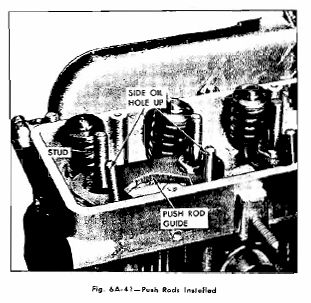

Have a question about push rod hole orientation. In the shop manual it says ’note: the side .050 oil hole in each push rod must be installed up...’ but the picture shows them pointing down(?)

Should the holes be orientated up vertically (towards the carb) or down (towards the exhaust manifold)?

Thanks for any help

1961 Greenbrier, 1962 Rampside and 1964 Monza cab.

Push rod .050 hole location

Re: Push rod .050 hole location

1961 Greenbrier, 1962 Rampside and 1964 Monza cab.

Re: Push rod .050 hole location

The rod will rotate during use so it doesn't matter. What they mean is that the little side hole in the rod must be towards the head (so it oils the rockers) so don't flip it around and put the end with the hole into the engine towards the lifters.

Whoever wrote that long ago probably was used to building engines with more vertical pushrods. In the photo, the head is shown in an odd position but the hole is "up" (as seen in the photo) as opposed to being on the other end (down in the block).

Whoever wrote that long ago probably was used to building engines with more vertical pushrods. In the photo, the head is shown in an odd position but the hole is "up" (as seen in the photo) as opposed to being on the other end (down in the block).

Dave W. from Gilbert, AZ

66 Corsa 140/4 Yenko Stinger Tribute

66 Corsa 140 Coupe w/factory A/C

65 Monza 4DR 140/PG w/factory A/C

65 Monza 4DR EJ20T/5

64 Greenbrier 110/PG, Standard 6-Door

66 Corsa 140/4 Yenko Stinger Tribute

66 Corsa 140 Coupe w/factory A/C

65 Monza 4DR 140/PG w/factory A/C

65 Monza 4DR EJ20T/5

64 Greenbrier 110/PG, Standard 6-Door

- bbodie52

- Corvair of the Month

- Posts: 11891

- Joined: Mon Aug 06, 2012 12:33 pm

- Location: Lake Chatuge Hayesville, NC

- Contact:

Re: Push rod .050 hole location

There is a small hole in the side of each push rod that is there to spray oil on the rocker arm to lubricate it. The push rods rotate during engine operation, so the oil is sprayed in all directions (something like a rotating lawn sprinkler). The shop manual refers to the side hole position, stating that the push rod hole must be "installed up", meaning with the side hole end up toward the rocker arm, as opposed to down toward the hydraulic lifter. If the push rod is inserted upside down, the side hole will be near the hydraulic lifter instead of the rocker, and the rocker arm would not get adequate lubrication! With the push rod inverted, the side oil hole would be spraying oil uselessly against the inside of the push rod tube wall, just above the hydraulic lifter.

You can see a hole in the side of the rocker arm, next to where the push rod seats. This hole permits oil sprayed from the side of the push rod to pass into the rocker pivot ball area, to lubricate the ball and rocker arm. If the push rod is inserted upside down, very little oil would get to the critical pivot area, causing the ball to run dry and not be lubricated. This would overheat the rocker arm and ball, causing the failed rocker arm results shown below. If the engine builder is unaware of the design in these push rods, he may insert the push rods without regard to the oil hole in the side. Some may be properly inserted, while others may not.

You can see a hole in the side of the rocker arm, next to where the push rod seats. This hole permits oil sprayed from the side of the push rod to pass into the rocker pivot ball area, to lubricate the ball and rocker arm. If the push rod is inserted upside down, very little oil would get to the critical pivot area, causing the ball to run dry and not be lubricated. This would overheat the rocker arm and ball, causing the failed rocker arm results shown below. If the engine builder is unaware of the design in these push rods, he may insert the push rods without regard to the oil hole in the side. Some may be properly inserted, while others may not.

Re: Push rod .050 hole location

Thanks for the info :)azdave wrote:The rod will rotate during use so it doesn't matter. What they mean is that the little side hole in the rod must be towards the head (so it oils the rockers) so don't flip it around and put the end with the hole into the engine towards the lifters.

Whoever wrote that long ago probably was used to building engines with more vertical pushrods. In the photo, the head is shown in an odd position but the hole is "up" (as seen in the photo) as opposed to being on the other end (down in the block).

1961 Greenbrier, 1962 Rampside and 1964 Monza cab.

Re: Push rod .050 hole location

Thanks for the info :)bbodie52 wrote:There is a small hole in the side of each push rod that is there to spray oil on the rocker arm to lubricate it. The push rods rotate during engine operation, so the oil is sprayed in all directions (something like a rotating lawn sprinkler). The shop manual refers to the side hole position, stating that the push rod hole must be "installed up", meaning with the side hole end up toward the rocker arm, as opposed to down toward the hydraulic lifter. If the push rod is inserted upside down, the side hole will be near the hydraulic lifter instead of the rocker, and the rocker arm would not get adequate lubrication! With the push rod inverted, the side oil hole would be spraying oil uselessly against the inside of the push rod tube wall, just above the hydraulic lifter.

You can see a hole in the side of the rocker arm, next to where the push rod seats. This hole permits oil sprayed from the side of the push rod to pass into the rocker pivot ball area, to lubricate the ball and rocker arm. If the push rod is inserted upside down, very little oil would get to the critical pivot area, causing the ball to run dry and not be lubricated. This would overheat the rocker arm and ball, causing the failed rocker arm results shown below. If the engine builder is unaware of the design in these push rods, he may insert the push rods without regard to the oil hole in the side. Some may be properly inserted, while others may not.

1961 Greenbrier, 1962 Rampside and 1964 Monza cab.