The attached section of the 1965 Corvair Shop Manual describes using a vacuum gauge in the

INSTRUMENT CHECK-OUT section beginning on page

ENGINE TUNE-UP 6-6. They describe connecting the vacuum gauge to both SPARK TUBES (vertical tubes) at the same time, for purposes of synchronizing the two primary carburetors with the throttle held open to 1100-1200 rpm.

Since the SPARK TUBES are intended for use supporting the distributor vacuum advance, they are blocked from manifold vacuum by the throttle butterfly at idle speed. As the throttle is opened, the spark port on each carburetor is exposed to intake manifold vacuum. The horizontal carburetor vacuum tubes are intended to be connected to the VACUUM BREAK devices. These horizontal ports are subject to intake manifold vacuum at all times (even at idle), so that the choke butterfly valves will be partially opened as soon as the engine has started.

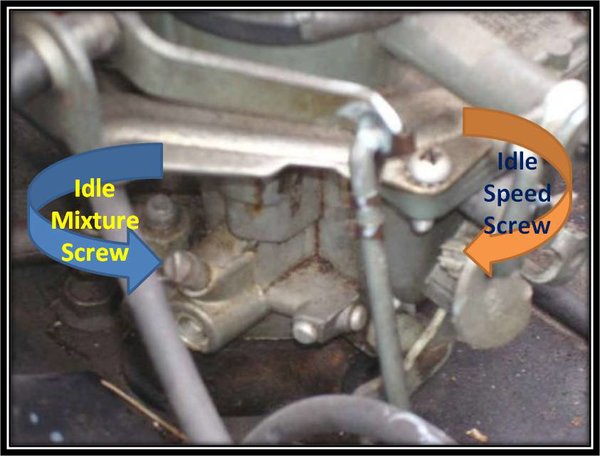

The tune-up procedure in the 1962-1963 supplement and the 1964 supplement page 7-2 (attached) connects the vacuum gauge to the BALANCE TUBE, at the connector normally plugged or connected to the Powerglide automatic transmission vacuum modulator. This connection ties the vacuum gauge to both intake manifolds using the balance tube. The goal with this test is to adjust the idle mixture screws on both carburetors to obtain peak steady vacuum at the given idle speed. A second test is then described using the horizontal vacuum tubes that are normally connected to the choke diaphragms (vacuum break). This procedure differs from the procedure in the 1965 shop manual.

If a turnbuckle is used to hold the throttle opened at a steady 1100-1200 RPM, I don't think there is much difference between the vacuum measured at the vertical spark ports or the horizontal choke ports. With the throttle fully closed, the manifold vacuum measured at the balance tube and at the horizontal carburetor choke tubes should also be essentially the same. The difference between the horizontal and vertical carburetor vacuum tubes is controlled by the position of the throttle butterfly, which only uncovers the spark tube (vertical), exposing it to intake manifold vacuum, when the throttle is opened above the idle position.

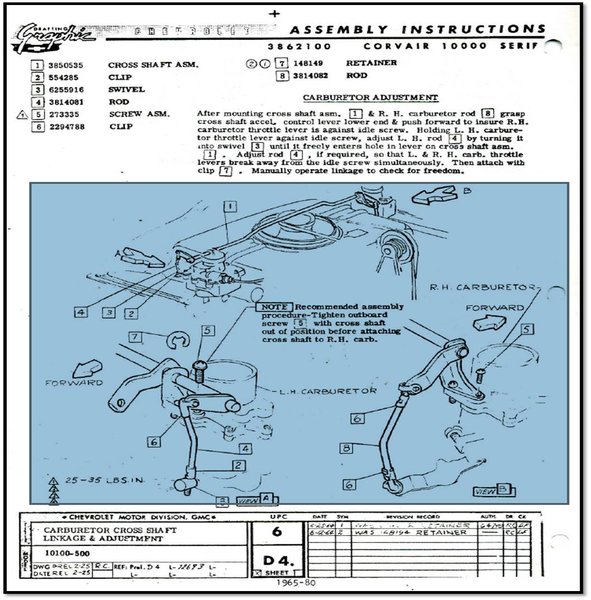

When synchronizing the carburetors at idle, and then at partial throttle, I normally utilize a UNI-SYN gauge, which measures airflow through the carburetor throat. The UNI-SYN allows me to balance airflow through both carburetors at idle, by adjusting the idle speed screws, and then at partial throttle (1100-1200 rpm), by holding the throttle opened with a turnbuckle and adjusting the throttle linkage at the left carburetor (adjustable linkage component [2] in the bottom diagram) to obtain a balanced airflow through each carburetor when the throttle linkage is holding both carburetors opened. (A static linkage adjustment is obtained first, as described in the shop manual tune-up section, using a strip of paper to determine the point where the idle speed screw just contacts the throttle linkage. 2½ turns are added to each idle speed screw to place the carburetor throttles at mechanical sync at idle. Fine tuning is then done with the UNI-SYN. Then the UNI-SYN is used to sync the throttle linkage at 1100-1200 rpm by adjusting the left swivel [2].

- Carburetor Idle Screws

- Carburetor Throttle Linkage Diagram

Details of each carburetor component and sub-section is described in the attached

DELCO ROCHESTER - Models H, HV Carburetor Service Manual.

1966 Corvair Corsa Convertible

1966 Corvair Corsa Convertible