I am not sure what is causing the idle to be so high on your engine. At that high idle speed it would be difficult to accurately adjust ignition settings and carburetor idle speed settings. I think I would backtrack a little to confirm that all cylinders are mechanically sound — before proceeding with a tuneup series of adjustments. Have you pulled the spark plugs and check the compression on each cylinder? If you run a compression test, you should also examine each spark plug to see if they all appear to be burning equally, or if one or more cylinders is showing signs of a mismatch or problem area.

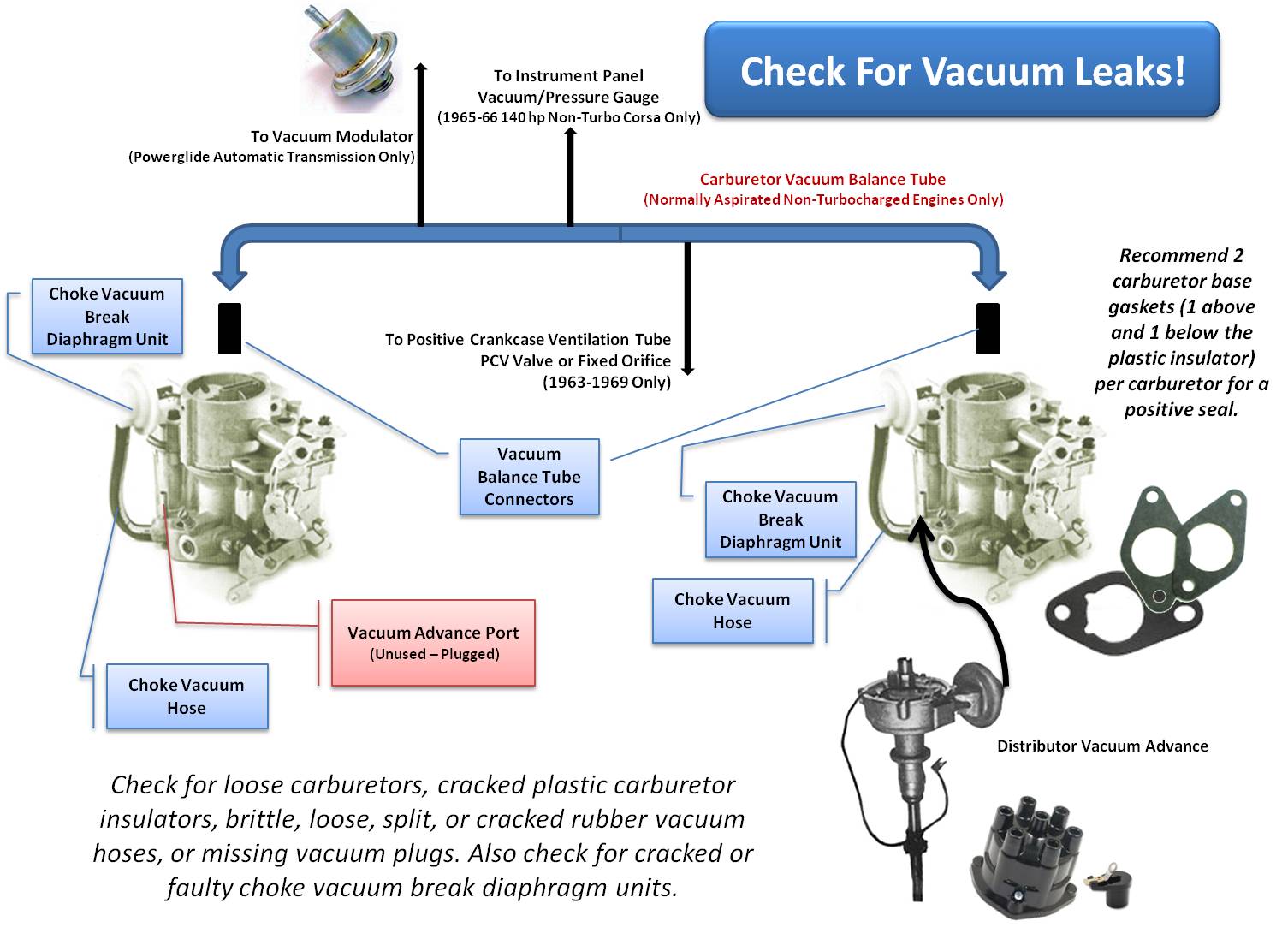

I would also recommend carefully checking all vacuum hoses and lines to make sure that there are no vacuum leaks. I noticed that it appears that the vacuum line for the PCV system fixed orifice is disconnected and plugged. The fixed orifice vacuum port should be examined and cleaned and then reconnected to the vacuum balance tube. This is part of the final operating configuration and should not be disconnected from the system when you go through the process of synchronizing and adjusting your carburetors.

You should disconnect the secondary carburetor linkages and ensure that the secondary throttle butterflies are completely closing. The accelerator pump assembly includes a spring that helps to exert pressure on the throttle linkage to keep the secondary carburetors fully closed unless they are opened by the main throttle linkage. By temporarily disconnecting the secondary carburetors and ensuring that the throttle butterflies are fully closed you are removing any problems with them from the system while you focus on synchronizing and adjusting your primary carburetor idle speed. (Sticking secondary throttle butterflies that do not fully close when the secondary carburetors are not operating is effectively a vacuum leak that could be impacting all of your remaining settings. Depending on your driving habits, secondary carburetors may see little operation and could accumulate dirt and other deposits on the throttle assembly that might prevent the secondary carburetors from fully closing when they are idle).

The initial settings of the primary carburetor idle mixture and idle speed screws should be physically set in accordance with the shop manual. This can be done with the linkage that ties the carburetors together temporarily disconnected. You want to establish the two idle speed screws settings at 1½ turns beyond the point where they make initial contact with the carburetor linkage. The shop manual procedure describes using a strip of paper to detect when the screw first comes into contact with the carburetor throttle linkage, and then adding one 1½ turns to establish the initial idle speed setting, which would be mechanically the same for each primary carburetor. The idle mixture screws should be lightly bottomed out and then backed out 1½ turns.

With these initial settings at the carburetors, and with the engine warmed up and operating at normal temperatures, you should be able to confirm that both choke assemblies and their associated fast idle cams are fully disengaged. If there are no vacuum leaks and the carburetors have been been mechanically synchronized, the idle speed should be slow enough (600-650 RPM) to eliminate any possibility of the ignition timing being advanced by either the vacuum advance or centrifugal advance. You should confirm the timing with a timing light of the vacuum advance temporarily disconnected from the distributor. Timing should be 16°-20° BTDC. At this point the engine idle should be close to the desired range. Final idle synchronization can then be accomplished with the UniSyn gauge. Another indicator of proper operation of the carburetors can be checked by checking the dual exhaust output. The exhaust sound and the amount of heat from each exhaust tailpipe should be fairly even.

The cross linkage between each primary carburetor should then be reconnected, while carefully checking that none of the linkage is binding. A turnbuckle can be used to hold the throttle open to approximately 1200 RPM. The linkage can be adjusted at the left carburetor while measuring airflow through each primary carburetor with the UniSyn gauge. Part-throttle airflow should be matched between the two primaries by adjusting the throttle linkage at the left carburetor.

Click on the link below to read another article on carburetor synchronization and use of the UniSyn gauge...

http://www.corvairforum.com/forum/viewt ... kle#p89750

http://www.corvairforum.com/forum/viewt ... kle#p89750

The final step would be to check the linkage and reconnect it at each secondary carburetor. The linkage operation and adjustments are described on page 12 of the attached

DELCO ROCHESTER - Models H, HV Carburetor Service Manual.

1966 Corvair Corsa Convertible

1966 Corvair Corsa Convertible