Electric fuel pump

Electric fuel pump

I'm sure I'm going to get all sorts of crap for this but I installed a bravex electric fuel pump in the engine bay. Against the firewall. I have a stock 102hp motor. Part number is ep12sl-bx. It was $20 on Amazon. I have read alot about electric pumps being good for pushing not pulling fuel. But I wanted to try it myself. I have had no issues whatsoever and it's way easier to install. The hardest part was routing wires to a cutoff switch under the dash. I'm by no means saying this is the best solution but it worked for me. Just wanted to throw that out there incase anyone else was thinking the same thing.

Sent from my SM-G970U using Corvair Forum mobile app

- bbodie52

- Corvair of the Month

- Posts: 12096

- Joined: Mon Aug 06, 2012 12:33 pm

- Location: Lake Chatuge Hayesville, NC

- Contact:

Re: Electric fuel pump

OK. Here is some electric fuel pump installation advice from a non-Corvair guy who enjoys custom cars and hot-rod building...

how-to-build-hotrods.com

Want an electric fuel pump to last forever and work right? We're going to show you how to install it and wire it up the correct way!

Ok, let's talk about electric fuel pumps. There is a lot of confusion and misunderstandings about them. There is also a lot of potential danger when people don't do it right because they don't know the right way to plumb them in or wire them...

So, let's break it down:

When do you need an electric fuel pump?

Is an electric fuel pump reliable?

How do you keep an electric fuel pump safe?

How should you wire an electric fuel pump?

-When do you need an electric fuel pump?

Usually, a mechanical pump is preferred over an "aftermarket" electric pump. They tend to be more reliable. However, sometimes that won't work.

In my old '47 Chevy, the engine I had swapped in had an issue. The crossmember was in the way of the mechanical pump. So, I ran an electrical pump and had many trouble free miles.

Sometimes, people will plumb them inline with a mechanical pump to add more volume and pressure. This is more for a full on drag car though...

-Is an electric fuel pump reliable?

Yes they are. Hey, there's about a billion cars running around right now with them. All new cars have them.

With aftermarket pumps though, YOU have to install them. That's where some problems can start.

We're here to show you the right way to do it!

So, what do I use? For a stock or performance street car, I like these Facet/Purolator pumps from Napa. They are quiet, and work well.

A lot of people complain about some aftermarket pumps being junk, but usually there is a reason they go out. It's often the way the person installed it. There are a few things that kill them.

Tip: Screw into metal to ground, not through it. "Star" washers are your friends...

- Do not run them dry.

- Always run a filter before the pump.

- Keep them as close to the tank as you can. Electric pumps push fuel much better than they can pull it.

- Mount them away from heat sources such as exhaust.

- Electrical power to them is everything. You must have the correct wire size to it. A relay is preferred. You may be getting the proper voltage to it, but not enough amps. Remember, the longer the run the more the power will drop.

- Also, the grounding of it is critical. Many people will scrape the area where they mount it, or even add a ground wire. However, they forget that they don't have a good ground from the body to the frame or to the engine. This will kill pumps real quick.

Preferably, run a ground wire to the front. Many professional auto electricians will run ground wires from a unit to a common grounding point in an older car, just like in a fiberglass car. That way, there is no question if your ground is good, and it's just 1 extra wire...

Once, a buddy and me were going to a show in his '26 Buick roadster. It was built much like a T-bucket and it had an electric fuel pump. It was wired in correctly, and grounded by screwing into the frame by the pump. We were about 50 miles out, and the pump quit...

Hmmmm...

What happened was the older metal of the frame simply wasn't carrying the current well enough. The pump overheated and shut down.

Fortunately, he had some extra wire and we screwed one end to the ground wire at the back and ran it to the front where we attached it to the negative side of the battery.

The pump started back up after it cooled down and we were trouble-free all the way there and back. When we got home he wired it in neatly and never had a problem after that...

-How do you keep an electric fuel pump safe?

Electric fuel pumps can be dangerous?

Yep, without some way to automatically shut them off, they can be VERY dangerous.

But they don't have to be.

If something lets go in your engine bay like a fuel line, the engine will eventually quit. However, if you don't have a way to automatically shut off your electric fuel pump you will keep spraying raw fuel all over your hot engine and wiring.

Also, in a crash, your pump can continue to run feeding a fire if you don't have a way to stop it.

Note: Never mount an electric fuel pump in an enclosed area such as the trunk or interior space...

OK, so how do I do it right?

The easiest way is to use an oil pressure switch. The switch will stop the pump whenever the oil pressure in the engine goes away. So, whenever the engine is off, the pump will turn off automatically.

Some switches just do that. But how do I get the pump to run when I'm trying to start the motor and the oil pressure's not up yet?

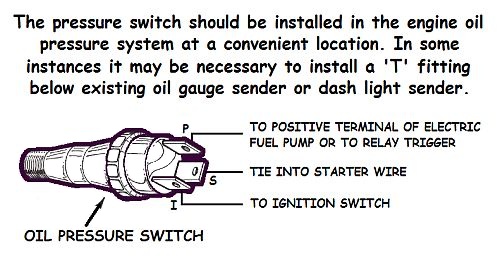

You use a three prong switch like this Standard Ignition PS-64:

The switch will also let the pump run when you hit the starter because the engine doesn't have oil pressure yet.

One wire goes to the pump, one to the start circuit, and the other to the ignition circuit. So, when there is no oil pressure, the switch connects START to PUMP, and as soon as you start cranking it runs the pump. When the oil pressure comes up, the switch connects IGN to PUMP, for normal running. When oil pressure goes away (because you just hit that rock and tore the pan off the engine, for example) it again connects START to PUMP, and disconnects IGN from PUMP, so the pump shuts off.

Don't worry, it's easy to wire...

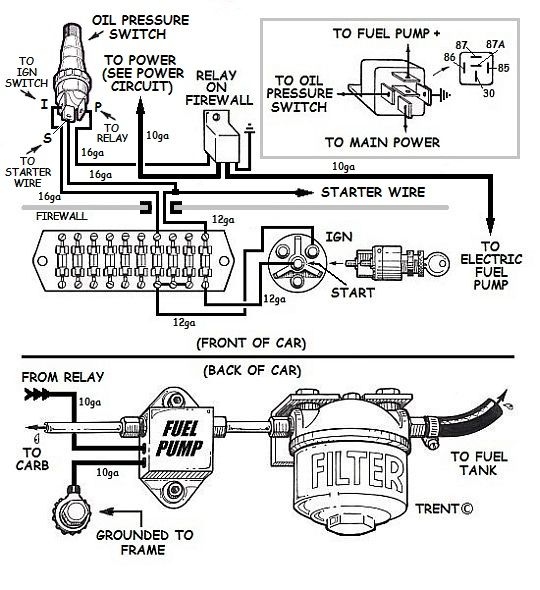

-How should you wire an electric fuel pump?

Since you need the fuel pump back by the tank and at the same level as the fuel or lower, that usually means you're going to have a long run of wire. So, you need to have really good wiring going back to it. Wiring that will carry enough current. Running the current through your ignition switch isn't a good idea since it's probably already overloaded, and will kill the voltage. That will kill the pump. However, it's nice for convenience. That's why a relay is really good to use.

It lets the ignition switch activate the pump, while keeping the power from having to run through it. It will keep your pump alive and happy because it is getting full voltage. A good way is to mount a relay beside a power distribution block on the firewall (see Improved Power Circuit) and get the power from there.

Here is a diagram on how to wire and plumb your pump:

I would guess that mounting your pump far from the fuel tank will give it plenty of opportunities to operate dry as it struggles to pull fuel all the way from the Corvair tank to the engine compartment. This ignores the tip that electric pumps often fail prematurely if you allow them to run dry. Also, if you install the pump without filtering the fuel from the tank before it reaches the pump, dirt and sediment form the tank can find its way into the pump mechanism — also promoting premature failure and less reliability.Airzack wrote:...I have read alot about electric pumps being good for pushing not pulling fuel. But I wanted to try it myself. I have had no issues whatsoever and it's way easier to install. The hardest part was routing wires to a cutoff switch under the dash.,,

A manual electric cutoff switch in the passenger compartment assumes you could be in a collision or accident and still be in condition to reach for the manual switch to turn the electric pump off to prevent a fire hazard. Would you bet your life on that???

Note that the cost of switching to an electric fuel pump SYSTEM is more than just the cost of the electric pump. Plumbing hardware and electrical wiring and connectors add to the cost. An automatic safety cutoff switch adds to the cost. A fuel inlet filter adds to the cost. Added complexity of the electric fuel pump system increases the possibility of a fault or failure while on the road. An improperly installed system reduces pump reliability and increases the possibility of a failure.

So why change to an electric pump system? What is wrong with the standard Corvair mechanical pump?

The mechanical Corvair fuel pump has been in service in Corvairs for decades and in 1,796,243 production Corvairs. Its failure rate is pretty low. (I have been riding in Corvairs since 1961, and never had a mechanical pump fail yet!) It is important, however, to make sure that no vacuum leaks form in the long fuel line between the tank and the pump. There are two short rubber fuel hoses — one at each end of the steel line. A leak in either hose may not be easy to notice, because it is likely that gasoline will not be leaking out. Instead, air will be leaking in to the line and can prevent the mechanical pump from being able to form a vacuum to pull the gasoline from the tank to the pump so that it can be pressurized and fed to the carburetors.

Brad Bodie

Lake Chatuge, North Carolina

1966 Corvair Corsa Convertible

1966 Corvair Corsa Convertible

Lake Chatuge, North Carolina

1966 Corvair Corsa Convertible

1966 Corvair Corsa ConvertibleRe: Electric fuel pump

Man, I never guessed you of all people would disapprove.

Sent from my SM-G970U using Corvair Forum mobile app

Sent from my SM-G970U using Corvair Forum mobile app

- bbodie52

- Corvair of the Month

- Posts: 12096

- Joined: Mon Aug 06, 2012 12:33 pm

- Location: Lake Chatuge Hayesville, NC

- Contact:

Re: Electric fuel pump

You did guess you would get disapproval...

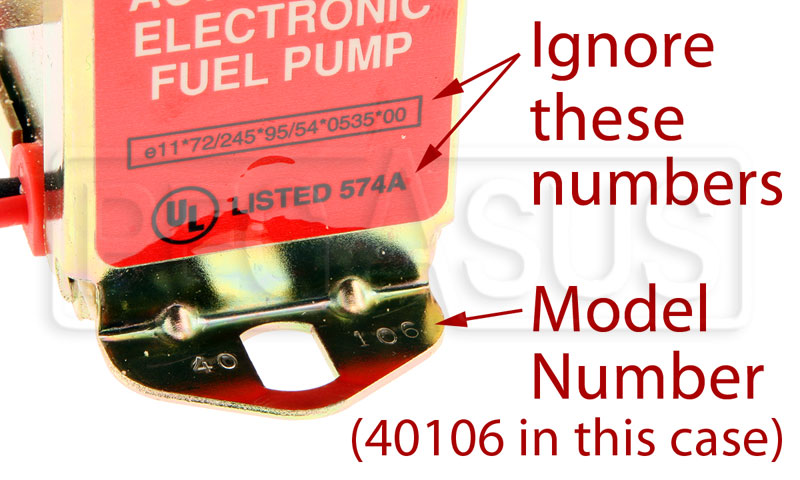

The Bravex EP12SL pump has a rated output pressure of 2.5-4 PSI, which matches the 4-5 psi specification for the mechanical pump. It appears to be nearly identical to the Facet pump (also sold on Amazon.com), but is only $19.99, while the Facet pump is $51.96. I don't know if the Bravex unit is a cheap knockoff of the Facet pump, or a re-branded unit. Quality and reliability???? Only time will tell.

The Bravex specs on Amazon.com state "100% Tested brand new and high quality. Reaches up to 12 inches for fuel suction... Pump is self priming and designed for Import Carburetor equipped Cars and Trucks and also Replacement Performance Carburetors..."

I believe your installation is more than 12" from the fuel tank (suction side), so your installation also chooses to ignore the manufacturer's specifications. Possibly running dry at startup, the life of the pump may be degraded over time.

I believe your installation is more than 12" from the fuel tank (suction side), so your installation also chooses to ignore the manufacturer's specifications. Possibly running dry at startup, the life of the pump may be degraded over time.

The installation is still considered to be dangerous and a fire hazard without an automatic power cutoff associated with engine operation. Other safety switches are available that are inertia switches which are designed to cut power when it detects a vehicle impact. Both safety switches can be incorporated into the power circuit for an electric fuel pump.

The installation is still considered to be dangerous and a fire hazard without an automatic power cutoff associated with engine operation. Other safety switches are available that are inertia switches which are designed to cut power when it detects a vehicle impact. Both safety switches can be incorporated into the power circuit for an electric fuel pump.

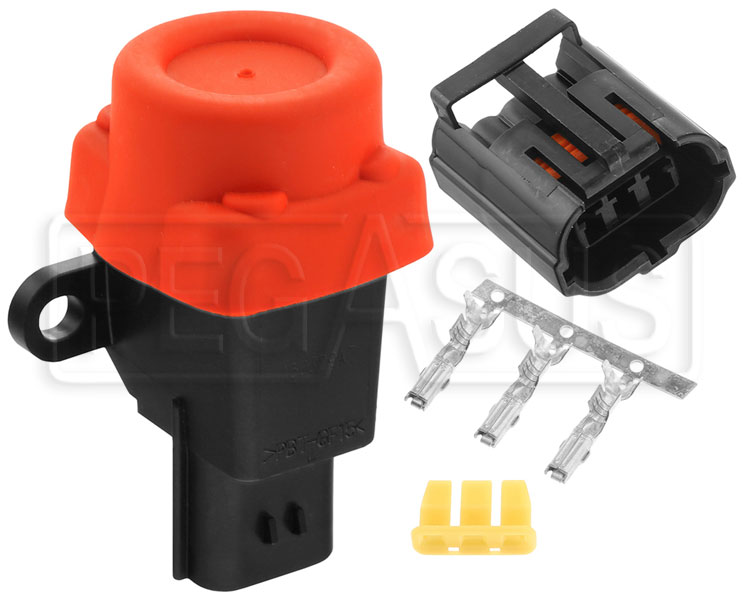

The material I found below about the inertia activated fuel pump shutoff switch indicates that this switch has a reset button on the top.

https://www.pegasusautoracing.com/produ ... oCZcHw_wcB

https://www.pegasusautoracing.com/produ ... oCZcHw_wcB

Pegasus Part No. 1108 - Fuel Pump Shut-Off Switch - Inertia Activated

So I would not want to disappoint you. And I couldn't just ignore this without posting a solid third-party opinion! Other Corvair owners read these posts and I would hope that — even though you choose to ignore the well-documented advice — others may want to hear the reasons for that advice.Airzack wrote:Man, I never guessed you of all people would disapprove...

...I'm sure I'm going to get all sorts of crap for this but I installed a bravex electric fuel pump...

The Bravex EP12SL pump has a rated output pressure of 2.5-4 PSI, which matches the 4-5 psi specification for the mechanical pump. It appears to be nearly identical to the Facet pump (also sold on Amazon.com), but is only $19.99, while the Facet pump is $51.96. I don't know if the Bravex unit is a cheap knockoff of the Facet pump, or a re-branded unit. Quality and reliability???? Only time will tell.

The Bravex specs on Amazon.com state "100% Tested brand new and high quality. Reaches up to 12 inches for fuel suction... Pump is self priming and designed for Import Carburetor equipped Cars and Trucks and also Replacement Performance Carburetors..."

azdave wrote: » Tue May 31, 2016 4:10 pmI have used these Ford Inertia Switches for years on my E-fuel pump installs. Never had one false trigger and never wrecked either.66vairguy wrote: ....If you are worried about an accident then put in an impact switch that shuts off the fuel pump and ignition if you get hit hard. Very common older Ford products with electric fuel pumps and has a reset button.

http://www.ebay.com/itm/FORD-INERTIA-SW ... pD&vxp=mtr

The material I found below about the inertia activated fuel pump shutoff switch indicates that this switch has a reset button on the top.

Pegasus Part No. 1108 - Fuel Pump Shut-Off Switch - Inertia Activated

Our Inertia Activated Fuel Pump Shut-Off Switch will cut power to an electric fuel pump after an impact of 10 to 12 G's or higher*, reducing the risk of post-crash fires caused by pressurized fuel sprayed from ruptured fuel lines. Resets with a simple push on the top of the switch.

This is such a cost effective safety item that many production cars have similar switches installed as original equipment. (Note: Although our switch is similar in operation to the switches found on street vehicles, it is not intended to be a replacement for any OEM switch.)

10 Amp continuous load rating allows the switch to handle the current of most electric fuel pumps (such as Facet low-pressure pumps) directly. Fuel pumps drawing 10 amps or more (such as the Bosch 044 and Aeromotive A1000 pumps) should use this switch to break contact on the fuel pump relay coil circuit. Includes switch, connector kit, and full instructions. Installation time averages less than 30 minutes. The kit is a universal fit for any vehicle with an electric fuel pump.

* A "typical" 8 mph fender-bender might generate a 2 g impact. Most OEM air bags are set to deploy in a 7 g impact, equivalent to hitting a solid wall at about 15 mph or a stationary vehicle at about 25 mph.

Brad Bodie

Lake Chatuge, North Carolina

1966 Corvair Corsa Convertible

1966 Corvair Corsa Convertible

Lake Chatuge, North Carolina

1966 Corvair Corsa Convertible

1966 Corvair Corsa ConvertibleRe: Electric fuel pump

Ignorant to assume I didn't install any other safety measures. I only installed the switch because it came with the relay kit I bought. I have an oil pressure cutoff installed. Thank you for your paragraphs of opinionated and argumentative information as usual. I drive my car almost every day so I will definitely be giving a truthful update as time goes on. Like I said I just wanted to try it. I don't really care about cost this is a fun car to play around with. I look forward to your next post of useless information.

Sent from my SM-G970U using Corvair Forum mobile app

Sent from my SM-G970U using Corvair Forum mobile app

- bbodie52

- Corvair of the Month

- Posts: 12096

- Joined: Mon Aug 06, 2012 12:33 pm

- Location: Lake Chatuge Hayesville, NC

- Contact:

Re: Electric fuel pump

The opinions are based on my 50+ years of experience with Corvairs, and from reading and learning the opinions of many other experienced Corvair enthusiasts, owners and other hot-rodders as well. I also try to pay attention to the standards, recommendations, and specifications established by Chevrolet and aftermarket parts manufacturers, and to the recommendations offered by many who post their opinions and experiences, and "lessons learned" that they offer to others here on the Corvair Forum. That is what the Forum exists for, and a large reason why CORSA club chapters exist... to promote the exchange of experiences, information, and opinions.Airzack wrote: » Wed Nov 27, 2019 8:10 pm

Ignorant to assume I didn't install any other safety measures. I only installed the switch because it came with the relay kit I bought. I have an oil pressure cutoff installed. Thank you for your paragraphs of opinionated and argumentative information as usual...

You opened this thread by challenging all who read your first entry to dare to disagree with you. I wanted to express my opinion, while referring as often as possible to the opinions written by others. Even the pump manufacturer mentions that their electric pump is designed on the suction side inlet to "reach up to 12 inches for fuel suction". So why would you choose to ignore that specification and install the pump perhaps 9 times that distance from the fuel tank? Its installation height is also several feet above the fuel tank outlet. And if you knew that the use of a oil pressure-actuated safety switch is recommended, why did you take the time to describe the installation of a manual on/off switch for your pump, but only revealed that you did actually install an oil pressure safety switch in your last rebuttal entry?

In the end, you chose to install a Facet-copy pump which appears to be a clone of the often-recommended Facet and an automatic safety switch and a fuel inlet filter. Only the location of the pump is in-question.

When I write something on the Corvair Forum I try to use references, illustrations, and comments/opinions from others to support a position or recommendation. I am aware that many Corvair owners may read this material in silence and may form opinions as they read, so I try to write a complete opinion that may be helpful to other readers as well as to the person who began the thread. I hope your pump installation continues to function well. Its location would seem to contradict the "DRY LIFT" recommendations of the manufacturer and others, but only time will tell.

Facet New Solid State Fuel Pump 12V 3-4.5Psi, 12" /30.48Cm Min Dry Lift

Facet recommends a 3 amp fuse. We have a Frequently Asked Questions document for Facet pumps on our website that contains this and many other answers. You can find it by searching our website for "Facet FAQ".

Best regards,

Chris Heitman, Co-owner

Pegasus Auto Racing Supplies see less

Facet Low-Pressure Fuel Pumps Frequently Asked Questions

Where can I mount a Facet pump? Can I put it in the engine bay?

Electric fuel pumps like these tend to push better than they pull. For this reason, you should mount the pump as close to the gas tank as possible and a low as practical. Each pump has a "dry lift" rating which must not be exceeded or the pump will starve.

FAC-40105 Facet Cube 12v Fuel Pump, 1/8 NPT, 3-4.5 psi

Brad Bodie

Lake Chatuge, North Carolina

1966 Corvair Corsa Convertible

1966 Corvair Corsa Convertible

Lake Chatuge, North Carolina

1966 Corvair Corsa Convertible

1966 Corvair Corsa Convertible-

California Racer

- Posts: 140

- Joined: Sun Oct 21, 2018 7:40 am

Re: Electric fuel pump

This from another 50 year Corvair guy.

I started to ask him about the fuel pump on Corvairs.

First thing he said was 'put an electric one on'.

Think it was because good rebuilds are expensive or hard to find.Maybe.

We do tube frames so all those tips from Brad are a little easier to apply.

I will remember the push part and put it near the tank.

Not 'under the hood' and near the carb like a mechanical pump.

I started to ask him about the fuel pump on Corvairs.

First thing he said was 'put an electric one on'.

Think it was because good rebuilds are expensive or hard to find.Maybe.

We do tube frames so all those tips from Brad are a little easier to apply.

I will remember the push part and put it near the tank.

Not 'under the hood' and near the carb like a mechanical pump.

THE CALIFORNIAN

Re: Electric fuel pump

Frank Metasavage

65 Corsa 140 4 speed with Weber IDAs

66 Corsa 140 4 speed Stock

65 Corsa 140 4 speed with Weber IDAs

66 Corsa 140 4 speed Stock

- bbodie52

- Corvair of the Month

- Posts: 12096

- Joined: Mon Aug 06, 2012 12:33 pm

- Location: Lake Chatuge Hayesville, NC

- Contact:

Re: Electric fuel pump

I think we ended up pretty-much all in agreement. I think you are right in that the applicable assumption is that "good [mechanical fuel pump] rebuilds are expensive and hard to find. However, that poor quality replacement track record may no longer be applicable (at least with mechanical pumps purchased from Clark's). Read below...California Racer wrote: » Sat Nov 30, 2019 2:31 pm

This from another 50 year Corvair guy. I started to ask him about the fuel pump on Corvairs. First thing he said was 'put an electric one on'.

Think it was because good rebuilds are expensive or hard to find. Maybe.

We do tube frames so all those tips from Brad are a little easier to apply. I will remember the push part and put it near the tank. Not 'under the hood' and near the carb like a mechanical pump.

Clark's Corvair Parts wrote:Fuel Pumps

We have only been able to locate 2 manufacturers of original style Corvair fuel pumps. Since 1973, we have consistently seen 1-2% of new fuel pumps fail. From about 1998-2001, the failure rate went to nearly 10%! We finally convinced the pump manufacturer that they were using the wrong diaphragm material! Currently, about 1%-2% of the fuel pumps continue to have problems. The problems have usually been seepage of fuel or complete failure resulting in no fuel or a rupture of the main diaphragm. The main supplier (C3403) is now using "antiwicking" diaphragms & has returned to all 3 diaphragms having fabric reinforced material. We've also added a pump from a 2nd supplier (C3403A). Our experience with both is nearly identical. A spare pump is always a good idea.

If your original mechanical fuel pump has actually failed (as in leaking fuel, torn pump diaphragm, etc.) the safe bet may be to install an electric fuel pump system properly and abandon the mechanical pump system, if it has failed! (Remember that a leaky fuel tank feed line or hose that is letting air in may look very much like a failed mechanical pump. But if the line between the tank and the pump is letting air in, it is like trying to sip a drink from a cup through a drinking straw that has a split in the side of the straw — you won't get much fluid no matter how hard you suck on the straw! You need a new straw!)

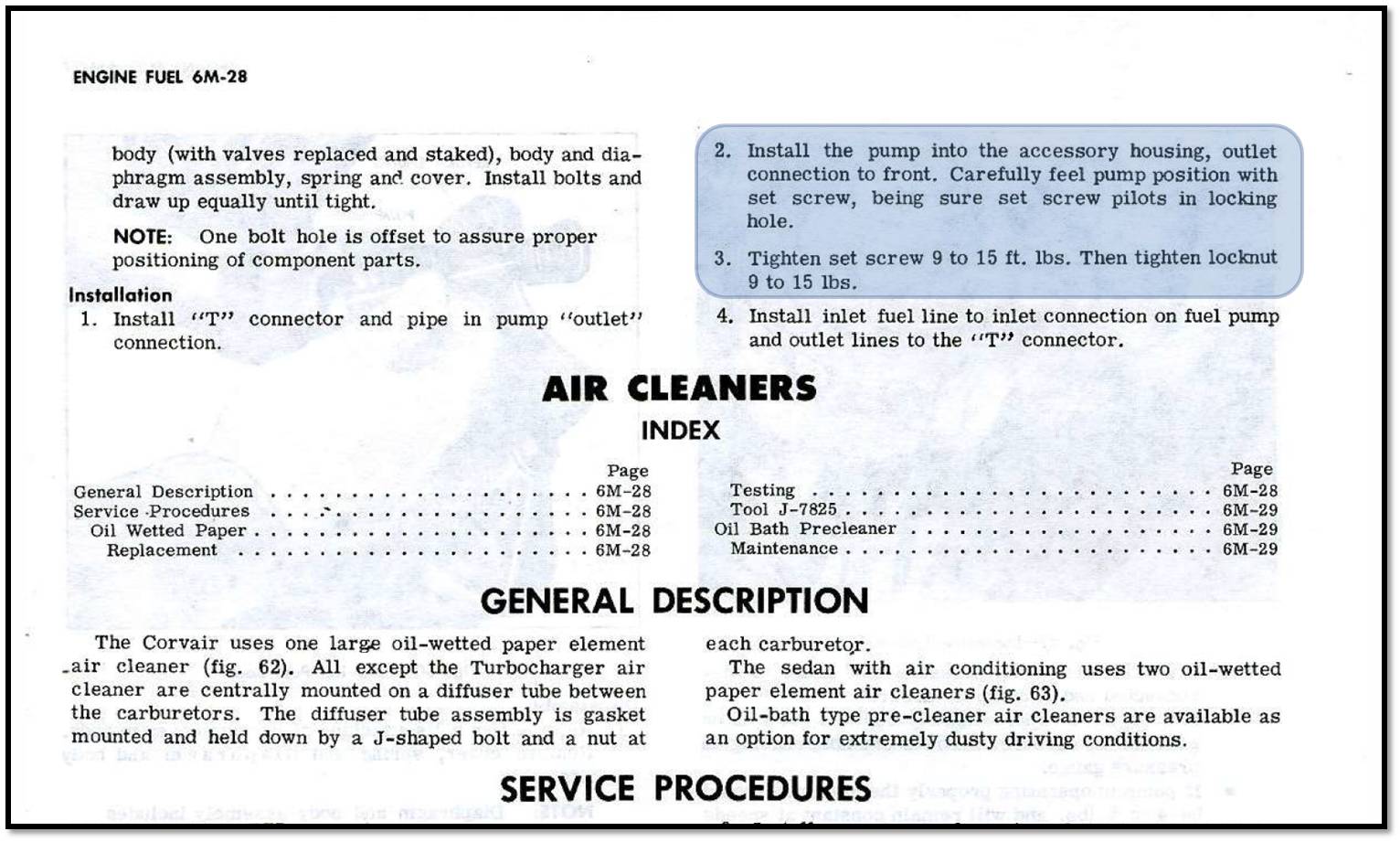

The other common mechanical fuel pump mistake is to improperly insert the pump at the wrong depth, with only the set screw (bolt) pressing against the side of the pump, instead of the tapered bolt tip being seated in the tapered hole in the side of the pump shaft. This can result in the pump mechanism barely making contact with the push rod that drives it. The pump only gets a partial push and never moves at a full stroke. The pump must me inserted fully, with the bolt properly seated into the tapered pump hole and the lock nut securing the bolt as shown and described in the shop manual).

I'll bet a lot of fully functional Corvair mechanical fuel pumps get targeted as having failed and then get tossed and replaced with an electric pump, when the real problem is a faulty feed line from the fuel tank or an improperly inserted fuel pump!

The cost of a replacement mechanical pump from Clark's isn't really that high ($65.55 vs. $69.50 for a Facet FEP42SV Cube Electric Fuel Pump 1.5-4 Psi, Includes Clamps/Fittings/Filter). Other electric pumps may be cheaper, but when you add the additional wiring and install hardware cost — including the safety cutoff switch system — the electric pump system will likely cost much more.

Clark's Corvair Parts wrote:Part number C3403: NON-GM FUEL PUMP-62-69 WILL FIT 60-61 IF ORDER C259 ROD

Weight: 2 lbs 4 oz

Catalog Page(s): 65

Price:

1 - 1 $ 65.55

2+ $ 63.60

bbodie52 wrote:The Corvair mechanical fuel pump is usually pretty good at pulling gasoline the length of the vehicle to prime the fuel pump so that gasoline can be pressurized to fill the carburetor float bowls. But a small air leak or crack in one of the short rubber hoses at either end of the fuel line between the tank and the pump can create what amounts to a vacuum leak in the fuel feed line that supplies the pump. The pump can cycle many times as the engine cranks and the battery drains while sucking mostly air from a fuel line air leak instead of getting a good "drink" of gasoline from the tank.

An improperly inserted mechanical fuel pump may also limit the motion of the pump diaphragm, if the pump insertion is too shallow and not allowing the push rod to take a full stroke. Refer to the notes and illustrations below to see how the pump set screw is supposed to insert into the tapered hole in the side of the pump shaft, and not just push against the side of the pump shaft. Proper installation ensures that the pump is properly positioned in relation to the push rod, so that the pump gets a full stroke with each rotation of the crankshaft. Good fuel volume from the pump is considered to be 1 pint of fuel in 40 seconds or less at cranking speed.

Where did you physically place the squeeze bulb that you added to prime the fuel circuit? Is it close the the tank so that if fully charges the length of the fuel line? Electric pumps are supposed to be physically located close to the tank, because they do a better job of pushing fuel than pulling it. Mechanical pumps are much better at creating a line vacuum to suck fuel from the tank through the very long "straw", but an air leak somewhere along the length of the feed line can severely limit the pump's ability to create a good vacuum inside that fuel line.

To check for the possibility of fuel starvation, did you actually measure fuel pump pressure AND volume? It is easy to have a pump that delivers correct pressure, but cannot produce adequate fuel volume. A feed line leak or cracked/damaged/loose rubber hose between the tank and the pump can create an air leak that will keep the pump from being able to create a solid vacuum to pull a good supply of fuel from the tank. Without adequate fuel supply, the pump can generate adequate fuel pressure to the carburetors, but only until it is starved for gasoline from the tank. The pump must also be installed to the proper depth and anchored properly using the tapered bolt that is screwed into the tapered hole on the side of the pump.

bbodie52 wrote:The pump push rod is driven by a cam lobe on the crankshaft. The repeated "upstroke" causes the pump to form a vacuum in the feed line from the fuel source (tank or gas can). As the fuel is drawn into the pump chamber, the one-way valve in the pump inlet closes at the top of the stroke, and the spring in the pump forces the diaphragm back down to push the fuel out of the pump through the other one-way valve, toward the carburetors. The spring tension determines the fuel pump outlet pressure.

Check to make sure you are fully inserting the pump so that the pushrod driving the pump gets a full stroke to drive the fuel pump. Proper installation of the new parts is critical,,,

Also...To remove and reinstall the fuel pump, be sure that you have installed it properly. It is important to ensure that the fuel pump is correctly seated and installed. There is a hole in the side of the pump shaft that the tapered bolt tip must seat into. If the pump is sitting too high and the bolt is simply pressing against the side of the pump housing, rather than seating inside the tapered hole, the pump push rod will not be doing its job. Fig. 57 in the shop manual page shows the tapered hole that the tip of the bolt fits into. This ensures proper installation and seating of the pump.

For a quick check on fuel availability in the carburetors, you can peer down the throat of each carburetor while holding the choke open. Open the throttle quickly. You should see a squirt of fuel injected into the carburetor throat from the accelerator pump. This confirms the presence of fuel in each float bowl.There are two relatively simple tests outlined in the Corvair shop manual. These tests measure output pressure and fuel delivery volume. The output pressure test utilizes a common vacuum/pressure gauge that is relatively inexpensive. The output pressure is regulated by an internal spring that is contained in the upper pump housing. Unless your pump springs a leak in one of the diaphragms or seals, it is likely that the output pressure will not change with age. However, new pumps may be fitted with a spring that produces an output pressure well in excess of the 4-5 psi standard. High-pressure can cause carburetor flooding, and is particularly a problem with the Carter YH carburetor found on turbocharged Corvairs, which is sensitive to excessive fuel pressure.

A new fuel pump should always be tested for output pressure. If the pressure is found to be excessive it may be possible to cut the spring or to exchange the spring from the old pump and fit it into the new pump. This may correct the output pressure.

The second test measures fuel flow at the fuel pump outlet. The standard in the shop manual states that the pump should be able to deliver 1 pint of fuel over a period of 40 seconds or less at engine cranking speed. If your pump does not appear to have any leaks and can pass the output pressure test, but fails to deliver the needed fuel volume, the problem may not be with the pump itself. There is a long fuel line that runs the length of the car from the fuel tank to the fuel pump. In order to pressurize and deliver fuel to the carburetors, the pump must be able to create a continuous vacuum in that fuel line to draw the fuel from the tank to the pump. Most of the fuel line is made up of steel tubing and is unlikely to develop a leak. However, there are two short lengths of rubber fuel hose in the fuel path. One section of hose is found at the fuel tank outlet, while the other is found adjacent to the starter motor — just before the line enters the engine compartment. The purpose of the second hose is to absorb vibration from the engine and prevent it from reaching the rigid steel fuel line. If either one of these two hoses develops a leak, the leak itself may not be apparent because the line is not under pressure so fuel will not be forced out. Instead, the leak amounts to a vacuum leak, which can allow air to enter the fuel line. This can prevent fuel from being drawn from the tank to the fuel pump, much like you might experience with a drinking straw if the straw was to split and developed an air leak in the side of the straw. What appears to be a faulty pump that is causing fuel starvation problems in the carburetors often turns out to be a leak in the fuel line at some point between the gas tank and the fuel pump. So if fuel starvation becomes a problem with your carburetors, there is a tendency to question the condition of the needle and seat valve inside the carburetor, or to blame the fuel filter at the carburetor inlet (thinking it is clogged), or to blame the fuel pump itself. Before you blame the pump and toss it, or abandon it and replace it with electric fuel pump, be sure to check the condition of the rubber fuel hoses at each end of the long fuel line between the fuel tank and the fuel pump. You may find that a couple of hose clamps and a few inches of replacement fuel hose is all that necessary to get you back on the road!

With the air cleaner assembly removed, when holding the choke open and peering down the throat of each carburetor, do you see a squirt of fuel from the accelerator pump in each carburetor when you open the throttle rapidly? If the jet of fuel is not observed, the float bowls may be dry, possibly due to stuck needle and seat assemblies blocking the fuel inlet.

Brad Bodie

Lake Chatuge, North Carolina

1966 Corvair Corsa Convertible

1966 Corvair Corsa Convertible

Lake Chatuge, North Carolina

1966 Corvair Corsa Convertible

1966 Corvair Corsa ConvertibleRe: Electric fuel pump

50 starts as of this morning. 40 mile round trips to work five days a week. Plus all my local driving around town.

Sent from my SM-G970U using Corvair Forum mobile app

Sent from my SM-G970U using Corvair Forum mobile app

Re: Electric fuel pump

Man Brad! I haven't posted here in months and what is this but someone is calling you opinionated and argumentative! The Brad I remember has been illuminated and helpful......Lol

Brad you keep going and I (and I am sure many many more) DO appreciate your input.

Ed Stevenson

Brad you keep going and I (and I am sure many many more) DO appreciate your input.

Ed Stevenson

Edwin Stevenson

Industrial Electrician

Electronics Technician

65 corvair corsa convertible turbo

65 corvair monza

Industrial Electrician

Electronics Technician

65 corvair corsa convertible turbo

65 corvair monza

-

California Racer

- Posts: 140

- Joined: Sun Oct 21, 2018 7:40 am

- davemotohead

- Corvair of the Month

- Posts: 1313

- Joined: Tue Aug 10, 2010 10:37 pm

- Location: rosamond california

- Contact:

Re: Electric fuel pump

I flirt with danger like its a red headed step child! I installed a facet pump on my daily driver in my engine compartment 30+ years ago and have worn out 3 engines and the same pump is still running fine! I was told "You can't do that!!" and " That won't work!" 30+ years later its still working fine, has never vapor locked or left me stranded, and if at this point it does quit working, I will replace it with another one in about 5 min without crawling under my car! So tell me again how its wrong?

Re: Electric fuel pump

Dave you are just a natural born rebel!

Ed Stevenson

Ed Stevenson

Edwin Stevenson

Industrial Electrician

Electronics Technician

65 corvair corsa convertible turbo

65 corvair monza

Industrial Electrician

Electronics Technician

65 corvair corsa convertible turbo

65 corvair monza

Re: Electric fuel pump

Oh my god thank you for understanding my point of installing the pump in the engine compartment. I have an extra pump in my trunk and it will take me about 5 minutes to replace if it fails.

Sent from my SM-G970U using Corvair Forum mobile app

Sent from my SM-G970U using Corvair Forum mobile app

Re: Electric fuel pump

Btw you are the man and I love your YouTube videos.

Sent from my SM-G970U using Corvair Forum mobile app

Sent from my SM-G970U using Corvair Forum mobile app