Leaking from fuel pump

Re: Leaking from fuel pump

I'm pretty sure it has to do with the gasket material itself. Mine is venting right at that casting notch in the middle section.

Rick Tylla

Sheboygan, Wisconsin

65 Monza Convertible

Sheboygan, Wisconsin

65 Monza Convertible

-

64powerglide

- Posts: 1604

- Joined: Tue Mar 25, 2014 9:18 pm

- Location: Kalamazoo Mi..

Re: Leaking from fuel pump

I was wondering what that notch was for.

64Powerglide, Jeff Phillips

Kalamazoo, Mi..

Kalamazoo, Mi..

Re: Leaking from fuel pump

The lower gasket has washer-type plates and a rod swaged in place. You can't make a new lower gasket at home.

Be careful. Some aftermarket pumps have a slightly dIfferent hole pattern and the gaskets won't fit properly in gm pumps.

I replace the bolts with longer ones and use lock nuts as said before in an earlier post.

If installing an electric pump always install a shut off switch for safety. Ot can also be used for security.

Sent from my SM-G930V using Corvair Forum mobile app

Be careful. Some aftermarket pumps have a slightly dIfferent hole pattern and the gaskets won't fit properly in gm pumps.

I replace the bolts with longer ones and use lock nuts as said before in an earlier post.

If installing an electric pump always install a shut off switch for safety. Ot can also be used for security.

Sent from my SM-G930V using Corvair Forum mobile app

-

64powerglide

- Posts: 1604

- Joined: Tue Mar 25, 2014 9:18 pm

- Location: Kalamazoo Mi..

Re: Leaking from fuel pump

If you can find the right gasket material you should be able to make one. The thickness is .050 / 1/20 in.. However that notch goes to the center of the pump and could be a relief groove for excess pressure. If someone know about the groove let us know. I thought this pump was full of dried up gunk but it's pretty clean so i'll clean it up & put it in my trunk. My lighting makes the gasket look brown but it's black, looks to be fabric reinforced neoprene.

64Powerglide, Jeff Phillips

Kalamazoo, Mi..

Kalamazoo, Mi..

- bbodie52

- Corvair of the Month

- Posts: 11894

- Joined: Mon Aug 06, 2012 12:33 pm

- Location: Lake Chatuge Hayesville, NC

- Contact:

Re: Leaking from fuel pump

64powerglide wrote:...My lighting makes the gasket look brown but it's black, looks to be fabric reinforced neoprene.

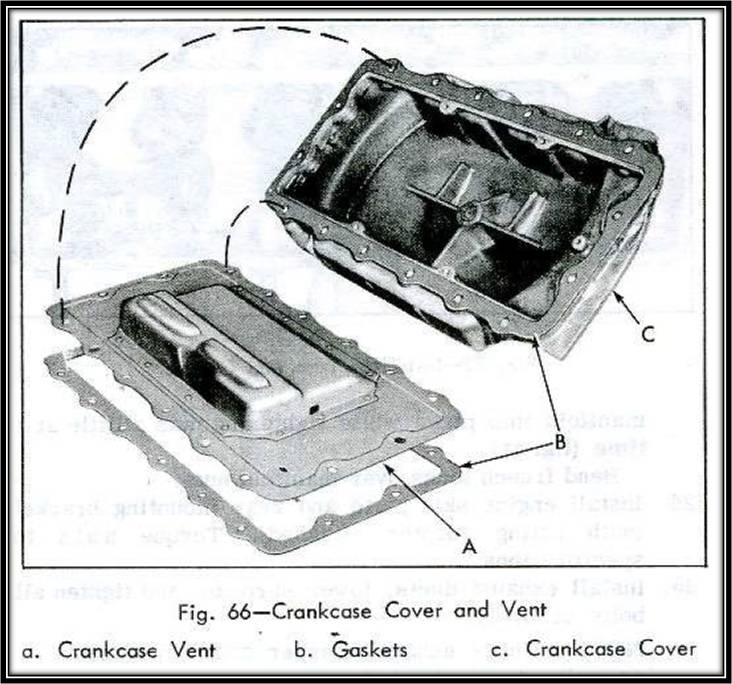

A careful examination of the fuel pump from the side would appear to show three gaskets that are sandwiched within the fuel pump body. These "gaskets" are really part of the flexible diaphragms that also serve as gaskets to seal the chambers of the pump. As noted in the quote above, these diaphragms are made of a neoprene rubber material that has been reinforced with fabric to provide it with additional strength. The reinforced rubber diaphragms would be needed since the diaphragm must withstand the continuous motion and stress associated with the pumping action. Because of this it would not be possible to create a gasket using regular bulk gasket material to replace, for example, the lower pulsator diaphragm, because the pulsator diaphragm must have the necessary flexibility and strength to withstand the pumping action.

The Pulsator Diaphragm is inside the pump fuel cavity. It creates an air pocket to minimize the pulsating of the fuel as it passes through the pump.

As far as I can tell, the groove that radiates from the center cavity of the pump (pushrod area) is a vent of some type, but it only exposes crankcase pressure to the outside air. That groove appears to serve as a pressure relief. The pulsator diaphragm also serves to seal and isolate the vent groove from the adjacent chambers that would be exposed to fuel. That vent groove does not appear to be exposed to any portion of the pump body that would contain gasoline.

The two valves shown in the illustration below are one-way valves. The inlet valve allows fuel to be drawn into the pump chamber from the gas tank. This occurs during the upward stroke of the pushrod. When the pushrod moves downward the spring at the top of the pump applies pressure to the main diaphragm to push the diaphragm downward, forcing the gasoline out through the other one-way valve towards the carburetors. This spring serves as a pressure regulator, to establish the 4-5 pounds of fuel pressure to drive the fuel into the carburetor float bowls.

If the carburetor float bowls are full, the floats apply pressure to the needle valve, which closes the valve and prevents additional fuel from entering the float bowl. This would create a "fuel fluid lock" that would prevent additional fuel from exiting the fuel pump chamber. When this condition exists the fuel pump return spring would be unable to push the diaphragm and pushrod pin downward toward the pushrod. Since the diaphragm would remain in the "up" position, subsequent upward strokes of the pushrod would not reach the diaphragm actuating pin, since the gasoline being held stationary in the chamber by the closed needle and seat assemblies in the carburetors would not permit the downward pressure of the spring to move the diaphragm into contact with the pushrod. As long as the carburetor float bowls are full, the fuel chamber in the fuel pump would also remain full and the diaphragm would remain in the upward position and would be isolated from the pushrod. This is essentially a neutral position that remains in effect as long as the carburetors are closed and cannot receive additional fuel. As soon as the carburetors drain enough to open the needle and seat assemblies, the fuel pump chamber would be drained as the spring forces gasoline through the one-way outlet valve. This would permit the diaphragm pin to once again come into contact with the pushrod, so that the next stroke would open the inlet valve and would draw additional fuel from the fuel tank. This new quantity of fuel in the pump chamber would be pressurized by the spring to be pushed in the direction of the carburetors to replenish the fuel supply in the carburetor float bowls.

It appears that my earlier suggestion to use bulk gasket material to replace the internal seals of the pump was incorrect. Both the upper fuel diaphragm and the lower pulsator diaphragm serve in a dual role. In addition to forming a gasket seal between the various pump chambers and the outside of the pump, they also serve as a mechanical diaphragm that must be able to absorb the constant pumping motion of the fuel pump. Normal gasket material would not be a suitable substitute for the special reinforced rubber material used in the pump diaphragms.bubba931 wrote:Fri Apr 28, 2017 3:23 pm

Yesterday I had to change the pump as it started leaking again. The new pump I put on is not leaking but there is vapor being emitted right at the notch in the pump. Is that a concern?

The vapor being emitted from the side of the pump, as described above, would appear to be a vapor emanating from the engine crankcase, and would be escaping from the pushrod area of the fuel pump. I would guess that a crankcase pressure buildup in the pushrod pin area might inhibit the acton of the pulsator diaphragm. The vent through the side prevents such a pressure buildup in the pump chamber. Gasoline should not be able to reach this area of the pump. If gasoline were being ejected from the side vent or from the top vent of the fuel pump, such a leak could only be caused by a damaged or ruptured fuel diaphragm or pulsator diaphragm. Such a leak might also be permitting gasoline to enter into the engine crankcase through the pushrod area. This type of leak would potentially be contaminating the engine oil with gasoline, as well as possibly ejecting flammable gasoline into the engine compartment. Such a condition is hazardous and should not be allowed to continue. The defective pump should be replaced immediately. Rebuild kits are not available.

Brad Bodie

Lake Chatuge, North Carolina

1966 Corvair Corsa Convertible

1966 Corvair Corsa Convertible

Lake Chatuge, North Carolina

1966 Corvair Corsa Convertible

1966 Corvair Corsa Convertible-

64powerglide

- Posts: 1604

- Joined: Tue Mar 25, 2014 9:18 pm

- Location: Kalamazoo Mi..

Re: Leaking from fuel pump

I don't know why the call number 7 diaphragm a pulsator as the material is to stiff to pulsate, the upper diaphragm is the only one that moves. The bottom is just a seal while the upper diaphragm does all the work, the bottom one only seal the pump. If you have an old one take it apart & you will see what I mean. If the bottom wasn't stiff enough it would flex to far under pressure and the pump would not work properly or not at all. The bottom diaphragm only serves to hold pressure while the upper one moves to build pressure via the valves. It's a very simple pump. Just like a Heart, if the wall of the chamber fails it won't pump blood from the chamber to your body & you die fast!!!!!  That's why i'm having trouble, my Heart muscle is weak & it's only pumping blood at 1/3 of it's capability making me real tired & unable to walk or do much of anything at times.

That's why i'm having trouble, my Heart muscle is weak & it's only pumping blood at 1/3 of it's capability making me real tired & unable to walk or do much of anything at times.

In summary, it's a 2 stroke pump the upward stroke pulls gas from the tank & the downward stroke pushes the gas to the carbs via the one way valves while the lower diaphragm seals the chamber so it will just hold the gas while the upper diaphragm does it's work.

In summary, it's a 2 stroke pump the upward stroke pulls gas from the tank & the downward stroke pushes the gas to the carbs via the one way valves while the lower diaphragm seals the chamber so it will just hold the gas while the upper diaphragm does it's work.

64Powerglide, Jeff Phillips

Kalamazoo, Mi..

Kalamazoo, Mi..

Re: Leaking from fuel pump

If you really wanted to experiment......

McMaster-Carr has BunaN which is fuel/oil resistant.

They also have neoprene in reinforced and both in different thicknesses.

I have had to make all kinds of replacement parts when I worked as a plant engineer in Chicago and McMaster-Carr was/is a great source for parts and material.

Ed Stevenson

McMaster-Carr has BunaN which is fuel/oil resistant.

They also have neoprene in reinforced and both in different thicknesses.

I have had to make all kinds of replacement parts when I worked as a plant engineer in Chicago and McMaster-Carr was/is a great source for parts and material.

Ed Stevenson

Edwin Stevenson

Industrial Electrician

Electronics Technician

65 corvair corsa convertible turbo

65 corvair monza

Industrial Electrician

Electronics Technician

65 corvair corsa convertible turbo

65 corvair monza

- bbodie52

- Corvair of the Month

- Posts: 11894

- Joined: Mon Aug 06, 2012 12:33 pm

- Location: Lake Chatuge Hayesville, NC

- Contact:

Re: Leaking from fuel pump

The pulsator diaphragm may be stiff, but apparently the diaphragm material properties chosen by the design engineer have just enough flexibility to allow it to act as a shock absorber, or damping mechanism to reduce fuel pulses created by the pump action from being transmitted through the outlet valve and on to the needle and seat in the float bowls. Such hydraulic pulses might disrupt the seal in the needle and seat valves in the float bowls and cause it to leak.

The sample illustration below of a Lycoming mechanical fuel pump shows similar design characteristics to the Corvair fuel pump, with a pulsator diaphragm and vent hole similar to the Corvair pump.

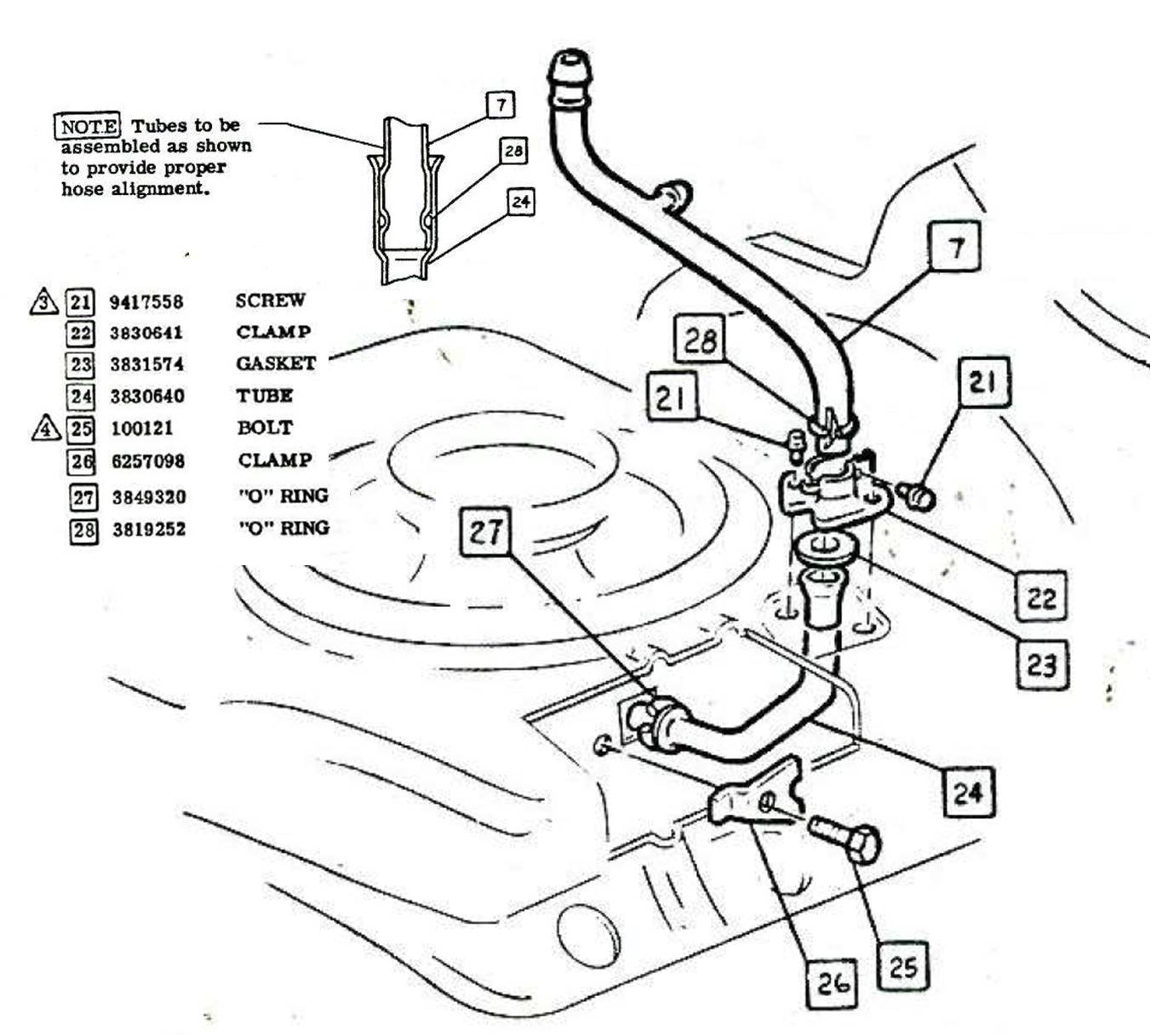

One more nugget of information...

The fuel return line "Z" shown below was added during the final few years of Corvair production. This fuel line runs from a "cross" 4-way connector at the fuel pump outlet. This small diameter fuel line is more restrictive than the lines routed to the carburetors. It permits a small but continual flow of gasoline to return to the fuel tank. Without it the fuel pump goes into NEUTRAL whenever the float bowls are full and the needle/seat valves are closed. This stops the flow of gasoline until the engine consumes enough gasoline to restore the fuel flow back into the float bowls again. By adding the fuel return line, some gasoline is constantly flowing through the fuel pump feed line from the fuel tank and then back again through the return line. Keeping a constant flow of fuel moving uses the cool liquid to cool the steel fuel feed line "D" to help prevent vapor lock.

The sample illustration below of a Lycoming mechanical fuel pump shows similar design characteristics to the Corvair fuel pump, with a pulsator diaphragm and vent hole similar to the Corvair pump.

One more nugget of information...

The fuel return line "Z" shown below was added during the final few years of Corvair production. This fuel line runs from a "cross" 4-way connector at the fuel pump outlet. This small diameter fuel line is more restrictive than the lines routed to the carburetors. It permits a small but continual flow of gasoline to return to the fuel tank. Without it the fuel pump goes into NEUTRAL whenever the float bowls are full and the needle/seat valves are closed. This stops the flow of gasoline until the engine consumes enough gasoline to restore the fuel flow back into the float bowls again. By adding the fuel return line, some gasoline is constantly flowing through the fuel pump feed line from the fuel tank and then back again through the return line. Keeping a constant flow of fuel moving uses the cool liquid to cool the steel fuel feed line "D" to help prevent vapor lock.

Brad Bodie

Lake Chatuge, North Carolina

1966 Corvair Corsa Convertible

1966 Corvair Corsa Convertible

Lake Chatuge, North Carolina

1966 Corvair Corsa Convertible

1966 Corvair Corsa Convertible-

64powerglide

- Posts: 1604

- Joined: Tue Mar 25, 2014 9:18 pm

- Location: Kalamazoo Mi..

Re: Leaking from fuel pump

The two lower gaskets are made of the same material & thickness, the upper middle one has holes for the screws & the center hole plus holes for the valves to push & pull the gas through all the bottom one is for is to seal the pump & make a chamber to hold the fuel. If the carb float bowls are full the pump will not pull any more fuel in and pressurize it. The pump only pumps non pressurized fuel, the upper diaphragm creates the pressure on the downward stroke via the spring. Just about any thickness of the bottom diaphragm "within reason" will work as it's job is sealing the fuel chamber as long as you use screws long enough to compensate for a thicker diaphragm, you don't want to strip the threads. If I were to bend either the middle or lower gasket/diaphragm to far they would crack for sure, unlike the upper diaphragm.

I thought I was was wrong once but I was mistaken Rick smell that vapor coming out at that notch & see if it smells like oil or gas. Take the oil filler cap off & see if the vapor still comes out.

Rick smell that vapor coming out at that notch & see if it smells like oil or gas. Take the oil filler cap off & see if the vapor still comes out.

Brad, I think you are right about the notch as it's a sealed groove that goes to the center of the pump, no fuel should get to it & it lets excess vapor escape from the crankcase.

I thought I was was wrong once but I was mistaken

Brad, I think you are right about the notch as it's a sealed groove that goes to the center of the pump, no fuel should get to it & it lets excess vapor escape from the crankcase.

64Powerglide, Jeff Phillips

Kalamazoo, Mi..

Kalamazoo, Mi..

Re: Leaking from fuel pump

Jeff, It is not gas vapor and it does pulse with the operation of the pump. I did think the notch was some sort of vent but not being an engineer I was not sure. I'll have to check tomorrow in daylight and open the oil filler cap off and see if vapor is still present. I sure didn't mean to open such a can of worms.

Rick Tylla

Sheboygan, Wisconsin

65 Monza Convertible

Sheboygan, Wisconsin

65 Monza Convertible

- bbodie52

- Corvair of the Month

- Posts: 11894

- Joined: Mon Aug 06, 2012 12:33 pm

- Location: Lake Chatuge Hayesville, NC

- Contact:

Re: Leaking from fuel pump

Brad Bodie

Lake Chatuge, North Carolina

1966 Corvair Corsa Convertible

1966 Corvair Corsa Convertible

Lake Chatuge, North Carolina

1966 Corvair Corsa Convertible

1966 Corvair Corsa ConvertibleRe: Leaking from fuel pump

Wow this got blow out of proportion. The fix was pretty easy and still working well

1966 Corsa turbo

1969 Monza convertible

1987 Buick Grand National

1969 Monza convertible

1987 Buick Grand National

Re: Leaking from fuel pump

I do believe the vapor is venting from the pump. When I remove the oil filler cap the venting disappears. That would be the only reason to have a cast feature in the middle housing. The odor is somewhat of a petroleum smell not strong like gas. Thanks Brad and Jeff for the time you took to research this.

Rick Tylla

Sheboygan, Wisconsin

65 Monza Convertible

Sheboygan, Wisconsin

65 Monza Convertible

- bbodie52

- Corvair of the Month

- Posts: 11894

- Joined: Mon Aug 06, 2012 12:33 pm

- Location: Lake Chatuge Hayesville, NC

- Contact:

Re: Leaking from fuel pump

The noticeable venting you found from your fuel pump is, I believe, somewhat unusual. Until you brought it up on this Forum I did not even know the vent existed on the side of the fuel pump. I had never seen any noticeable venting escaping from the side of the pump in all of the decades that I have worked with Corvairs. The fact that you can visualize this venting and that it disappears when you remove the oil filler cap may be an indicator of a crankcase pressure buildup on your engine that is somewhat excessive. (The somewhat common indicator of excessive crankcase pressure buildup is oil being pushed out of the dipstick tube).

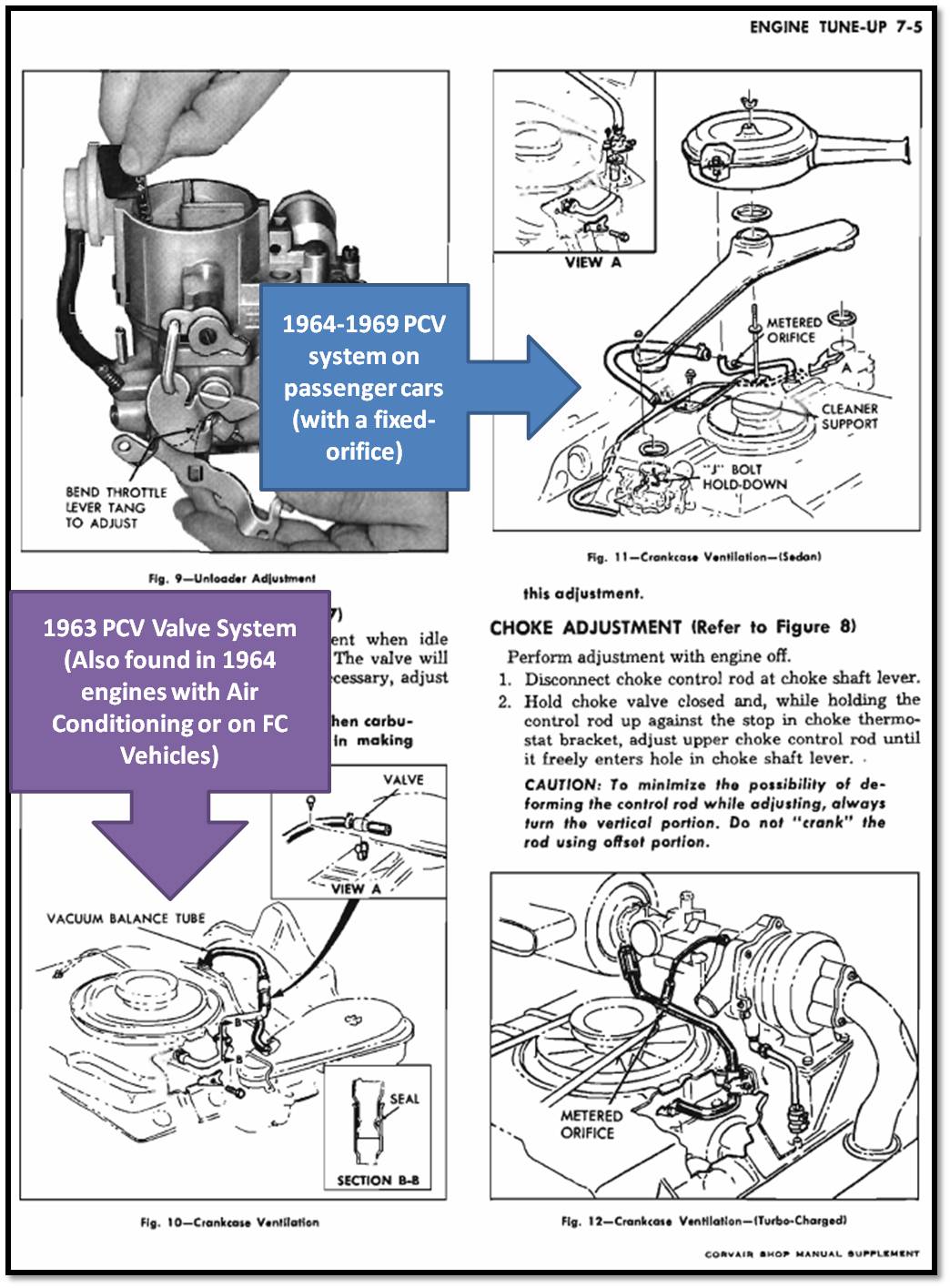

I would suggest checking and cleaning your Positive Crankcase Ventilation (PCV) system on your Corvair. There is a fixed orifice vacuum tube connection on the side of the PCV system main tube that often becomes dirty and clogged. The shop manual recommends cleaning this regularly, usually in conjunction with a periodic tuneup. But it is often neglected.

The procedure for cleaning and servicing the PCV system is simple and brief. It is described on page 6-5 of the attached shop manual section: 1965 Corvair Chassis Shop Manual - SECTION 6 - ENGINE TUNE-UP. Performing this procedure on your engine may reduce the amount of pressure buildup within the crankcase to the degree that it is no longer noticeable as an emission from the side of your fuel pump.

If cleaning and servicing your PCV system fails to reduce the crankcase pressure, you may want to perform a compression check on all cylinders of your engine to determine the health of the piston rings and the piston seal that restricts the amount of engine blow-by that enters your crankcase. Excessive crankcase pressures can be an early warning sign of engine wear in this area.

I would suggest checking and cleaning your Positive Crankcase Ventilation (PCV) system on your Corvair. There is a fixed orifice vacuum tube connection on the side of the PCV system main tube that often becomes dirty and clogged. The shop manual recommends cleaning this regularly, usually in conjunction with a periodic tuneup. But it is often neglected.

The procedure for cleaning and servicing the PCV system is simple and brief. It is described on page 6-5 of the attached shop manual section: 1965 Corvair Chassis Shop Manual - SECTION 6 - ENGINE TUNE-UP. Performing this procedure on your engine may reduce the amount of pressure buildup within the crankcase to the degree that it is no longer noticeable as an emission from the side of your fuel pump.

If cleaning and servicing your PCV system fails to reduce the crankcase pressure, you may want to perform a compression check on all cylinders of your engine to determine the health of the piston rings and the piston seal that restricts the amount of engine blow-by that enters your crankcase. Excessive crankcase pressures can be an early warning sign of engine wear in this area.

- Attachments

-

- 1965 Corvair Chassis Shop Manual - SECTION 6 - ENGINE TUNE-UP.pdf

- 1965 Corvair Chassis Shop Manual - SECTION 6 - ENGINE TUNE-UP

- (2.92 MiB) Downloaded 14 times

Brad Bodie

Lake Chatuge, North Carolina

1966 Corvair Corsa Convertible

1966 Corvair Corsa Convertible

Lake Chatuge, North Carolina

1966 Corvair Corsa Convertible

1966 Corvair Corsa ConvertibleRe: Leaking from fuel pump

Thanks, I'll get on that this week as soon as the weather cooperates a little.

Rick Tylla

Sheboygan, Wisconsin

65 Monza Convertible

Sheboygan, Wisconsin

65 Monza Convertible

-

64powerglide

- Posts: 1604

- Joined: Tue Mar 25, 2014 9:18 pm

- Location: Kalamazoo Mi..

Re: Leaking from fuel pump

Brad's explanation of the crankcase ventilation system was going to be my next suggestion after finding what happened after taking the oil filler cap off. You may want to do a valve adjustment just to be sure you don't have an intake valve that's not closing completely & causing a bit of back pressure. I wouldn't say it's a can of worms but a lesson, I didn't know much about these pumps but after taking one apart it's easy to see how they work or don't work. Like most things on a Corvair they are easy to figure out & easy to fix. I still say the Corvair was one of the best cars GM has ever made.

64Powerglide, Jeff Phillips

Kalamazoo, Mi..

Kalamazoo, Mi..