Idle and backfire

-

wes_anderson4

- Posts: 3

- Joined: Sat Sep 26, 2020 9:36 pm

Idle and backfire

I am new to this forum. I recently got a 64 monza 2 door hard top. I am having trouble keeping a good idle and it tends to backfire a bit. I did the initial carb adjustment. And the cap plugs and wires are new. I installed a new fuel filter and ran sea foam through the fuel system. Should I do a cold valve adjustment and see where that gets me? Thanks in advance for help.

-

joelsplace

- Posts: 2009

- Joined: Wed Oct 13, 2010 12:51 pm

- Location: Northlake, TX

Re: Idle and backfire

Check the compression. If it is ok I wouldn't mess with the valves unless you can't get them quiet. I would clean the carburetors. Is the dwell and timing set correctly?

157 Corvairs, 5 Ultravans and counting

Northlake, TX

Northlake, TX

- bbodie52

- Corvair of the Month

- Posts: 11897

- Joined: Mon Aug 06, 2012 12:33 pm

- Location: Lake Chatuge Hayesville, NC

- Contact:

Re: Idle and backfire

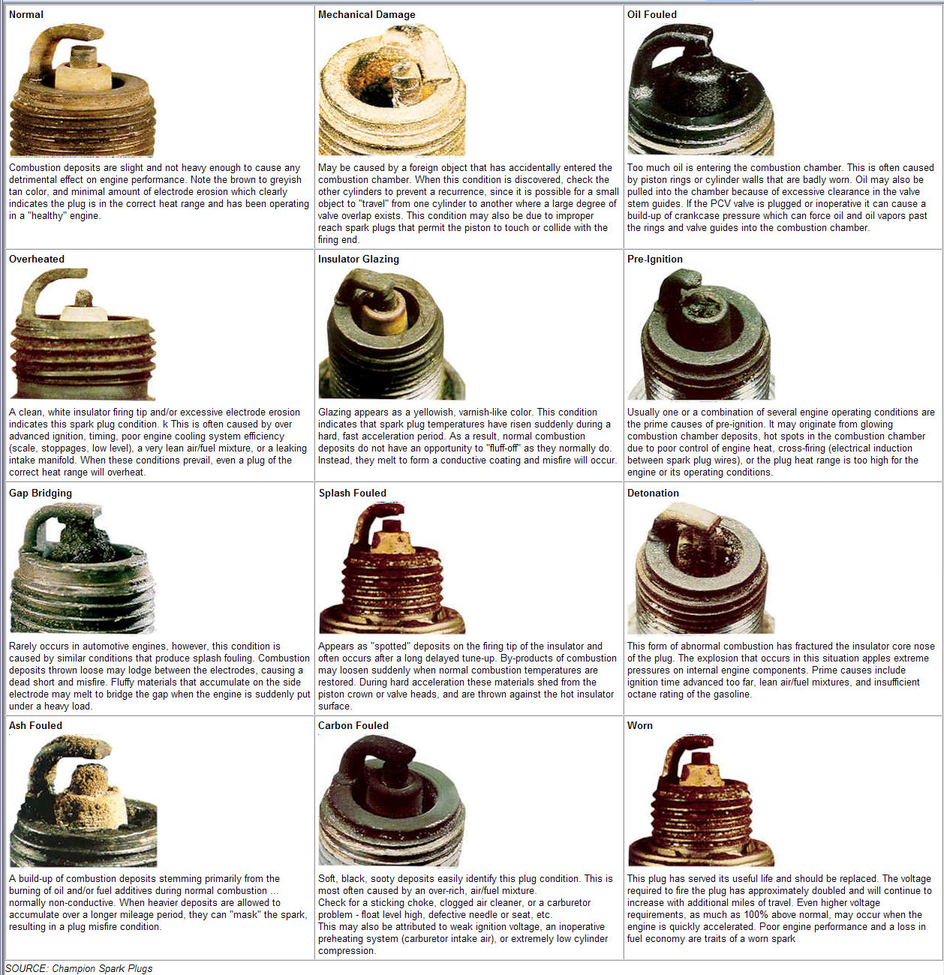

The backfire you described is somewhat troubling, as its cause has not been determined. As recommended above, a cylinder compression test is a good start, as it may identify a problem such as a sticking or damaged valve in one or more cylinders that could be causing the backfiring. Replacing the distributor cap and spark plug wires should have helped to eliminate those possibilities as a cause of the backfiring. Examining the spark plugs may also provide a clue if one cylinder is running differently from the others, or if the possibility of a vacuum leak or other carburetor problem might be causing the engine to run lean or have an improper fuel/air mix on one side of the engine (or both).

A logical tuning/troubleshooting sequence is needed to help to identify and correct faults or problem areas. Jumping around or improperly adjusting one area to compensate for or mask another problem area can make achieving a properly tuned engine difficult. The two GM/Corvair training videos below are pretty good in providing guidance in performing a logical and methodical tune-up on a Corvair. Hopefully you will find them to be helpful.

Watching the video presentations below helps to provide insight and understanding about proper sequencing of the tune-up steps and procedures. Skipping around can insert obstacles and problems with getting the engine properly tuned.

Tuning the Corvair Engine — Part 1

Tuning The Corvair Engine — Part 2

Tuning The Corvair Engine — Part 2

The entire shop manual (and supplements) and many other Corvair technical references can be downloaded at no cost using the following link...

Common and Useful Corvair Websites

- Attachments

-

- Tuning the Corvair Engine - Sound-Slide Film Reprint.pdf

- Tuning the Corvair Engine - Sound-Slide Film Reprint

- (4.6 MiB) Downloaded 33 times

-

- DELCO ROCHESTER - Models H, HV Carburetor Service Guide.pdf

- DELCO ROCHESTER - Models H, HV Carburetor Service Guide

- (1.79 MiB) Downloaded 33 times

-

- 1961 Chevrolet Corvair Shop Manual - Section 7 - Engine Tune-Up.pdf

- 1961 Chevrolet Corvair Shop Manual - Section 7 - Engine Tune-Up

- (644.51 KiB) Downloaded 26 times

-

- 1964 Supplement - Chevrolet Corvair Shop Manual - Section 7 - Engine Tune-Up.pdf

- 1964 Supplement - Chevrolet Corvair Shop Manual - Section 7 - Engine Tune-Up

- (931.65 KiB) Downloaded 31 times

Brad Bodie

Lake Chatuge, North Carolina

1966 Corvair Corsa Convertible

1966 Corvair Corsa Convertible

Lake Chatuge, North Carolina

1966 Corvair Corsa Convertible

1966 Corvair Corsa Convertible- terribleted

- Posts: 4584

- Joined: Sun Apr 18, 2010 2:36 pm

- Location: Atlanta, GA

- Contact:

Re: Idle and backfire

Once I was positive about condition of ignition parts and settings, and carbs (rebuilt) and settings, then I might do running valve adjustment as backfire could be a sticking or to tightly adjusted valve just as it could be a timing or fuel delivery issue. A compression test may show which cylinder or cylinders to look at.

If the car has been sitting and not run in a long time (ands I assume this is the case otherwise why would someone put seafoam in their engine...yuck), I would ensure a fresh fuel supply (old fuel over 6 months old I would drain and dispose of. run the engine from a can of fresh premium fuel, which is what you should run it on always), rebuild the carbs (or replace them with know good ones if I had them), Clean up the ignition with some new parts if needed, balance the carbs and set the timing and idle per the manual. I would then run the engine through a few hot and cool down cycles over a few days as long as the backfire (popping back through the carbs) was not making flames or was too severe. If it is an exhaust explosion and not a backfire the same constraints apply. Often lifter, valves and rings are gummed up after a long sleep and will free up after come operation. If you are lucky the misfiring will go away

If the car has been sitting and not run in a long time (ands I assume this is the case otherwise why would someone put seafoam in their engine...yuck), I would ensure a fresh fuel supply (old fuel over 6 months old I would drain and dispose of. run the engine from a can of fresh premium fuel, which is what you should run it on always), rebuild the carbs (or replace them with know good ones if I had them), Clean up the ignition with some new parts if needed, balance the carbs and set the timing and idle per the manual. I would then run the engine through a few hot and cool down cycles over a few days as long as the backfire (popping back through the carbs) was not making flames or was too severe. If it is an exhaust explosion and not a backfire the same constraints apply. Often lifter, valves and rings are gummed up after a long sleep and will free up after come operation. If you are lucky the misfiring will go away

Corvair guy since 1982. I have personally restored at least 20 Vairs, many of them restored ground up.

Currently working full time repairing Corvairs and restoring old cars.

https://www.facebook.com/tedsautorestoration/

Located in Snellville, Georgia

Currently working full time repairing Corvairs and restoring old cars.

https://www.facebook.com/tedsautorestoration/

Located in Snellville, Georgia

-

wes_anderson4

- Posts: 3

- Joined: Sat Sep 26, 2020 9:36 pm

Re: Idle and backfire

Thank you for your insight. A little background on me I am an aircraft mechanic and have been for 15 years. I specifically work on the engines. I am a vet of the Marines and proud of it. My goal is to bring my corvair back to it's original glory. Keeping everything as it was in 64. I am big on keeping vehicles original. I am thinking about just pulling the motor and going through everything. I have rebuilt vw bug engines and many others before. I have never owned a corvair, but I do like it a lot and it seems very easy to work on.

- terribleted

- Posts: 4584

- Joined: Sun Apr 18, 2010 2:36 pm

- Location: Atlanta, GA

- Contact:

Re: Idle and backfire

Very expensive to rebuild a Corvair engine correctly. It may not need it. Run it some more to see what it does. I have run them for 3-5 hours before after sitting before they settled down. These "settled down" engines then had good compression and delivered good service. I have also done the same to a few others that did not settle down and needed overhaul, but, the ones that turned out to be good far outnumber the ones that did not. being air cooled, unless they are worn out before they sat or got water inside they will generally come back ok. It is worth spending some dollars on externals (carb rebuilds and ignition. which you will need whether to rebuild the engine or not) to possibly save the thousands of dollars it costs to really fully rebuild a Corvair engine.

I am also a Vet and also spent quite a few years in the USAF working on aircraft. Welcome.

I am also a Vet and also spent quite a few years in the USAF working on aircraft. Welcome.

Corvair guy since 1982. I have personally restored at least 20 Vairs, many of them restored ground up.

Currently working full time repairing Corvairs and restoring old cars.

https://www.facebook.com/tedsautorestoration/

Located in Snellville, Georgia

Currently working full time repairing Corvairs and restoring old cars.

https://www.facebook.com/tedsautorestoration/

Located in Snellville, Georgia

-

wes_anderson4

- Posts: 3

- Joined: Sat Sep 26, 2020 9:36 pm

Re: Idle and backfire

I have got a good idle now. A little high. I need to put a timing light on it. I will have to buy a new one. The kids got a hold of mine. Also I need a new dwell meter. Should I go ahead and get a vacuume guage as well? I tried to upload a video of it running but the site said it didnt support mp4.

- terribleted

- Posts: 4584

- Joined: Sun Apr 18, 2010 2:36 pm

- Location: Atlanta, GA

- Contact:

Re: Idle and backfire

I almost never use a vacuum gauge on these. A Unisyn carb synchronizer tool is very useful. I also basically never use a dwell meter either. I adjust points per manual and press on , but, I almost never run points preferring a FAST XR700 electronic points replacement unit. A tachometer is useful. Looks like a nice car.

Corvair guy since 1982. I have personally restored at least 20 Vairs, many of them restored ground up.

Currently working full time repairing Corvairs and restoring old cars.

https://www.facebook.com/tedsautorestoration/

Located in Snellville, Georgia

Currently working full time repairing Corvairs and restoring old cars.

https://www.facebook.com/tedsautorestoration/

Located in Snellville, Georgia

- bbodie52

- Corvair of the Month

- Posts: 11897

- Joined: Mon Aug 06, 2012 12:33 pm

- Location: Lake Chatuge Hayesville, NC

- Contact:

Re: Idle and backfire

A compression test would give a fairly good "snapshot" of the mechanical internal state of affairs. If the readings are sound, much can be done by just playing the fuel system and ignition system game.

Nothing wrong with keeping it "all original", but I sincerely believe that if the 1960's GM design engineers had access to inexpensive breakerless optical trigger technology like the Crane Cams/FAST XR700 add on to the stock distributor, the ignition points and condenser would have hit the trash can long ago, and the breakerless ignition system would have been included in the "all original" category. Besides, you can hide the evidence (the XR-700 module) under the spare tire. (You don't even have to bypass the primary ignition resistor wire — the XR700 is designed to run on 7-8 VDC (normal reduced operating voltage with the standard Corvair wiring harness. The XR700 module taps its power from the ignition coil positive terminal. The system is very reliable, never needs adjusting, and the coil thinks it is points.

You might want to give it some consideration...

ELECTRONIC DISTRIBUTOR UPGRADE/REPLACEMENT OPTIONS

24 years in the Air Force... about 59 years around Corvairs (1961 - Age 7 — 2020 - Age 67)

Brad Bodie

Lake Chatuge, North Carolina

1966 Corvair Corsa Convertible

1966 Corvair Corsa Convertible

Lake Chatuge, North Carolina

1966 Corvair Corsa Convertible

1966 Corvair Corsa Convertible- bbodie52

- Corvair of the Month

- Posts: 11897

- Joined: Mon Aug 06, 2012 12:33 pm

- Location: Lake Chatuge Hayesville, NC

- Contact:

Re: Idle and backfire

Here is some info on the Uni-Syn, mentioned earlier...

Balancing the two carburetors at idle would be done by fine-tuning the idle speed screws. Balancing the two carburetors at part throttle is done by adjusting the throttle linkage on the left carburetor, which has an adjustment to lengthen or shorten the throttle rod so that the butterfly valve openings can be matched for equal airflow at a steady part-throttle opening held with a turnbuckle.

With the throttle fully closed on a running engine, the intake manifold vacuum level is at maximum. The horizontal vacuum pot is drilled so that it taps into the carburetor bore BELOW the throttle butterfly valve. The vertical spark port taps into the carburetor bore slightly ABOVE the throttle butterfly valve, so it is not exposed to intake manifold vacuum until the butterfly valve begins to open. (If the vacuum aadvance mechanism on the distributor were to be connected to the horizontal vacuum port, maximum intake manifold vacuum would pull the vacuum advance mechanism to FULL ADVANCE when the engine is only idling. At idle you don't want any vacuum advance being added to the timing — you only want the vacuum advance to begin dialing in timing advance as you start to accelerate — as the throttle butterfly begins to open. As acceleration begins to take place, the vacuum advance system is adding timing advance to the distributor. At higher throttle settings, the butterfly valve opens further to bring in more fuel/air mixture to the intake manifold. Increasing exposure to the air intake because of the opening throttle butterfly cause intake manifold vacuum to decline, which reduces vacuum to the vacuum advance mechanism, so timing begins to drop from the vacuum advance, while at the same time increasing engine RPM speed has more affect on the CENTRIFUGAL ADVANCE mechanism inside the distributor, so it begins to take over the job of advancing the timing. This is a process of handing the job of managing engine timing advance from te initial vacuum advance at low engine speeds to centrifugal advance at higher engine speeds. The two distributor advance mechanisms (VACUUM and CENTRIFUGAL) work together, continually transferring timing advance resonsibility back and forth betwern the two systems as engine speeds rise and fall.

Since you realise that you are measuring vacuum levels at the vertical spark port on each carburetor, the vacuum at these ports can only be equalized by matching the amount that the throttle is opened on each side at 1200 RPM. The accelerator pedal pulls the throttles open from the center. The link to the right carburetor throttle is fixed in length and is not adjustable, BUT THE LENGTH OF THE LINK TO THE LEFT CARBURETOR THROTTLE BUTTERFLY IS ADJUSTABLE! There is a swivel at the bottom of that link where it clips to the carburetor. By disconncting the top of that link from the main throttle linkage, you can rotate te link in the swivel connector to screw or unscrew the link, which lengthens or shortens the throttle link rod. This is how you balance the opening of the throttle butterfly valves on both sides while maintaining a constant engine speed at open throttle (approximately 1200 rpm as a sample point). The goal is to see equal amounts of vacuum at the spark port as you compare the readings while you pinch off one side or the other. You then adjust the length of the left side throttle rod so tht the vacuum readings on both sides are the same.

The Uni-syn gauge does much the same thing, except is measures total airflow through each carburetor intake instead of using a vacuum gauge connected to the spark port. I prefer the use of the Uni-syn gauge because it permits an actual air flow through the carburetor throat to be measured and both sides to be equalized based on that reading instead of relying on a simple mechanical static measurement at the carburetor linkage and a manifold vacuum reading. Also the Uni-syn gauge can be used to visually measure the air flow at both the engine idle and at a steady-state partial throttle, so that air flow balance can be obtained at idle and at open throttle.

The Uni-syn gauge has been around since the late-1950's or early 1960's and is one of the fastest and easiest ways to synchronize multiple carburetors. It was originally intended for British multi-carburetor engines, motorcycles, etc. and was a natural addition to the Corvair mechanic's tool box. It can usually be found for $20-$40. Only one is needed.

This balancing process is done twice — once with the idle speed screws (Pages 8-9 of the attached Tuning the Corvair Engine) and again at 1200 RPM using the vacuum gauge, as shown on pages 11-13.

The Uni-syn gauge can be used to synchronize both carburetors at idle — first physically synchronizing them as shown in the attached guide by adjusting the screws for first contact with the throttle mechanism, and then adjusting the screw on each side an additional 2½ turns. Then with this mechanical preset established, the Uni-syn is used to measure the air velocity through each carburetor, and the speed screws are balanced to achieve the desired idle speed and a balanced airflow through each carburetor. The process is then repeated with the Uni-syn — but this time a turnbuckle is used to hold the throttle open at 1200 RPM, and the link on the left carburetor is adjusted to achieve equal airflow through each carburetor.

TIPS & CLARIFICATION...

With the engine at idle, you want to open the Uni-Syn flow control as much as possible, but still keep the float in the sight glass at about mid-level. Then check the other carburetor, which you want to read the same flow rate. You may have to adjust the flow control a few times as you adjust the carburetor settings. Just remember to check each carburetor with the flow control set at the same point, and to keep the sight glass in the vertical to prevent the float from hanging up in the tube.

The wheel in the Uni-Syn venturi controls the flow through the tube, or in other words how high the bead is in the cylinder for a given engine speed. You need enough flow to not strangle the engine, and the bead works just as well in the lower third (which still lets good air flow through). Make sure the idle speed doesn't drop when you place the tool on the carb: if it does, open it up.

Before setting the carbs, make sure that the ignition is right: points and timing set, good wires and plugs. Rich running is often blamed on carbs when in fact it's a weak, retarded spark. Check the throttle shafts: loose ones let in air and lean the mixture, raising idle speed, as well as throw off the linkage action. Check the linkage that connects the carburetors. if it's loose, one will open before the other. Make sure there are no vacuum leaks.

With a twin carburetor set up, disconnect the linkage that connects one carburetor to the other. Set the idle speed with the linkage screws first. Use the Uni-Syn to check that each carburetor is drawing equally at idle. This may take a few tries until you get both drawing equally at the speed you want. Blip the throttle to see if they come back to those settings (worn throttle shafts can fool you). Set the idle mixture screws in accordance with the shop manual instructions. Check the balance again. Hook the linkage back up. If one carburetor now draws more, adjust the linkage until it's back to roughly equal.

Once the carburetors are drawing equally at idle, hold an engine speed: at about 1200 RPM. This checks that the mechanical linkage is pulling equally. You'll need to open up the Uni-Syn center wheel to draw more air and bring the bead down in the tube. If both carburetors are within a bead's thickness of each other, that's good. If one is definitely off from the other, the higher flow carburetor's linkage is being pulled more than the other. You'll need to figure out why that's happening mechanically to rectify it.

- Attachments

-

- Tuning the Corvair Engine.pdf

- Tuning the Corvair Engine

- (4.6 MiB) Downloaded 27 times

Brad Bodie

Lake Chatuge, North Carolina

1966 Corvair Corsa Convertible

1966 Corvair Corsa Convertible

Lake Chatuge, North Carolina

1966 Corvair Corsa Convertible

1966 Corvair Corsa Convertible