Back again tuning carbs

- 66corsaguy

- Posts: 256

- Joined: Sat Apr 01, 2017 10:34 pm

Back again tuning carbs

Every few months i make time to work on my 66 Corvair. I am back trying to make final adjustments but I’m still struggling.

I have new set of 4 carbs from Wolf Ent. So they are good. But i am having trouble getting the car to run at peak performance and after it’s super warmed having trouble with stalling.

How do i know if the car is running lean or rich? (Other than fouled spark plugs)

I’ve got my idle set around 550. I feel it’s too low.

I’ve used the carb metering devise that sits on the bowl and the left side i set the red ball to the middle when i put it on the right carb the ball shoots up to the top out of view. Also if i put my hand over left carb it stumbles a little but i put on the right carb and it stumbles and wants to die. So which one is the correct one. I assume the right one does that mean base the left to it and if so - How!

I’m starting to get a little lost because i read 12 different articles and it all starts to just get confusing.

I check my timing and realize i forgot to pull and plug the vacuum tube. Just for knowledge-why does it matter?

How do i get both carbs balanced-which one am i trying to balance the other too? What’s the ideal idle i should shoot for?

The idle speed i assume only controls idle speed-rpm. And the mixture controls fuel and air. How do those two things affect the other? Or do they? If i softly seat mixture what’s the most common amount of turns out. 3? And same question with idle speed screw.

If i leave as the book says i will def stall

Too many questions? Anyone want to come to my woodshop in SF and go over carb tune ? I will trade something.

Any questions answered is helpful. I have been searching the forum and i know the topic is covered but i am still struggling

One last question. I assume i am to do all the tuning without the filters in place. It seems when i put the filters back on the car runs poorly to the point of stall. Maybe I’m imagining things tho

Thanks everyone

Sent from my iPhone using Corvair Forum mobile app

I have new set of 4 carbs from Wolf Ent. So they are good. But i am having trouble getting the car to run at peak performance and after it’s super warmed having trouble with stalling.

How do i know if the car is running lean or rich? (Other than fouled spark plugs)

I’ve got my idle set around 550. I feel it’s too low.

I’ve used the carb metering devise that sits on the bowl and the left side i set the red ball to the middle when i put it on the right carb the ball shoots up to the top out of view. Also if i put my hand over left carb it stumbles a little but i put on the right carb and it stumbles and wants to die. So which one is the correct one. I assume the right one does that mean base the left to it and if so - How!

I’m starting to get a little lost because i read 12 different articles and it all starts to just get confusing.

I check my timing and realize i forgot to pull and plug the vacuum tube. Just for knowledge-why does it matter?

How do i get both carbs balanced-which one am i trying to balance the other too? What’s the ideal idle i should shoot for?

The idle speed i assume only controls idle speed-rpm. And the mixture controls fuel and air. How do those two things affect the other? Or do they? If i softly seat mixture what’s the most common amount of turns out. 3? And same question with idle speed screw.

If i leave as the book says i will def stall

Too many questions? Anyone want to come to my woodshop in SF and go over carb tune ? I will trade something.

Any questions answered is helpful. I have been searching the forum and i know the topic is covered but i am still struggling

One last question. I assume i am to do all the tuning without the filters in place. It seems when i put the filters back on the car runs poorly to the point of stall. Maybe I’m imagining things tho

Thanks everyone

Sent from my iPhone using Corvair Forum mobile app

Re: Back again tuning carbs

Carb tuning seems complicated. It can be if the carburetors have issues.

First I've run into rebuilt carburetors put into cars with no extra fuel filter between the tank and carburetors and the carburetors idle circuits get plugged up again. Unless you replaced the gas tank and fuel lines with new then installing a extra replaceable fuel filter is recommended. The brass filters at the carburetor inlets just keep out the big stuff that could cause the float check valves to jamb and flood the carburetors (and possibly cause a fire). To keep out the little stuff that can plug the idle circuit you need a good paper fuel filter in a metal canister.

The timing affects idle speed so set timing first per the book (make sure the RPM is at of less than specified for static timing). The vacuum advance hose is disconnected to make sure the vacuum advance has no effect on the timing when the static timing is set (usually at idle there is NO vacuum to the canister, but if the carburetors are not adjusted correctly there could be a vacuum). To make sure there is no vacuum advance the manual says to temporarily disconnect the hose to the distributor canister.

Bob Helts carburetor book explains the basic adjustments. Set the idle mixture to recommendations, then you disconnect the linkage between the carburetors (explained in the shop manual). Next the idle speed for each carburetor is "balanced". Most use the simple Uni-Sync that you adjust to get an indicated air flow. You want both carburetors to flow the same - that's it. If the idle is too low or two high, then BOTH carburetors idle speed screws have to be adjusted and then make sure the Uni-Sync says they are the same. Next go back and do a minor idle mixture screw adjustment. Usually it has little or a minor impact on the idle air flow balance, check it. Once done balancing the carburetors the linkage must be adjusted so BOTH carburetors don't fight each other when the linkage is hooked up (one holds the other off the idle stop) - linkage adjustment is in the manual.

Hope this takes the mystery out of it.

First I've run into rebuilt carburetors put into cars with no extra fuel filter between the tank and carburetors and the carburetors idle circuits get plugged up again. Unless you replaced the gas tank and fuel lines with new then installing a extra replaceable fuel filter is recommended. The brass filters at the carburetor inlets just keep out the big stuff that could cause the float check valves to jamb and flood the carburetors (and possibly cause a fire). To keep out the little stuff that can plug the idle circuit you need a good paper fuel filter in a metal canister.

The timing affects idle speed so set timing first per the book (make sure the RPM is at of less than specified for static timing). The vacuum advance hose is disconnected to make sure the vacuum advance has no effect on the timing when the static timing is set (usually at idle there is NO vacuum to the canister, but if the carburetors are not adjusted correctly there could be a vacuum). To make sure there is no vacuum advance the manual says to temporarily disconnect the hose to the distributor canister.

Bob Helts carburetor book explains the basic adjustments. Set the idle mixture to recommendations, then you disconnect the linkage between the carburetors (explained in the shop manual). Next the idle speed for each carburetor is "balanced". Most use the simple Uni-Sync that you adjust to get an indicated air flow. You want both carburetors to flow the same - that's it. If the idle is too low or two high, then BOTH carburetors idle speed screws have to be adjusted and then make sure the Uni-Sync says they are the same. Next go back and do a minor idle mixture screw adjustment. Usually it has little or a minor impact on the idle air flow balance, check it. Once done balancing the carburetors the linkage must be adjusted so BOTH carburetors don't fight each other when the linkage is hooked up (one holds the other off the idle stop) - linkage adjustment is in the manual.

Hope this takes the mystery out of it.

- bbodie52

- Corvair of the Month

- Posts: 11897

- Joined: Mon Aug 06, 2012 12:33 pm

- Location: Lake Chatuge Hayesville, NC

- Contact:

Re: Back again tuning carbs

I hope that the material I write below will serve to clarify some things and not just overload you with technical information. I know that you have stated that you have read many articles about tuning the Corvair, but I have no way of knowing which articles you have read and what they contained. Based on the information you provided I can only tell you what I would do if I were working on your engine and attempting to troubleshoot and tune the ignition and fuel system. The following is an attempt to outline my train of thought and how I would approach working my way through critical engine operating parameters. Although there could be an internal flaw in one of the new [rebuilt] carburetors on your engine, I would try to begin by working my way through the external ignition and carburetor settings to see if the problem can be resolved without tearing down the carburetors to look for internal problems.66corsaguy wrote:Mon Mar 12, 2018 6:16 pm

Every few months i make time to work on my 66 Corvair. I am back trying to make final adjustments but I’m still struggling.

I have new set of 4 carbs from Wolf Ent. So they are good. But i am having trouble getting the car to run at peak performance and after it’s super warmed having trouble with stalling.

How do i know if the car is running lean or rich? (Other than fouled spark plugs)

I’ve got my idle set around 550. I feel it’s too low.

I’ve used the carb metering devise that sits on the bowl and the left side i set the red ball to the middle when i put it on the right carb the ball shoots up to the top out of view. Also if i put my hand over left carb it stumbles a little but i put on the right carb and it stumbles and wants to die. So which one is the correct one. I assume the right one does that mean base the left to it and if so - How!

I’m starting to get a little lost because i read 12 different articles and it all starts to just get confusing.

I check my timing and realize i forgot to pull and plug the vacuum tube. Just for knowledge-why does it matter?

How do i get both carbs balanced-which one am i trying to balance the other too? What’s the ideal idle i should shoot for?

The idle speed i assume only controls idle speed-rpm. And the mixture controls fuel and air. How do those two things affect the other? Or do they? If i softly seat mixture what’s the most common amount of turns out. 3? And same question with idle speed screw.

If i leave as the book says i will def stall...

"...But i am having trouble getting the car to run at peak performance and after it’s super warmed having trouble with stalling..."

I wanted to start by making sure that some important insulators were not accidentally omitted when you installed the replacement carburetors…

Carburetor rebuild kits often contain a thin gasket to seal the underside of the carburetor where it mounts on the intake manifold. The Corvair carburetors need a plastic insulator to isolate the base of the carburetor from the intake manifold, which prevents the gasoline inside the carburetor from boiling or vaporizing if excessive heat is allowed to transfer from the hot aluminum intake manifold on the cylinder head to the carburetor body. These plastic insulators can be easily damaged when removed. Clark's Corvair Parts bundles gaskets and insulators together. They are listed near the top of page 56 in the catalog http://www.corvair.com/user-cgi/catalog ... ow_page=56.

"I’ve got my idle set around 550. I feel it’s too low.

I’ve used the carb metering devise that sits on the bowl and the left side i set the red ball to the middle when i put it on the right carb the ball shoots up to the top out of view. Also if i put my hand over left carb it stumbles a little but i put on the right carb and it stumbles and wants to die. So which one is the correct one. I assume the right one does that mean base the left to it and if so - How!"

The low idle speed of 550 RPM is likely the result of your engine idling on the right three cylinders only. It appears that the right carburetor linkage has been adjusted to compensate for the lack of contribution from the left primary, while keeping the engine idling and not stalling using the right three cylinders to make up for a problem on the left side.

The Uni-Syn gauge is apparently indicating that the airflow through the right carburetor is much higher than the airflow in the left carburetor. You may also find that there is a difference in the exhaust output of the left muffler when comparing it to the right muffler. The right side exhaust may be much warmer and have a different sound which indicates that the right side is doing all the work, while the left three cylinders are just going along for the ride! This could be caused by an internal blockage within the left primary carburetor, but before you tear into the left carburetor I would recommend going to the procedures outlined below to mechanically synchronize the throttle linkage and idle mixture settings of the left and right primary carburetors. After synchronizing the carburetor linkage mechanically, any adjustment to the idle speed setting on one side must be matched by the same adjustment on the other side to keep the carburetors mechanically in sync. Once the engine appears to be idling at the correct speed with an equal contribution from all six cylinders, the Uni-Syn gauge can be used to fine tune the idle speed settings to obtain an equal airflow through each primary carburetor. (The Uni-Syn gauge represents the actual airflow through the throat of each carburetor, and is more accurate than the simple initial mechanical adjustments made following the shop manual procedures to establish an initial starting point).

You may ultimately find that the left side is getting mostly air and no fuel, or a very lean mixture possibly caused by a vacuum leak on the left side. You might also try disconnecting the throttle linkage on the left carburetor and see what happens if you open the throttle on the left carburetor only. If the engine speed increases significantly with an open throttle on the left carburetor only that might be an indication that the primary fuel circuits are functional, but the idle circuits may be obstructed. If a careful inspection seems to point to a fault in the left primary carburetor, you may have to open up the carburetor to look for an internal problem or blockage. Start by checking to see if the left carburetor float bowl has a normal level of fuel in it. If the carburetor float bowl contains fuel, but the engine does not appear to be idling with an equal contribution from both primary carburetors, it may be necessary to dismantle the left carburetor and attempt to clean the fuel passages in the carburetor body (possibly with a blast of high pressure air or by chemically cleaning the carburetor body in carburetor parts dip.

The procedure below highlights the mechanical synchronization process outlined in the shop manual. You may find that your carburetors — when mechanically synchronized — will not allow the engine to idle properly, likely due to a fault in one of the carburetors where fuel is not being properly mixed with air during engine idle.

bbodie52 wrote:There is no simple, or compressed method to tune and troubleshoot a Corvair engine. A certain amount of knowledge or understanding is essential for the person doing the tuneup to interpret the results and then to be able to make logical adjustments accordingly. I would encourage you to do your homework, ask questions for clarification when needed. and follow the guidance below and in the shop manual to ultimately get the desired results with your Corvair.

bbodie52 wrote:Here is a fair amount of tune-up info, but if you can work your way through it the explanations may help with your understanding of how the various subsystems interact with each other, and why the proper sequence should be followed so you don't end up adjusting one area improperly to compensate for another area that isn't functioning properly.

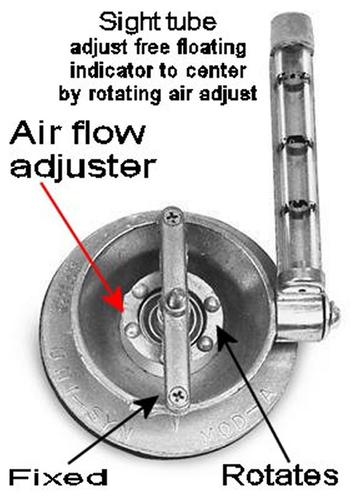

The dwell tachometer and timing light are the most common items thought of when working with an older engine in a classic car. As previously mentioned, however, there are ways to work around the lack of these tools. Adjusting the ignition points gap with a flat feeler gauge is a substitute for having a dwell tachometer. Setting the dwell with an electronic instrument is more accurate, however. The tachometer portion is needed to measure idle speeds and possibly to perform other tests where engine speed measurement is needed. It is possible to static-time your ignition system with a strip of paper placed between the ignition points. The engine timing mark can be manually positioned to the desired setting on the crankshaft pulley, and the distributor can be slowly rotated until the points just start to open and release the strip of paper. The distributor is then tightened and the mechanic has established an initial static timing setting. Of course, having a timing light makes things much easier, improves accuracy, and permits visual confirmation that the centrifugal advance is functioning. A vacuum gauge can be used for carburetor synchronization and other carburetor tests, and most vacuum gauges also double as a pressure gauge for measuring fuel pump output pressure. A UniSyn gauge, as shown below, measures airflow through each carburetor throat, and is an accurate way for synchronizing multiple carburetors at idle speeds and at partial throttle. A multimeter is a useful tool for troubleshooting and diagnosing electrical and charging system problems.

Many ignition systems in Corvairs have been upgraded by fitting an electronic ignition system to the distributor. These electronic ignition systems eliminate ignition points and condenser, which makes engine tuning somewhat easier and eliminates the need to periodically replace worn ignition points. The breakerless ignition system utilizes an optical or magnetic trigger to control the ignition coil. The system eliminates the need for a dwell meter or flat feeler gauge for ignition points adjustments. (A wire-type feeler gauge is needed for adjusting spark plug gaps). The tachometer portion of a dwell-tachometer, however, is still useful.

Learning to work with the two Rochester primary carburetors on the Corvair really isn't all that difficult. But you should take the time to review the shop manuals and other attached manuals to get a better feel for what you are trying to accomplish. It is important to perform tuning steps in the right sequence, as outlined in the shop manuals and in the video below. Many of the tuning steps can impact the results found in other steps. There is a logical progression in tuning a Corvair engine, and skipping around or tuning components in a random order can only serve to confuse the outcome. The Delco Rochester service manual that I have attached is a good supplement to the Corvair shop manual. About half of the manual is dedicated to explaining the various subsystems and components of the Rochester HV carburetor. To some extent these carburetors perform as you would expect a computer-controlled fuel injection system and ignition system to operate — but they were designed at a time when computer-controlled systems that were designed to respond to sensor input throughout the car would only have been a dream. The various carburetor and ignition subsystems respond to engine temperature, engine speed, airflow and vacuum changes, etc. much like a modern engine — but without all of the sophisticated electronics and sensors. Engineers were attempting to accomplish the things we do now, but with much less sophistication — but still making changes as engine speed, throttle position, engine vacuum, and fluid and air flow characteristics varied. If you take the time to read through the Delco Rochester manual, you might come to understand how the choke system functions, what an accelerator pump does and why it exists, and how the distributor is designed to adjust timing at low engine speeds and at higher engine speeds using both a vacuum advance and a centrifugal advance to provide the correct timing at various engine speeds and load settings. A good understanding of how these systems work and what they are supposed to do can be a great help when tuning and troubleshooting your engine.

The links, videos, and attachments below should help you to understand how to work with a dual carburetor engine. Try not to be intimidated by two physically separated carburetors. They really function very much like a single two-barrel carburetor, but are physically separated from each other out of necessity due to the layout of the flat air cooled engine with cylinders opposed to each other. The Corvair engine layout is in many ways similar to many motorcycle engine configurations. It usually takes an experienced automobile mechanic a little adjustment time to get used to the way things are done on a motorcycle. The aluminum, air cooled flat six Corvair engine often is seen as a challenge to an automobile mechanic, who is not used to the "strange configuration" found in a Corvair.

viewtopic.php?f=55&t=13170&p=90875#p90875

The entire shop manual and many other Corvair technical references can be downloaded at no cost using the following link...

Common and Useful Corvair Websites

viewtopic.php?f=225&t=6007

Watching the video presentations below helps to provide insight and understanding about proper sequencing of the tuneup steps and procedures. Skipping around can insert obstacles and problems with getting the engine properly tuned.

The portion of the first video segment toward the end (Part 1, 5:10) and at the beginning of the second segment discusses throttle linkage adjustments and carburetor synchronization.

Tuning the Corvair Engine — Part 1

Tuning The Corvair Engine — Part 2

bbodie52 wrote: The Uni-Syn Carburetor Balancing Instrument is a tool that I remember as far back as the 1950s and 1960s. It was designed for use in multi-carburetor automobiles, motorcycles, etc. that were initially common in European vehicles, but were later found in American vehicles like the Corvair.

The Uni-Syn is an airflow gauge that must be calibrated to match the specific engine airflow moving through the carburetor throat. The flow control in the center of the Uni-Syn is mounted on a threaded pin. Rotating the flow control raises or lowers it, which increases/decreases the air gap, which impacts the air velocity passing the oriface that allows some airflow to pass through the gauge. With the Uni-Syn held firmly on the carburetor intake with the engine idling, the flow control is adjusted so that the plastic float is approximately centered in the glass sight tube. Once calibrated, the Uni-Syn can be moved back and forth between the two primary carburetors to compare airflow at idle. The goal is to play with the idle speed screws to get an even airflow level that matches between both carburetors, and at the same time produces the desired idle speed. Before fine-tuning this idle balance with a Uni-Syn, the ignition system, idle speed and idle mixture should have been adjusted following the standard procedures as described in the factory shop manual. The balancing step with the Uni-Syn gauge is added at the end of the tuning procedure to measure actual airflow though both carburetors at idle, and balancing that airflow using the airflow meter as a measuring tool, rather than simply relying on a physical balanced "calibration" using a strip of paper to detect initial contact between the idle speed adjustment screws and the carburetor linkage, followed by counting the screw turns needed to obtain the desired idle speed (and ensuring that the same number of screw turns are applied to each screw). That procedure achieves a fairly close initial setup. The use of the Uni-Syn airflow gauge as a final step ensures balance between the two carburetors by measuring actual airflow.

Once the balanced idle airflow and desired idle speed have been achieved, a similar procedure can be used to synchronize the airflow when the carburetors are held open at a faster engine speed by the throttle linkage. Again, the shop manual procedure can be used to set the initial mechanical balance between the two sides of the throttle linkage. The linkage segment connecting the accelerator pedal to the cross-linkage between the two carburetors is temporarily disconnected, and a turnbuckle is temporarily attached to hold the throttle opened against the pull of the throttle return spring.

The turnbuckle can be adjusted to hold the throttle open at approximately 1500 RPM. The Uni-Syn center flow control is readjusted to re-calibrate the float to a position somewhere in the center travel of the sight tube, based on the increased airflow through the carburetors at the higher steady RPM maintained by the turnbuckle arrangement. As with the idle synchronization procedure, the re-calibrated Uni-Syn is used to measure the airflow moving through the two carburetors. The goal is to fine-tune the threaded portion of the carburetor actuation linkage so that the same airflow reading is attained on each carburetor, but this time with the throttles held open by a pull on the throttle linkage, instead of by the setting of the idle speed screws. When the airflow has been balanced using the throttle linkage adjustment, the balancing procedure has been completed and the normal accelerator pedal throttle linkage can be reconnected.

TIPS & CLARIFICATION...

With the engine at idle, you want to open the Uni-Syn flow control as much as possible, but still keep the float in the sight glass at about mid-level. Then check the other carburetor, which you want to read the same flow rate. You may have to adjust the flow control a few times as you adjust the carburetor settings. Just remember to check each carburetor with the flow control set at the same point, and to keep the sight glass in the vertical to prevent the float from hanging up in the tube.

The wheel in the Uni-Syn venturi controls the flow through the tube, or in other words how high the bead is in the cylinder for a given engine speed. You need enough flow to not strangle the engine, and the bead works just as well in the lower third (which still lets good air flow through). Make sure the idle speed doesn't drop when you place the tool on the carb: if it does, open it up.

Before setting the carbs, make sure that the ignition is right: points and timing set, good wires and plugs. Rich running is often blamed on carbs when in fact it's a weak, retarded spark. Check the throttle shafts: loose ones let in air and lean the mixture, raising idle speed, as well as throw off the linkage action. Check the linkage that connects the carburetors. if it's loose, one will open before the other. Make sure there are no vacuum leaks.

With a twin carburetor set up, disconnect the linkage that connects one carburetor to the other. Set the idle speed with the linkage screws first. Use the Uni-Syn to check that each carburetor is drawing equally at idle. This may take a few tries until you get both drawing equally at the speed you want. Blip the throttle to see if they come back to those settings (worn throttle shafts can fool you). Set the idle mixture screws in accordance with the shop manual instructions. Check the balance again. Hook the linkage back up. If one carburetor now draws more, adjust the linkage until it's back to roughly equal.

Once the carburetors are drawing equally at idle, hold an engine speed: at about 1500 RPM. This checks that the mechanical linkage is pulling equally. You'll need to open up the Uni-Syn center wheel to draw more air and bring the bead down in the tube. If both carburetors are within a bead's thickness of each other, that's good. If one is definitely off from the other, the higher flow carburetor's linkage is being pulled more than the other. You'll need to figure out why that's happening mechanically to rectify it.

After reading through the above material please let me know if you need any further clarification.

Brad Bodie

Lake Chatuge, North Carolina

1966 Corvair Corsa Convertible

1966 Corvair Corsa Convertible

Lake Chatuge, North Carolina

1966 Corvair Corsa Convertible

1966 Corvair Corsa Convertible- terribleted

- Posts: 4584

- Joined: Sun Apr 18, 2010 2:36 pm

- Location: Atlanta, GA

- Contact:

Re: Back again tuning carbs

Procedure for balancing with the bubble carb synch tool. Only primary carbs are balanced. Disconnect any secondary carb linkage from the cross shaft. Disconnect the LEFT link from the cross shaft to the L carb throttle lever (with stock linkage this one should be the adjustable length one).You must be sure to keep the left carb throttle closed against the idle speed screw while you are doing this procedure Might can use rubber band...I usually just make sure it stays at idle and sometimes will hand hold it there if it needs it. With engine idling place balancer device on top of RIGHT carb. Set tool adjustment so that bubble is in the middle. Now place tool on the LEFT carb. Adjust idle speed screw on L carb until the bubble is in the middle. Place tool again on the RIGHT carb. Is it still in the middle? If not again adjust the TOOL so bubble is in the middle. Place tool on LEFT carb and adjust idle speed screw if needed to get the bubble in the middle. Now adjust the throttle shaft linkage to the LEFT carb so that it just enters the hole with the carb at its now balanced idle position, and re-attach it. You have now balanced your carbs. At this point you adjust overall engine speed which may be fast or slow after balancing. You do this by increasing or decreasing idle on both carbs by the same number of turns of their idle speed screws. (so too slow?...go up 1/4 turn each side...more? another 1/8 or 1/4 etc. till you get what you want.

550 idle speed is pretty low...most times they are happier a bit higher. I tend to idle my standard shift Corvairs between 700 and 850RPM. Automatics I set as low as possible where they will idle ok in gear.

550 idle speed is pretty low...most times they are happier a bit higher. I tend to idle my standard shift Corvairs between 700 and 850RPM. Automatics I set as low as possible where they will idle ok in gear.

Corvair guy since 1982. I have personally restored at least 20 Vairs, many of them restored ground up.

Currently working full time repairing Corvairs and restoring old cars.

https://www.facebook.com/tedsautorestoration/

Located in Snellville, Georgia

Currently working full time repairing Corvairs and restoring old cars.

https://www.facebook.com/tedsautorestoration/

Located in Snellville, Georgia

- 66corsaguy

- Posts: 256

- Joined: Sat Apr 01, 2017 10:34 pm

Re: Back again tuning carbs

66vairguy wrote:Carb tuning seems complicated. It can be if the carburetors have issues.

First I've run into rebuilt carburetors put into cars with no extra fuel filter between the tank and carburetors and the carburetors idle circuits get plugged up again. Unless you replaced the gas tank and fuel lines with new then installing a extra replaceable fuel filter is recommended. The brass filters at the carburetor inlets just keep out the big stuff that could cause the float check valves to jamb and flood the carburetors (and possibly cause a fire). To keep out the little stuff that can plug the idle circuit you need a good paper fuel filter in a metal canister.

The timing affects idle speed so set timing first per the book (make sure the RPM is at of less than specified for static timing). The vacuum advance hose is disconnected to make sure the vacuum advance has no effect on the timing when the static timing is set (usually at idle there is NO vacuum to the canister, but if the carburetors are not adjusted correctly there could be a vacuum). To make sure there is no vacuum advance the manual says to temporarily disconnect the hose to the distributor canister.

Bob Helts carburetor book explains the basic adjustments. Set the idle mixture to recommendations, then you disconnect the linkage between the carburetors (explained in the shop manual). Next the idle speed for each carburetor is "balanced". Most use the simple Uni-Sync that you adjust to get an indicated air flow. You want both carburetors to flow the same - that's it. If the idle is too low or two high, then BOTH carburetors idle speed screws have to be adjusted and then make sure the Uni-Sync says they are the same. Next go back and do a minor idle mixture screw adjustment. Usually it has little or a minor impact on the idle air flow balance, check it. Once done balancing the carburetors the linkage must be adjusted so BOTH carburetors don't fight each other when the linkage is hooked up (one holds the other off the idle stop) - linkage adjustment is in the manual.

Hope this takes the mystery out of it.

That’s very helpful. I will print out.

I have a brand new fuel filter after the tank and before the carbs. I have the glass and paper and it down by the starter. Thinking now maybe the metal is better just in case a rock shoots out and breaks it?

I also have the new linkage system from roger parent. And New electronic ignition. So everything is up to date other than my tuning

I also have bob belts book. And print out of the original Chevy Corvair tune up procedure and all other manuals etc

With my timing: set it when car is warm and in appropriate RPM. after i have adjusted my carbs etc in theory would i have to go back and re set my timing? Or it should be in spec still?

The rubber balance tube that runs in the back of carbs do i need to do anything to that? I understand linkage needs to be off.

I will go thru procedure again. Correctly

Sent from my iPhone using Corvair Forum mobile app

- 66corsaguy

- Posts: 256

- Joined: Sat Apr 01, 2017 10:34 pm

Re: Back again tuning carbs

Thanks ted. This is the most helpful explanation i have read and will print out for permanent installation in my manual.terribleted wrote:Procedure for balancing with the bubble carb synch tool. Only primary carbs are balanced. Disconnect any secondary carb linkage from the cross shaft. Disconnect the LEFT link from the cross shaft to the L carb throttle lever (with stock linkage this one should be the adjustable length one).You must be sure to keep the left carb throttle closed against the idle speed screw while you are doing this procedure Might can use rubber band...I usually just make sure it stays at idle and sometimes will hand hold it there if it needs it. With engine idling place balancer device on top of RIGHT carb. Set tool adjustment so that bubble is in the middle. Now place tool on the LEFT carb. Adjust idle speed screw on L carb until the bubble is in the middle. Place tool again on the RIGHT carb. Is it still in the middle? If not again adjust the TOOL so bubble is in the middle. Place tool on LEFT carb and adjust idle speed screw if needed to get the bubble in the middle. Now adjust the throttle shaft linkage to the LEFT carb so that it just enters the hole with the carb at its now balanced idle position, and re-attach it. You have now balanced your carbs. At this point you adjust overall engine speed which may be fast or slow after balancing. You do this by increasing or decreasing idle on both carbs by the same number of turns of their idle speed screws. (so too slow?...go up 1/4 turn each side...more? another 1/8 or 1/4 etc. till you get what you want.

550 idle speed is pretty low...most times they are happier a bit higher. I tend to idle my standard shift Corvairs between 700 and 850RPM. Automatics I set as low as possible where they will idle ok in gear.

According to everything else i have read i would not have done it this way. I’m always basing my carbs from the drivers side so this is incredibly useful.

Sent from my iPhone using Corvair Forum mobile app

- 66corsaguy

- Posts: 256

- Joined: Sat Apr 01, 2017 10:34 pm

Re: Back again tuning carbs

bbodie52 wrote:I hope that the material I write below will serve to clarify some things and not just overload you with technical information. I know that you have stated that you have read many articles about tuning the Corvair, but I have no way of knowing which articles you have read and what they contained. Based on the information you provided I can only tell you what I would do if I were working on your engine and attempting to troubleshoot and tune the ignition and fuel system. The following is an attempt to outline my train of thought and how I would approach working my way through critical engine operating parameters. Although there could be an internal flaw in one of the new [rebuilt] carburetors on your engine, I would try to begin by working my way through the external ignition and carburetor settings to see if the problem can be resolved without tearing down the carburetors to look for internal problems.66corsaguy wrote:Mon Mar 12, 2018 6:16 pm

Every few months i make time to work on my 66 Corvair. I am back trying to make final adjustments but I’m still struggling.

I have new set of 4 carbs from Wolf Ent. So they are good. But i am having trouble getting the car to run at peak performance and after it’s super warmed having trouble with stalling.

How do i know if the car is running lean or rich? (Other than fouled spark plugs)

I’ve got my idle set around 550. I feel it’s too low.

I’ve used the carb metering devise that sits on the bowl and the left side i set the red ball to the middle when i put it on the right carb the ball shoots up to the top out of view. Also if i put my hand over left carb it stumbles a little but i put on the right carb and it stumbles and wants to die. So which one is the correct one. I assume the right one does that mean base the left to it and if so - How!

I’m starting to get a little lost because i read 12 different articles and it all starts to just get confusing.

I check my timing and realize i forgot to pull and plug the vacuum tube. Just for knowledge-why does it matter?

How do i get both carbs balanced-which one am i trying to balance the other too? What’s the ideal idle i should shoot for?

The idle speed i assume only controls idle speed-rpm. And the mixture controls fuel and air. How do those two things affect the other? Or do they? If i softly seat mixture what’s the most common amount of turns out. 3? And same question with idle speed screw.

If i leave as the book says i will def stall...

"...But i am having trouble getting the car to run at peak performance and after it’s super warmed having trouble with stalling..."

I wanted to start by making sure that some important insulators were not accidentally omitted when you installed the replacement carburetors…

Carburetor rebuild kits often contain a thin gasket to seal the underside of the carburetor where it mounts on the intake manifold. The Corvair carburetors need a plastic insulator to isolate the base of the carburetor from the intake manifold, which prevents the gasoline inside the carburetor from boiling or vaporizing if excessive heat is allowed to transfer from the hot aluminum intake manifold on the cylinder head to the carburetor body. These plastic insulators can be easily damaged when removed. Clark's Corvair Parts bundles gaskets and insulators together. They are listed near the top of page 56 in the catalog http://www.corvair.com/user-cgi/catalog ... ow_page=56.

"I’ve got my idle set around 550. I feel it’s too low.

I’ve used the carb metering devise that sits on the bowl and the left side i set the red ball to the middle when i put it on the right carb the ball shoots up to the top out of view. Also if i put my hand over left carb it stumbles a little but i put on the right carb and it stumbles and wants to die. So which one is the correct one. I assume the right one does that mean base the left to it and if so - How!"

The low idle speed of 550 RPM is likely the result of your engine idling on the right three cylinders only. It appears that the right carburetor linkage has been adjusted to compensate for the lack of contribution from the left primary, while keeping the engine idling and not stalling using the right three cylinders to make up for a problem on the left side.

The Uni-Syn gauge is apparently indicating that the airflow through the right carburetor is much higher than the airflow in the left carburetor. You may also find that there is a difference in the exhaust output of the left muffler when comparing it to the right muffler. The right side exhaust may be much warmer and have a different sound which indicates that the right side is doing all the work, while the left three cylinders are just going along for the ride! This could be caused by an internal blockage within the left primary carburetor, but before you tear into the left carburetor I would recommend going to the procedures outlined below to mechanically synchronize the throttle linkage and idle mixture settings of the left and right primary carburetors. After synchronizing the carburetor linkage mechanically, any adjustment to the idle speed setting on one side must be matched by the same adjustment on the other side to keep the carburetors mechanically in sync. Once the engine appears to be idling at the correct speed with an equal contribution from all six cylinders, the Uni-Syn gauge can be used to fine tune the idle speed settings to obtain an equal airflow through each primary carburetor. (The Uni-Syn gauge represents the actual airflow through the throat of each carburetor, and is more accurate than the simple initial mechanical adjustments made following the shop manual procedures to establish an initial starting point).

You may ultimately find that the left side is getting mostly air and no fuel, or a very lean mixture possibly caused by a vacuum leak on the left side. You might also try disconnecting the throttle linkage on the left carburetor and see what happens if you open the throttle on the left carburetor only. If the engine speed increases significantly with an open throttle on the left carburetor only that might be an indication that the primary fuel circuits are functional, but the idle circuits may be obstructed. If a careful inspection seems to point to a fault in the left primary carburetor, you may have to open up the carburetor to look for an internal problem or blockage. Start by checking to see if the left carburetor float bowl has a normal level of fuel in it. If the carburetor float bowl contains fuel, but the engine does not appear to be idling with an equal contribution from both primary carburetors, it may be necessary to dismantle the left carburetor and attempt to clean the fuel passages in the carburetor body (possibly with a blast of high pressure air or by chemically cleaning the carburetor body in carburetor parts dip.

The procedure below highlights the mechanical synchronization process outlined in the shop manual. You may find that your carburetors — when mechanically synchronized — will not allow the engine to idle properly, likely due to a fault in one of the carburetors where fuel is not being properly mixed with air during engine idle.

I always find your information useful. I will print and go thru. Thanks for taking the time to go thrubbodie52 wrote:There is no simple, or compressed method to tune and troubleshoot a Corvair engine. A certain amount of knowledge or understanding is essential for the person doing the tuneup to interpret the results and then to be able to make logical adjustments accordingly. I would encourage you to do your homework, ask questions for clarification when needed. and follow the guidance below and in the shop manual to ultimately get the desired results with your Corvair.

bbodie52 wrote:Here is a fair amount of tune-up info, but if you can work your way through it the explanations may help with your understanding of how the various subsystems interact with each other, and why the proper sequence should be followed so you don't end up adjusting one area improperly to compensate for another area that isn't functioning properly.

The dwell tachometer and timing light are the most common items thought of when working with an older engine in a classic car. As previously mentioned, however, there are ways to work around the lack of these tools. Adjusting the ignition points gap with a flat feeler gauge is a substitute for having a dwell tachometer. Setting the dwell with an electronic instrument is more accurate, however. The tachometer portion is needed to measure idle speeds and possibly to perform other tests where engine speed measurement is needed. It is possible to static-time your ignition system with a strip of paper placed between the ignition points. The engine timing mark can be manually positioned to the desired setting on the crankshaft pulley, and the distributor can be slowly rotated until the points just start to open and release the strip of paper. The distributor is then tightened and the mechanic has established an initial static timing setting. Of course, having a timing light makes things much easier, improves accuracy, and permits visual confirmation that the centrifugal advance is functioning. A vacuum gauge can be used for carburetor synchronization and other carburetor tests, and most vacuum gauges also double as a pressure gauge for measuring fuel pump output pressure. A UniSyn gauge, as shown below, measures airflow through each carburetor throat, and is an accurate way for synchronizing multiple carburetors at idle speeds and at partial throttle. A multimeter is a useful tool for troubleshooting and diagnosing electrical and charging system problems.

Many ignition systems in Corvairs have been upgraded by fitting an electronic ignition system to the distributor. These electronic ignition systems eliminate ignition points and condenser, which makes engine tuning somewhat easier and eliminates the need to periodically replace worn ignition points. The breakerless ignition system utilizes an optical or magnetic trigger to control the ignition coil. The system eliminates the need for a dwell meter or flat feeler gauge for ignition points adjustments. (A wire-type feeler gauge is needed for adjusting spark plug gaps). The tachometer portion of a dwell-tachometer, however, is still useful.

Learning to work with the two Rochester primary carburetors on the Corvair really isn't all that difficult. But you should take the time to review the shop manuals and other attached manuals to get a better feel for what you are trying to accomplish. It is important to perform tuning steps in the right sequence, as outlined in the shop manuals and in the video below. Many of the tuning steps can impact the results found in other steps. There is a logical progression in tuning a Corvair engine, and skipping around or tuning components in a random order can only serve to confuse the outcome. The Delco Rochester service manual that I have attached is a good supplement to the Corvair shop manual. About half of the manual is dedicated to explaining the various subsystems and components of the Rochester HV carburetor. To some extent these carburetors perform as you would expect a computer-controlled fuel injection system and ignition system to operate — but they were designed at a time when computer-controlled systems that were designed to respond to sensor input throughout the car would only have been a dream. The various carburetor and ignition subsystems respond to engine temperature, engine speed, airflow and vacuum changes, etc. much like a modern engine — but without all of the sophisticated electronics and sensors. Engineers were attempting to accomplish the things we do now, but with much less sophistication — but still making changes as engine speed, throttle position, engine vacuum, and fluid and air flow characteristics varied. If you take the time to read through the Delco Rochester manual, you might come to understand how the choke system functions, what an accelerator pump does and why it exists, and how the distributor is designed to adjust timing at low engine speeds and at higher engine speeds using both a vacuum advance and a centrifugal advance to provide the correct timing at various engine speeds and load settings. A good understanding of how these systems work and what they are supposed to do can be a great help when tuning and troubleshooting your engine.

The links, videos, and attachments below should help you to understand how to work with a dual carburetor engine. Try not to be intimidated by two physically separated carburetors. They really function very much like a single two-barrel carburetor, but are physically separated from each other out of necessity due to the layout of the flat air cooled engine with cylinders opposed to each other. The Corvair engine layout is in many ways similar to many motorcycle engine configurations. It usually takes an experienced automobile mechanic a little adjustment time to get used to the way things are done on a motorcycle. The aluminum, air cooled flat six Corvair engine often is seen as a challenge to an automobile mechanic, who is not used to the "strange configuration" found in a Corvair.

viewtopic.php?f=55&t=13170&p=90875#p90875

The entire shop manual and many other Corvair technical references can be downloaded at no cost using the following link...

Common and Useful Corvair Websites

viewtopic.php?f=225&t=6007

Watching the video presentations below helps to provide insight and understanding about proper sequencing of the tuneup steps and procedures. Skipping around can insert obstacles and problems with getting the engine properly tuned.

The portion of the first video segment toward the end (Part 1, 5:10) and at the beginning of the second segment discusses throttle linkage adjustments and carburetor synchronization.

Tuning the Corvair Engine — Part 1

Tuning The Corvair Engine — Part 2

After reading through the above material please let me know if you need any further clarification.

I have watched the old Chevy Corvair tune up videos. I have shop manual, bob belts book and i have read both forums and google search Corvair tune etc etc. too much information starts to get overwhelming so asking in the forum and getting clear answers for specific questions works better for me at this point.

Thanks again!!!

Sent from my iPhone using Corvair Forum mobile app

-

joepad

- Corvair of the Month

- Posts: 43

- Joined: Fri Jan 01, 2010 1:44 pm

- Location: new jersey

- Contact:

Re: Back again tuning carbs

Just because Wolf rebuilt the carbs doesn't mean they were done correctly. He rebuilt mine years ago and once they were on they caused the engine to smoke like crazy. Couldn't figure out why. The carbs were running too rich and he left parts loose in each carb, which the next rebuilder found. My carbs are now rebuilt by Rafee Corvair. He tests them on a Corvair engine when done to make sure they run right and to pre balance them too.

- terribleted

- Posts: 4584

- Joined: Sun Apr 18, 2010 2:36 pm

- Location: Atlanta, GA

- Contact:

Re: Back again tuning carbs

With the stock linkage the only adjustable rod is the one on the left carb so you must take reference from the right and then make the left one match. With Roger's linkage you could do it either way as both side are adjustable. Were you very careful in setting up the linage? Are you absolutly sure that the primary and secondary carbs are getting all the way closed particularly but fully closed and fully open as well. I just installed a 65 style Parent linkage yesterday I had to do quite alot of tinkering to get it just right. The right primary had an issue where the bottom heim joint was hitting the sheet metal before the throttle was fully closed (fix was to bend the throttle arm a little and dimple the sheet metal a bit below the heim). Carbs must be fully close to set them up per his instructions which means you have to back out the idle speed screws so that the throttle can actually hit the stops (if they are not both against the stops the linkage will be uneven). (hint count how many turns out on the idle speed screw you did to get them to fully closed and after install turn the idle screws back in the same amount...car will not run with the throttles fully closed and it should put your idle back to about where it was).66corsaguy wrote: ↑Wed Mar 14, 2018 11:52 amThanks ted. This is the most helpful explanation i have read and will print out for permanent installation in my manual.terribleted wrote:Procedure for balancing with the bubble carb synch tool. Only primary carbs are balanced. Disconnect any secondary carb linkage from the cross shaft. Disconnect the LEFT link from the cross shaft to the L carb throttle lever (with stock linkage this one should be the adjustable length one).You must be sure to keep the left carb throttle closed against the idle speed screw while you are doing this procedure Might can use rubber band...I usually just make sure it stays at idle and sometimes will hand hold it there if it needs it. With engine idling place balancer device on top of RIGHT carb. Set tool adjustment so that bubble is in the middle. Now place tool on the LEFT carb. Adjust idle speed screw on L carb until the bubble is in the middle. Place tool again on the RIGHT carb. Is it still in the middle? If not again adjust the TOOL so bubble is in the middle. Place tool on LEFT carb and adjust idle speed screw if needed to get the bubble in the middle. Now adjust the throttle shaft linkage to the LEFT carb so that it just enters the hole with the carb at its now balanced idle position, and re-attach it. You have now balanced your carbs. At this point you adjust overall engine speed which may be fast or slow after balancing. You do this by increasing or decreasing idle on both carbs by the same number of turns of their idle speed screws. (so too slow?...go up 1/4 turn each side...more? another 1/8 or 1/4 etc. till you get what you want.

550 idle speed is pretty low...most times they are happier a bit higher. I tend to idle my standard shift Corvairs between 700 and 850RPM. Automatics I set as low as possible where they will idle ok in gear.

According to everything else i have read i would not have done it this way. I’m always basing my carbs from the drivers side so this is incredibly useful.

Sent from my iPhone using Corvair Forum mobile app

You keep mentioning you have new rebuilt Wolf carbs. This means little. Just because they are "rebuilt" does not mean they are functional. I have had seen a number of issues with rebuilt carbs over the years from Clark's a couple times and Wolf carbs a number of times...we will not even talk about regular Corvair enthusiast rebuilds...man people need to use the manual:). Clark's issues were in both cases flooding issues because the float level was too high, likely caused in shipping when some UPS guy threw or dropped the package. The Wolf issues were varied from totally inadequate adjustments to flooding to missing parts to mismatched carbs. This was alot of years ago, I have heard better things recently. The key is just because they are "rebuilt" means little if they are screwed up.

Corvair guy since 1982. I have personally restored at least 20 Vairs, many of them restored ground up.

Currently working full time repairing Corvairs and restoring old cars.

https://www.facebook.com/tedsautorestoration/

Located in Snellville, Georgia

Currently working full time repairing Corvairs and restoring old cars.

https://www.facebook.com/tedsautorestoration/

Located in Snellville, Georgia

Re: Back again tuning carbs

terribleted supplied some great details.

The Roger Parent linkage, unlike stock, is adjustable at various points. It can be time consuming to initially set up, but easier to make minor adjustments later. Accurate and it sure looks good.

Changing the timing will change the idle speed. Changing the idle speed has no effect on "static" timing, but as the engine speed increased the mechanical advance increases the timing - when that occurs depends on the distributor. Some of the 66 air injection systems (SMOG control) used a distributor that advanced aggressively between 600 and 800RPM - or you have to have the idle speed down to 600 to set static timing. Great fun with a PG that idles at 900RPM in neutral. A buddy had an "expert" tune his 66 A.I.R. PG car and it couldn't go over 65MPH and was lethargic. I set his idle down and found the timing was way off. Set the timing - reset the idle - car ran great. That said, the whole process was time consuming.

If you have points, then changing the dwell changes the timing, but changing the timing has NO effect on the points dwell (assumes the distributor is not worn out).

So ---- adjust dwell (if appropriate), adjust static timing at specified RPM, balance and set idle speed at carburetors. Done - assuming everything is working correctly. When things don't respond properly then good old troubleshooting skills are needed. An experienced car buddy who likes pizza can come in handy.

As far as carburetor rebuilds go - you never know how a carburetor will work until it goes on an engine (and few rebuilders do that). I had one I did that would not keep a steady idle, and had several experienced folks look at it. Everything looked good. I got another base and that fixed it.

The Roger Parent linkage, unlike stock, is adjustable at various points. It can be time consuming to initially set up, but easier to make minor adjustments later. Accurate and it sure looks good.

Changing the timing will change the idle speed. Changing the idle speed has no effect on "static" timing, but as the engine speed increased the mechanical advance increases the timing - when that occurs depends on the distributor. Some of the 66 air injection systems (SMOG control) used a distributor that advanced aggressively between 600 and 800RPM - or you have to have the idle speed down to 600 to set static timing. Great fun with a PG that idles at 900RPM in neutral. A buddy had an "expert" tune his 66 A.I.R. PG car and it couldn't go over 65MPH and was lethargic. I set his idle down and found the timing was way off. Set the timing - reset the idle - car ran great. That said, the whole process was time consuming.

If you have points, then changing the dwell changes the timing, but changing the timing has NO effect on the points dwell (assumes the distributor is not worn out).

So ---- adjust dwell (if appropriate), adjust static timing at specified RPM, balance and set idle speed at carburetors. Done - assuming everything is working correctly. When things don't respond properly then good old troubleshooting skills are needed. An experienced car buddy who likes pizza can come in handy.

As far as carburetor rebuilds go - you never know how a carburetor will work until it goes on an engine (and few rebuilders do that). I had one I did that would not keep a steady idle, and had several experienced folks look at it. Everything looked good. I got another base and that fixed it.

- terribleted

- Posts: 4584

- Joined: Sun Apr 18, 2010 2:36 pm

- Location: Atlanta, GA

- Contact:

Re: Back again tuning carbs

This unfortunately seems to be a somewhat common occurrence. Some chunk of something lodged in an idle passage that defies removal is my guess. I have pitched more than one such base into the trash can after trying multiple times to clear this type issue.66vairguy wrote: ↑Wed Mar 14, 2018 3:23 pm

As far as carburetor rebuilds go - you never know how a carburetor will work until it goes on an engine (and few rebuilders do that). I had one I did that would not keep a steady idle, and had several experienced folks look at it. Everything looked good. I got another base and that fixed it.

Corvair guy since 1982. I have personally restored at least 20 Vairs, many of them restored ground up.

Currently working full time repairing Corvairs and restoring old cars.

https://www.facebook.com/tedsautorestoration/

Located in Snellville, Georgia

Currently working full time repairing Corvairs and restoring old cars.

https://www.facebook.com/tedsautorestoration/

Located in Snellville, Georgia

- 66corsaguy

- Posts: 256

- Joined: Sat Apr 01, 2017 10:34 pm

Back again tuning carbs

terribleted wrote:With the stock linkage the only adjustable rod is the one on the left carb so you must take reference from the right and then make the left one match. With Roger's linkage you could do it either way as both side are adjustable. Were you very careful in setting up the linage? Are you absolutly sure that the primary and secondary carbs are getting all the way closed particularly but fully closed and fully open as well. I just installed a 65 style Parent linkage yesterday I had to do quite alot of tinkering to get it just right. The right primary had an issue where the bottom heim joint was hitting the sheet metal before the throttle was fully closed (fix was to bend the throttle arm a little and dimple the sheet metal a bit below the heim). Carbs must be fully close to set them up per his instructions which means you have to back out the idle speed screws so that the throttle can actually hit the stops (if they are not both against the stops the linkage will be uneven). (hint count how many turns out on the idle speed screw you did to get them to fully closed and after install turn the idle screws back in the same amount...car will not run with the throttles fully closed and it should put your idle back to about where it was).66corsaguy wrote: ↑Wed Mar 14, 2018 11:52 amThanks ted. This is the most helpful explanation i have read and will print out for permanent installation in my manual.terribleted wrote:Procedure for balancing with the bubble carb synch tool. Only primary carbs are balanced. Disconnect any secondary carb linkage from the cross shaft. Disconnect the LEFT link from the cross shaft to the L carb throttle lever (with stock linkage this one should be the adjustable length one).You must be sure to keep the left carb throttle closed against the idle speed screw while you are doing this procedure Might can use rubber band...I usually just make sure it stays at idle and sometimes will hand hold it there if it needs it. With engine idling place balancer device on top of RIGHT carb. Set tool adjustment so that bubble is in the middle. Now place tool on the LEFT carb. Adjust idle speed screw on L carb until the bubble is in the middle. Place tool again on the RIGHT carb. Is it still in the middle? If not again adjust the TOOL so bubble is in the middle. Place tool on LEFT carb and adjust idle speed screw if needed to get the bubble in the middle. Now adjust the throttle shaft linkage to the LEFT carb so that it just enters the hole with the carb at its now balanced idle position, and re-attach it. You have now balanced your carbs. At this point you adjust overall engine speed which may be fast or slow after balancing. You do this by increasing or decreasing idle on both carbs by the same number of turns of their idle speed screws. (so too slow?...go up 1/4 turn each side...more? another 1/8 or 1/4 etc. till you get what you want.

550 idle speed is pretty low...most times they are happier a bit higher. I tend to idle my standard shift Corvairs between 700 and 850RPM. Automatics I set as low as possible where they will idle ok in gear.

According to everything else i have read i would not have done it this way. I’m always basing my carbs from the drivers side so this is incredibly useful.

Sent from my iPhone using Corvair Forum mobile app

You keep mentioning you have new rebuilt Wolf carbs. This means little. Just because they are "rebuilt" does not mean they are functional. I have had seen a number of issues with rebuilt carbs over the years from Clark's a couple times and Wolf carbs a number of times...we will not even talk about regular Corvair enthusiast rebuilds...man people need to use the manual:). Clark's issues were in both cases flooding issues because the float level was too high, likely caused in shipping when some UPS guy threw or dropped the package. The Wolf issues were varied from totally inadequate adjustments to flooding to missing parts to mismatched carbs. This was alot of years ago, I have heard better things recently. The key is just because they are "rebuilt" means little if they are screwed up.

I rebuilt my old carbs and still had a ton leaking fuel problems and didn’t trust them anymore reading about other people’s Car fires. I put wolfs on and the car already runs better. Albeit i had to buy copper gaskets for fuel inlet as i think they were seated for my old carbs and not used to the new and leaked. No leaks anymore and i am constantly looking!! I’m not willing to open the new carbs and check any work at this point as i think the only thing that has to be done to the car is proper tuning. I’m not relying on how they came tuned. Just trying to figure out sequencing and what is right or wrong. Unfortunately when you are doing something wrong and don’t know it you travel pretty far down the wrong path.

End rant.

Sent from my iPhone using Corvair Forum mobile app

Last edited by 66corsaguy on Wed Mar 14, 2018 7:11 pm, edited 1 time in total.

- 66corsaguy

- Posts: 256

- Joined: Sat Apr 01, 2017 10:34 pm

Re: Back again tuning carbs

terribleted wrote:With the stock linkage the only adjustable rod is the one on the left carb so you must take reference from the right and then make the left one match. With Roger's linkage you could do it either way as both side are adjustable. Were you very careful in setting up the linage? Are you absolutly sure that the primary and secondary carbs are getting all the way closed particularly but fully closed and fully open as well. I just installed a 65 style Parent linkage yesterday I had to do quite alot of tinkering to get it just right. The right primary had an issue where the bottom heim joint was hitting the sheet metal before the throttle was fully closed (fix was to bend the throttle arm a little and dimple the sheet metal a bit below the heim). Carbs must be fully close to set them up per his instructions which means you have to back out the idle speed screws so that the throttle can actually hit the stops (if they are not both against the stops the linkage will be uneven). (hint count how many turns out on the idle speed screw you did to get them to fully closed and after install turn the idle screws back in the same amount...car will not run with the throttles fully closed and it should put your idle back to about where it was).66corsaguy wrote: ↑Wed Mar 14, 2018 11:52 amThanks ted. This is the most helpful explanation i have read and will print out for permanent installation in my manual.terribleted wrote:Procedure for balancing with the bubble carb synch tool. Only primary carbs are balanced. Disconnect any secondary carb linkage from the cross shaft. Disconnect the LEFT link from the cross shaft to the L carb throttle lever (with stock linkage this one should be the adjustable length one).You must be sure to keep the left carb throttle closed against the idle speed screw while you are doing this procedure Might can use rubber band...I usually just make sure it stays at idle and sometimes will hand hold it there if it needs it. With engine idling place balancer device on top of RIGHT carb. Set tool adjustment so that bubble is in the middle. Now place tool on the LEFT carb. Adjust idle speed screw on L carb until the bubble is in the middle. Place tool again on the RIGHT carb. Is it still in the middle? If not again adjust the TOOL so bubble is in the middle. Place tool on LEFT carb and adjust idle speed screw if needed to get the bubble in the middle. Now adjust the throttle shaft linkage to the LEFT carb so that it just enters the hole with the carb at its now balanced idle position, and re-attach it. You have now balanced your carbs. At this point you adjust overall engine speed which may be fast or slow after balancing. You do this by increasing or decreasing idle on both carbs by the same number of turns of their idle speed screws. (so too slow?...go up 1/4 turn each side...more? another 1/8 or 1/4 etc. till you get what you want.

550 idle speed is pretty low...most times they are happier a bit higher. I tend to idle my standard shift Corvairs between 700 and 850RPM. Automatics I set as low as possible where they will idle ok in gear.

According to everything else i have read i would not have done it this way. I’m always basing my carbs from the drivers side so this is incredibly useful.

Sent from my iPhone using Corvair Forum mobile app

You keep mentioning you have new rebuilt Wolf carbs. This means little. Just because they are "rebuilt" does not mean they are functional. I have had seen a number of issues with rebuilt carbs over the years from Clark's a couple times and Wolf carbs a number of times...we will not even talk about regular Corvair enthusiast rebuilds...man people need to use the manual:). Clark's issues were in both cases flooding issues because the float level was too high, likely caused in shipping when some UPS guy threw or dropped the package. The Wolf issues were varied from totally inadequate adjustments to flooding to missing parts to mismatched carbs. This was alot of years ago, I have heard better things recently. The key is just because they are "rebuilt" means little if they are screwed up.

I rebuilt my old carbs and still had a ton leaking fuel problems and didn’t trust them anymore reading about other people’s Car fires. I put wolfs on and the car already runs better. Albeit i had to buy copper gaskets for fuel inlet as i think they were seated for my old carbs and not used to the new and leaked. No leaks anymore and i am constantly looking!! I’m not willing to open the new carbs and check any work at this point as i think the only thing that has to be done to the car is proper tuning. I’m not relying on how they came tuned. Just trying to figure out sequencing and what is right or wrong. Unfortunately when you are doing something wrong and don’t know it you travel pretty far down the wrong path. I just don’t want to F up my car cos the last mechanic i gave $4grand to and i got completely ripped off. Yes “the only Corvair specialist in San Francisco” mechanic. He got mad at me when i questioned my car continually being parked on the street in the rain in one of THE worst neighborhoods in SF. I should’ve kept on driving when i met him.

Anyway. Now i do all work myself. But a steep learning curve

End rant.

Sent from my iPhone using Corvair Forum mobile app

- 66corsaguy

- Posts: 256

- Joined: Sat Apr 01, 2017 10:34 pm

Re: Back again tuning carbs

terribleted wrote:With the stock linkage the only adjustable rod is the one on the left carb so you must take reference from the right and then make the left one match. With Roger's linkage you could do it either way as both side are adjustable. Were you very careful in setting up the linage? Are you absolutly sure that the primary and secondary carbs are getting all the way closed particularly but fully closed and fully open as well. I just installed a 65 style Parent linkage yesterday I had to do quite alot of tinkering to get it just right. The right primary had an issue where the bottom heim joint was hitting the sheet metal before the throttle was fully closed (fix was to bend the throttle arm a little and dimple the sheet metal a bit below the heim). Carbs must be fully close to set them up per his instructions which means you have to back out the idle speed screws so that the throttle can actually hit the stops (if they are not both against the stops the linkage will be uneven). (hint count how many turns out on the idle speed screw you did to get them to fully closed and after install turn the idle screws back in the same amount...car will not run with the throttles fully closed and it should put your idle back to about where it was).66corsaguy wrote: ↑Wed Mar 14, 2018 11:52 amThanks ted. This is the most helpful explanation i have read and will print out for permanent installation in my manual.terribleted wrote:Procedure for balancing with the bubble carb synch tool. Only primary carbs are balanced. Disconnect any secondary carb linkage from the cross shaft. Disconnect the LEFT link from the cross shaft to the L carb throttle lever (with stock linkage this one should be the adjustable length one).You must be sure to keep the left carb throttle closed against the idle speed screw while you are doing this procedure Might can use rubber band...I usually just make sure it stays at idle and sometimes will hand hold it there if it needs it. With engine idling place balancer device on top of RIGHT carb. Set tool adjustment so that bubble is in the middle. Now place tool on the LEFT carb. Adjust idle speed screw on L carb until the bubble is in the middle. Place tool again on the RIGHT carb. Is it still in the middle? If not again adjust the TOOL so bubble is in the middle. Place tool on LEFT carb and adjust idle speed screw if needed to get the bubble in the middle. Now adjust the throttle shaft linkage to the LEFT carb so that it just enters the hole with the carb at its now balanced idle position, and re-attach it. You have now balanced your carbs. At this point you adjust overall engine speed which may be fast or slow after balancing. You do this by increasing or decreasing idle on both carbs by the same number of turns of their idle speed screws. (so too slow?...go up 1/4 turn each side...more? another 1/8 or 1/4 etc. till you get what you want.

550 idle speed is pretty low...most times they are happier a bit higher. I tend to idle my standard shift Corvairs between 700 and 850RPM. Automatics I set as low as possible where they will idle ok in gear.

According to everything else i have read i would not have done it this way. I’m always basing my carbs from the drivers side so this is incredibly useful.

Sent from my iPhone using Corvair Forum mobile app

You keep mentioning you have new rebuilt Wolf carbs. This means little. Just because they are "rebuilt" does not mean they are functional. I have had seen a number of issues with rebuilt carbs over the years from Clark's a couple times and Wolf carbs a number of times...we will not even talk about regular Corvair enthusiast rebuilds...man people need to use the manual:). Clark's issues were in both cases flooding issues because the float level was too high, likely caused in shipping when some UPS guy threw or dropped the package. The Wolf issues were varied from totally inadequate adjustments to flooding to missing parts to mismatched carbs. This was alot of years ago, I have heard better things recently. The key is just because they are "rebuilt" means little if they are screwed up.

I rebuilt my old carbs and still had a ton leaking fuel problems and didn’t trust them anymore reading about other people’s Car fires. I put wolfs on and the car already runs better. Albeit i had to buy copper gaskets for fuel inlet as i think they were seated for my old carbs and not used to the new and leaked. No leaks anymore and i am constantly looking!! I’m not willing to open the new carbs and check any work at this point as i think the only thing that has to be done to the car is proper tuning. I’m not relying on how they came tuned. Just trying to figure out sequencing and what is right or wrong. Unfortunately when you are doing something wrong and don’t know it you travel pretty far down the wrong path. I just don’t want to F up my car cos the last mechanic i gave $4grand to and i got completely ripped off. Yes “the only Corvair specialist in San Francisco” mechanic. He got mad at me when i questioned my car continually being parked on the street in the rain in one of THE worst neighborhoods in SF. I should’ve kept on driving when i met him.

Anyway. Now i do all work myself. But a steep learning curve

End rant.

Sent from my iPhone using Corvair Forum mobile app

- 66corsaguy

- Posts: 256

- Joined: Sat Apr 01, 2017 10:34 pm

Re: Back again tuning carbs