Engine Stand, easy question to answer

Engine Stand, easy question to answer

It seems corvairs need special engine stands. Is this true , and why if so?

Re: Engine Stand, easy question to answer

Is it because you can't split the cases on a normal one?

- bbodie52

- Corvair of the Month

- Posts: 11965

- Joined: Mon Aug 06, 2012 12:33 pm

- Location: Lake Chatuge Hayesville, NC

- Contact:

Re: Engine Stand, easy question to answer

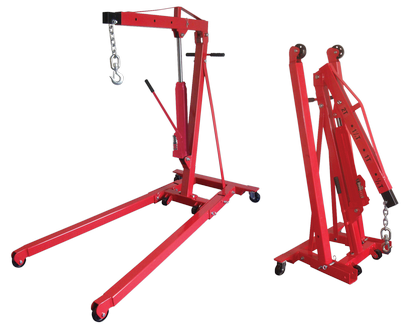

A generic engine stand like the one above can be used to mount a Corvair engine, but then you have the issue of removing the completed, heavy engine from the stand when you want to transfer it back into the vehicle. Most V8 engines are lifted back into the front engine compartment using a chain hoist or "cherry picker".

But a Corvair engine is normally reinstalled by placing it on a hydraulic floor jack, using a small plywood panel to protect the bottom of the engine. The engine and transaxle are wheeled under the vehicle that has been raised using jack stands. Building a Corvair engine on a conventional engine stand will still require you to get the engine down on the floor so it can be reconnected to the transaxle. Then the entire power train is rolled under the car using a floor jack or transmission jack of some type. The powertrain is then carefully raised from below the car, up to the three engine and transaxle mounts.

I usually work with the engine on the floor — supported by a couple of stacks of 2x4's so that I can reconnect the engine to the transaxle and then balance it on a floor jack and a piece of plywood. I use a jack like the one shown below...

bbodie52 wrote:The first time I removed a Corvair engine, I thought I could do it by pulling the engine alone, while leaving the transaxle in the car. While I was successful, success only came because the transmission was a Powerglide automatic. The torque converter allowed me to detach the connection from the engine crankshaft (flex plate) so that the torque converter remained on the differential. I managed to juggle the engine bell housing around the torque converter enough to lower the engine alone balanced on a hydraulic floor jack, and I did it without dropping the engine! However, I discovered that it would have been easier and safer to lower the entire engine and transaxle as a unit, and then separate them while stabilized on some 2x4 wood supports that supported the engine close to the floor.

In any case, it would not be possible to separate a manual transmission transaxle from the engine while leaving the transaxle mounted in the car. The way the input shaft connects to the clutch assembly just would not allow the engine to be removed within the car. Powerglide or manual transaxle — it is just safer and easier to lower the complete engine and transaxle (powertrain) from the car as a unit, as described in the attached shop manual and the attached Chevrolet publication: Corvair and Corvair 95 Power Train Removal & Installation.

I was 16 and working alone when I removed my first Corvair powertrain. I was nervously sweating like a pig in fear of dropping that heavy powertrain, but I managed to remove and lower it successfully! However, I would suggest having a few mechanically inclined/experienced friends on-hand to assist you with a safe removal. If there is a CORSA (Corvair Society of America) club chapter in your area, joining the club and asking for experienced advice, and perhaps recruiting some experienced helpers may be a good idea. The link below will provide you with some useful websites, shop manuals, parts suppliers, etc. There is also a listing of CORSA club chapters around the country. There might be an active club in your area.

Common and Useful Corvair Websites

Corvair Forumviewtopic.php?f=225&t=6007

The first time I ever separated a manual transaxle from a Corvair engine, well, I didn't exactly approach it correctly. I had the engine resting upon some stacks of two by fours. I removed the starter, and I unbolted the transaxle from the engine. Being young (17), overconfident, and healthy I decided that I could simply lift the heavy transaxle away from the engine and set it on the garage floor!

If you can picture this...

I straddled the transaxle and bent over and cupped my hands under it — cradling all of its weight in my hands as I was completely bent over and expecting to walk away with this heavy transaxle between my legs! That was when I discovered the issue with the long input shaft that inevitably remains embedded in the clutch disc. I was confronted with this very awkward moment (working alone, of course) when I had to try to figure out how to keep the alignment between the face of the differential and the clutch housing while balancing all of that weight in my hands, between my legs. I managed to take a whole series of very small backward steps while desperately trying to maintain the necessary alignment so that I would not damage the input shaft. That input shaft seemed soooooo long! But the small splined end finally came out of the differential and I was able to set the transaxle on the floor. I think I simply went into the house after that to lay down for awhile.

- Attachments

-

- 1965 Corvair Chassis Shop Manual - SECTION 6 - ENGINE MOUNTS.pdf

- 1965 Corvair Chassis Shop Manual - SECTION 6 - ENGINE MOUNTS

- (1 MiB) Downloaded 3 times

-

- 1965 Corvair Chassis Shop Manual - SECTION 6 - ENGINE.pdf

- 1965 Corvair Chassis Shop Manual - SECTION 6 - ENGINE

- (19.37 MiB) Downloaded 4 times

-

- Corvair and Corvair 95 Power Train Removal & Installation.pdf

- Corvair and Corvair 95 Power Train Removal & Installation

- (3.35 MiB) Downloaded 4 times

Last edited by bbodie52 on Thu May 09, 2024 11:40 am, edited 2 times in total.

Brad Bodie

Lake Chatuge, North Carolina

1966 Corvair Corsa Convertible

1966 Corvair Corsa Convertible

Lake Chatuge, North Carolina

1966 Corvair Corsa Convertible

1966 Corvair Corsa Convertible- American Mel

- Posts: 133

- Joined: Fri Jan 26, 2024 7:35 am

Re: Engine Stand, easy question to answer

Short answer: It depends.

What are you doing?

Many of us use a standard engine stand for SOME work on Corvair engines.

Davemotohead was supplying engine stands at one time, I think. (or at least plans for them?)

I know he was doing Corvair specific engine lift-cradles

Currently own: '66Monza Coupe, '67Monza Vert, '67A/C Monza Sport Sedan

Have owned: '61Monza Coupe, '62Monza Wagon, '63Spyder, '65 Corsa

Loc: WA, One mile south of Canadian border.

Have owned: '61Monza Coupe, '62Monza Wagon, '63Spyder, '65 Corsa

Loc: WA, One mile south of Canadian border.

- toms73novass

- Posts: 217

- Joined: Sat Mar 04, 2017 6:58 am

- Location: Grand Island NY

Re: Engine Stand, easy question to answer

I use a engine stand that I extended the bottom center support and have a permanent old differential on. This way I can break in an engine on the stand with a manual flywheel. Once I have the case together and bellhousing on it goes on stand.

I use hoyer lift to lift engine or trans to lift table, but I can slide engine over lift table and lift to unbolt from stand.

I also have two metal bars that I put on the skid plate to the front bottom of the engine stand when I run it so that there is some support at the front.

I use hoyer lift to lift engine or trans to lift table, but I can slide engine over lift table and lift to unbolt from stand.

I also have two metal bars that I put on the skid plate to the front bottom of the engine stand when I run it so that there is some support at the front.

1962 700 Wagon

1963 Spyder convertable

1965 Monza

1967 UltraVan 211

1963 Spyder convertable

1965 Monza

1967 UltraVan 211

Re: Engine Stand, easy question to answer

You guys are great to answer so timely.

I am familiar with Removing the engine. I have done it thanks to some plans I found online to make a cart made specifically for my motorcycle jack. All I did on that o ocasion was remove a transmission seal.

It was documented on here.

What I am going to do now is rebuild a 140 engine. Send the heads in, new rings and bearings, clean it up, the whole thing. Make it really nice. I know where an engine is so I'm all set. Except for engine stand. I found one but I don't know if it's right.

I am familiar with Removing the engine. I have done it thanks to some plans I found online to make a cart made specifically for my motorcycle jack. All I did on that o ocasion was remove a transmission seal.

It was documented on here.

What I am going to do now is rebuild a 140 engine. Send the heads in, new rings and bearings, clean it up, the whole thing. Make it really nice. I know where an engine is so I'm all set. Except for engine stand. I found one but I don't know if it's right.

Re: Engine Stand, easy question to answer

I used bolt holes in the one half of the bottom for bottom end build. They were already there and tapped. Dennis

-

Lane66Monza

- Posts: 246

- Joined: Thu Sep 28, 2023 7:01 am

- Location: Southeast Georgia

Re: Engine Stand, easy question to answer

I use an engine stand to tear down and buld up an engine, excluding spitting the case. I have a wood stand I lay the block in on its side to split the case halves apart.

I use and engine hoist to move the engine to and from the engine stand, my engine test stant, Dave Motohead's lift cradle on a HF transmission jack or to a lift table, depending on the need at the time.

Normally the lift table is used to hold an engine to install bell housing after being on the engine stand, or to remove the PG bell housing I run with on my test stand back to a manual bellhousing. Higher up, so less back strain in doing the tasks.

I also have a leveling that I use to fine tune the engine position when moving it from on location to another. No need to jostle it around as much.

Last few photos are tools I assembled to help in car movement with no emgine, a block half with legs to help in setting up cylinder assemblies ,and tools to hold the cylinders in place once they are placed on the block..

Engine case disassembly / Assembly Stand

HF Engine Stand

HF Engine Hoist

Engine cradle & HF 800 lb.Transmission Jack

HF Lift Table 1000 lb

HF Engine Leveling Bar Differential Support Cylinder Assembly Support Cylinder to Block Securing Tools

I use and engine hoist to move the engine to and from the engine stand, my engine test stant, Dave Motohead's lift cradle on a HF transmission jack or to a lift table, depending on the need at the time.

Normally the lift table is used to hold an engine to install bell housing after being on the engine stand, or to remove the PG bell housing I run with on my test stand back to a manual bellhousing. Higher up, so less back strain in doing the tasks.

I also have a leveling that I use to fine tune the engine position when moving it from on location to another. No need to jostle it around as much.

Last few photos are tools I assembled to help in car movement with no emgine, a block half with legs to help in setting up cylinder assemblies ,and tools to hold the cylinders in place once they are placed on the block..

Engine case disassembly / Assembly Stand

HF Engine Stand

HF Engine Hoist

Engine cradle & HF 800 lb.Transmission Jack

HF Lift Table 1000 lb

HF Engine Leveling Bar Differential Support Cylinder Assembly Support Cylinder to Block Securing Tools

Al Lane

Southeast Georgia

1966 Coupe 110 4 spd

1966 More Door 110 PG FOR SALE

Southeast Georgia

1966 Coupe 110 4 spd

1966 More Door 110 PG FOR SALE

Re: Engine Stand, easy question to answer

To quote Charles Bronson in the movie Breakout, "There are ways..., and there are ways." Some of us just find ways out of necessity. Whoever designed that milk crate just knew someday it would be used to assemble a Corvair engine and placed the metal rods accordingly. Later it went on the narrow cart used to remove/install the engine. And, yes, it did fit out the door..., BaReLy.

Last edited by Wittsend on Thu May 09, 2024 8:05 pm, edited 1 time in total.

'61 Lakewood in a coma for 50 years - now has a pulse

Re: Engine Stand, easy question to answer

Good work Wittsend. The only problem is I have a severe aversion to HF.

Most my friends are at their Wittsend with me as I won't step foot in the store as i am a leftist against filling our landfills with there merchandise.

I will not o into the store, I've become a complete bore because it's quality I adore.

Anyway, Hence forth I buy alot of used tools. But there good tools.

Most my friends are at their Wittsend with me as I won't step foot in the store as i am a leftist against filling our landfills with there merchandise.

I will not o into the store, I've become a complete bore because it's quality I adore.

Anyway, Hence forth I buy alot of used tools. But there good tools.

Re: Engine Stand, easy question to answer

https://albuquerque.craigslist.org/for/ ... 79473.html

Here's what I'm looking at.

It's got wheels. The rust is way only surface rust and that silver paint on the top not galvanized steel.

Here's what I'm looking at.

It's got wheels. The rust is way only surface rust and that silver paint on the top not galvanized steel.

Re: Engine Stand, easy question to answer

I don't really know where it's made but I'm guessing it's USA Made. Even if it isn't it's way over buildt for my intentions. Sp, I'll paint it and call it good.

- Frank DuVal

- Posts: 528

- Joined: Wed Dec 09, 2009 4:58 pm

Re: Engine Stand, easy question to answer

I never used a normal engine stand to build my Corvair engines. I always set them on the workbench. That is after I stopped building them on the floor. I mean the dolly setting on the floor. Heck I built a Buick 455 on a moving dolly. It was too heavy to get on the bench.

Frank DuVal

Fredericksburg, VA

Hey look, blue background!

Fredericksburg, VA

Hey look, blue background!

Re: Engine Stand, easy question to answer

Well, the milk crate is probably USA made. :-) Yes, I too buy a lot of older tools. Even the 1970's era Taiwanese stuff was OK - for the price (and likely better than modern day Craftsman). However, the currently $329 at HF engine hoist I got second hand, delivered to my house for $75. That is what it cost to rent it for a day here. Price recouped on the first use and the residual value went to an American.

The temptation (if you will) is that I live less than 10 miles from the old Harbor Freight warehouse in Camarillo. And back then (before they moved to Moreno Valley) they had REAL parking lot sales. A 60 gallon compressor $80, drain cleaner $45, small lathe $100. That day I had "stopped by" to purchase a $3 item and within 15 minutes I was calling the wife to take the seats out of the van and get down there. I got $1,200 retail for $300 (a few of those items pictured below).

Yes, some of their stuff is total junk. Some is worth the price for the limited use it will get (like their $10 angle grinder - using a thin cut off disc). If one is a professional using their tools every day to earn a living, no HF is not the tool to use. But for some of us the price and functionality fits the limited need we will have. And frankly a lot of the American NAMED products are now made in China too.

BTW, Frank, the famed Pro Stock racer Bob Glidden (85 major event wins) use to build all his engines on the floor too!

'61 Lakewood in a coma for 50 years - now has a pulse

Re: Engine Stand, easy question to answer

I built a simple wooden cradle that will hold the engine case on its side if I need to spit it. I put a mirror in the bottom of the cradle so I can see the bolt heads :)

1965 Monza vert

Central VA

Central VA

Re: Engine Stand, easy question to answer

I have an old steel milk crate that I have had for over 40 years. I don't remember exactly where I first got it, but I once had it mounted to the luggage rack on the back of my old 450 Honda. Toss lunch box in, go to work, no problem. It still has the yellow reflectors I bolted to it. I believe it held at least some Corvair parts here and there recently. Dennis