how-to-build-hotrods.com

Want an electric fuel pump to last forever and work right? We're going to show you how to install it and wire it up the correct way!

Ok, let's talk about electric fuel pumps. There is a lot of confusion and misunderstandings about them. There is also a lot of potential danger when people don't do it right because they don't know the right way to plumb them in or wire them...

So, let's break it down:

When do you need an electric fuel pump?

Is an electric fuel pump reliable?

How do you keep an electric fuel pump safe?

How should you wire an electric fuel pump?

-When do you need an electric fuel pump?

Usually, a mechanical pump is preferred over an "aftermarket" electric pump. They tend to be more reliable. However, sometimes that won't work.

In my old '47 Chevy, the engine I had swapped in had an issue. The crossmember was in the way of the mechanical pump. So, I ran an electrical pump and had many trouble free miles.

Sometimes, people will plumb them inline with a mechanical pump to add more volume and pressure. This is more for a full on drag car though...

-Is an electric fuel pump reliable?

Yes they are. Hey, there's about a billion cars running around right now with them. All new cars have them.

With aftermarket pumps though, YOU have to install them. That's where some problems can start.

We're here to show you the right way to do it!

So, what do I use? For a stock or performance street car, I like these Facet/Purolator pumps from Napa. They are quiet, and work well.

A lot of people complain about some aftermarket pumps being junk, but usually there is a reason they go out. It's often the way the person installed it. There are a few things that kill them.

- Do not run them dry.

- Always run a filter before the pump.

- Keep them as close to the tank as you can. Electric pumps push fuel much better than they can pull it.

- Mount them away from heat sources such as exhaust.

- Electrical power to them is everything. You must have the correct wire size to it. A relay is preferred. You may be getting the proper voltage to it, but not enough amps. Remember, the longer the run the more the power will drop.

- Also, the grounding of it is critical. Many people will scrape the area where they mount it, or even add a ground wire. However, they forget that they don't have a good ground from the body to the frame or to the engine. This will kill pumps real quick.

Tip: Screw into metal to ground, not through it. "Star" washers are your friends...

Preferably, run a ground wire to the front. Many professional auto electricians will run ground wires from a unit to a common grounding point in an older car, just like in a fiberglass car. That way, there is no question if your ground is good, and it's just 1 extra wire...

Once, a buddy and me were going to a show in his '26 Buick roadster. It was built much like a T-bucket and it had an electric fuel pump. It was wired in correctly, and grounded by screwing into the frame by the pump. We were about 50 miles out, and the pump quit...

Hmmmm...

What happened was the older metal of the frame simply wasn't carrying the current well enough. The pump overheated and shut down.

Fortunately, he had some extra wire and we screwed one end to the ground wire at the back and ran it to the front where we attached it to the negative side of the battery.

The pump started back up after it cooled down and we were trouble-free all the way there and back. When we got home he wired it in neatly and never had a problem after that...

-How do you keep an electric fuel pump safe?

Electric fuel pumps can be dangerous?

Yep, without some way to automatically shut them off, they can be VERY dangerous.

But they don't have to be.

If something lets go in your engine bay like a fuel line, the engine will eventually quit. However, if you don't have a way to automatically shut off your electric fuel pump you will keep spraying raw fuel all over your hot engine and wiring.

Also, in a crash, your pump can continue to run feeding a fire if you don't have a way to stop it.

Note: Never mount an electric fuel pump in an enclosed area such as the trunk or interior space...

OK, so how do I do it right?

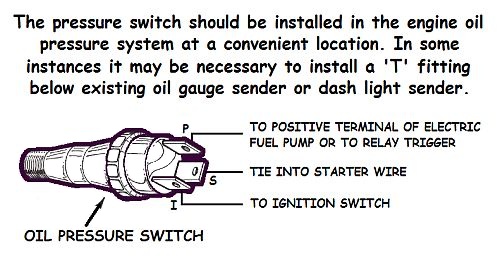

The easiest way is to use an oil pressure switch. The switch will stop the pump whenever the oil pressure in the engine goes away. So, whenever the engine is off, the pump will turn off automatically.

Some switches just do that. But how do I get the pump to run when I'm trying to start the motor and the oil pressure's not up yet?

You use a three prong switch like this Standard Ignition PS-64:

The switch will also let the pump run when you hit the starter because the engine doesn't have oil pressure yet.

One wire goes to the pump, one to the start circuit, and the other to the ignition circuit. So, when there is no oil pressure, the switch connects START to PUMP, and as soon as you start cranking it runs the pump. When the oil pressure comes up, the switch connects IGN to PUMP, for normal running. When oil pressure goes away (because you just hit that rock and tore the pan off the engine, for example) it again connects START to PUMP, and disconnects IGN from PUMP, so the pump shuts off.

Don't worry, it's easy to wire...

-How should you wire an electric fuel pump?

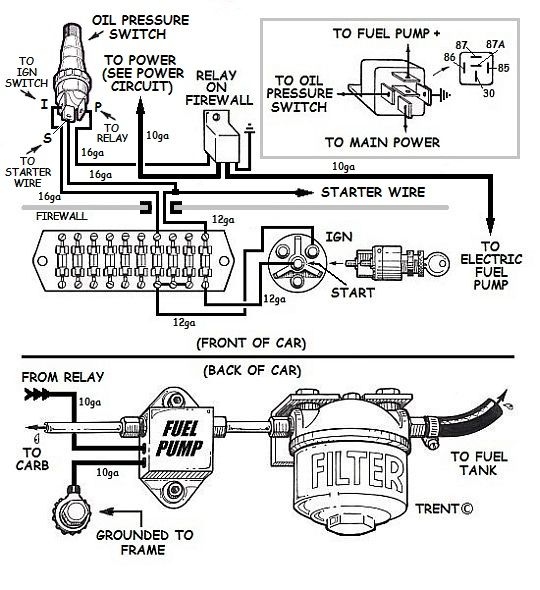

Since you need the fuel pump back by the tank and at the same level as the fuel or lower, that usually means you're going to have a long run of wire. So, you need to have really good wiring going back to it. Wiring that will carry enough current. Running the current through your ignition switch isn't a good idea since it's probably already overloaded, and will kill the voltage. That will kill the pump. However, it's nice for convenience. That's why a relay is really good to use.

It lets the ignition switch activate the pump, while keeping the power from having to run through it. It will keep your pump alive and happy because it is getting full voltage. A good way is to mount a relay beside a power distribution block on the firewall (see Improved Power Circuit) and get the power from there.

Here is a diagram on how to wire and plumb your pump:

1966 Corvair Corsa Convertible

1966 Corvair Corsa Convertible