Mechanical Fuel Pump

Mechanical Fuel Pump

My 1965 Corvair Monza 110 would not run on the stock mechanical pump. Ran fine on the electric pump. I checked the pressure out of the mechanical pump with the electric off…0 psi. I replaced the mechanical pump with a new one, checking plunger operation before installation and it was fine. After installation of the new pump, car would still not operate on mechanical pump alone. I removed the new pump and looked down the hole, and discovered there is nothing to actuate the mechanical pump off of the cam. The distance between the bottom of the installed pump plunger to the cam is about 1.5 inches. No way the cam can operate the plunger rod. Question: is the a part or adapter missing that would connect the pump plunger to the cam? I can’t find an exploded view of that area to confirm my suspicion. Any help or reference you can point me to would be appreciated.

-

Jerry Whitt

- Posts: 887

- Joined: Thu Sep 26, 2013 2:42 pm

Re: Mechanical Fuel Pump

There is supposed to be a short shaft with a return spring attached.

Check Clark’s catalog. Probably will show the part.

Sent from my iPhone using Corvair Forum mobile app

Check Clark’s catalog. Probably will show the part.

Sent from my iPhone using Corvair Forum mobile app

Jerry Whitt

ASE CERTIFIED MASTER TECHNICIAN

Retired

Hemet, Callifornia

65 Monza, purchased new

65 Corsa convertible

ASE CERTIFIED MASTER TECHNICIAN

Retired

Hemet, Callifornia

65 Monza, purchased new

65 Corsa convertible

-

joelsplace

- Posts: 2019

- Joined: Wed Oct 13, 2010 12:51 pm

- Location: Northlake, TX

Re: Mechanical Fuel Pump

The push rod is way longer than 1.5" and has a spring on it. I'll bet the person that installed the electric pump took it out to disable the mechanical pump.

157 Corvairs, 5 Ultravans and counting

Northlake, TX

Northlake, TX

- bbodie52

- Corvair of the Month

- Posts: 11910

- Joined: Mon Aug 06, 2012 12:33 pm

- Location: Lake Chatuge Hayesville, NC

- Contact:

Re: Mechanical Fuel Pump

The link below will provide you with a list of useful websites that are Corvair-related. Some of the links will lead you to an extensive technical library that will allow you to download shop manuals and other technical references in Adobe Reader (.pdf) format at no cost. There is also a link that will help you to locate nearby CORSA (Corvair Society of America) club chapters. While the Corvair Forum can be very helpful as you work on your Corvair, having local friends and contacts in your region who are knowledgeable about the Corvair can also be very helpful. These family-friendly CORSA club chapters often offer picnics, group scenic drives, technical training and assistance, car shows, and competition events that can greatly enhance your enjoyment of Corvair ownership. You will also find a list of essential Corvair parts suppliers.

Common and Useful Corvair Websites

There are a number of things that can go wrong between the fuel tank and the carburetors that can prevent your mechanical fuel pump from working. You have discovered one of them with your missing pump push rod. The material below will also cover the other possibilities. I've posted a somewhat lengthy fuel pump technical piece that hopefully will give you a good idea of how the system functions — and how to effectively troubleshoot the fuel system.

Clark's Corvair Parts wrote:Fuel Pumps

We have only been able to locate 2 manufacturers of original style Corvair fuel pumps. Since 1973, we have consistently seen 1-2% of new fuel pumps fail. From about 1998-2001, the failure rate went to nearly 10%! We finally convinced the pump manufacturer that they were using the wrong diaphragm material! Currently, about 1%-2% of the fuel pumps continue to have problems. The problems have usually been seepage of fuel or complete failure resulting in no fuel or a rupture of the main diaphragm. The main supplier (C3403) is now using "antiwicking" diaphragms & has returned to all 3 diaphragms having fabric reinforced material. We've also added a pump from a 2nd supplier (C3403A). Our experience with both is nearly identical. A spare pump is always a good idea.

If your original mechanical fuel pump has actually failed (as in leaking fuel, torn pump diaphragm, etc.) the safe bet may be to install an electric fuel pump system properly and abandon the mechanical pump system, if it has failed! (Remember that a leaky fuel tank feed line or hose that is letting air in may look very much like a failed mechanical pump. But if the line between the tank and the pump is letting air in, it is like trying to sip a drink from a cup through a drinking straw that has a split in the side of the straw — you won't get much fluid no matter how hard you suck on the straw! You need a new straw!)

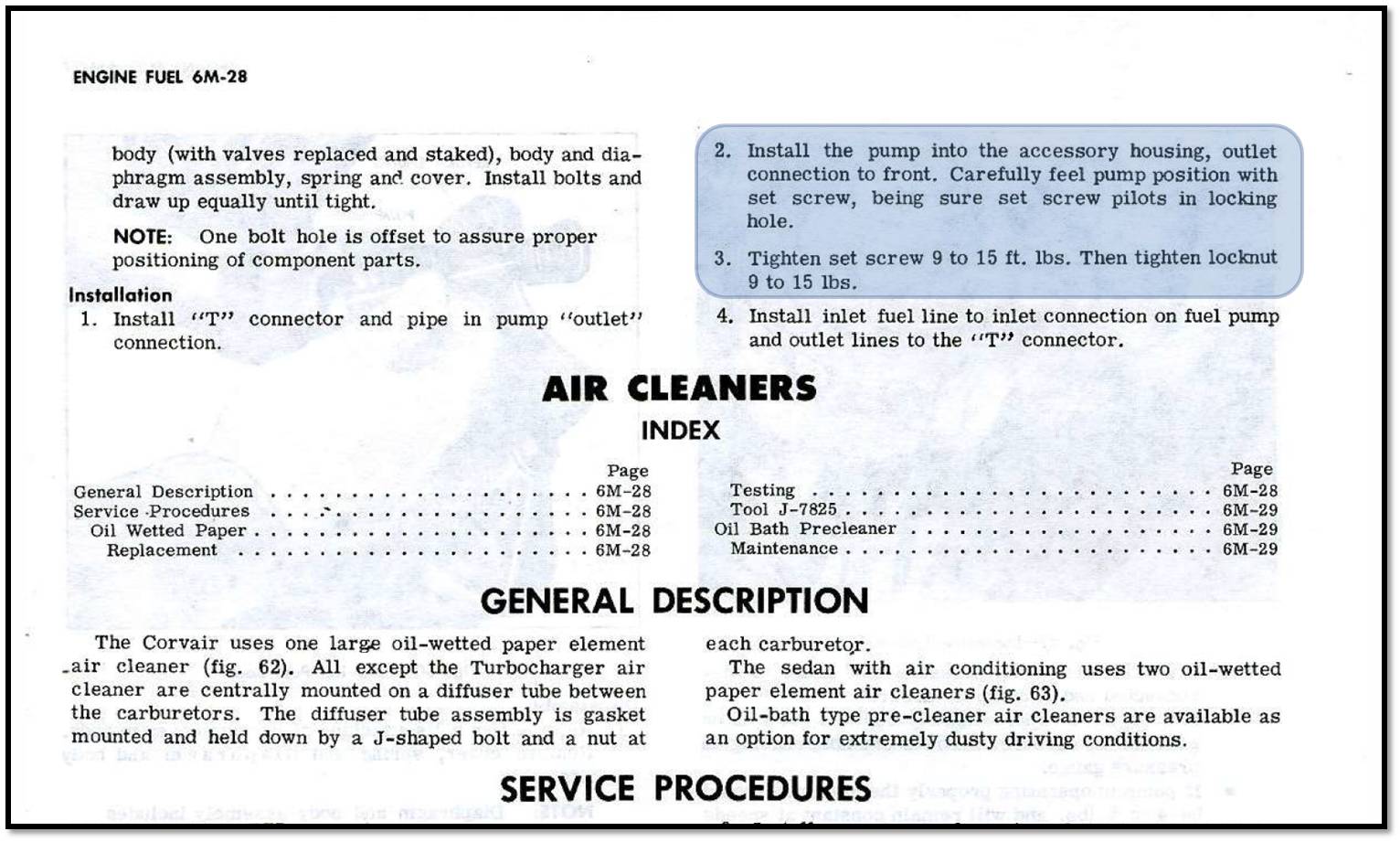

The other common mechanical fuel pump mistake is to improperly insert the pump at the wrong depth, with only the set screw (bolt) pressing against the side of the pump, instead of the tapered bolt tip being seated in the tapered hole in the side of the pump shaft. This can result in the pump mechanism barely making contact with the push rod that drives it. The pump only gets a partial push and never moves at a full stroke. The pump must me inserted fully, with the bolt properly seated into the tapered pump hole and the lock nut securing the bolt as shown and described in the shop manual).

I'll bet a lot of fully functional Corvair mechanical fuel pumps get targeted as having failed and then get tossed and replaced with an electric pump, when the real problem is a faulty feed line from the fuel tank or an improperly inserted fuel pump!

The cost of a replacement mechanical pump from Clark's isn't really that high ($65.55 vs. $69.50 for a Facet FEP42SV Cube Electric Fuel Pump 1.5-4 Psi, Includes Clamps/Fittings/Filter). Other electric pumps may be cheaper, but when you add the additional wiring and install hardware cost — including the safety cutoff switch system — the electric pump system will likely cost much more.

Clark's Corvair Parts wrote:Part number C3403: NON-GM FUEL PUMP-62-69 WILL FIT 60-61 IF ORDER C259 ROD

Weight: 2 lbs 4 oz

Catalog Page(s): 65

Price:

1 - 1 $ 65.55

2+ $ 63.60

bbodie52 wrote:The Corvair mechanical fuel pump is usually pretty good at pulling gasoline the length of the vehicle to prime the fuel pump so that gasoline can be pressurized to fill the carburetor float bowls. But a small air leak or crack in one of the short rubber hoses at either end of the fuel line between the tank and the pump can create what amounts to a vacuum leak in the fuel feed line that supplies the pump. The pump can cycle many times as the engine cranks and the battery drains while sucking mostly air from a fuel line air leak instead of getting a good "drink" of gasoline from the tank.

An improperly inserted mechanical fuel pump may also limit the motion of the pump diaphragm, if the pump insertion is too shallow and not allowing the push rod to take a full stroke. Refer to the notes and illustrations below to see how the pump set screw is supposed to insert into the tapered hole in the side of the pump shaft, and not just push against the side of the pump shaft. Proper installation ensures that the pump is properly positioned in relation to the push rod, so that the pump gets a full stroke with each rotation of the crankshaft. Good fuel volume from the pump is considered to be 1 pint of fuel in 40 seconds or less at cranking speed.

To check for the possibility of fuel starvation, you should measure fuel pump pressure AND volume! It is easy to have a pump that delivers correct pressure, but cannot produce adequate fuel volume. A feed line leak or cracked/damaged/loose rubber hose between the tank and the pump can create an air leak that will keep the pump from being able to create a solid vacuum to pull a good supply of fuel from the tank. Without adequate fuel supply, the pump can generate adequate fuel pressure to the carburetors, but only until it is starved for gasoline from the tank. The pump must also be installed to the proper depth and anchored properly using the tapered bolt that is screwed into the tapered hole on the side of the pump.

http://www.corvair.com/user-cgi/catalog ... nd_page=65

Part number C259: 62-69 FUEL PUMP ROD-REPRO (3 13/16") 60-61 ROD=C7256

Weight: 0 lbs 4 oz

Catalog Page(s): 11(28),65

Price: $ 19.15

Part number C1604: FUEL PUMP SPRING

Weight: 0 lbs 2 oz

Catalog Page(s): 11(34),65

Price: $ 3.55

bbodie52 wrote:The pump push rod is driven by a cam lobe on the crankshaft. The repeated "upstroke" causes the pump to form a vacuum in the feed line from the fuel source (tank or gas can). As the fuel is drawn into the pump chamber, the one-way valve in the pump inlet closes at the top of the stroke, and the spring in the pump forces the diaphragm back down to push the fuel out of the pump through the other one-way valve, toward the carburetors. The spring tension determines the fuel pump outlet pressure.

Check to make sure you are fully inserting the pump so that the pushrod driving the pump gets a full stroke to drive the fuel pump. Proper installation of the new parts is critical,,,

Also...To remove and reinstall the fuel pump, be sure that you have installed it properly. It is important to ensure that the fuel pump is correctly seated and installed. There is a hole in the side of the pump shaft that the tapered bolt tip must seat into. If the pump is sitting too high and the bolt is simply pressing against the side of the pump housing, rather than seating inside the tapered hole, the pump push rod will not be doing its job. Fig. 57 in the shop manual page shows the tapered hole that the tip of the bolt fits into. This ensures proper installation and seating of the pump.

For a quick check on fuel availability in the carburetors, you can peer down the throat of each carburetor while holding the choke open. Open the throttle quickly. You should see a squirt of fuel injected into the carburetor throat from the accelerator pump. This confirms the presence of fuel in each float bowl.There are two relatively simple tests outlined in the Corvair shop manual. These tests measure output pressure and fuel delivery volume. The output pressure test utilizes a common vacuum/pressure gauge that is relatively inexpensive. The output pressure is regulated by an internal spring that is contained in the upper pump housing. Unless your pump springs a leak in one of the diaphragms or seals, it is likely that the output pressure will not change with age. However, new pumps may be fitted with a spring that produces an output pressure well in excess of the 4-5 psi standard. High-pressure can cause carburetor flooding, and is particularly a problem with the Carter YH carburetor found on turbocharged Corvairs, which is sensitive to excessive fuel pressure.

A new fuel pump should always be tested for output pressure. If the pressure is found to be excessive it may be possible to cut the spring or to exchange the spring from the old pump and fit it into the new pump. This may correct the output pressure.

The second test measures fuel flow at the fuel pump outlet. The standard in the shop manual states that the pump should be able to deliver 1 pint of fuel over a period of 40 seconds or less at engine cranking speed. If your pump does not appear to have any leaks and can pass the output pressure test, but fails to deliver the needed fuel volume, the problem may not be with the pump itself. There is a long fuel line that runs the length of the car from the fuel tank to the fuel pump. In order to pressurize and deliver fuel to the carburetors, the pump must be able to create a continuous vacuum in that fuel line to draw the fuel from the tank to the pump. Most of the fuel line is made up of steel tubing and is unlikely to develop a leak. However, there are two short lengths of rubber fuel hose in the fuel path. One section of hose is found at the fuel tank outlet, while the other is found adjacent to the starter motor — just before the line enters the engine compartment. The purpose of the second hose is to absorb vibration from the engine and prevent it from reaching the rigid steel fuel line. If either one of these two hoses develops a leak, the leak itself may not be apparent because the line is not under pressure so fuel will not be forced out. Instead, the leak amounts to a vacuum leak, which can allow air to enter the fuel line. This can prevent fuel from being drawn from the tank to the fuel pump, much like you might experience with a drinking straw if the straw was to split and developed an air leak in the side of the straw. What appears to be a faulty pump that is causing fuel starvation problems in the carburetors often turns out to be a leak in the fuel line at some point between the gas tank and the fuel pump. So if fuel starvation becomes a problem with your carburetors, there is a tendency to question the condition of the needle and seat valve inside the carburetor, or to blame the fuel filter at the carburetor inlet (thinking it is clogged), or to blame the fuel pump itself. Before you blame the pump and toss it, or abandon it and replace it with electric fuel pump, be sure to check the condition of the rubber fuel hoses at each end of the long fuel line between the fuel tank and the fuel pump. You may find that a couple of hose clamps and a few inches of replacement fuel hose is all that necessary to get you back on the road!

With the air cleaner assembly removed, when holding the choke open and peering down the throat of each carburetor, do you see a squirt of fuel from the accelerator pump in each carburetor when you open the throttle rapidly? If the jet of fuel is not observed, the float bowls may be dry, possibly due to stuck needle and seat assemblies blocking the fuel inlet.

- Attachments

-

- 1965 Corvair Chassis Shop Manual - SECTION 6M - ENGINE FUEL.pdf

- 1965 Corvair Chassis Shop Manual - SECTION 6M - ENGINE FUEL

- (8.87 MiB) Downloaded 23 times

Brad Bodie

Lake Chatuge, North Carolina

1966 Corvair Corsa Convertible

1966 Corvair Corsa Convertible

Lake Chatuge, North Carolina

1966 Corvair Corsa Convertible

1966 Corvair Corsa Convertible