Identification of nitrided crankshaft

-

lonestranger

- Posts: 92

- Joined: Sun Jan 30, 2011 5:59 pm

- Location: Bradenton, FL

Identification of nitrided crankshaft

what are the identifying features of a corvair nitride crankshaft? marking or part number of casting etc.

- bbodie52

- Corvair of the Month

- Posts: 11897

- Joined: Mon Aug 06, 2012 12:33 pm

- Location: Lake Chatuge Hayesville, NC

- Contact:

Re: Identification of nitrided crankshaft

If you remove the top engine cover to expose the crankshaft, the number cast into the crankshaft identifies the stroke...

5607 signifies it from an early 145 CI engine.

7293 signifies it from an early 145 CI turbo engine.

8409 signifies it's from the late 164 CI engines, regardless of HP.

The 164 CI 140 hp and 180 hp Turbo engines had a heavy-duty nitrided crankshaft — identified with an ampersand (&) stamped on the flywheel end of the crankshaft.

martyscarr wrote:All of the Corvair turbocharged engines had nitrided crankshafts for added strength. They are identified by an ampersand "&" stamped on the flywheel end of the crankshaft. These nitrided cranks were also used in the 4 carb 140 engines...

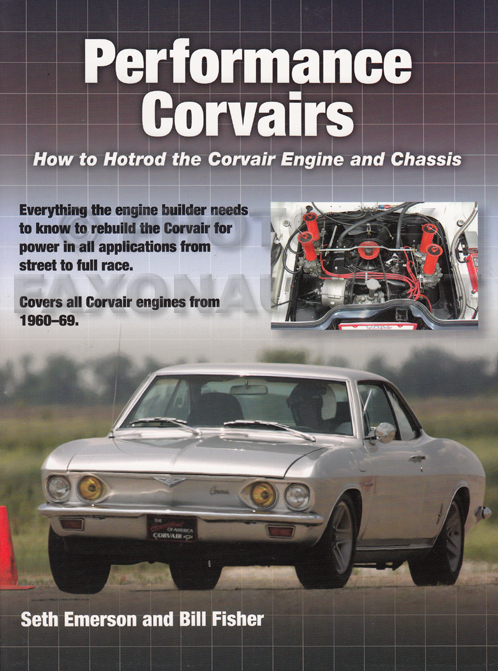

This ampersand stamp indicating a nitrided crankshaft is also mentioned on page 69 in the book Performance Corvairs: How to Hotrod the Corvair Engine and Chassis by Bill Fisher and Seth Emerson. The book also mentions that GM lab tests showed Spyder model (1962-1963) crankshafts (forged in SAE 5140 chromium alloy steel and surface hardened by nitriding) were five times more resistant to cracking than the plain carbon steel models. In 1964 alloy steel crankshafts were used in place of the previous forged carbon steel in all models as the displacement was increased to 164 cubic inches by raising the stroke from 2.6 inches to 2.94 inches. A harmonic balancer was also used on all engines except the 95 hp unit. As previously mentioned, nitriding was included on the highest horsepower 140 hp and turbocharged engines.

The above book is also now available in a digital Kindle version for only $11.99 or in paperback for $23.86 on Amazon.com.

Bob Helt wrote:Date: September 25, 2009 09:35AM

Bob Coffin / Dr Yenko wrote:

Turbo and 140 cranks ARE nitrided, IE surface hardened..

To a depth of up to .015".

Even one turned down by .005" per side on the diameter will have some of this

process remaining in the parent material.

What is wrong with using one of these like everyone else does for a Corvair

racing engine?

BC

What's wrong?

Well here is something to consider.

The purpose of nitriding or Tufftriding a crankshaft is mainly to prevent incipient fractures, cracks, or fissures from occurring at any sharp points on the crank. It's not to prevent wear, but to forstall cracks from occuring during undamped torsional vibrations allowed by insufficient or incorrect harmonic dampening.

OK here's the possible reason about what is wrong.....regrinding may leave some hardening, but it also disturbs the existing fillets by allowing a sharp transitioning from the fillet to the new (lower) journal being ground. This can be a new sharp point that is now allowed to fracture if it occurs at a possible point not containing a sufficient hardening depth.

Any crank regrinding should also ensure a re-establishment of the original fillets and even increase them. So who does that? Not most regrinders.

And even if the reground crank is nitrided after grinding, any new sharp points are susceptible to fracture, etc.

Regards,

Bob Helt

Nitrided crankshaftsgnvair wrote:Date: September 25, 2009 12:09PM

From my own experience with other engines, nitriding of tufftriding is seldom required or done anymore. A true forged steel crankshaft already is inherently stronger than a cast iron crank. The key I have found is making sure that there is a proper fillet on all the journals, proper balancing and dampening.

The 2 things I see that break cranks are lots of rpm and detonation on a forced inducted engine.

My best example is the Buick Grand National engine which came equipt with a cast iron crank with hydraulically rolled fillets. These things can take same major abuse IF they arent detonated.

On a Corvair I would have to say that any of the 64-up cranks would be fine for a turbocharged engine IF you dont detonate it and/or keep the rpms at a reasonable level (under 6500). Detonation on a naturally aspirated engine is like hitting parts with a hammer. Forced induction detonation is like having a bomb going off and thus the typical broken/collapsed ring lands, broken rings, bent rods, loss of bearing crush and cracked/broken cranks.

Brad Bodie

Lake Chatuge, North Carolina

1966 Corvair Corsa Convertible

1966 Corvair Corsa Convertible

Lake Chatuge, North Carolina

1966 Corvair Corsa Convertible

1966 Corvair Corsa Convertible-

lonestranger

- Posts: 92

- Joined: Sun Jan 30, 2011 5:59 pm

- Location: Bradenton, FL

Re: Identification of nitrided crankshaft

I thank you for the excellent and timely reply/illustrated examples to my question. That is what I find so valuable about the corvair community in general and the forums in particular; the depth of knowledge available on line. Much better than " learning from experience" don't ya know!! Seriously, thanks again and keep the shiny side up!!

- bbodie52

- Corvair of the Month

- Posts: 11897

- Joined: Mon Aug 06, 2012 12:33 pm

- Location: Lake Chatuge Hayesville, NC

- Contact:

Re: Identification of nitrided crankshaft

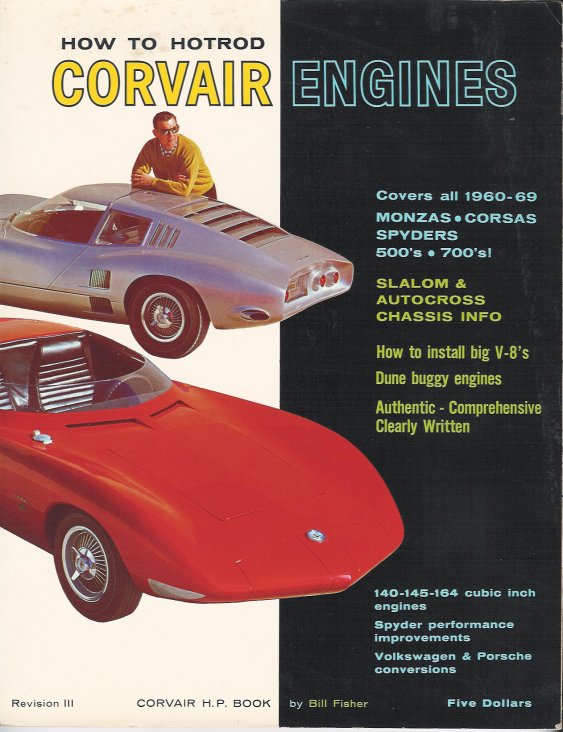

I never imagined as a teenager in 1970 that things I read about in the original 'Bill Fisher book below would prove useful when answering a question about Corvair crankshafts using a home computer 19 years into the new century when I was 66 years old!

If you want to know something about what works in the Corvair world, you might start with a reading assignment. This book contains a great deal of performance information about the Corvair. As a teenager I read the earlier version of this book in 1970 and found it to be very valuable and informative. It is a personal favorite, and here is a recent update...

https://www.amazon.com/Performance-Corv ... +to+hotrod

https://www.amazon.com/Performance-Corv ... +to+hotrod

If you want to know something about what works in the Corvair world, you might start with a reading assignment. This book contains a great deal of performance information about the Corvair. As a teenager I read the earlier version of this book in 1970 and found it to be very valuable and informative. It is a personal favorite, and here is a recent update...

Many Corvair enthusiasts will remember the original version of this book. I have had a copy since about 1970...

How to Hotrod Corvair Engines by Bill Fisher (1970)

How to Hotrod Corvair Engines by Bill Fisher (1970)

Brad Bodie

Lake Chatuge, North Carolina

1966 Corvair Corsa Convertible

1966 Corvair Corsa Convertible

Lake Chatuge, North Carolina

1966 Corvair Corsa Convertible

1966 Corvair Corsa Convertible