63' Spyder

-

Fnine 63' Spyder

- Posts: 4

- Joined: Sun Oct 04, 2015 11:47 am

63' Spyder

Hello All - New to this forum. My 63" Spyder coupe has been a labor of love the past few years. I've been conducting a frame on restoration in my garage and have run into a motor problem. I'm sure this issue I'm having has been addressed prior, but with thousands of post it's hard to search thru all the discussions.

A buddy and I have been working on rebuilding/replacing everything from the frame rails south. New fuel system from the tank to engine (including lines), 100% rebuild of engine using Clark parts, Carter YH Carb rebuilt by local company (All American Carb) - sent rebuilt carb to Clarks and had turbo rebuilt and road tested by Clarks, converted to electronic ignition (Pertronix Ignitor 1162A) did not replace distributor but did dissemble to ensure the flyweights worked freely. Engine fired up after a few try's and routing the hot wire to the distributor to ensure 12V (reading the instructions fully would have helped with that goof up), ran and accelerated on initial start - just really rich.

So we adjusted the mixer screw out a 1/4 turn (by recommendation from Clarks) with not much luck. On the 3rd weekend after initial engine start, car wouldn't start. We were thinking a fuel starvation issue. Read a few blogs about carb float adjustment - leaving the carb installed we took out the float made the adjustments as talked about in Bob Helt's book, rigged the accelerator linkage and verified the timing of the distributor at 24. Car runs at about 700 rpm but has ZERO throttle response. With the pedal floored - we only get 1000 rpm.

I live in the Jacksonville Florida area and people I've found don't know much about these awesome cars so no luck using grey bread knowledge. Any advise would be greatly appreciated. Thanks.

Mike

A buddy and I have been working on rebuilding/replacing everything from the frame rails south. New fuel system from the tank to engine (including lines), 100% rebuild of engine using Clark parts, Carter YH Carb rebuilt by local company (All American Carb) - sent rebuilt carb to Clarks and had turbo rebuilt and road tested by Clarks, converted to electronic ignition (Pertronix Ignitor 1162A) did not replace distributor but did dissemble to ensure the flyweights worked freely. Engine fired up after a few try's and routing the hot wire to the distributor to ensure 12V (reading the instructions fully would have helped with that goof up), ran and accelerated on initial start - just really rich.

So we adjusted the mixer screw out a 1/4 turn (by recommendation from Clarks) with not much luck. On the 3rd weekend after initial engine start, car wouldn't start. We were thinking a fuel starvation issue. Read a few blogs about carb float adjustment - leaving the carb installed we took out the float made the adjustments as talked about in Bob Helt's book, rigged the accelerator linkage and verified the timing of the distributor at 24. Car runs at about 700 rpm but has ZERO throttle response. With the pedal floored - we only get 1000 rpm.

I live in the Jacksonville Florida area and people I've found don't know much about these awesome cars so no luck using grey bread knowledge. Any advise would be greatly appreciated. Thanks.

Mike

Re: 63' Spyder

How's the accelator pedal feel? If one person floors the pedal (engine off), does the carb look fully open when viewed by a helper?

Jeremy (cad-kid)

Kronenwetter, WI (Central Wisconsin)

SOLD 9-2016 65 Monza 4spd/140

My 65 Monza thread

My YouTube page

My YouTube page

Kronenwetter, WI (Central Wisconsin)

SOLD 9-2016 65 Monza 4spd/140

My 65 Monza thread

-

Fnine 63' Spyder

- Posts: 4

- Joined: Sun Oct 04, 2015 11:47 am

Re: 63' Spyder

There is no binding in the pedal and the butterfly is full open

Re: 63' Spyder

I'm sure others will jump in. Perhaps a video showing the poor running motor would be helpful

Jeremy (cad-kid)

Kronenwetter, WI (Central Wisconsin)

SOLD 9-2016 65 Monza 4spd/140

My 65 Monza thread

My YouTube page

My YouTube page

Kronenwetter, WI (Central Wisconsin)

SOLD 9-2016 65 Monza 4spd/140

My 65 Monza thread

Re: 63' Spyder

Fuel pressure. Not more than 2.5psi. YH's are very sensitive to that b/c the float is so little.

Nick

1964 Monza Spyder Convertible #435 - Rotisserie restored - SOLD ON BRING A TRAILER 4/30/2019 - Check out my restoration thread here: [corvaircenter.com]

Thanks to all the awesome CCF, CF, COG, and CORSA members who helped me with the restoration!

1964 Monza Spyder Convertible #435 - Rotisserie restored - SOLD ON BRING A TRAILER 4/30/2019 - Check out my restoration thread here: [corvaircenter.com]

Thanks to all the awesome CCF, CF, COG, and CORSA members who helped me with the restoration!

-

Fnine 63' Spyder

- Posts: 4

- Joined: Sun Oct 04, 2015 11:47 am

Re: 63' Spyder Carb Issues

Checked fuel pressure last night and it falls between 1.5 and 2 psi.

Cars idle is low (700) - so i'm fighting this issue now along with no throttle response.

Hooked up a vacuum gauge and it reads about 5, which I know is way low. Sprayed WD-40 around vacuum fittings and found a leak around the rubber hose between turbo and intake.

Does anyone know of a good technique to ensure the hose is installed and seated correctly?

Thanks for the help.

Mike

Cars idle is low (700) - so i'm fighting this issue now along with no throttle response.

Hooked up a vacuum gauge and it reads about 5, which I know is way low. Sprayed WD-40 around vacuum fittings and found a leak around the rubber hose between turbo and intake.

Does anyone know of a good technique to ensure the hose is installed and seated correctly?

Thanks for the help.

Mike

Re: 63' Spyder

There's not really a technique to tightening the hose. Tighten it until it's tight. If the turbo outlet is not straight to the crossover pipe inlet then you may have to clock the turbo a bit by loosening the little nut on the clamp that holds the exhaust housing on. Once that is loose you can turn the compressor housing to perfectly line up with the crossover pipe. You have something else wrong though if you are flooring it and it only goes to 1000 rpm. That doesn't make much sense.

Nate Wolfe

65 Corsa 180

61 Lakewood 140

65 Corsa 180

61 Lakewood 140

- bbodie52

- Corvair of the Month

- Posts: 11897

- Joined: Mon Aug 06, 2012 12:33 pm

- Location: Lake Chatuge Hayesville, NC

- Contact:

Re: 63' Spyder

I have seen installations where the turbocharger output is misaligned with the intake manifold tube, which can cause the turbo outlet hose to distort in order to connect to both the turbocharger and the intake manifold tube. Check the alignment between the two components, and inspect the outlet hose and clamps to make sure they are in good condition.

http://www.corvair.com/user-cgi/catalog ... ow_page=49

http://www.corvair.com/user-cgi/catalog ... ow_page=49

Part number C11: TURBO OUTLET HOSE GEAR CLAMPS=C11A (2 NEEDED)

Weight: 0 lbs 4 oz

Catalog Pages(s): 49(8),50

Price: $ 13.70

I have attached a copy of the 1962-1963 Supplement - Chevrolet Corvair Shop Manual - Section 9 - Fuel & Exhaust Systems, which covers the turbocharger maintenance and installation, just in case you don't have a copy. There is a turbo-specific troubleshooting chart on page 9-16. The only instruction reference concerning the turbo assembly installation is on page 9-28.

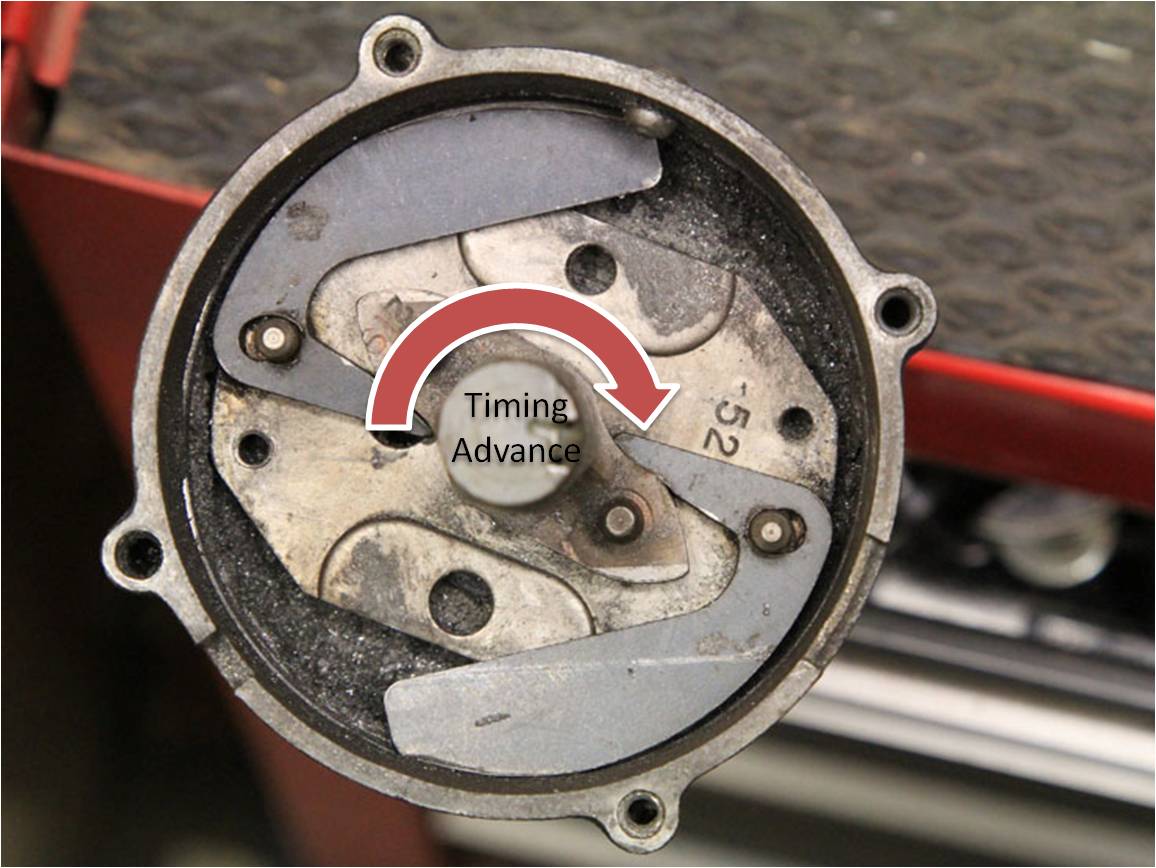

You might monitor the ignition timing with a timing light to ensure that the ignition timing is increasing as the engine RPM increases. You mentioned disassembling the distributor to check the centrifugal advance.

Back in 1970 I discovered a loose drive gear on my distributor. I decided to completely disassemble the distributor and give it a thorough cleaning, inspection, lubrication, etc. while removing and reinstalling the drive gear and roll pin to tighten the gear. After carefully rebuilding the distributor and installing new points, condenser, rotor, and cap, I reinserted the distributor and carefully static timed it (adjusting its position so that the points just opened with the crankshaft pulley timing mark positioned correctly). I started the engine and rechecked the timing with my timing light, and confirmed the correct timing.

Later in the day, I took the car out for a test drive. Everything seemed normal at idle, but when I attempted to accelerate the car felt like I had run into a barrier of some kind... it had no power at all! The more I revved the engine, the less power I had! What had I done wrong???

I limped back home and reconnected my timing light, and confirmed that all was right. But then I discovered something new... when I revved the engine I expected to observe the timing mark advancing, but instead it was going the WRONG WAY!

I had discovered my mistake. I had reassembled the centrifugal advance weights upside down, and had created a centrifugal retard mechanism. I didn't even know that was possible, but if you look at the photo you can see that the weights can be flipped so that they are pressing on the wrong side of the distributor cam mechanism. The return springs can still be connected, and everything is in place, but as the weights move outward the cam is turning in the wrong direction. It felt like I was driving with a bungee cord attached to the rear bumper.

Part number C11: TURBO OUTLET HOSE GEAR CLAMPS=C11A (2 NEEDED)

Weight: 0 lbs 4 oz

Catalog Pages(s): 49(8),50

Price: $ 13.70

I have attached a copy of the 1962-1963 Supplement - Chevrolet Corvair Shop Manual - Section 9 - Fuel & Exhaust Systems, which covers the turbocharger maintenance and installation, just in case you don't have a copy. There is a turbo-specific troubleshooting chart on page 9-16. The only instruction reference concerning the turbo assembly installation is on page 9-28.

You might monitor the ignition timing with a timing light to ensure that the ignition timing is increasing as the engine RPM increases. You mentioned disassembling the distributor to check the centrifugal advance.

Back in 1970 I discovered a loose drive gear on my distributor. I decided to completely disassemble the distributor and give it a thorough cleaning, inspection, lubrication, etc. while removing and reinstalling the drive gear and roll pin to tighten the gear. After carefully rebuilding the distributor and installing new points, condenser, rotor, and cap, I reinserted the distributor and carefully static timed it (adjusting its position so that the points just opened with the crankshaft pulley timing mark positioned correctly). I started the engine and rechecked the timing with my timing light, and confirmed the correct timing.

Later in the day, I took the car out for a test drive. Everything seemed normal at idle, but when I attempted to accelerate the car felt like I had run into a barrier of some kind... it had no power at all! The more I revved the engine, the less power I had! What had I done wrong???

I limped back home and reconnected my timing light, and confirmed that all was right. But then I discovered something new... when I revved the engine I expected to observe the timing mark advancing, but instead it was going the WRONG WAY!

I had discovered my mistake. I had reassembled the centrifugal advance weights upside down, and had created a centrifugal retard mechanism. I didn't even know that was possible, but if you look at the photo you can see that the weights can be flipped so that they are pressing on the wrong side of the distributor cam mechanism. The return springs can still be connected, and everything is in place, but as the weights move outward the cam is turning in the wrong direction. It felt like I was driving with a bungee cord attached to the rear bumper.

- Attachments

-

- 1962-1963 Supplement - Chevrolet Corvair Shop Manual - Section 9 - Fuel & Exhaust Systems.pdf

- 1962-1963 Supplement - Chevrolet Corvair Shop Manual - Section 9 - Fuel & Exhaust Systems

- (3.83 MiB) Downloaded 16 times

Brad Bodie

Lake Chatuge, North Carolina

1966 Corvair Corsa Convertible

1966 Corvair Corsa Convertible

Lake Chatuge, North Carolina

1966 Corvair Corsa Convertible

1966 Corvair Corsa ConvertibleRe: 63' Spyder

I had low vacuum at idle causing flooding on my Spyder before I started my restoration. Once I disassembled the engine I found two cracked pistons. Leakdown test blew by the rings on cyl #1. Cracks were on two other cylinders. Funny, compression tests were within spec on all cylinders!

Nick

1964 Monza Spyder Convertible #435 - Rotisserie restored - SOLD ON BRING A TRAILER 4/30/2019 - Check out my restoration thread here: [corvaircenter.com]

Thanks to all the awesome CCF, CF, COG, and CORSA members who helped me with the restoration!

1964 Monza Spyder Convertible #435 - Rotisserie restored - SOLD ON BRING A TRAILER 4/30/2019 - Check out my restoration thread here: [corvaircenter.com]

Thanks to all the awesome CCF, CF, COG, and CORSA members who helped me with the restoration!

-

Fnine 63' Spyder

- Posts: 4

- Joined: Sun Oct 04, 2015 11:47 am

Re: 63' Spyder

Thanks for the inputs. Do to work schedule wont be able to work on car until next week. I'm going to write out a troublehsooting tree of ideas from this post and readings and hope to get this figured out. Completely frustrated!

Thanks again for the help.

Mike

Thanks again for the help.

Mike