Back in the day when I drove Corvairs as my one and only car, I learned to always carry 2 extra fan belts, 2- 9/16" wrenches and a tire iron (pry bar). I did this with my 63 and 66.

Yesterday, while at my local repair shop, the belt 'popped off' of my current 66. What used to be a 5 minute job back when took almost a 1/2 hr. When did Chevy change the engine? Not only were there guards to be moved, but the oil filter was in the way (and the spare tire). Spare tire was always stored in the trunk, as the battery was in the right fender well. And I could see the crankshaft pulley, which is now hid by the oil filter & fuel pump.

When did this all change?

Replacing Fan Belt

- bbodie52

- Corvair of the Month

- Posts: 11897

- Joined: Mon Aug 06, 2012 12:33 pm

- Location: Lake Chatuge Hayesville, NC

- Contact:

Re: Replacing Fan Belt

Here is a long answer, but it should cover most of the bases...

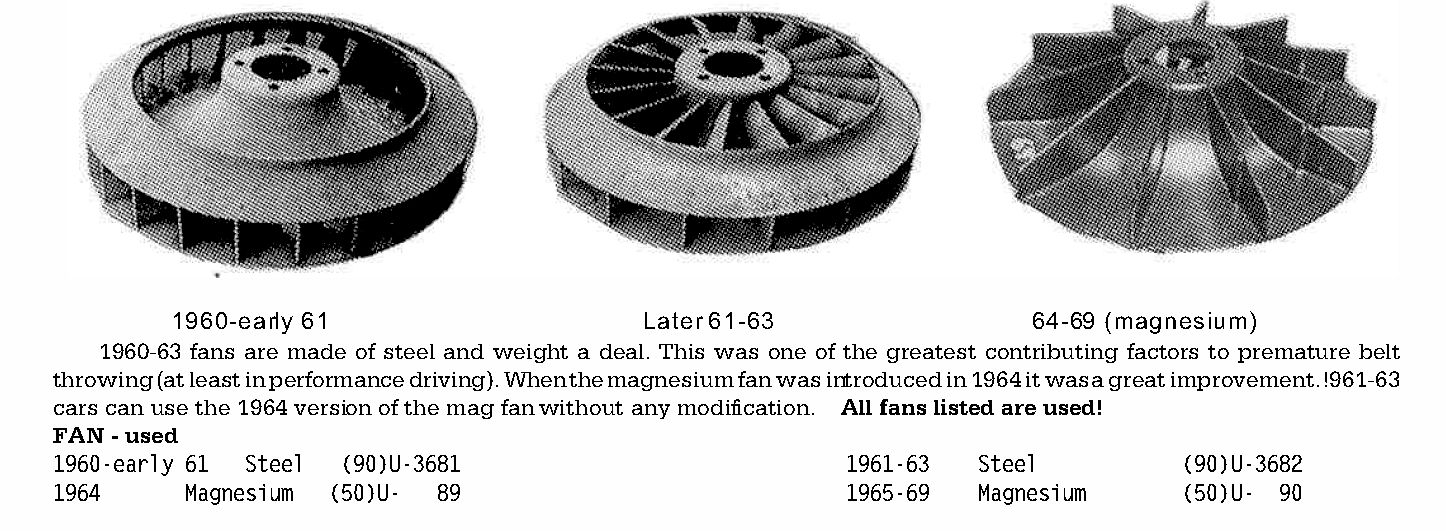

It is unusual for a street-driven late model (1965-1969) Corvair to flip fan belts. The cumulative mass of the rotating fan and generator/alternator is continually at war with the changing rotation speed of the crankshaft pulley. Manual transmission cars in particular place a lot of stress on the belt as the engine revs up to speed and then suddenly drops off at each shift. The "flywheel effect" of the heavier steel fans put a lot of strain on the fan belt as the crankshaft speed changes and the heavy steel fan resists the engine RPM change. The fan belt ends up straining with each engine speed variation, and the lightweight magnesium fan greatly reduces the stresses involved. The lightweight magnesium blower and belt guides seem to work very well — with minimal stress on the belt.

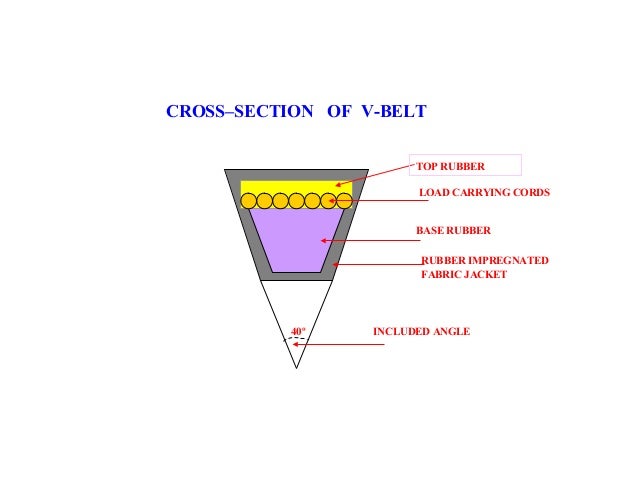

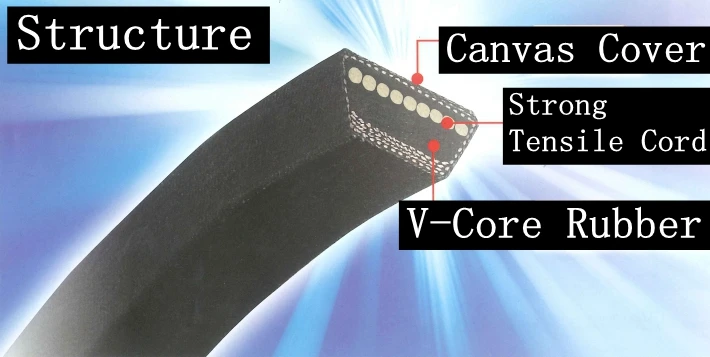

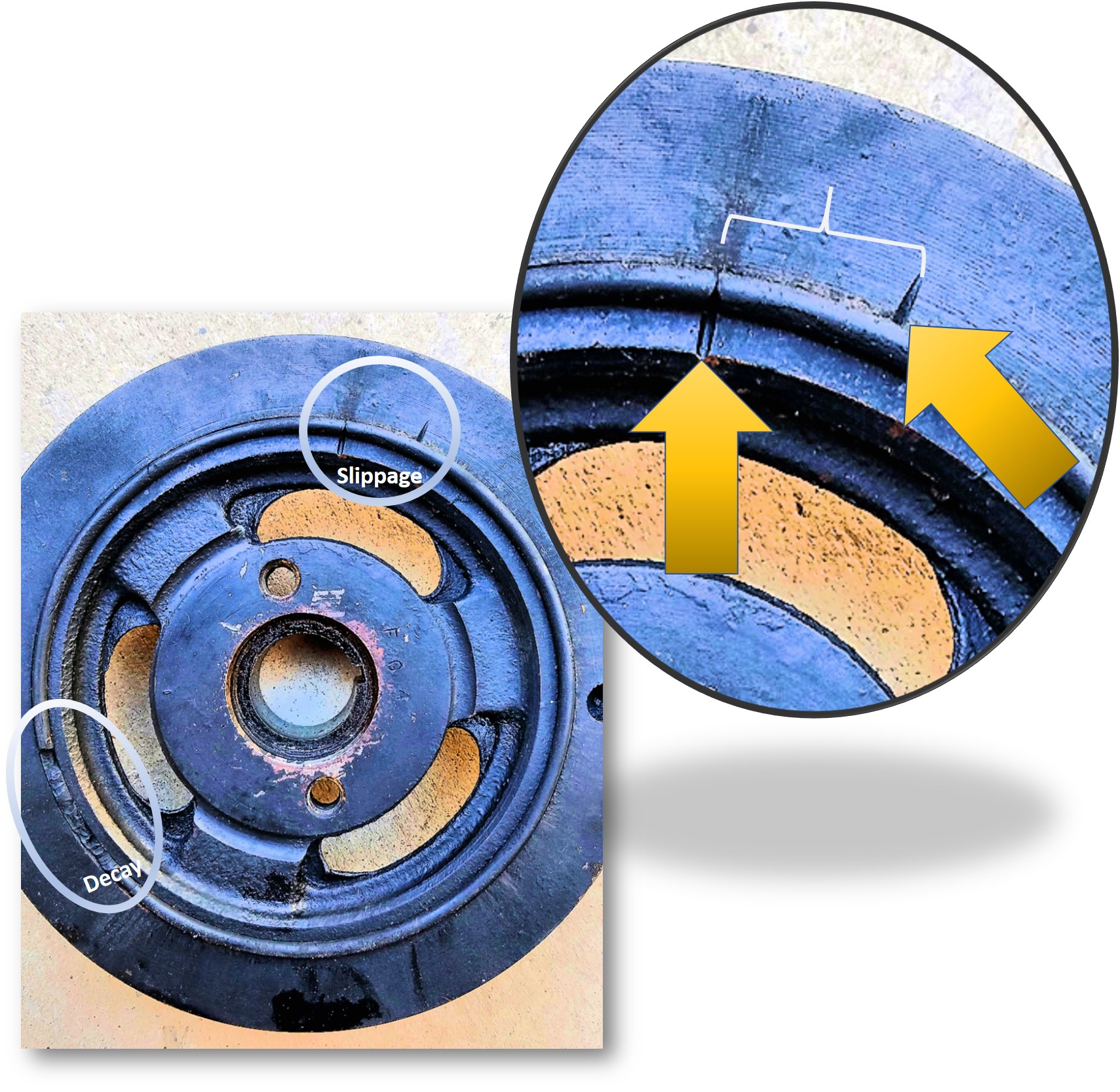

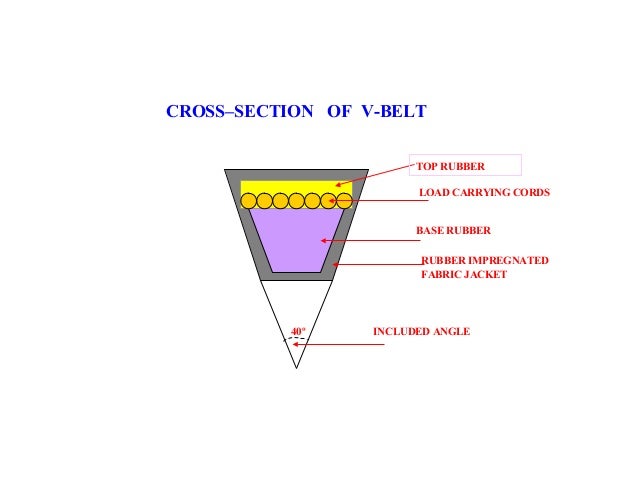

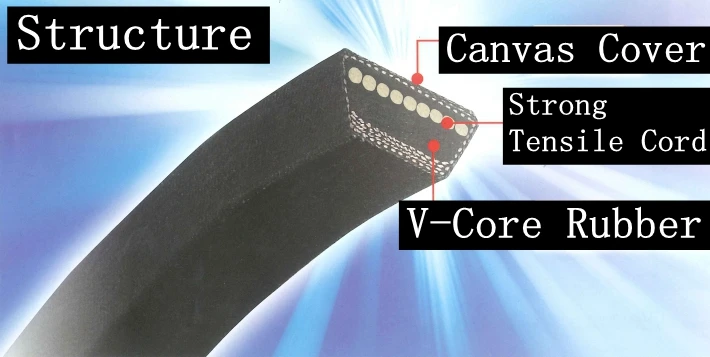

The belts do fatigue with age and should be replaced every few years as a precautionary measure. It is usually not a good idea to reuse one after it has flipped — even if it looks OK and seems to be intact. Internal damage to the hidden tensile support strands can occur if the belt flips and is forced to ride up over the pulley structure. If a new belt flips it may have stretched with "break-in" mileage and might have needed to be re-adjusted. If you repeatedly have such problems with your Corvair there may be a problem with excessive drag in a faulty fan or idler pulley bearing, or a problem with the alternator bearings. A failing harmonic balancer can also cause belt problems.

The image above displays the support strands that are embedded around the perimeter of the belt to provide it with tensile strength. A belt that has flipped off from the Corvair pulleys on its own may have suffered damage to these support strands that are internal and hidden from view. However, one or more damaged strands within the belt can severely weaken its overall tensile strength, which means it is likely to flip off again as it stretches if a damaged belt is reused.

There are two 9/16 inch fasteners securing the idler pulley. The hole and the separate groove (or slot) in the above photograph shows the locations where bolt and nut tension is applied to secure the idler pulley in place. Late-model cars that are fitted with a magnesium blower also have belt guides at the idler pulley and at the main fan pulley. Specified clearance between the belt/pulley and each belt guide is 1/16 of an inch. The idler pulley tension must be adjusted to provide both proper belt tension and proper clearance between the belt and the belt guide.

A good rule of thumb (literally) when adjusting belt tension is that proper tension has been achieved if there is a slight slippage between the belt and the alternator/generator pulley when pressure is applied with your thumb to the alternator/generator cooling fan blade. If there is no slippage the belt is likely too tight.

Tightening a Corvair fan belt w/ordinary tools

Apparently the difficulty you are experiencing with inadequate oil filter clearance to permit fan belt replacement is not uncommon. It was discussed extensively on the Corvair Center website without really coming to a solution...

Apparently the difficulty you are experiencing with inadequate oil filter clearance to permit fan belt replacement is not uncommon. It was discussed extensively on the Corvair Center website without really coming to a solution...

http://corvaircenter.com/phorum/read.ph ... 683,372703

http://corvaircenter.com/phorum/read.ph ... 683,372703

It is unusual for a street-driven late model (1965-1969) Corvair to flip fan belts. The cumulative mass of the rotating fan and generator/alternator is continually at war with the changing rotation speed of the crankshaft pulley. Manual transmission cars in particular place a lot of stress on the belt as the engine revs up to speed and then suddenly drops off at each shift. The "flywheel effect" of the heavier steel fans put a lot of strain on the fan belt as the crankshaft speed changes and the heavy steel fan resists the engine RPM change. The fan belt ends up straining with each engine speed variation, and the lightweight magnesium fan greatly reduces the stresses involved. The lightweight magnesium blower and belt guides seem to work very well — with minimal stress on the belt.

The belts do fatigue with age and should be replaced every few years as a precautionary measure. It is usually not a good idea to reuse one after it has flipped — even if it looks OK and seems to be intact. Internal damage to the hidden tensile support strands can occur if the belt flips and is forced to ride up over the pulley structure. If a new belt flips it may have stretched with "break-in" mileage and might have needed to be re-adjusted. If you repeatedly have such problems with your Corvair there may be a problem with excessive drag in a faulty fan or idler pulley bearing, or a problem with the alternator bearings. A failing harmonic balancer can also cause belt problems.

The image above displays the support strands that are embedded around the perimeter of the belt to provide it with tensile strength. A belt that has flipped off from the Corvair pulleys on its own may have suffered damage to these support strands that are internal and hidden from view. However, one or more damaged strands within the belt can severely weaken its overall tensile strength, which means it is likely to flip off again as it stretches if a damaged belt is reused.

There are two 9/16 inch fasteners securing the idler pulley. The hole and the separate groove (or slot) in the above photograph shows the locations where bolt and nut tension is applied to secure the idler pulley in place. Late-model cars that are fitted with a magnesium blower also have belt guides at the idler pulley and at the main fan pulley. Specified clearance between the belt/pulley and each belt guide is 1/16 of an inch. The idler pulley tension must be adjusted to provide both proper belt tension and proper clearance between the belt and the belt guide.

A good rule of thumb (literally) when adjusting belt tension is that proper tension has been achieved if there is a slight slippage between the belt and the alternator/generator pulley when pressure is applied with your thumb to the alternator/generator cooling fan blade. If there is no slippage the belt is likely too tight.

Tightening a Corvair fan belt w/ordinary tools

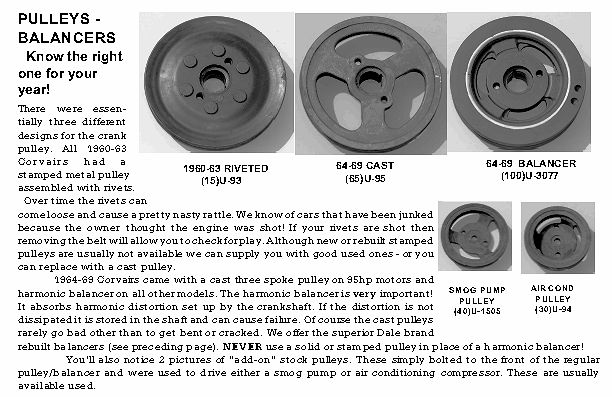

If you have a harmonic balancer on your engine, you should check it for signs of slippage between the center crankshaft hub and the outer harmonic dampener. The two steel components are held together in a press-fit by a rubber ring. This rubber component can deteriorate with age, which can permit slippage of the outer steel dampener. A slipping outer dampener makes for an inaccurate timing mark, and the outer ring will eventually completely separate. If the register mark between the inner hub and the outer ring shows signs of slippage, the harmonic balancer should be replaced with a new harmonic balancer.1961 Shop Manual, Page 7-4 wrote:Adjust belt (if necessary) to give a 3/8" deflection between blower and idler pulley under a 15 pound load. If a new belt is installed, adjust deflection as described above, then operate the engine at 1500 rpm for at least one minute to "seat" the new belt. Recheck deflection.

Some Corvairs were fitted with a 90 degree filter adapter to permit clearance to accommodate air conditioner or smog pump drive belts. Used adapters are available and could help with your belt clearance problems.I've had that problem with one of mine. It seems that the engine is further back or something...

I was able to gently use a crowbar (not against the adapter) to widen the space enough to slip it past...

...Got the exact same situation with mine. I have it from no less of an expert that Larry Claypool (who rebuilt my engine) that the engine mounts allow enough give. As flaming says, use a pry bar to give yourself a momentary gap. The spot he pointed was right behind the hood latch (and I now store my crowbar in the trunk of my Vair!)...

Brad Bodie

Lake Chatuge, North Carolina

1966 Corvair Corsa Convertible

1966 Corvair Corsa Convertible

Lake Chatuge, North Carolina

1966 Corvair Corsa Convertible

1966 Corvair Corsa Convertible- terribleted

- Posts: 4584

- Joined: Sun Apr 18, 2010 2:36 pm

- Location: Atlanta, GA

- Contact:

Re: Replacing Fan Belt

All that changed was you memory. Belt guards exists on all Corvairs (unless removed along the way) Oil filter is not in the way unless engine mounts are compromised or the rear of the car has been hit pushing the center of the rear crossmember in toward the engine eliminating clearance (common unfortunately). The Battery as never been in the right rear...always the left rear. Yes the spare in i'ts normal location in the right rear (excluding A/C cars) is it the way a bit, but , can be worked around. The cars have not changed...only the memories have changed.gjb49 wrote: ↑Thu Jul 27, 2017 5:53 am Back in the day when I drove Corvairs as my one and only car, I learned to always carry 2 extra fan belts, 2- 9/16" wrenches and a tire iron (pry bar). I did this with my 63 and 66.

Yesterday, while at my local repair shop, the belt 'popped off' of my current 66. What used to be a 5 minute job back when took almost a 1/2 hr. When did Chevy change the engine? Not only were there guards to be moved, but the oil filter was in the way (and the spare tire). Spare tire was always stored in the trunk, as the battery was in the right fender well. And I could see the crankshaft pulley, which is now hid by the oil filter & fuel pump.

When did this all change?

Corvair guy since 1982. I have personally restored at least 20 Vairs, many of them restored ground up.

Currently working full time repairing Corvairs and restoring old cars.

https://www.facebook.com/tedsautorestoration/

Located in Snellville, Georgia

Currently working full time repairing Corvairs and restoring old cars.

https://www.facebook.com/tedsautorestoration/

Located in Snellville, Georgia

Re: Replacing Fan Belt

Battery: In my '63 the battery was in the right fender well, and it wa HUGE! It was over double the size (length) of normal batteries. Belt guards were not on the '63 (they came later). I remember replacing the belt on my earlier '66 in the barracks parking lot at Tinker and it took only about 5 minutes. No guards (except at the gates)

-

64powerglide

- Posts: 1604

- Joined: Tue Mar 25, 2014 9:18 pm

- Location: Kalamazoo Mi..

Re: Replacing Fan Belt

I bought a new 62 102 HP 4 speed & there were no belt guards, this 64 I now have doesn't have belt guards and there are no holes in the fan shroud to put one at the fan end. There is a place for a hole could be drilled to add one. No guard by the idler pulley either. This is an October 63 built 64 with the 63 PCV system. I wonder if GM didn't use them on powerglides, I did toss a few belts on the 62.

64Powerglide, Jeff Phillips

Kalamazoo, Mi..

Kalamazoo, Mi..