest step of the fast idle cam and then adjusting the idle speed screw for .078 clearance (fuels section of the shop manual showing assembly and adjustments.

This setting will normally place initial curb idle around 1000 or a few more RPM once the timing is set. And yes the 2 carb idle speed screws are really the only way to adjust idle speed. Timing will increase idle speed to a point ass it is advanced, and vis versa if retarded, but the idle speed is set using the 2 carb idle speed screws. Changing the idle speed will slightly change the timing, this is why for the best tuning you adjust idle speed and then readjust timing if needed and readjust idle speed if needed a couple times around maybe until the idle speed is what is desired, and the timing is also as desired,

Idle mixture screws can also slightly affect idle speed, but, set them at 2.5 or so turns out from seated and once idle speed is set you can try making them a little leaner (less that 2.5 turns). you turn them in and note for the first hint of rpm drop and then turn them out a hair so RPM did not drop. most engines like between 2 and 3 turns out on these.

This setting will normally place initial curb idle around 1000 or a few more RPM once the timing is set. And yes the 2 carb idle speed screws are really the only way to adjust idle speed. Timing will increase idle speed to a point ass it is advanced, and vis versa if retarded, but the idle speed is set using the 2 carb idle speed screws. Changing the idle speed will slightly change the timing, this is why for the best tuning you adjust idle speed and then readjust timing if needed and readjust idle speed if needed a couple times around maybe until the idle speed is what is desired, and the timing is also as desired,

Idle mixture screws can also slightly affect idle speed, but, set them at 2.5 or so turns out from seated and once idle speed is set you can try making them a little leaner (less that 2.5 turns). you turn them in and note for the first hint of rpm drop and then turn them out a hair so RPM did not drop. most engines like between 2 and 3 turns out on these.

Corvair guy since 1982. I have personally restored at least 20 Vairs, many of them restored ground up.

Currently working full time repairing Corvairs and restoring old cars.

https://www.facebook.com/tedsautorestoration/

Located in Snellville, Georgia

Currently working full time repairing Corvairs and restoring old cars.

https://www.facebook.com/tedsautorestoration/

Located in Snellville, Georgia

Re: Revisiting the topic for a newbie - - - HIGH IDLE SPEED

Thanks terribleted . . . I did set the carbs with the second highest step method and the .078" clearance and all the other carb rebuild steps as seen in Bob Helt's book and then again by the Shop Manual sequence. Once again, I assumed(??!!) that those settings were what would give required idle and fuel mix for proper performance. I see now my underestimation of the complexity of the situation.

In the next couple days, after dealing with my new brake light demon, and a little time away from the last day or two of aggravation, I will re-apply myself to the idle issue.

I really appreciate your time and knowledge helping here.

In the next couple days, after dealing with my new brake light demon, and a little time away from the last day or two of aggravation, I will re-apply myself to the idle issue.

I really appreciate your time and knowledge helping here.

- bbodie52

- Corvair of the Month

- Posts: 11949

- Joined: Mon Aug 06, 2012 12:33 pm

- Location: Lake Chatuge Hayesville, NC

- Contact:

Re: Revisiting the topic for a newbie - - - HIGH IDLE SPEED

The mechanical adjustment of the idle speed simply involves disconnecting the throttle linkage from the carburetors, and backing off the idle speed screw. The screw is then tightened until it just comes into contact with the carburetor throttle link. It is then tightened 2½ additional turns to set the starting position for the idle speed. This same procedure is duplicated on the other carburetor. This results in a mechanically synchronized pair of carburetors, which are both set to the same starting point. Later, with the engine running and warmed up (off choke) the idle speed is fine-tuned to the desired speed (about 600 RPM). ANY CHANGE ON ONE SIDE MUST BE DUPLICATD ON THE OTHER SIDE.

Watching the video presentations below helps to provide insight and understanding about proper sequencing of the tune-up steps and procedures. Skipping around can insert obstacles and problems with getting the engine properly tuned.

The mechanical linkage and idle adjustment of both carburetors is also shown in the first video above, about five minutes in from the start.

The mechanical linkage and idle adjustment of both carburetors is also shown in the first video above, about five minutes in from the start.

Watching the video presentations below helps to provide insight and understanding about proper sequencing of the tune-up steps and procedures. Skipping around can insert obstacles and problems with getting the engine properly tuned.

Tuning the Corvair Engine — Part 1

Tuning The Corvair Engine — Part 2

The procedure shown starting on page 8 specifically shows how to set the base idle speed and mechanically synchronize the two carburetors...Tuning The Corvair Engine — Part 2

Brad Bodie

Lake Chatuge, North Carolina

1966 Corvair Corsa Convertible

1966 Corvair Corsa Convertible

Lake Chatuge, North Carolina

1966 Corvair Corsa Convertible

1966 Corvair Corsa ConvertibleRe: Revisiting the topic for a newbie - - - HIGH IDLE SPEED

THANK YOU for the videos and the written info . . . much easier to read than listen to someone talking so fast without being present.

Appreciate all of your help and insight!!

Appreciate all of your help and insight!!

Re: Revisiting the topic for a newbie - - - HIGH IDLE SPEED

Well, I just finished going thru all carb setup again . . especially following page 8 & 9. I again read 1700 rpm on my digital meter (which I checked against 5 motors in my workshop yesterday to be within <1% error) and am still puzzled.

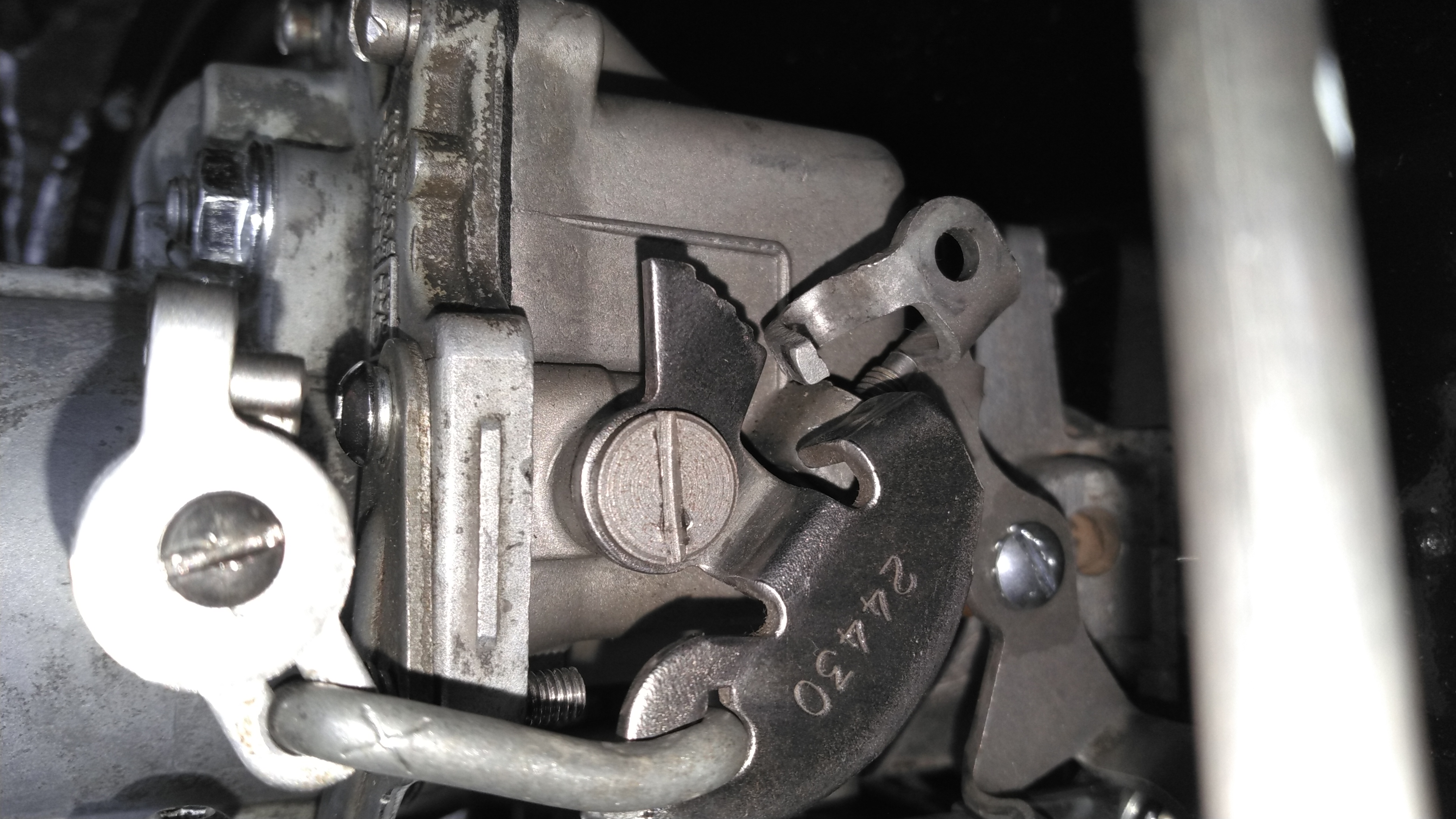

One thing I just noticed is seen in the photo below . . . compare to top left photo on page 10 of the Tuning pdf . . the toothed cam is not in contact with the tang? This is after running the motor for 5+ minutes, the choke plates are fully open. When rebuilding the carbs last month (again) the fast idle was set with the tang resting on the second highest step as seen on page 99 of the Bob Helt book.

Here I am again . . . frustrated!! Would love to complete the tuning procedure but 600 rpm is allusive . . .

Sorry about the photo being sideways . . the program here has rotated it?! I've tried twice . . .

What about backing entirely off the idle speed screw entirely?!

One thing I just noticed is seen in the photo below . . . compare to top left photo on page 10 of the Tuning pdf . . the toothed cam is not in contact with the tang? This is after running the motor for 5+ minutes, the choke plates are fully open. When rebuilding the carbs last month (again) the fast idle was set with the tang resting on the second highest step as seen on page 99 of the Bob Helt book.

Here I am again . . . frustrated!! Would love to complete the tuning procedure but 600 rpm is allusive . . .

Sorry about the photo being sideways . . the program here has rotated it?! I've tried twice . . .

What about backing entirely off the idle speed screw entirely?!

Re: Revisiting the topic for a newbie - - - HIGH IDLE SPEED

Your idle speed screw appears to be turned in to far , possibly holding open throttle plate, in photo. Tang looks excessively bent upwards. as compared to mine. driver side

Steve

Bakersfield,CA

1969 monza coupe

110, 4speed

Bakersfield,CA

1969 monza coupe

110, 4speed

- bbodie52

- Corvair of the Month

- Posts: 11949

- Joined: Mon Aug 06, 2012 12:33 pm

- Location: Lake Chatuge Hayesville, NC

- Contact:

Re: Revisiting the topic for a newbie - - - HIGH IDLE SPEED

The fast idle cam should ONLY be contacting the throttle mechanism when the choke is set and the engine is cold. Under those conditions the idle speed screw has no effect. When the engine is warm and the choke has disengaged, the fast idle cam should not be in contact with the throttle linkage. At normal operating temperatures, the idle speed screw is the only thing that determines idle speed, and how far the throttle on the left and right carburetors are held open when the engine is idling.

Brad Bodie

Lake Chatuge, North Carolina

1966 Corvair Corsa Convertible

1966 Corvair Corsa Convertible

Lake Chatuge, North Carolina

1966 Corvair Corsa Convertible

1966 Corvair Corsa ConvertibleRe: Revisiting the topic for a newbie - - - HIGH IDLE SPEED

In the photo[s] above it appears that the choke fast idle link is installed incorrectly per the Helt book which I have also been referencing to battle a carb problem of my own very recently. On page 108, photos 9-44 and 9-46 show the link positioned so that it supposedly will not bind, and allow proper operation. The link is also pictured on the front cover of this book. Some of the factory illustrations show a contradictory position so who knows? Playing around with carburetors is kind of like bleeding brake systems, sometimes everything goes ok and comes out ok, and sometimes seemingly no matter what you do something is still not quite right.

Last edited by m37aswell on Sun Mar 06, 2022 7:55 am, edited 5 times in total.

- bbodie52

- Corvair of the Month

- Posts: 11949

- Joined: Mon Aug 06, 2012 12:33 pm

- Location: Lake Chatuge Hayesville, NC

- Contact:

Re: Revisiting the topic for a newbie - - - HIGH IDLE SPEED

These pictures may help to clarify the proper assembly...

Incorrect Assembly

Incorrect Assembly

Brad Bodie

Lake Chatuge, North Carolina

1966 Corvair Corsa Convertible

1966 Corvair Corsa Convertible

Lake Chatuge, North Carolina

1966 Corvair Corsa Convertible

1966 Corvair Corsa ConvertibleRe: Revisiting the topic for a newbie - - - HIGH IDLE SPEED

THANKS TO ALL FOR YOUR REPLIES . . .

by m37aswell » Sat Mar 05, 2022 10:48 pm

In the photo[s] above it appears that the choke fast idle link is installed incorrectly per the Helt book . . . photos 9-44 and 9-46 show the link positioned so that it supposedly will not bind, and allow proper operation.

YES . . . looking at those two photos, it appears that I was in too big a hurry on my last re-assembly and I did not place the linkage to the inside?

ALSO . . . I notice that the photo I just took today, as opposed to the one yesterday which was after the motor was run for 5 minutes, that the

cold position of the choke shaft outer lever appears to be horizontal, whereas mine is pointed S.E. (downward 45 degrees to the right - a 4-

o'clock position). The lever was horizontal yesterday with a warmed up engine? Obviously I have a problem!! THANKS for seeing it.

Helts book

My photo today

'65 Shop Manual

by steve57 » Sat Mar 05, 2022 7:22 pm

Your idle speed screw appears to be turned in to far , possibly holding open throttle plate, in photo.

Yes, this was after a frustrating day of trying to lower the idle speed. I had, as seen in the photo, tried to adjust the idle by turning the screw.

Because of m37aswel seeing the incorrect position of the tripper and fast idle link, I'm hoping that reworking these items may help my issue?!

Tang looks excessively bent upwards.

This is the position attained while doing the fast idle setting according to Helt book Photo 10-3. Perhaps this may change with the adjustments to

be made above?

Very interesting that your photo also shows the fast idle link on the outside as opposed to the Helt book and Shop Manual? Different year?

by m37aswell » Sat Mar 05, 2022 10:48 pm

In the photo[s] above it appears that the choke fast idle link is installed incorrectly per the Helt book . . . photos 9-44 and 9-46 show the link positioned so that it supposedly will not bind, and allow proper operation.

YES . . . looking at those two photos, it appears that I was in too big a hurry on my last re-assembly and I did not place the linkage to the inside?

ALSO . . . I notice that the photo I just took today, as opposed to the one yesterday which was after the motor was run for 5 minutes, that the

cold position of the choke shaft outer lever appears to be horizontal, whereas mine is pointed S.E. (downward 45 degrees to the right - a 4-

o'clock position). The lever was horizontal yesterday with a warmed up engine? Obviously I have a problem!! THANKS for seeing it.

Helts book

My photo today

'65 Shop Manual

by steve57 » Sat Mar 05, 2022 7:22 pm

Your idle speed screw appears to be turned in to far , possibly holding open throttle plate, in photo.

Yes, this was after a frustrating day of trying to lower the idle speed. I had, as seen in the photo, tried to adjust the idle by turning the screw.

Because of m37aswel seeing the incorrect position of the tripper and fast idle link, I'm hoping that reworking these items may help my issue?!

Tang looks excessively bent upwards.

This is the position attained while doing the fast idle setting according to Helt book Photo 10-3. Perhaps this may change with the adjustments to

be made above?

Very interesting that your photo also shows the fast idle link on the outside as opposed to the Helt book and Shop Manual? Different year?